AES in Pharma: A Comprehensive Guide to Surface Contamination & Failure Analysis for Drug Development

This article provides researchers, scientists, and drug development professionals with a detailed guide to Auger Electron Spectroscopy (AES) for surface contamination and failure analysis.

AES in Pharma: A Comprehensive Guide to Surface Contamination & Failure Analysis for Drug Development

Abstract

This article provides researchers, scientists, and drug development professionals with a detailed guide to Auger Electron Spectroscopy (AES) for surface contamination and failure analysis. It covers foundational principles, modern methodological workflows for pharmaceutical applications, strategies for troubleshooting analytical challenges and optimizing results, and a critical evaluation of AES against complementary techniques like XPS and TOF-SIMS. The content synthesizes the latest advances to empower professionals in ensuring product quality, safety, and regulatory compliance in biomedical research and manufacturing.

AES Decoded: Core Principles for Surface Science in Pharmaceutical Research

What is AES? The Physics of Auger Electron Emission Explained

Auger Electron Spectroscopy (AES) is a surface-sensitive analytical technique used to determine the elemental composition of the top 0.5-10 nm of a solid material. Its core principle is based on the Auger effect, a physical process of electron emission. Within a thesis on surface contamination and failure analysis research, AES is a cornerstone technique for identifying trace contaminants, mapping elemental distributions, and diagnosing root causes of material and device failures in fields ranging from semiconductor fabrication to biomedical device development.

The Physics of Auger Electron Emission

The Auger process is a non-radiative relaxation mechanism for an excited atom. It involves three key steps:

- Ionization: A high-energy primary electron beam (typically 3-20 keV) ejects a core-level electron from a target atom, creating a vacancy and leaving the atom in a highly excited, positively charged state.

- Relaxation: An electron from a higher-energy level (e.g., L-shell) fills the core vacancy (e.g., K-shell).

- Auger Electron Emission: The energy released from the relaxation step is transferred to another electron (e.g., from the L-shell), which is ejected from the atom. This ejected electron is the Auger electron.

The kinetic energy of the emitted Auger electron is characteristic of the parent element and the specific energy levels involved, denoted by a three-letter notation (e.g., KL₁L₂₃ for a transition involving the K, L₁, and L₂₃ shells). This characteristic energy forms the basis for elemental identification.

Core Quantitative Data in AES

Table 1: Characteristic Auger Electron Energies for Key Elements

| Element | Primary Transition | Typical Kinetic Energy (eV) | Information Depth (nm) |

|---|---|---|---|

| Carbon (C) | KLL | ~272 | 0.5-1.5 |

| Oxygen (O) | KLL | ~503 | 0.5-1.5 |

| Nitrogen (N) | KLL | ~379 | 0.5-1.5 |

| Silicon (Si) | LVV | ~92 | 1-3 |

| Gold (Au) | MNN | ~2024 | 1.5-3 |

| Iron (Fe) | LMM | ~703 | 1-2.5 |

| Sodium (Na) | KLL | ~990 | 0.5-1.5 |

Table 2: Typical AES Operational Parameters

| Parameter | Common Range | Function/Impact |

|---|---|---|

| Primary Beam Energy | 3 - 20 keV | Determines ionization cross-section & penetration. |

| Beam Current | 1 nA - 1 μA | Affects signal intensity, spatial resolution, and sample damage. |

| Beam Diameter (Spot Size) | 10 nm - 1 μm | Defines spatial resolution for point analysis and mapping. |

| Base Pressure | < 1 x 10⁻⁹ Torr | Maintains surface cleanliness during analysis. |

| Energy Analyzer Resolution | 0.1 - 1.0 % | Governs peak separation and identification accuracy. |

Experimental Protocol: Standard AES Point Analysis for Surface Contamination

Objective: To identify unknown particulate or film-like contamination on a device surface (e.g., a sensor or implant).

Materials & Reagents: See "The Scientist's Toolkit" below.

Procedure:

Sample Preparation:

- Mounting: Securely mount the sample on a standard AES stub using conductive carbon tape or clips. Ensure electrical continuity to prevent charging for non-conductive samples.

- Cleaning (if required): If the sample is not vacuum-compatible for in-situ cleaning, pre-clean via solvent rinsing (IPA, acetone) and drying under inert gas. Document any pre-cleaning steps.

- Loading: Transfer the sample into the fast-entry load-lock chamber of the AES system.

System Preparation:

- Pump down the load-lock to a pressure below 1 x 10⁻⁷ Torr.

- Transfer the sample to the analysis chamber and allow it to equilibrate until the base pressure (< 5 x 10⁻¹⁰ Torr) is restored.

- Optional: Perform in-situ surface cleaning via argon ion sputtering (1-5 keV, 1-5 μA/cm², 30-60 seconds) to remove adventitious carbon, but only if the contaminant itself is not the analysis target.

Instrument Setup:

- Activate the electron gun. Set primary beam energy to 10 keV and beam current to 10 nA.

- Select a spot size appropriate for the contamination feature (e.g., 50 nm for a small particle).

- Position the electron beam onto the area of interest using the scanning electron microscopy (SEM) imaging mode.

Data Acquisition:

- Switch the cylindrical mirror analyzer (CMA) or hemispherical analyzer (HSA) to the desired energy range (e.g., 0-1000 eV for light elements).

- Acquire a survey spectrum in the direct N(E) mode or, more commonly, the derivative dN(E)/dE mode to enhance visibility of low-intensity peaks on a high background.

- Set a low scan rate (e.g., 1 eV/s) and sufficient time constant for good signal-to-noise ratio.

- Collect the spectrum over at least 3 sweeps and average the data.

Data Analysis & Reporting:

- Identify elements present by comparing the kinetic energies of observed peaks to standard reference databases.

- For semi-quantitative analysis, use relative sensitivity factors (RSFs) to calculate approximate atomic concentrations from peak-to-peak heights (in derivative spectra) or peak areas (in direct spectra).

- Report the identified elements, their approximate concentrations, and the exact location of analysis.

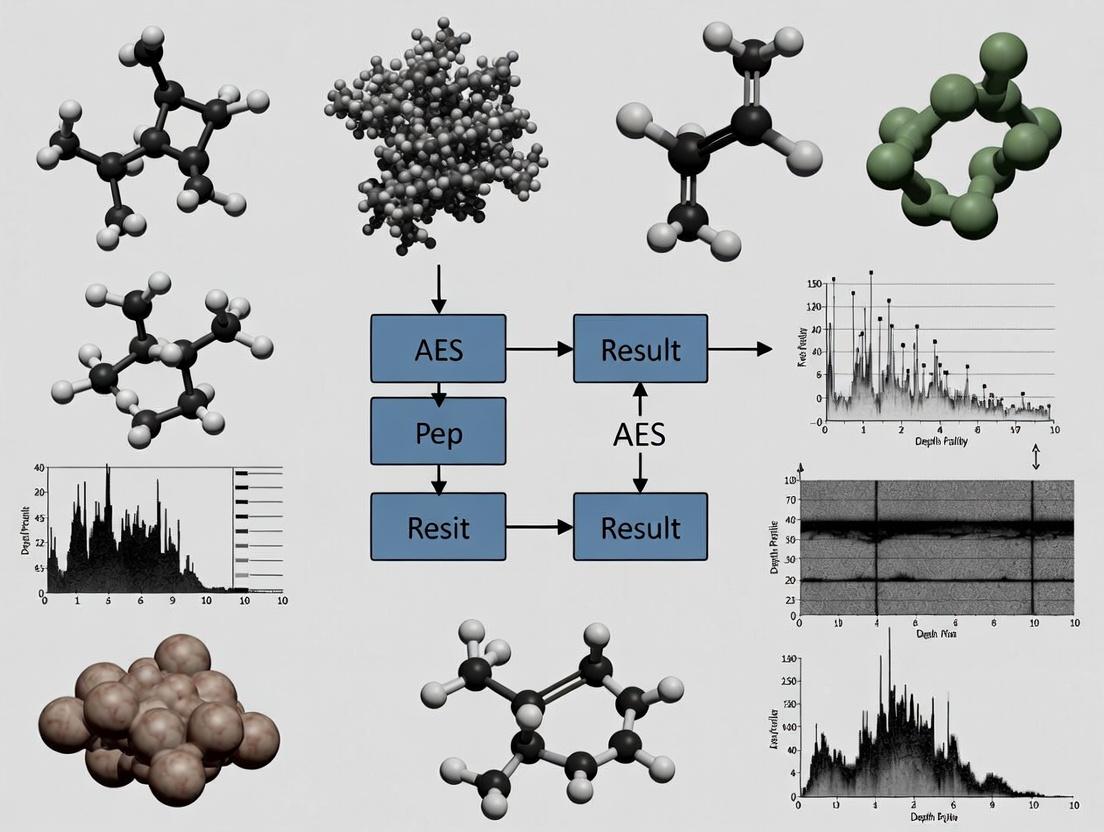

Visualization: AES Process and Analytical Workflow

Title: The Auger Electron Emission Process and Analysis Chain

Title: AES Protocol for Surface Contamination & Failure Analysis

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 3: Key Materials for AES-Based Surface Analysis

| Item | Function/Application in AES |

|---|---|

| Conductive Adhesives (Carbon Tape, Silver Paint, Copper Tape) | Provides stable, electrical grounding of the sample to the holder to mitigate charging effects from the electron beam. Critical for insulating materials. |

| Standard Reference Materials (Pure Au, Ag, Cu foils, SiO₂/Si wafers) | Used for energy calibration of the spectrometer, verification of instrumental resolution, and checking relative sensitivity factors. |

| In-situ Sputter Ion Source (Argon Gas, ≥99.999% purity) | Provides controlled, in-situ surface cleaning to remove adventitious carbon/oxide layers and enables depth profiling by sequentially removing material. |

| Ultrasonic Cleaner & High-Purity Solvents (Isopropanol, Acetone, Methanol) | For ex-situ sample pre-cleaning to remove gross contaminants and salts prior to insertion into the ultra-high vacuum (UHV) system. |

| Specimen Stubs & Holders (Standard sizes for the instrument) | Mechanically secures the sample in the correct geometry for analysis. May include heating or cooling stages for in-situ studies. |

| Charge Neutralization System (Low-energy Electron Flood Gun or Ar⁺ Flood Source) | Essential for analyzing insulating samples (e.g., polymers, ceramics) by providing low-energy positive ions/electrons to compensate for surface positive charge buildup. |

Application Notes: Core Analytical Strengths in Failure Analysis

Auger Electron Spectroscopy (AES) provides unique capabilities for investigating surface contamination and material failures at the nanoscale, forming a critical thesis in modern analytical science. The following notes detail its principal advantages.

Table 1: Quantitative Comparison of AES with Competing Surface Techniques

| Feature / Parameter | AES | XPS (ESCA) | EDS (on SEM) | TOF-SIMS |

|---|---|---|---|---|

| Primary Information | Elemental (Z≥3) & Chemical State | Elemental (Z≥3) & Detailed Chemical State | Elemental (Z≥5) | Elemental & Molecular |

| Sampling Depth | 2-10 nm (5-10 Å escape depth) | 5-10 nm | 1-2 µm | 1-2 nm (top monolayer) |

| Lateral Resolution | < 10 nm (Field Emission) | 3-10 µm | 0.5-2 µm | 50-200 nm |

| Detection Limits (at.%) | 0.1 - 1% | 0.1 - 1% | 0.1 - 1% | ppm - ppb |

| Quantitative Accuracy | Good (±10-20%) with standards | Very Good (±5-10%) | Semi-Quantitative (±15-20%) | Poor (Requires standards) |

| Sputtering for Depth Profiling | Excellent: High-Speed, High-Resolution | Good | Poor | Good (Low Damage) |

| Sample Damage | Moderate (Electron Beam) | Very Low | Low | Very Low (Static) |

| Key Strength for Failure Analysis | High-Resolution 2D/3D Elemental Mapping & Interface Analysis | Chemical Bonding at Surfaces | Bulk Microanalysis | Ultra-Trace Surface Contamination |

Thesis Context: For research on electronic device failures or particulate contamination in pharmaceutical devices, AES’s combination of nanoscale lateral resolution and superb depth-profiling allows precise 3D reconstruction of contaminant layers, oxide films, and interfacial diffusion phenomena that are inaccessible to techniques with poorer spatial or depth resolution.

Experimental Protocols

Protocol 1: AES Depth Profiling of a Thin-Film Dielectric Failure

Objective: To determine the elemental composition and contamination depth distribution in a failed 50nm HfO₂ dielectric stack on a Si wafer.

Materials & Equipment:

- Field Emission Auger Electron Spectrometer (e.g., from Thermo Fisher, JEOL, or ULVAC-PHI)

- Argon ion sputtering gun (1-5 keV)

- Low-energy electron flood gun for charge neutralization (for insulating films)

- Standard reference materials (e.g., pure Cu, SiO₂)

- Conductive adhesive tape (e.g., carbon tape)

- Sample holders (stainless steel)

Procedure:

- Sample Preparation:

- Cleave the failed device to expose the region of interest (~5x5 mm).

- Mount using conductive tape on a standard holder. Ensure electrical contact.

- Optionally, mark the analysis area with a low-power optical microscope.

Instrument Setup:

- Insert sample into the analysis chamber. Achieve ultra-high vacuum (< 5 x 10⁻⁹ Torr).

- Align sample height to the spectrometer focal point.

- Set primary electron beam: 10 keV, 10 nA, beam diameter < 10 nm.

- Configure the cylindrical mirror analyzer (CMA) for a survey spectrum (e.g., 0-2000 eV with 1 eV step).

Initial Surface Analysis:

- Acquire a survey spectrum from the as-received surface at three representative points.

- Identify all elements present (C, O, Hf, Si, potential contaminants like Na, Cl, F).

- Perform high-resolution multiplex scans for key elemental peaks (e.g., C KLL, O KLL, Hf MNN) for chemical state information.

Sputter Depth Profiling:

- Program the sequential analysis cycle: a. Acquire Auger peak-to-peak heights (or area) for elements of interest (C, O, Hf, Si). b. Sputter the surface with a focused Ar⁺ ion beam (2 keV, 1x1 mm raster, calibrated sputter rate ~5 nm/min for SiO₂ equivalent). c. Repeat cycle.

- Use a low sputter rate initially to avoid interface mixing. Collect data until the Si substrate signal stabilizes.

Data Analysis:

- Convert sputter time to depth using the calibrated rate (confirmed via a SiO₂/Si standard).

- Plot atomic concentration (%) vs. depth (nm) using relative sensitivity factors (RSFs).

- Identify the interface width and correlate contaminant peaks (e.g., C) with failure locations.

Protocol 2: 2D Elemental Mapping of a Micron-Scale Contaminant Particle

Objective: To identify the elemental composition and distribution of an isolated particulate contaminant (~1µm) on a drug-eluting implant surface.

Procedure:

- Locate Particle:

- Transfer the sample to the AES stage.

- Use the instrument's secondary electron imaging (SEI) capability at low beam current to locate the particle without significant damage.

Mapping Acquisition:

- Define a raster area (e.g., 10x10 µm) encompassing the particle and surrounding substrate.

- Set the electron beam parameters: 10 keV, 1 nA (to reduce beam damage).

- For each pixel in the raster, acquire the Auger spectrum or set the CMA to sequentially detect specific elemental energies.

- Acquire maps for C KLL, O KLL, N KLL, and any suspected metal peaks (e.g., from processing tools: Fe, Cr, Ni).

- Acquisition time per map: typically 5-15 minutes, depending on signal-to-noise requirements.

Point Analysis:

- After mapping, perform a stationary point analysis on the center of the particle and on the clean substrate adjacent to it.

- Acquire high-resolution spectra for quantitative comparison.

Data Interpretation:

- Overlay elemental maps to assess co-localization.

- Compare spectra from the particle and substrate to confirm the exogenous nature of the contaminant.

Visualization: Experimental & Analytical Workflows

Diagram 1: AES Failure Analysis Decision Pathway

Title: AES Failure Analysis Decision Tree

Diagram 2: AES Instrumentation & Signal Generation Logic

Title: AES Signal Generation & Analysis Chain

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions and Materials for AES Surface Analysis

| Item | Function / Purpose |

|---|---|

| Argon (Ar), 99.999% Pure | Inert sputtering gas for depth profiling and surface cleaning. High purity minimizes introduction of new contaminants. |

| Conductive Adhesives (Carbon Tape, Silver Paste) | To mount non-conductive or powder samples, providing a path for charge dissipation and stable grounding. |

| Standard Reference Materials (e.g., Pure Cu foil, SiO₂/Si wafer) | For quantitative calibration, sputter rate determination, and instrument performance verification. |

| In-Situ Cleaving Tool (for UHV chambers) | To expose a fresh, uncontaminated surface of brittle materials (semiconductors, oxides) inside the vacuum. |

| Low-Energy Electron Flood Gun Source | Provides low-energy electrons to neutralize surface charge on insulating samples, enabling accurate analysis. |

| HPLC-Grade Solvents (Isopropanol, Methanol) | For ultrasonic cleaning of sample holders and tools prior to introduction into the UHV chamber to reduce hydrocarbon background. |

| Calibrated Sputter Rate Standards (Ta₂O₅, SiO₂) | Thin films with known thickness used to calibrate ion sputter rates for accurate depth scale conversion. |

| Certified Particle/Density Standards (e.g., Polystyrene Latex Spheres) | For verifying the lateral resolution and magnification of the AES microprobe. |

Within the broader thesis on Auger Electron Spectroscopy (AES) for surface contamination and failure analysis in pharmaceutical and materials research, mastering three critical parameters—sampling depth, lateral resolution, and detection limits—is paramount. These parameters dictate the technique's efficacy in identifying nanoscale contaminants, mapping element distribution on device surfaces, and pinpointing the root cause of failures in drug delivery systems or microelectronic components. This application note provides a detailed protocol framework for researchers to optimize these parameters, ensuring reliable and interpretable data for critical quality attribute (CQA) assessment.

Core Parameter Definitions and Quantitative Data

Sampling Depth in AES is defined by the inelastic mean free path (IMFP) of Auger electrons, which is material- and energy-dependent. It typically ranges from 0.5 to 10 nm, making AES an ultra-surface-sensitive technique.

Lateral Resolution is determined by the diameter of the primary electron beam. State-of-the-art field emission AES systems can achieve resolutions below 10 nm.

Detection Limits vary by element and matrix but generally range from 0.1 to 1.0 atomic percent for most elements under optimal conditions.

Table 1: Summary of Critical AES Parameters for Common Applications

| Parameter | Typical Range | Key Influencing Factors | Impact on Failure Analysis |

|---|---|---|---|

| Sampling Depth | 0.5 – 10 nm | Auger electron kinetic energy, material density | Defines probed volume for contamination layers. |

| Lateral Resolution | 10 – 50 nm (FE sources) | Electron gun brightness, beam alignment, astigmatism | Determines smallest contaminant particle or feature that can be chemically identified. |

| Detection Limit | 0.1 – 1.0 at.% | Signal-to-noise ratio, background subtraction, peak overlap | Determines minimum concentration of a contaminant that can be reliably detected. |

| Analysis Area | ~1 µm² for point analysis | Beam diameter, scan coil settings | Must be optimized to target specific failure sites. |

Table 2: Inelastic Mean Free Path (IMFP, in nm) for Select Elements (Approx. 1000 eV)

| Matrix Material | C (272 eV) | O (503 eV) | Fe (703 eV) | Si (1619 eV) |

|---|---|---|---|---|

| Carbon | ~1.0 nm | ~1.5 nm | ~1.8 nm | ~2.8 nm |

| Silicon | ~0.9 nm | ~1.4 nm | ~1.7 nm | ~2.6 nm |

| Iron | ~0.7 nm | ~1.1 nm | ~1.4 nm | ~2.2 nm |

| Gold | ~0.6 nm | ~0.9 nm | ~1.1 nm | ~1.8 nm |

Experimental Protocols

Protocol 1: Determining Effective Sampling Depth via Angle-Resolved AES (AR-AES)

Objective: To experimentally determine the thickness of an ultra-thin oxide or contamination layer. Reagents/Materials: See "The Scientist's Toolkit" below. Method:

- Sample Mounting: Mount the sample on a stage capable of precise azimuthal rotation (tilt) relative to the analyzer.

- Initial Alignment: At 0° tilt (normal emission), locate the analysis area using secondary electron imaging.

- Data Acquisition: a. Acquire a survey spectrum (e.g., 0-1000 eV) to identify key substrate (e.g., Si) and overlayer (e.g., O, C) peaks. b. Set multiplex windows for the key substrate (e.g., Si LVV at 92 eV) and overlayer (e.g., O KLL at 503 eV) peaks. c. Acquire peak intensities while incrementally tilting the sample from 0° to 60° (e.g., in 10° steps). Note: Tilt increases the effective path length of electrons through the overlayer, enhancing surface sensitivity.

- Data Analysis: Plot the normalized substrate signal intensity (I/I₀) versus 1/cos(θ). The slope is related to the overlayer thickness via a simple exponential attenuation model.

Protocol 2: Optimizing Lateral Resolution for Contaminant Mapping

Objective: To achieve the highest spatial resolution for mapping elemental distribution of a particulate contaminant. Reagents/Materials: See "The Scientist's Toolkit" below. Method:

- Beam Alignment & Stigmation: a. Using a Faraday cup or a sharp, high-contrast feature on a calibration sample (e.g., Au on Si), focus the electron beam at the desired analysis energy (e.g., 10 keV). b. Adjust the stigmator coils to obtain a symmetrical, circular beam spot. This is critical for sub-50 nm resolution.

- Resolution Verification: Image a known nanostructure (e.g., a Ti/Pt test grid) and perform a line scan across a sharp edge. Measure the distance between 20% and 80% intensity points on the edge response function.

- Contaminant Analysis: a. Locate the contaminant particle or feature of interest using high-resolution SEM. b. Acquire a point spectrum on the particle and an adjacent "clean" area to identify differentiating elements. c. Set up elemental maps for these key elements (e.g., Na, Cl, Al) using the smallest practical beam current that provides acceptable count rates. d. Acquire maps with pixel density sufficient to resolve the feature (typically 256 x 256 pixels over the area of interest).

Protocol 3: Pushing Detection Limits for Trace Surface Contamination

Objective: To detect and quantify trace-level surface contaminants (e.g., <0.5 at.%). Reagents/Materials: See "The Scientist's Toolkit" below. Method:

- Spectrum Acquisition for Optimal SNR: a. Select a primary beam energy (Ep) that maximizes the Auger yield for the element of interest (typically 3-5 times the Auger transition energy). b. Use a low beam current to minimize sample damage, but increase dwell time per data point to improve statistics. c. Acquire a high-resolution multiplex spectrum over a narrow energy range containing the peak of interest and its background. Use a minimum of 0.1 eV/step.

- Background Subtraction & Peak Identification: a. Apply a Shirley or linear background subtraction to the raw spectrum. b. Identify the peak position and measure the peak-to-peak height (in derivative mode) or integrated area (in direct N(E) mode).

- Quantification: a. Compare the measured peak intensity to sensitivity factors derived from standard samples. b. Report detection limits based on a signal-to-noise ratio (SNR) > 3. The noise is typically measured as the root-mean-square variation in the background.

Visualizations

Diagram Title: AES Parameter Optimization Workflow

Diagram Title: Sampling Depth & Signal Attenuation in AES

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for AES Surface Analysis

| Item | Function in AES Protocols | Example/Notes |

|---|---|---|

| Conductive Tape/Adhesive | Provides electrical and mechanical grounding of insulating samples to prevent charging. | Carbon tape, silver paste, or copper tape. |

| Reference Calibration Samples | For verifying lateral resolution, energy calibration, and sensitivity factors. | Au grid on Si, pure elemental foils (e.g., Cu, Al, Ag). |

| Argon Gas (Ultra-High Purity) | Source for ion sputtering guns used for depth profiling and surface cleaning. | 99.999% purity to minimize implantation of reactive gases. |

| Standard Reference Materials (SRMs) | Thin film standards with known composition/thickness for quantitative accuracy. | NIST-certified SiO₂ on Si, multi-layer metal films. |

| Charge Neutralization Source | Low-energy electron or ion flood gun for analyzing insulating samples (e.g., drug particles). | Essential for pharmaceuticals and polymers. |

| Ultrasonic Solvent Cleaner | For preliminary sample cleaning in solvents (acetone, ethanol, IPA) to remove gross contamination. | Must be followed by in-situ cleaning (sputtering) for valid analysis. |

| Handling Tools (Tweezers, Gloves) | For contamination-free sample transfer and mounting. | Anti-magnetic, non-particulating tweezers; powder-free nitrile gloves. |

This application note is framed within a broader thesis that asserts Auger Electron Spectroscopy (AES) is a critical, high-sensitivity surface analysis technique for root-cause investigation in pharmaceutical development and manufacturing. The core thesis is that AES provides unparalleled spatial resolution (down to ~10 nm) and elemental sensitivity (typically 0.1-1 at.%) for mapping surface chemistry, making it indispensable for solving problems related to invisible contaminants, thin-film coating integrity, and material interactions that directly impact drug safety, efficacy, and stability.

Application Note: Identification of Inorganic Contaminants on Tablet Surfaces

Problem: Discoloration spots observed on compressed tablet cores prior to coating. Energy-Dispersive X-Ray Spectroscopy (EDS) detected only trace levels of silicon and aluminum, insufficient for definitive identification.

AES Protocol & Results:

- Sample Preparation: A tablet with a visible spot was carefully fractured in a laminar flow hood to expose the sub-surface region near the discoloration. A cross-section was mounted on an AES sample holder using conductive carbon tape.

- Instrument Parameters:

- Instrument: Field Emission-Auger Electron Spectrometer.

- Primary Beam Energy: 10 keV.

- Beam Current: 10 nA.

- Analysis Mode: Secondary Electron Imaging (SEI) for localization, followed by point analysis and elemental mapping.

- Analysis Workflow: a. SEI identified a ~5 µm particulate at the center of the discoloration. b. High-resolution point AES spectrum acquired from the particle. c. Elemental mapping performed for C, O, Al, Si, and Mg over a 20x20 µm area.

- Data Interpretation: The point spectrum showed intense Al and Si peaks with minor Mg. The map revealed a correlated Al-Si-Mg signal localized to the particle, surrounded by a carbon/oxygen matrix (excipients). Quantitative analysis confirmed a silicate-based contaminant (e.g., kaolin or clay).

Table 1: Quantitative AES Analysis of Tablet Contaminant

| Element | Atomic % (Particle) | Atomic % (Clean Bulk) | Likely Origin |

|---|---|---|---|

| O | 62.1 | 22.3 | Silicate, Excipients |

| C | 5.8 | 71.5 | Organic Excipients |

| Si | 18.4 | 0.2 | Contaminant (Clay) |

| Al | 12.5 | 0.0 | Contaminant (Clay) |

| Mg | 1.2 | 0.0 | Contaminant (Clay) |

Note: Balance includes trace Na, Ca.

Application Note: Failure Analysis of a Pinhole Defect in a Controlled-Release Film Coating

Problem: Pinhole defects in a polymer-based controlled-release coating lead to premature drug release (dose dumping). Optical and scanning electron microscopy (SEM) revealed the defect morphology but not the chemical cause.

AES Protocol & Results:

- Sample Preparation: A coated tablet with a identified pinhole was cross-sectioned using a focused ion beam (FIB) mill to create a pristine, contamination-free vertical slice through the pinhole defect. This preserves the interface chemistry for analysis.

- Instrument Parameters:

- Primary Beam Energy: 15 keV (for high spatial resolution mapping).

- Beam Current: 1 nA.

- Analysis Mode: AES line scan and depth profiling across the pinhole wall.

- Analysis Workflow: a. SEI located the FIB-cut cross-section of the pinhole. b. A line scan (50 points, 10 nm step) was performed from the intact coating, across the pinhole edge, to the tablet core. c. A depth profile (sputtering with 1 keV Ar⁺ ions) was performed at the pinhole edge to examine interfacial layers.

- Data Interpretation: The line scan showed a sudden loss of polymer-specific elements (C, O) and a coincident spike in magnesium stearate at the pinhole boundary. Depth profiling confirmed a ~50 nm thick layer of magnesium stearate (lubricant) embedded at the coating-substrate interface, acting as a dewetting site and causing coating failure.

Table 2: AES Depth Profile at Pinhole Interface (First 3 Minutes Sputtering)

| Sputter Time (min) | Atomic % C | Atomic % O | Atomic % Mg | Atomic % P (API) | Interpreted Layer |

|---|---|---|---|---|---|

| 0.0 | 78.5 | 21.2 | 0.3 | 0.0 | Polymer Coating |

| 0.5 | 72.1 | 18.5 | 9.4 | 0.0 | Mg Stearate Rich |

| 1.0 | 65.8 | 15.2 | 18.9 | 0.1 | Mg Stearate Rich |

| 2.0 | 10.5 | 58.3 | 1.2 | 30.0 | API Layer |

Experimental Protocols

Protocol 1: AES Analysis of Particulate Contaminants on Medical Devices

- Isolation: Use micro-manipulators or adhesive carbon tabs in a clean bench to transfer the particulate to a clean, polished silicon wafer.

- Mounting: Secure the wafer to the AES sample holder with a metal clamp.

- Charge Neutralization: For insulating particles, use a low-energy (~1 eV) electron flood gun. Optimize flux to stabilize the AES signal without degrading the sample.

- Screening: Acquire a survey spectrum from 20-1200 eV at the particle.

- High-Resolution Mapping: For key elements (e.g., Cl, S, F, metals), acquire high-count maps with a step size ≤50 nm to define morphology.

- Quantification: Use instrument sensitivity factors and a standardless routine, but corroborate with a known standard (e.g., pure Cu foil) if absolute accuracy is critical.

Protocol 2: AES Depth Profiling for Interface Failure in Multi-Layer Tablets

- Cross-Section Prep: Critical Step. Use FIB milling to prepare a trench with a smooth, vertical wall exposing all layers. Avoid smearing with a protective Pt/Pd deposition layer.

- Align Sample: Tilt the sample so the analysis surface is normal to the electron beam. Pre-sputter the area with a broad, low-energy Ar⁺ beam to remove ambient contamination.

- Define Profile Parameters: Set a rastered ion beam (1-3 keV Ar⁺) over an area ~50% larger than the analysis area. Use an electron beam for analysis in the center of the sputtered crater.

- Acquisition: Cycle between short sputter intervals (e.g., 5-15 seconds) and AES survey/high-resolution scans for key elements. Continuously monitor peak shapes for chemical state changes.

- Data Reduction: Plot atomic concentration vs. sputter time/depth. Identify interfaces where significant concentration gradients occur (>50% change over <5 nm is indicative of a sharp interface).

Visualizations

AES Surface Failure Analysis Workflow

AES vs EDX Signal Generation Depth

The Scientist's Toolkit: Key Research Reagent Solutions

| Item/Reagent | Function in AES Pharma Analysis | Critical Specification |

|---|---|---|

| Polished Silicon Wafers | Ideal, ultra-clean substrate for mounting and analyzing particulate contaminants. Low background AES signal. | Prime grade, 99.999% pure, native oxide layer acceptable. |

| Conductive Carbon Tabs/Dots | For mounting insulating samples (tablet fragments, powders) to minimize charging. | High-purity, adhesive, compatible with ultra-high vacuum (UHV). |

| FIB Lift-Out Kit (Pt/Ga sources) | For preparing site-specific cross-sections of coating defects or interfaces. | Electron beam- and ion beam-deposited precursor gases (e.g., Pt, W). |

| Argon Gas (Research Grade) | Sputtering gas for depth profiling and surface cleaning. Must be ultra-pure to avoid implantation artifacts. | 99.9999% purity, with integrated gas purifier/filter. |

| Standard Reference Materials | For quantitative calibration and instrument performance verification (e.g., pure Cu, Au, SiO₂). | Certified, clean, and stable under electron beam. |

| Micro-manipulators & Probes | For the precise isolation and transfer of microscopic contaminants under optical control. | Tungsten or stainless steel tips, vibration-isolated stage. |

Within the context of advancing surface contamination and failure analysis research, Auger Electron Spectroscopy (AES) remains a critical technique for elemental and chemical-state characterization of solid surfaces. This application note details the core components of a modern AES system, providing protocols and resources tailored for researchers and drug development professionals focused on particulate contamination, thin-film delamination, and corrosion analysis in biomedical devices and pharmaceutical manufacturing.

Core Instrumentation Components

Electron Optics Column

The electron gun and focusing lenses are fundamental for generating a stable, high-brightness primary electron beam. Modern systems utilize field emission guns (FEG) for superior spatial resolution (<10 nm). The column includes electrostatic or electromagnetic lenses for beam focusing and scanning coils for rastering the beam across the sample surface.

Electron Energy Analyzer

The heart of the AES system, typically a hemispherical sector analyzer (HSA) or cylindrical mirror analyzer (CMA). It disperses emitted electrons based on kinetic energy, providing the high energy resolution necessary for chemical state identification.

Ultra-High Vacuum (UHV) Chamber

Essential for maintaining surface cleanliness and enabling the detection of low-energy Auger electrons without gas-phase scattering. Base pressures typically range from 10⁻⁸ to 10⁻¹⁰ Pa.

Sample Handling and Stage

A precision, multi-axis manipulator that allows for heating, cooling (often from -120°C to 1000°C), and tilt/rotation for depth profiling and angle-resolved measurements.

Sputter Ion Gun

A focused ion source (usually Ar⁺) for depth profiling by controlled surface erosion and for in-situ cleaning of sample surfaces.

Detection System

An electron multiplier or channel electron multiplier array that converts the energy-resolved electron current into an amplified signal for processing.

Data Acquisition and Control System

Computer-controlled software for instrument operation, spectral acquisition, data processing (including differentiation, background subtraction, and peak fitting), and elemental mapping.

Quantitative Performance Data

Table 1: Performance Specifications of Modern AES Components

| Component | Key Parameter | Typical Specification Range | Impact on Analysis |

|---|---|---|---|

| Electron Gun | Beam Energy | 1 keV to 30 keV | Controls sampling depth & excitation efficiency |

| Beam Current | 100 pA to 1 µA | Affects spatial resolution & signal-to-noise | |

| Probe Size (FEG) | 5 - 20 nm | Determines ultimate spatial resolution | |

| Energy Analyzer | Energy Resolution (ΔE/E) | 0.05% - 0.6% | Dictates peak separation & chemical state ID |

| Constant Pass Energy | 10 - 200 eV | Balances resolution & transmission | |

| Ion Gun | Sputter Rate (SiO₂) | 0.1 - 10 nm/min | Controls depth profiling speed & resolution |

| Beam Energy (Ar⁺) | 0.5 - 5 keV | Affects depth resolution & sample damage | |

| Detection Limit | Atomic Concentration | 0.1 - 1.0 at.% | Minimum detectable elemental concentration |

| Lateral Resolution | X-Y Mapping | < 10 nm (FEG systems) | Detail in contamination mapping |

Experimental Protocols

Protocol 1: AES Point Analysis for Surface Contamination Identification

Objective: To identify unknown particulate or thin-film contamination on a device surface. Materials: Sample, conductive adhesive (if insulating), standard reference materials (e.g., pure Cu, Si). Procedure:

- Sample Mounting: Secure sample on holder using clips or conductive tape. Ensure electrical contact for charge compensation if non-conductive.

- Load & Pump: Insert into UHV load lock, pump to <10⁻⁵ Pa, then transfer to analysis chamber (<10⁻⁸ Pa).

- Locate Feature: Use integrated SEM or optical microscope to navigate to the feature of interest.

- Optimize Beam: Set primary beam energy (typically 10 keV for survey, 5-10 keV for high-resolution). Adjust beam current to 1-10 nA for point analysis.

- Acquire Survey Spectrum: Set analyzer to constant retard ratio (e.g., 4) or constant pass energy (e.g., 100 eV). Acquire spectrum from 30 eV to 2000 eV.

- Identify Elements: Differentiate spectrum (dN(E)/dE) to enhance Auger peaks. Identify all elements present from peak positions.

- High-Resolution Scan: For key elements (e.g., C, O, N), acquire narrow scans over relevant energy windows with higher energy resolution (e.g., 20 eV pass energy, 0.1 eV/step).

- Data Analysis: Compare peak shapes and energies to standard spectral libraries to infer chemical states (e.g., carbide vs. graphitic carbon).

Protocol 2: AES Depth Profiling for Thin-Film Failure Analysis

Objective: To determine the elemental composition as a function of depth at a site of interfacial failure (e.g., delamination). Materials: Sample, argon gas supply (99.999% purity). Procedure:

- Initial Surface Analysis: Perform Protocol 1, Step 5-7 at the analysis site.

- Select Sputter Parameters: Define a sputter crater larger than the analysis area. Typical settings: 1-4 keV Ar⁺, beam current density 10-50 µA/cm², raster over 2x2 mm area.

- Set Profiling Sequence: Program an alternating cycle of: a. Sputter Etch: Apply ion beam for a time calculated to remove ~1-5 nm per cycle (calibrated on a standard like Ta₂O₅). b. Analysis: Move sample to center of crater. Acquire spectra for major element peaks identified in the survey. Use same analyzer settings for each cycle.

- Execute Profile: Run automated sequence for 50-200 cycles, depending on desired depth.

- Data Quantification: Use relative sensitivity factors (RSFs) to convert peak-to-peak heights in differentiated spectra to atomic concentrations for each element at each cycle.

- Depth Calibration: Convert cycle number to depth (nm) using known sputter rate for a standard or by measuring final crater depth with a profilometer.

Visualizations

Diagram 1: AES System Workflow

Diagram 2: AES Signal Acquisition Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AES-Based Contamination Analysis

| Item | Function & Application | Key Consideration |

|---|---|---|

| Conductive Adhesive Tapes/Carbon Paints | Mounting insulating samples to prevent charging. | Low outgassing in UHV; minimal contaminant background (low Na, K, Cl). |

| Argon Gas (99.999%+) | Source gas for sputter ion gun for depth profiling and cleaning. | High purity critical to avoid implanting reactive contaminants (e.g., O₂, H₂O). |

| Standard Reference Materials (NIST-traceable) | Quantification calibration (e.g., pure Cu, Au, Si) and sputter rate calibration (e.g., Ta₂O₅, SiO₂/Si). | Certified composition and known, stable oxide thickness. |

| Charge Neutralization Source (Flood Gun) | Low-energy electron/ion beam for stabilizing potential on insulators. | Essential for analyzing polymers or ceramic contaminants. |

| In-situ Cleaving/Fracture Stage | Creates clean, fresh surfaces within UHV for analyzing bulk composition or grain boundary chemistry. | Used in failure analysis of brittle fractures. |

| UHV-Compatible Solvents (e.g., HPLC-grade Isopropanol) | For pre-cleaning samples in a controlled manner before insertion to reduce hydrocarbon load. | Minimizes adventitious carbon layer, reducing analysis time. |

Practical AES Workflows: From Sample Prep to Data Interpretation in Drug Development

Article Context

This application note, framed within a broader thesis on Auger Electron Spectroscopy (AES) for surface contamination and failure analysis research, details a comprehensive protocol for conducting a complete AES investigation. It provides researchers, scientists, and drug development professionals with a standardized methodology for identifying elemental surface composition, mapping spatial distribution, and obtaining quantitative depth profiles, which is critical for root-cause analysis in device failures, coating integrity assessment, and contamination studies in pharmaceutical manufacturing.

Auger Electron Spectroscopy is a surface-sensitive analytical technique used to determine the elemental composition (for elements Z > 2) of the top 0.5-10 nm of a solid surface. The core workflow involves three sequential phases: Spectral Acquisition for qualitative and quantitative analysis, Elemental Mapping for spatial distribution, and Sputter Depth Profiling for compositional analysis as a function of depth.

Detailed Experimental Protocols

Objective: To introduce a contamination-free, electrically stabilized sample into the ultra-high vacuum (UHV) analysis chamber. Materials: Conductive adhesive tape (e.g., carbon tape), ultrasonic cleaner, high-purity solvents (isopropanol, acetone), inert gas duster, standard sample holder. Procedure:

- Cleaning: For non-delicate samples, perform sequential ultrasonic cleaning in acetone and isopropanol for 5 minutes each. Dry with a stream of dry, oil-free nitrogen gas.

- Mounting: For electrically insulating samples, apply a strip of conductive carbon tape to the sample holder and affix the sample. Ensure a secure mechanical and electrical connection to minimize charging.

- Introduction: Transfer the mounted sample to the UHV introduction chamber. Pump down to a pressure of ≤ 1 x 10⁻⁶ mbar.

- Transfer: Open the gate valve and transfer the sample to the analysis chamber (pressure ≤ 5 x 10⁻⁹ mbar). Allow thermal equilibration for 15-30 minutes.

Protocol 2.2: Spectral Acquisition and Qualitative Analysis

Objective: To acquire a survey spectrum from a point on the sample to identify all detectable elements present. Instrument Parameters (Typical):

- Primary Electron Beam: 10 keV, 10 nA beam current.

- Beam Diameter: ~100 nm (dependent on instrument).

- Analysis Area: Typically 1 x 1 µm² to 10 x 10 µm².

- Detector: Cylindrical Mirror Analyzer (CMA). Set pass energy to 100 eV for survey scans, 20-50 eV for high-resolution multiplex scans. Procedure:

- Region Selection: Using the microscope, navigate to a representative area of interest on the sample.

- Beam Alignment: Optimize the electron gun alignment and adjust the sample's Z-position (working distance) for maximum signal.

- Survey Scan Acquisition: Acquire a spectrum over a kinetic energy range of 30 eV to 2000 eV. Use an energy step size of 0.5-1 eV and a dwell time of 50-100 ms per point.

- Peak Identification: Process the spectrum by applying a smoothing function (e.g., Savitzky-Golay) and a linear or Shirley background subtraction. Identify all major and minor Auger peaks by matching their kinetic energies to standard reference databases.

- Multiplex Scan: For quantitative analysis, acquire high-resolution scans over the energy range of each identified elemental peak (e.g., C KLL, O KLL, Fe LMM). Use a pass energy of 20-50 eV.

Protocol 2.3: Quantitative Analysis (Sensitivity Factor Method)

Objective: To convert measured peak intensities into atomic concentrations. Procedure:

- Peak Intensity Measurement: For each element identified, measure the peak-to-peak height (in derivative dN(E)/dE mode) or the integrated area under the peak (in direct N(E) mode after background subtraction) from the high-resolution multiplex scan.

- Apply Relative Sensitivity Factors (RSFs): Calculate atomic concentration using the formula: [ Cx = \frac{Ix / Sx}{\sum{i} (Ii / Si)} ] where (Cx) is the atomic concentration of element (x), (Ix) is the measured peak intensity, and (S_x) is the relative sensitivity factor for that element under the specific instrument conditions. RSFs are typically provided by the instrument manufacturer or derived from standard samples.

Table 1: Example Quantitative AES Data from a Contaminated Silicon Wafer

| Element | Peak Energy (eV) | Peak Intensity (a.u.) | RSF (Provided) | Atomic Concentration (%) |

|---|---|---|---|---|

| C (KLL) | 272 | 125,400 | 0.18 | 32.5% |

| O (KLL) | 503 | 89,200 | 0.34 | 12.3% |

| Si (KLL) | 1619 | 305,000 | 0.32 | 45.2% |

| Fe (LMM) | 703 | 12,500 | 0.25 | 2.3% |

| Na (KLL) | 990 | 8,750 | 0.15 | 2.7% |

Protocol 2.4: Elemental Mapping

Objective: To visualize the two-dimensional spatial distribution of elements on the sample surface. Procedure:

- Parameter Setup: Define the analysis area (e.g., 50 x 50 µm²). Set the electron beam parameters (e.g., 10 keV, 10 nA).

- Peak and Background Selection: For each element of interest, select the kinetic energy window for the peak (P) and two background windows (B1, B2) on either side of the peak.

- Scan Acquisition: Raster the focused electron beam over the defined area. At each pixel, the analyzer sequentially acquires counts at the peak and background energies. The net signal is calculated as (P - (B1+B2)/2).

- Image Generation: Construct a 2D map where the pixel intensity is proportional to the net Auger signal for the selected element.

- Overlay: Create composite overlay maps to show co-localization of different elements.

Protocol 2.5: Sputter Depth Profiling

Objective: To determine the in-depth elemental composition of thin films or contamination layers. Procedure:

- Initial Surface Analysis: Acquire a survey spectrum from the analysis point.

- Sputter Source Setup: Use an inert gas ion gun (typically Ar⁺) with an acceleration voltage of 0.5 - 5 keV and a rastered beam over an area larger than the analysis area to ensure a flat-bottomed crater.

- Cyclic Data Acquisition: A single profile cycle consists of: a. Sputtering: Erode the surface for a fixed time interval (e.g., 5-30 seconds), defining the depth resolution. b. Analysis: Acquire multiplex spectra for all elements of interest from the central, flat portion of the crater.

- Repetition: Repeat the sputter-analysis cycle until the substrate or a layer of interest is fully exposed.

- Depth Calibration: Convert sputter time to depth by measuring the total crater depth post-analysis using a stylus profilometer and assuming a constant sputter rate. Sputter rates are material-dependent.

Table 2: Sputter Depth Profiling Parameters for a 100 nm TiN Coating

| Parameter | Setting 1 (High Res) | Setting 2 (Through Layer) |

|---|---|---|

| Ion Species | Ar⁺ | Ar⁺ |

| Ion Energy | 1 keV | 3 keV |

| Ion Current Density | 0.5 µA/cm² | 2 µA/cm² |

| Raster Area | 2 x 2 mm² | 2 x 2 mm² |

| Analysis Area | 100 x 100 µm² | 100 x 100 µm² |

| Cycle Time (Sputter + Analyze) | 20 s | 15 s |

| Estimated Depth Resolution (at interface) | ~3 nm | ~8 nm |

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for AES Sample Preparation and Analysis

| Item | Function/Benefit |

|---|---|

| High-Purity Solvents (HPLC Grade Acetone & Isopropanol) | Removes organic contaminants and particles from sample surfaces without leaving significant residues. |

| Conductive Carbon Tape | Provides a reliable, low-outgassing method for mounting and electrically grounding non-conductive or irregularly shaped samples. |

| Dry, Oil-Free Nitrogen Gas | Provides a clean, non-contaminating method for drying solvents from sample surfaces after cleaning. |

| Argon Gas (99.9999% purity) | Source gas for the ion gun used in sputter cleaning and depth profiling. High purity minimizes introduction of new contaminants. |

| Standard Reference Materials (e.g., Pure Cu, Au, Si) | Used for instrumental energy calibration, verifying resolution, and determining relative sensitivity factors (RSFs) for quantification. |

| Cleaned, Polished Stainless Steel or Mo Sample Holders | Provide a uniform, low-outgassing, and electrically conductive platform for mounting samples in the UHV system. |

Visualized Workflows and Relationships

Title: Comprehensive AES Analysis Workflow Diagram

Title: AES Signal Generation and Detection Pathway

1.0 Introduction

Within the broader thesis on the application of Auger Electron Spectroscopy (AES) for surface contamination and failure analysis, this case study exemplifies its critical role in medical device diagnostics. Inorganic surface contaminants, such as salts, residual processing chemicals, and particulate matter, can compromise device performance, lead to adverse biological reactions, and cause product failure. AES provides unparalleled sensitivity for light elements and offers high spatial resolution (<10 nm), enabling the precise localization and chemical state identification of inorganic residues at the outermost surface layers (1-5 nm), which are often undetectable by bulk techniques.

2.0 Key Contaminants & Data Summary

The following table summarizes common inorganic contaminants identified on medical device surfaces via AES, their potential sources, and associated risks.

Table 1: Common Inorganic Contaminants on Medical Devices

| Contaminant | Chemical Species | Potential Source | Identified Risk/Effect |

|---|---|---|---|

| Chlorides | NaCl, KCl, MgCl₂ | Fingerprints, saline solutions, process water | Pitting corrosion on stainless steel alloys, altered surface energy. |

| Sulfates | (NH₄)₂SO₄, CaSO₄ | Cleaning agents, water, environmental exposure | Can act as stress corrosion cracking initiators. |

| Silicates | SiO₂, Siloxanes | Molding release agents, dust, glassware | Insulating layers, poor adhesion of coatings, inflammatory response. |

| Phosphates | PO₄³⁻ compounds | Biologic residues, cleaning detergents | May interfere with intended bioactive surface modifications. |

| Calcium Salts | CaCO₃, Ca₃(PO₄)₂ | Hard water, biologic fluids | Occlusion of micro-fluidic channels, nucleation site for biofilms. |

| Transition Metals | Fe, Ni, Cr particles | Tooling wear, manufacturing debris | Catalytic degradation of polymers, cytotoxic effects. |

3.0 Experimental Protocols

3.1 Protocol for AES Analysis of a Coronary Stent Surface

- Objective: To map the distribution and identify the composition of particulate contamination on a laser-cut stainless steel coronary stent.

- Sample Preparation:

- Use conductive carbon tape to mount the stent to an AES sample holder.

- If the stent is non-conductive (e.g., polymer-coated), employ a low-voltage, short-duration carbon coating to prevent charging, ensuring it does not obscure surface contaminants.

- Handle all samples with powder-free nitrile gloves and ceramic tweezers to prevent additional contamination.

- AES Instrument Parameters (Typical):

- Primary Electron Beam: 10 keV, 10 nA.

- Beam Diameter: ~20 nm for point analysis; raster for mapping.

- Analysis Chamber Pressure: < 5 x 10⁻⁹ Torr.

- Sputtering Ion Gun (for depth profiling): Ar⁺, 1-3 keV, raster over 2x2 mm area.

- Procedure:

- Survey Scan: Acquire a wide energy survey spectrum (0-1000 eV) from multiple visually identified points of interest (clean area and particulate spots).

- High-Resolution Multiplex Scan: Perform narrow window scans on key elemental peaks (e.g., O KLL, C KLL, Cl LMM, Si KLL, Na KLL, Ca LMM) to determine chemical states.

- Elemental Mapping: Set the cylindrical mirror analyzer (CMA) to the kinetic energy of a specific Auger transition (e.g., Cl 181 eV). Raster the electron beam to create a 2D map of chlorine distribution.

- Depth Profiling: On a contaminated spot, alternately sputter the surface with the Ar⁺ ion gun and acquire AES spectra to determine the in-depth distribution of the contaminant layer.

- Data Interpretation: Compare the peak energies and line shapes from contaminant regions with reference spectra from known salts. Quantification using relative sensitivity factors (RSFs) provides atomic concentrations.

3.2 Protocol for Contaminant Removal Efficiency Validation

- Objective: To assess the efficacy of a new plasma cleaning process in removing residual silicate mold release agent from a polymer catheter hub.

- Procedure:

- Select 10 devices: 5 as-cleaned with the standard method, 5 cleaned with the new plasma method.

- Perform AES survey scans on an identical location (e.g., inner rim) on each device.

- Measure the intensity (peak-to-peak height in the derivative spectrum) of the Si KLL (1619 eV) signal.

- Normalize the Si signal to the dominant C KLL (272 eV) signal for each spectrum to account for slight topographic variations.

- Data Presentation: Report the mean normalized Si intensity and standard deviation for each batch. A statistical t-test confirms the significance of the reduction.

Table 2: AES Results for Cleaning Validation (Hypothetical Data)

| Cleaning Method | Mean Normalized Si Signal (a.u.) | Standard Deviation | Atomic % Si (Estimated) |

|---|---|---|---|

| Standard Wash | 0.85 | 0.15 | 12.5% |

| New Plasma Process | 0.04 | 0.02 | 0.6% |

4.0 Visualization: AES Failure Analysis Workflow

AES Failure Analysis Workflow

5.0 The Scientist's Toolkit: Research Reagent Solutions & Materials

Table 3: Essential Materials for AES-Based Contaminant Analysis

| Item | Function/Application |

|---|---|

| Conductive Carbon Tape/Dots | Provides electrical and thermal contact between sample and holder, preventing charging under electron beam. |

| Argon Gas (99.999% purity) | Source gas for the ion sputtering gun used for depth profiling and cleaning analysis areas. |

| Standard Reference Materials (e.g., SiO₂, NaCl wafer) | Used for instrument calibration, verification of energy scale, and confirming sensitivity factors. |

| High-Purity Solvents (IPA, Acetone) | For ultrasonic cleaning of sample holders and tools to prevent cross-contamination. |

| Ceramic or Non-Metallic Tweezers | To handle samples without transferring metallic ions or particles to critical surfaces. |

| Particle-Free Gloves (Nitrite) | Essential for sample preparation to avoid contamination from skin oils and salts (Na, K, Cl). |

| Gold or Carbon Sputter Coater | For applying a thin, conductive layer on insulating samples to facilitate AES analysis. |

This application note presents a systematic failure analysis protocol for delaminated drug-eluting coatings (DECs), framed within a broader thesis on the application of Auger Electron Spectroscopy (AES) for surface contamination and interfacial failure research. DELAMINATION is a critical failure mode in biomedical implants (e.g., stents, orthopedic devices) and can lead to loss of therapeutic efficacy, adverse biological responses, and device malfunction. AES provides nanoscale elemental mapping and depth profiling essential for identifying sub-micrometer contaminants, interfacial chemistry, and bonding failures invisible to optical or electron microscopy alone.

Based on current literature and failure analyses, primary mechanisms for DEC delamination are summarized in Table 1.

Table 1: Primary Mechanisms and Contributing Factors for DEC Delamination

| Mechanism | Description | Typical AES Findings | Frequency in Studies* (%) |

|---|---|---|---|

| Adhesive Failure | Separation at the coating-substrate interface. | Detection of interfacial contaminants (C, O, Si, S), absence of substrate elements (e.g., Co, Cr, Ti) in coating underside. | 45-60% |

| Cohesive Failure | Fracture within the coating polymer matrix itself. | Uniform elemental composition on both fracture faces; may show phase separation or filler agglomeration. | 20-30% |

| Hydrolitic Degradation | Polymer bond cleavage due to moisture ingress. | Increased oxygen at interface; possible correlation with coating thickness and porosity. | 10-20% |

| Stress-Induced Failure | Mismatch in thermal expansion or residual stress. | Clean interface in AES; failure correlates with mechanical testing data (e.g., adhesion pull-off). | 5-15% |

*Frequency data aggregated from recent studies (2020-2024).

Table 2: Common Interfacial Contaminants Identified by AES in Delaminated DECs

| Contaminant Element | Probable Source | Impact on Adhesion |

|---|---|---|

| Silicon (Si) | Silicone release agents, dust, process residues. | Severe reduction; forms weak boundary layer. |

| Sulfur (S) | Antioxidants, processing aids, or environmental exposure. | Moderate to severe reduction. |

| Chlorine (Cl) | Saline processing, residual solvents. | Promotes corrosive undercutting and adhesion loss. |

| Alkali Metals (Na, K) | Handling contaminants, biological fluids. | Catalyzes polymer degradation, reduces interfacial strength. |

Experimental Protocols

Protocol 1: AES-Based Failure Interface Analysis

Objective: To perform chemical characterization of both fracture surfaces (coating side and substrate side) of a delaminated DEC to determine failure mode.

Materials: See "The Scientist's Toolkit" below.

Method:

- Sample Preparation:

- Carefully separate delaminated fragments using ceramic tweezers.

- Mount each fragment (coating underside and substrate topside) on a conductive carbon tab or holder. Ensure electrical contact for charge compensation.

- Sputter-clean a small, non-critical area with a low-energy (500 eV, 1 µA) Ar⁺ ion beam for 30 seconds to remove adventitious carbon.

- AES Survey Scan:

- Operate AES system with a base pressure < 5 x 10⁻¹⁰ Torr.

- Set primary electron beam: 10 keV, 10 nA, spot size ~20 nm.

- Acquire survey spectra (0-1000 eV) from a minimum of 5 distinct points on each fracture surface.

- Identify all elements present (excluding Ar from sputtering).

- High-Resolution Mapping & Point Analysis:

- For elements of interest (e.g., C, O, N, substrate metals, contaminants), acquire high-resolution multiplex spectra.

- Perform elemental mapping (e.g., for Si, S, Cl) over a 20 µm x 20 µm area to visualize contaminant distribution.

- Depth Profiling (If Interface is Accessible):

- On a partially delaminated edge, perform AES depth profiling using a sequenced Ar⁺ sputter (2 keV, 2 µA, rastered).

- Monitor key element signals versus sputter time to reconstruct the interfacial chemistry.

Protocol 2: Correlative Microscopy Workflow for Root-Cause Analysis

Objective: To integrate AES data with structural and compositional data from other techniques for comprehensive root-cause determination.

Method:

- Initial Inspection: Use optical microscopy and scanning electron microscopy (SEM) to document delamination morphology and locate representative areas for analysis.

- Focused Ion Beam (FIB) Cross-Sectioning:

- At the delamination front, deposit a protective Pt strap.

- Mill a trench to create a thin electron-transparent lamella (~100 nm thick) perpendicular to the interface using Ga⁺ ions (30 keV then 5 keV for cleaning).

- Transmission Electron Microscopy (TEM) & EDS: Analyze the lamella via TEM for crystallographic and morphological defects. Perform energy-dispersive X-ray spectroscopy (EDS) for elemental composition.

- Targeted AES: Transfer the bulk sample (not the lamella) to the AES system. Use SEM images as a map to navigate to the exact region adjacent to the FIB site for AES point analysis as per Protocol 1.

- Data Correlation: Overlay AES contaminant maps with SEM/EDS data to identify if contaminants originate from the substrate, coating, or external environment.

Visualization of Analysis Workflow

Diagram Title: DEC Delamination Failure Analysis Decision Workflow

Diagram Title: Correlative Microscopy for DEC Failure Analysis

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for AES-Based DEC Failure Analysis

| Item | Function in Analysis | Key Considerations |

|---|---|---|

| Conductive Carbon Tape/Dots | Mounting fragile delaminated fragments for SEM/AES. | Must be ultra-high purity to avoid introducing Si, S, or Cl contaminants detectable by AES. |

| Ceramic-Coated Tweezers | Handling samples to prevent introduction of metallic contamination. | Prevents false-positive detection of Fe, Ni, Cr from stainless steel tweezers. |

| Argon (Ar), 99.9999% | Gas for ion sputter cleaning and depth profiling in AES. | High purity is critical to avoid implanting residual gas contaminants (e.g., H₂O, N₂) into the analysis area. |

| AES Reference Standards | Thin film standards (e.g., Au, Cu, SiO₂ on Si) for instrument calibration. | Essential for ensuring spatial and energy calibration, guaranteeing accuracy in mapping and peak identification. |

| FIB-Pt Gas Precursor | (e.g., Trimethylcyclopentadienyl Pt) Deposits protective Pt strap during FIB cross-sectioning. | Allows for precise site-specific analysis and protects the delicate polymer interface from ion beam damage. |

| Charge Neutralization Source | Low-energy electron flood gun or Ar⁺ flood source. | Mitigates charging on insulating polymer coatings during AES analysis, enabling stable spectroscopy and mapping. |

| High-Purity Solvents | HPLC-grade water, isopropanol for controlled cleaning of substrate pre-analysis. | Used in control experiments to clean substrates, establishing a baseline AES spectrum for a "clean" interface. |

1.0 Introduction Within the broader thesis on Auger Electron Spectroscopy (AES) for surface contamination and failure analysis, this case study addresses a critical challenge in pharmaceutical manufacturing: the detection and source identification of low-level active pharmaceutical ingredient (API) cross-contamination on shared equipment surfaces. This application note details the analytical protocols for utilizing AES alongside complementary techniques to provide chemical state and spatial mapping data crucial for root-cause analysis.

2.0 Key Research Reagent Solutions & Materials Table 1: Essential Toolkit for Surface Contamination Investigation

| Item | Function in Analysis |

|---|---|

| AES Instrument (Scanning Auger Microprobe) | Provides elemental identification and high-spatial-resolution (≤ 20 nm) mapping of surface contaminants. |

| ToF-SIMS (Time-of-Flight Secondary Ion Mass Spectrometry) | Offers molecular speciation and high-sensitivity detection of organic contaminants (e.g., API fragments). |

| XPS (X-ray Photoelectron Spectroscopy) | Delivers quantitative elemental analysis and chemical state information for the top 5-10 nm. |

| VCR/DCR Standard Samples | Certified reference materials for instrument calibration and validation of quantitative AES results. |

| Inert Transfer Vessel (e.g., Vacuum Sealable Container) | Preserves surface state of swab or coupon samples from cleanroom to spectrometer. |

| Conductive Adhesive Tape (Carbon) | Mounts non-conductive samples for AES/XPS analysis to mitigate charging effects. |

| Argon Gas Cluster Ion Source (for ToF-SIMS/XPS) | Enables depth profiling of organic materials with minimal molecular damage. |

3.0 Experimental Protocols

3.1 Protocol: Surface Sampling & Preliminary Screening Objective: To collect and initially screen for the presence of contaminant elements.

- Sample Collection: Using pre-cleaned stainless-steel coupons or dry wipes, perform a standardized swab of a defined area (e.g., 10 cm²) from the suspected equipment surface (e.g., blender door gasket). Include a negative control swab from a cleaned area.

- Transfer: Immediately place samples in an inert transfer vessel under nitrogen purge.

- SEM/EDX Screening: Load the swab or coupon into a Scanning Electron Microscope (SEM) equipped with Energy Dispersive X-Ray Spectroscopy (EDX). Acquire secondary electron images and perform broad-area EDX to identify particulate contaminants and detect anomalous elements (e.g., sulfur, fluorine indicative of specific APIs).

3.2 Protocol: Auger Electron Spectroscopy (AES) Analysis Objective: To perform high-resolution elemental mapping and point analysis on identified contaminant spots.

- Sample Mounting: Affix the coupon or a section of the wipe to a sample stub using conductive carbon tape.

- Instrument Parameters: Insert into UHV chamber (< 5 x 10⁻⁹ Torr). Set primary electron beam energy to 10 kV, beam current to 10 nA.

- Survey Scan: On a suspect particle or area, acquire a survey spectrum from 30 eV to 2000 eV to identify all elements present (excluding H, He).

- Multipoint Analysis: Acquire high-resolution spectra for key elements (e.g., C KLL, O KLL, N KLL, F KLL, S LMM) at minimum of 5 distinct points on the contaminant and the clean substrate.

- Elemental Mapping: Set Auger peak energies for contaminant-specific elements (e.g., F, S) and the substrate (e.g., Fe, Cr). Acquire a map over a selected area (e.g., 50 x 50 μm) with 256 x 256-pixel resolution.

3.3 Protocol: Complementary ToF-SIMS Confirmation Objective: To confirm the molecular identity of the organic contaminant.

- Sample Transfer: Under controlled atmosphere, transfer the same sample to the ToF-SIMS instrument.

- Static SIMS Analysis: Use a Bi³⁺ primary ion source (25 keV) for surface analysis. Acquire positive and negative ion spectra from areas defined by AES maps.

- Fragment Matching: Identify molecular fragments and adduct ions ([M+H]⁺, [M+Na]⁺) corresponding to the suspected API. Compare spectra to a pure API standard analyzed under identical conditions.

4.0 Data Presentation

Table 2: Quantitative AES Point Analysis of Contaminant vs. Substrate

| Element | Atomic % (Contaminant Spot) | Atomic % (Clean 316L SS Substrate) | Probable Origin |

|---|---|---|---|

| C | 68.5 ± 3.2 | 24.1 ± 2.1 | API / Adventitious Carbon |

| O | 18.2 ± 1.8 | 61.3 ± 2.5 | Oxide Layer / API |

| F | 9.8 ± 1.1 | 0.0 ± 0.0 | Fluorinated API Marker |

| N | 3.5 ± 0.7 | 0.0 ± 0.0 | API Marker |

| Fe | 0.0 ± 0.0 | 8.5 ± 0.9 | Stainless Steel Substrate |

| Cr | 0.0 ± 0.0 | 6.1 ± 0.7 | Stainless Steel Substrate |

Table 3: ToF-SIMS Key Ion Fragments Match

| Detected Ion (m/z) | Fragment Assignment | Matches API Standard? |

|---|---|---|

| 304.1 | [M+H]⁺ of API | Yes |

| 326.1 | [M+Na]⁺ of API | Yes |

| 138.0 | Characteristic fluorinated moiety | Yes |

| 280.0 | [M-HF+H]⁺ | Yes |

5.0 Visualized Workflows & Pathways

Title: Cross-Contamination Analytical Workflow

Title: Cross-Contamination Failure Pathway

Auger Electron Spectroscopy (AES) is a cornerstone analytical technique for investigating surface contamination and failure mechanisms in materials critical to semiconductor manufacturing, biomedical device production, and pharmaceutical development. The core analytical challenge lies in moving beyond qualitative elemental identification to robust, quantitative composition analysis. This transition—from measuring raw Auger peak heights to reporting reliable atomic concentrations—is fundamental for determining trace contaminant levels, understanding interfacial chemistry in drug delivery systems, and identifying root causes of device failures. This protocol details the systematic methodology required for this quantitative transformation.

Foundational Principles and Sensitivity Factors

Quantitative AES analysis relies on the comparison of measured peak intensities to standard sensitivity factors. The atomic concentration ( C_x ) of element ( x ) is calculated from the differentiated spectrum using the formula:

[ Cx = \frac{Ix / Sx}{\sumj (Ij / Sj)} ]

Where:

- ( I_x ) is the measured peak-to-peak height (in the derivative spectrum) for element ( x ).

- ( S_x ) is the relative elemental sensitivity factor for that specific Auger transition.

- The denominator sums the normalized intensities for all detected elements ( j ).

These sensitivity factors are matrix- and instrument-dependent. Table 1 compiles commonly used relative sensitivity factors (RSFs) for key elements, typically referenced to the Ag MNN (356 eV) transition.

Table 1: Common Relative Sensitivity Factors for Quantitative AES

| Element & Transition | Kinetic Energy (eV) | Relative Sensitivity Factor (S) | Primary Application Note |

|---|---|---|---|

| C KLL | 272 | 0.20 | Ubiquitous contaminant; use for adventitious carbon or carbide analysis. |

| O KLL | 503 | 0.50 | Critical for oxide, hydroxide, and organic contaminant quantification. |

| N KLL | 381 | 0.32 | Essential for analyzing nitrides, amines, or proteinaceous contamination. |

| Si LVV | 92 | 0.30 | Core element for semiconductor failure analysis. |

| Fe LMM | 703 | 0.25 | Key for corrosion product analysis on stainless steel components. |

| Ag MNN | 356 | 1.00 | Reference standard. |

| Au MNN | 69 | 1.10 | Used for coating thickness and diffusion studies. |

Detailed Experimental Protocol for Quantitative AES Analysis

Protocol 3.1: Sample Preparation and Instrument Setup

- Objective: Obtain a clean, representative, and electrically stable surface for analysis.

- Materials: Conductive tape (carbon or copper), ultrasonic cleaner, argon gas supply, in-situ argon ion sputtering gun.

- Procedure:

- Mount sample using conductive tape to minimize charging. For powders, press into indium foil.

- If bulk conductivity is poor, consider depositing a thin, discontinuous Au or C coating via sputtering after initial analysis of the pristine area.

- Insert into UHV chamber (< 5 × 10⁻⁹ Torr) and allow for sufficient outgassing (typically 1-12 hours).

- For depth profiling or cleaning of native oxides, configure argon ion sputtering gun (e.g., 1-5 keV, 10-50 µA/cm², rastered). Sputter a standard SiO₂/Si sample to calibrate sputter rate if depth quantification is needed.

Protocol 3.2: Data Acquisition for Quantification

- Objective: Acquire high signal-to-noise Auger spectra suitable for peak height measurement.

- Materials: Electron gun (typically 3-20 keV, 10-50 nA), cylindrical mirror analyzer (CMA) or hemispherical analyzer (HSA).

- Procedure:

- Select a primary beam energy (typically 10 keV) that provides sufficient ionization cross-section for elements of interest without excessive sample damage.

- Use a beam current (typically 10-20 nA) that provides strong signal without inducing rapid carbon contamination or damage to sensitive organics.

- Acquire survey spectrum from 20-2000 eV with a modulation amplitude of 4-6 eV (for derivative spectra) to identify all elements present.

- Acquire high-resolution multiplex spectra for each identified element. Use a lower modulation amplitude (2-3 eV) for better energy resolution on sharp peaks. Ensure sufficient dwell time per channel for adequate counting statistics.

Protocol 3.3: Data Processing and Concentration Calculation

- Objective: Transform raw spectra into atomic percentages.

- Software: Standard AES data processing suite (e.g., in Thermo Avantage, Ulvac-PHI MultiPak).

- Procedure:

- Apply a smoothing function (e.g., Savitzky-Golay) to multiplex spectra to reduce high-frequency noise without distorting peak shape.

- Subtract a linear or Shirley-type background from the direct (N(E)) spectrum if quantifying from integrated peak areas. For standard peak-to-peak height quantification in derivative mode, background subtraction is often minimal.

- Measure Peak-to-Peak Heights: In the differentiated spectrum (dN(E)/dE), measure the vertical distance from the most negative trough to the most positive peak for each elemental transition.

- Apply Sensitivity Factors: For each element ( x ), divide the measured peak-to-peak height ( Ix ) by its appropriate relative sensitivity factor ( Sx ) (e.g., from Table 1 or a manufacturer's library calibrated for your instrument).

- Normalize to 100%: Sum all the ( (I/S) ) values. The atomic percent of element ( x ) is calculated as: ( At.\%x = [(Ix/Sx) / \sum(Ij/S_j)] \times 100\% ).

Diagram: Quantitative AES Workflow

Case Study: Quantifying Silicon Wafer Contamination

- Scenario: A patterned silicon wafer from a drug delivery micro-pump manufacturing line shows localized functionality failure. AES is used to analyze a contaminated region versus a clean reference region.

- Data: Survey spectra identified C, O, N, F, and Si.

- Quantitative Analysis: High-resolution spectra were acquired for C KLL, O KLL, N KLL, F KLL, and Si LVV. Peak-to-peak heights were measured and quantified using the RSFs in Table 1 (F KLL assumed S=0.35).

Table 2: Quantitative AES Analysis of Contaminated Silicon Wafer

| Analysis Region | Atomic Concentration (%) | ||||

|---|---|---|---|---|---|

| C | O | N | F | Si | |

| Clean Reference Area | 12.5 | 28.1 | 1.2 | 0.0 | 58.2 |

| Contaminated Failure Site | 38.7 | 32.5 | 8.9 | 15.4 | 4.5 |

| Interpretation | High carbon suggests organic residue. | Elevated oxygen indicates possible oxide or organic compounds. | Significant nitrogen points to amine-containing compound. | Fluorine is a key contaminant from etchants or lubricants. | Drastic Si reduction confirms thick overlying contaminant layer. |

- Conclusion: The quantitative data confirms a thick, fluorine- and nitrogen-rich organic contaminant layer at the failure site, likely a residue from a cleaning or etching process, obstructing the micro-pump mechanism.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Quantitative AES Studies

| Item / Reagent | Function & Application Note |

|---|---|

| Ultra-High Purity Argon (Ar) Gas | Source gas for ion sputtering guns used for sample cleaning and depth profiling. Impurities can cause sample re-contamination. |

| Reference Standard Samples | Certified homogeneous standards (e.g., pure Ag, Au, Si) are crucial for periodically verifying/updating instrument-specific sensitivity factors. |

| Conductive Mounting Substrates | High-purity indium foil, carbon tape, or copper tape for securing samples. Must be free of elements that could interfere with analysis (e.g., avoid Zn-containing adhesives). |

| In-situ Cleaving/Fracture Stage | For preparing atomically clean, oxidation-free cross-sections of interfaces relevant to failure analysis (e.g., coating delaminations). |

| Ion Sputter Rate Calibration Samples | Thin thermally-grown SiO₂ on Si or calibrated thin film structures (e.g., Ta₂O₅ on Ta) are used to convert sputtering time to depth (nm). |

| Charge Neutralization System | Low-energy electron flood gun or adjustable low-energy ion beam is essential for analyzing insulating samples (e.g., pharmaceutical powders, oxides). |

Diagram: AES Quantitative Analysis Logical Pathway

Optimizing AES Analysis: Solving Common Challenges in Pharmaceutical Surface Science

Mitigating Electron Beam Damage on Organic and Polymeric Samples

Context within AES Thesis: This work supports a broader thesis on Auger Electron Spectroscopy (AES) for surface contamination and failure analysis by establishing reliable protocols for analyzing beam-sensitive materials, which are critical in pharmaceutical development and polymer science, without compromising chemical state information.

Quantitative Data on Electron Beam Effects

The following table summarizes key parameters and their impact on common organic/polymeric samples, based on current literature.

Table 1: Electron Beam Parameters and Damage Thresholds for Sensitive Materials

| Material Class | Typical Damage Dose (e⁻/nm²) | Recommended E-beam Energy (kV) | Recommended Beam Current (pA) | Critical Dose for AES Analysis (e⁻/nm²) | Primary Damage Manifestation |

|---|---|---|---|---|---|

| Conductive Polymers (PEDOT:PSS) | 10² – 10³ | 5 – 10 | 10 – 100 | ~500 | Loss of volatile components, carbonization |

| Pharmaceutical APIs (Crystalline) | 10¹ – 10² | 2 – 5 | 1 – 10 | ~100 | Amorphization, mass loss, halogen loss |

| Organic Thin Films (Alq3, etc.) | 10² | 3 – 7 | 5 – 50 | ~300 | Molecular fragmentation, reduced luminescence |

| Biological Macromolecules | 10⁰ – 10¹ | 1 – 3 | < 1 | ~10 | Denaturation, bond scission, bubbling |

| Polyethylene Terephthalate (PET) | 10³ – 10⁴ | 10 – 15 | 50 – 200 | ~2000 | Chain scission, mass loss, CO/CO₂ evolution |

Detailed Experimental Protocols

Protocol A: Low-Dose AES Survey and Point Analysis for Contamination Mapping

This protocol is designed for initial assessment of surface contaminants on a drug formulation coating.

- Sample Preparation: Sputter-coat a 5-10 nm layer of ultra-pure, thermally evaporated carbon using a dedicated coating system. Avoid gold or platinum coating for AES to prevent interference with key elemental peaks.

- Instrument Pre-conditioning: Pump the AES chamber to a base pressure of < 5 x 10⁻⁹ Torr. Use a liquid nitrogen cold trap to minimize hydrocarbon contamination from residual gases.

- Low-Dose Imaging:

- Set the electron gun to 5 kV acceleration voltage and 50 pA beam current.

- Use a fast scan (dwell time < 100 ns/pixel) to acquire a secondary electron (SE) image at 1000x magnification to locate the region of interest (ROI).

- Total dose for this survey should not exceed 10² e⁻/nm².

- Auger Point Analysis:

- Move the beam to the identified ROI without further scanning.

- For analysis, use a reduced current of 10 pA at 5 kV.

- Acquire a survey spectrum from 20 eV to 1000 eV with a high signal-to-noise ratio (SNR) setting (e.g., 5 eV step, 500 ms dwell).

- Dose Monitoring: Calculate the accumulated dose. If multiplex spectra of specific elements (C, O, N, F) are needed, limit total acquisition time to keep the local dose below the critical threshold (see Table 1).

- Validation: Immediately after analysis, acquire a second fast SE image of the analyzed point to check for visible damage (e.g., bubbling, cracking).

Protocol B: Cryogenic Sample Holder Protocol for Hydrated/Polymeric Samples

This protocol mitigates damage by stabilizing samples thermally and reducing radical mobility.

- Holder Preparation: Cool the cryo-stage in the AES load-lock to -170°C using liquid nitrogen at least 30 minutes prior to sample loading.

- Sample Transfer: Mount the sample on a pre-cooled cryo-holder under an inert atmosphere (Ar or N₂) glovebox if the sample is air-sensitive. Use a vacuum transfer shuttle to introduce the holder into the AES system, preventing frost formation.

- In-situ Analysis:

- Maintain stage temperature at <-150°C throughout the analysis.

- Perform AES analysis using parameters from Protocol A, but with a slightly higher permissible beam current (e.g., 20 pA), as the cryo-condition reduces damage propagation.

- For depth profiling, use a low-energy (100-500 eV) Ar⁺ ion gun with a grazing incidence angle (15-30°) and a low sputter rate (≤ 0.1 nm/s equivalent on SiO₂). Pause for 30 seconds between sputter cycles to allow heat dissipation.

- Post-analysis: Warm the sample to room temperature under high vacuum (> 2 hours) before venting the chamber to avoid condensation.

Visualization: Workflow and Pathways

Diagram 1: Workflow for AES analysis of beam-sensitive samples.

Diagram 2: Primary electron beam damage pathways leading to AES artifacts.

The Scientist's Toolkit: Research Reagent Solutions