Atomic Force Microscopy (AFM) for Semiconductor Surface Defects: A Complete Guide to Analysis, Optimization, and Advanced Applications

This comprehensive guide explores Atomic Force Microscopy (AFM) as an indispensable tool for analyzing semiconductor surface defects.

Atomic Force Microscopy (AFM) for Semiconductor Surface Defects: A Complete Guide to Analysis, Optimization, and Advanced Applications

Abstract

This comprehensive guide explores Atomic Force Microscopy (AFM) as an indispensable tool for analyzing semiconductor surface defects. We detail foundational AFM principles for defect identification, covering core operational modes like Contact, Tapping, and PeakForce Tapping. The article provides a step-by-step methodological workflow for defect characterization, addresses common troubleshooting and optimization challenges for reliable data, and validates AFM's capabilities through comparative analysis with techniques like SEM and TEM. Designed for researchers, scientists, and process engineers, this resource synthesizes current best practices to enhance yield and reliability in semiconductor manufacturing and advanced material development.

Understanding AFM Fundamentals: How Atomic Force Microscopy Reveals Semiconductor Surface Defects

This application note details the core operating principles of Atomic Force Microscopy (AFM) for probing nanoscale surface topography and mechanical properties. Within the broader thesis on AFM for semiconductor surface defect analysis, these principles form the foundational framework. They enable the correlation of topographic anomalies (e.g., pits, protrusions, pattern irregularities) with local variations in mechanical properties (e.g., modulus, adhesion, hardness), which is critical for identifying root causes of defects in advanced semiconductor fabrication processes.

Core Principles & Quantitative Data

Topography Probing Principle

AFM measures surface topography by scanning a sharp tip attached to a flexible cantilever across a sample. A laser beam reflected off the cantilever onto a photodiode detector monitors the tip's vertical deflection. In contact mode, a constant deflection (force) is maintained, and the scanner's vertical movement maps the topography. In tapping mode, the oscillating cantilever's amplitude or phase change due to tip-sample interaction is used as feedback.

Table 1: Key AFM Operational Modes for Semiconductor Analysis

| Mode | Feedback Parameter | Typical Force | Lateral Resolution | Best For Semiconductor Defects | Key Limitation |

|---|---|---|---|---|---|

| Contact | Constant Deflection | 0.1 - 100 nN | ~0.5 nm | Hard materials, frictional mapping | Sample damage, tip wear |

| Tapping (AM-AFM) | Amplitude Damping | 0.01 - 1 nN (peak) | ~1 nm | Soft/hard surfaces, particle contamination | Phase interpretation complexity |

| PeakForce Tapping | Peak Force (cyclic) | 10 - 500 pN | ~1 nm | High-res mechanical mapping on fragile structures | Optimization of oscillation parameters |

| Non-Contact (FM-AFM) | Frequency Shift | < 0.1 nN | Atomic resolution | Atomic-scale defects, ultra-sensitive surfaces | Requires ultra-high vacuum |

Mechanical Property Probing Principle

Mechanical properties are derived from force-distance (F-D) spectroscopy. The tip is brought into contact with the sample, and the cantilever deflection vs. Z-piezo displacement is recorded. The slope of the contact region indicates stiffness, and adhesion is measured from the pull-off force.

Table 2: Extracted Mechanical Properties from F-D Curves

| Property | Definition | Derived from F-D Curve | Typical Values (Semiconductors) | Relevance to Defect Analysis |

|---|---|---|---|---|

| Reduced Modulus (E*) | Sample stiffness | Slope of the unloading/loading curve | Si: ~130 GPa; SiO₂: ~70 GPa; Low-k dielectric: 5-20 GPa | Identifying material delamination, voids, or contamination. |

| Adhesion Force (F_ad) | Tip-sample attraction | Minimum force during retraction | 1 - 100 nN, varies with humidity & chemistry | Detecting organic residues or hydrophobic/hydrophilic regions. |

| Deformation (δ) | Sample indentation | Difference between piezo & tip motion | Sub-nm to nm scale | Assessing soft contaminants or porous material collapse. |

| Energy Dissipation | Work lost per cycle | Hysteresis area in F-D loop | eV to keV range | Mapping viscoelastic behavior of polymeric residues. |

Detailed Experimental Protocols

Protocol 3.1: Correlative Topography and Modulus Mapping for Defect Identification

Objective: To simultaneously map surface topography and elastic modulus of a semiconductor wafer to identify and characterize sub-surface defects.

Materials: See "The Scientist's Toolkit" below.

Method:

- Sample Preparation: Cleave a ~1 cm x 1 cm sample from the wafer. Use an air duster to remove loose particles. Mount on a magnetic stainless steel puck using double-sided carbon tape.

- Probe Selection & Mounting: Select a silicon probe with a nominal spring constant (k) of 0.4 - 40 N/m and a resonant frequency suitable for tapping or PeakForce mode. Calibrate the spring constant via the thermal tune method.

- System Setup: Load sample. Align laser on the cantilever's end and center the sum signal on the photodiode. Engage in tapping mode on a stable, defect-free region to find setpoint.

- Switch to Quantitative Nanomechanical Mapping (QNM/PeakForce): Transition to the proprietary mode (e.g., Bruker's PeakForce QNM, JPK's QI). Input the calibrated spring constant, deflection sensitivity, and tip radius. Set the PeakForce amplitude (typically 50-150 nm) and frequency (0.25-2 kHz).

- Parameter Optimization: Adjust the PeakForce setpoint to ensure gentle, repulsive contact (force < 1 nN for delicate features). Optimize scan rate (0.5-1 Hz) for a 5 µm x 5 µm area.

- Data Acquisition: Scan the area of interest. Acquire height, DMT modulus, adhesion, and deformation channels simultaneously.

- Analysis: Use the software's grain analysis or section tool to measure defect dimensions (from height). Correlate with modulus map: a subsurface void will appear as a topographic depression with a locally reduced modulus.

Protocol 3.2: Force-Volume Spectroscopy on a Suspected Defect

Objective: To acquire a grid of F-D curves over a region containing a suspected defect to quantitatively compare mechanical properties.

Method:

- Locate Defect: Use optical microscope or a large AFM scan to identify the defect coordinate.

- Define Grid: Over a 2 µm x 2 µm area encompassing the defect, define a 16x16 or 32x32 grid of measurement points.

- Set F-D Parameters:

- Z-length: 500 nm (ensures full approach-retract cycle).

- Approach/Retract Velocity: 500 nm/s to 1 µm/s.

- Trigger Mode: Relative trigger (e.g., trigger on a deflection of 1-5 nN).

- Dwell Time: 0 ms at maximum force to minimize creep.

- Acquisition: Run the force-volume scan. This may take 10-30 minutes.

- Offline Processing: Use the software to fit each F-D curve with an appropriate contact mechanics model (e.g., DMT, Hertz, Sneddon). Generate maps of derived modulus, adhesion, and deformation.

- Statistical Comparison: Use the software's ROI tool to select pixels from the defect and the surrounding reference material. Export data and perform a Student's t-test to determine if the modulus/adhesion difference is statistically significant (p < 0.05).

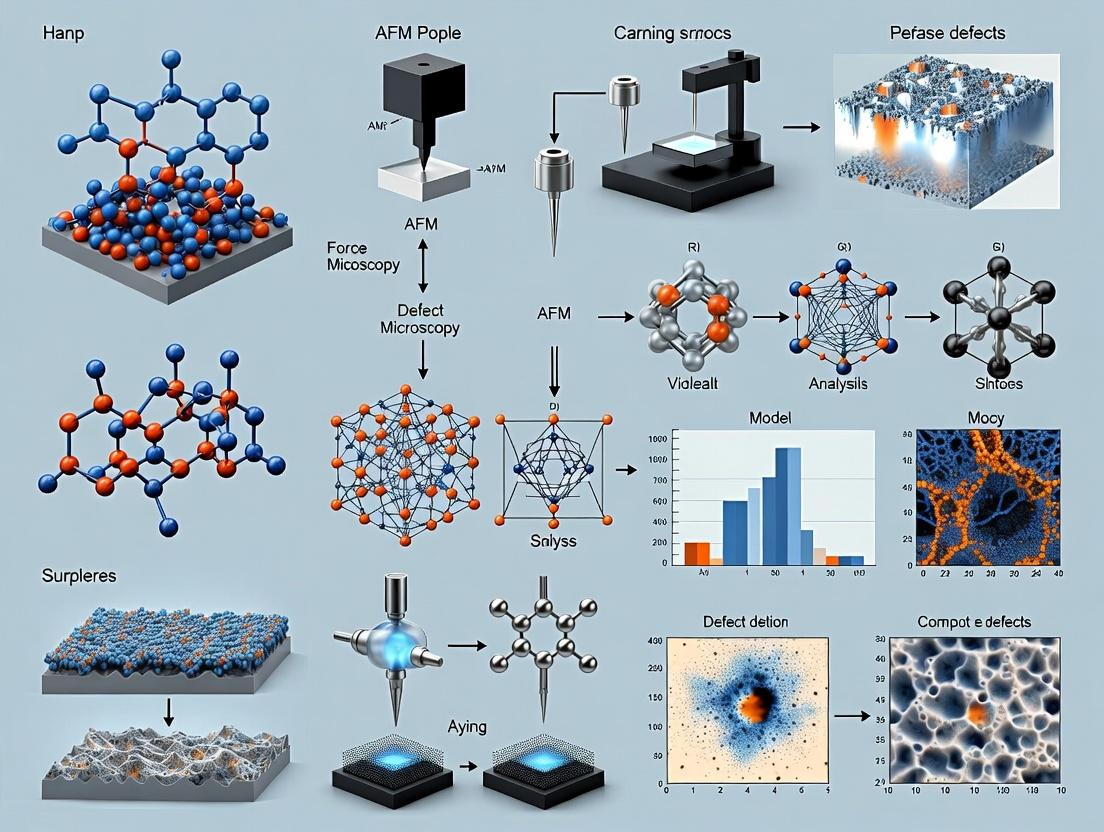

Diagrams

AFM Core Feedback Loop for Topography

Force-Distance Curve Analysis Workflow

Thesis Correlative Defect Analysis Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AFM-Based Semiconductor Defect Analysis

| Item | Function & Relevance to Semiconductor Analysis |

|---|---|

| Silicon Probes (Tapping Mode) | Standard topography imaging. High resonance frequency for stability on flat, hard surfaces. |

| Diamond-Coated Probes (Contact Mode) | For wear-resistant scanning of rough surfaces or long-term frictional studies on hard films. |

| Silicon Probes with Conductive Coating (PtIr, Doped Diamond) | For electrical modes (SCM, SSRM) to correlate topographic defects with carrier concentration. |

| PeakForce Tapping Probes (e.g., Bruker ScanAsyst) | Silicon nitride probes with optimized geometry and reflective coating for high-sensitivity force control. Essential for QNM on delicate low-k dielectrics. |

| Calibration Gratings (e.g., TGZ1, PG) | Grids with known pitch and step height for verifying lateral and vertical scanner calibration, critical for defect sizing. |

| Reference Sample for Modulus (e.g., Polystyrene, PDMS) | Samples with known, homogeneous modulus for validating QNM/Force spectroscopy calibration and models. |

| Vibration Isolation Platform | Active or passive isolation table to minimize acoustic/floor vibrations, crucial for high-resolution (<1 nm) defect imaging. |

| Sample Mounting Accessories | Magnetic pucks, double-sided carbon tape, or vacuum chucks to ensure flat, rigid mounting of wafer pieces to prevent drift. |

| Particle-Free Air Duster | To remove environmental contaminants from the sample surface before loading into the AFM, avoiding artifact "defects." |

| Cleaning Solutions (IPA, DI Water) | For probe and sample cleaning protocols, though sample cleaning is often avoided to preserve the native defect state. |

This application note, framed within a broader thesis on Atomic Force Microscopy (AFM) for semiconductor surface defects analysis research, details three primary operational modes: Contact Mode, Tapping Mode, and PeakForce Tapping Mode. Each mode offers distinct advantages for imaging and characterizing nanoscale defects, contamination, and morphological irregularities critical to semiconductor yield and performance, with parallel applications in nanoscale biomaterial analysis for drug development.

Comparative Analysis of AFM Modes

The table below summarizes the key operational parameters, strengths, and limitations of each mode for defect analysis.

| Parameter | Contact Mode | Tapping Mode | PeakForce Tapping Mode |

|---|---|---|---|

| Tip-Sample Interaction | Constant physical contact, sliding. | Intermittent contact, oscillating at resonance. | Precisely controlled, periodic force "taps." |

| Lateral Forces | High, can distort or damage soft samples. | Negligible, minimized by vertical oscillation. | Very low, force control prevents damage. |

| Typical Force Control | Deflection (normal force) is constant via feedback. | Amplitude (or phase) is constant via feedback. | Peak Force is directly set and controlled (pN-nN). |

| Best for Defect Types | Hard, flat, electrically conductive surfaces. | Soft contaminants, polymer residues, sticky layers. | All defect types, especially for quantitative mapping. |

| Quantitative Data | Friction (LFM), topography. | Phase (material contrast), topography. | Adhesion, Modulus, Deformation, Dissipation maps. |

| Risk of Artifact/ Damage | High (scratching, particle sweeping). | Medium-Low. | Very Low. |

| Semiconductor Application | Limited due to high risk of damaging fragile nanostructures. | Common for post-CMP particles and photoresist patterns. | Ideal for advanced node patterning, EUV mask defects, low-k dielectric analysis. |

Detailed Experimental Protocols

Protocol 1: Contact Mode AFM for Scratch/Step Height Analysis on Wafer Surfaces

Objective: To quantify the depth and profile of deliberate scratches or step edges on a test semiconductor wafer.

- Probe Selection: Use a stiff cantilever (spring constant > 0.2 N/m) with a sharp Si3N4 tip to minimize wear.

- Mounting: Secure the wafer sample on a magnetic stub using a conductive adhesive tab.

- Engagement: Approach the surface in a clean, particle-free area using the automated engage routine.

- Feedback Parameter Optimization:

- Set

Setpointto achieve a low, stable deflection (~0.5-1.0 V). - Adjust

IntegralandProportionalgains to maintain tracking without oscillation.

- Set

- Scanning: Acquire a 50 µm x 50 µm topograph at a scan rate of 1.0 Hz and 512 samples/line resolution.

- Analysis: Use plane correction (1st or 2nd order). Draw a line profile across the scratch to measure depth (nm) and full width at half maximum (FWHM).

Protocol 2: Tapping Mode AFM for Nanoparticle Contamination Mapping

Objective: To image and localize sub-100 nm contaminant particles on a silicon oxide surface without dislodging them.

- Probe Selection: Use a standard silicon probe (frequency ~300 kHz, spring constant ~40 N/m).

- Tuning: Before engagement, tune the cantilever to find its resonance frequency (f0). Set the drive frequency to f0.

- Engagement & Setpoint: Engage with a high free amplitude (A0 ~ 100 nm). Reduce the

Setpoint(A/A0) to ~0.7-0.8 for stable imaging. - Dual-Channel Acquisition: Simultaneously acquire the Topography (height) and Phase channels. Phase contrast highlights material differences between particles and substrate.

- Scanning: Acquire a 10 µm x 10 µm image at a scan rate of 0.5 Hz, 512 samples/line.

- Analysis: Use particle analysis software to threshold the phase image, count particles, and determine their areal density (particles/µm²).

Protocol 3: PeakForce Tapping AFM for Quantitative Mechanical Property Mapping of Defects

Objective: To correlate topographic defects with changes in local mechanical properties (elastic modulus, adhesion).

- Probe Selection: Use a probe calibrated for quantitative nanomechanics (spring constant ~0.4 N/m, known tip radius).

- Frequency & Peak Force Setpoint: Set the PeakForce frequency to 1 kHz. Set the

Peak Force Setpointas low as possible while maintaining tracking (50-200 pN). - Multi-Channel Acquisition: Acquire channels for Height, Peak Force Error, DMT Modulus, and Adhesion.

- Scanning: Acquire a 2 µm x 2 µm image at a scan rate of 0.2 Hz, 256 samples/line for sufficient force curve sampling.

- Model Fitting: Ensure the Derjaguin-Muller-Toporov (DMT) model is selected for modulus calculation. Set the Poisson's ratio of the sample (~0.3 for silicon).

- Analysis: Overlay the modulus or adhesion map on the topography. Extract line profiles or region statistics to quantify property differences at defect sites vs. the pristine surface.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in AFM Defect Analysis |

|---|---|

| Standard Silicon Probes (e.g., RTESPA-300) | General-purpose tapping mode imaging of semiconductor surfaces and contaminants. |

| SCANASYST-FLUID+ Probes | Specialized for PeakForce Tapping in liquid, essential for biological samples in drug development (e.g., protein aggregates on surfaces). |

| Diamond-Coated Probes (e.g., CDT-NCHR) | For contact mode or hard materials imaging; resistant to wear when scanning rough or abrasive surfaces. |

| Conductive Diamond Probes | For electrical modes (SCM, SSRM) to map doping or electrical properties of defects. |

| PFQNE-AL Probes | Designed for high-resolution PeakForce Tapping with a well-defined tip shape for accurate nanomechanical mapping. |

| VLSI Standards Calibration Gratings (e.g., TGZ1, TGX1) | For lateral (XY) and vertical (Z) calibration of the AFM scanner, ensuring quantitative measurement accuracy. |

| Nano-World ARROW-NCR Probes | Ultra-long cantilevers for imaging high-aspect-ratio structures like deep trench defects. |

| Anti-Vibration Table / Acoustic Enclosure | Critical infrastructure to isolate the AFM from building vibrations for stable, high-resolution imaging. |

Visualized Workflows

AFM Mode Selection Workflow for Defect Analysis

Force Curve Yields Quantitative Property Maps

Application Notes: Atomic Force Microscopy (AFM) for Semiconductor Defect Analysis

Within the context of advancing semiconductor surface defects analysis research, Atomic Force Microscopy (AFM) has emerged as a critical tool for non-destructive, three-dimensional nanoscale characterization. Its high resolution enables precise differentiation between common defect types, which is paramount for yield enhancement in manufacturing and for research into next-generation device materials. This analysis is particularly relevant for professionals in advanced materials science and nanotechnology-driven fields, including pharmaceutical development where semiconductor-based biosensors and lab-on-a-chip devices are employed.

AFM operates by scanning a sharp tip across a surface, measuring interatomic forces to map topography. This allows for the unambiguous identification of:

- Particles: Discrete, often spherical or irregular protrusions from the surface.

- Scratches: Linear depressions with characteristic depth profiles and sidewall angles.

- Pitfalls (Pits): Localized, often irregular cavities or voids in the substrate.

- Pattern Discrepancies: Deviations from intended photolithographic patterns, including line edge roughness (LER), bridging, and CD (critical dimension) variation.

The quantitative data derived from AFM, such as root-mean-square (RMS) roughness, defect density, and precise dimensional measurements, provides actionable metrics for process control and root-cause analysis.

Quantitative Defect Characterization Data

Table 1: Typical AFM Measurement Parameters and Defect Signatures

| Defect Type | Key AFM Measurable | Typical Scale (nm) | Characteristic AFM Signature | Primary Impact |

|---|---|---|---|---|

| Particles | Height, Diameter, Density | 20 - 500 | Abrupt, positive topographical change. Spherical or irregular shape. | Short circuits, leakage current, lithography focus errors. |

| Scratches | Depth, Width, Length, Sidewall Angle | Depth: 5-100; Width: 50-1000 | Continuous, linear trench. Cross-sectional profile shows V or U shape. | Conductive path interruption, particle traps, weakened structural integrity. |

| Pits | Depth, Diameter, Spatial Density | 10 - 200 | Localized, negative topographical change. May have steep or sloped sidewalls. | Reduced dielectric thickness, optical scattering, stress concentration points. |

| Pattern Discrepancies | Line Width (CD), LER (3σ), Sidewall Angle | LER: 1-5 nm; CD Variation: ±2-10% | Deviation from designed pattern edge. Quantified via statistical analysis of line profiles. | Device performance variability, timing errors, reduced operational windows. |

Experimental Protocols for AFM-Based Defect Analysis

Protocol 1: Defect Identification and Classification Workflow

Objective: To systematically identify, locate, and classify surface defects on a semiconductor wafer sample. Materials: Semiconductor wafer sample, AFM system (e.g., Bruker Dimension Icon, Park NX20), vibration isolation table, cleanroom wipes, tweezers. Procedure:

- Sample Preparation: Cleave or mount the wafer segment onto an AFM puck using a conductive adhesive tab. Use a clean, dry nitrogen stream to remove loose particles.

- Macro-Location: Use optical microscopy integrated with the AFM to locate the region of interest (e.g., a specific die or a suspected defect zone).

- AFM Setup: Select an appropriate probe (e.g., a high-resolution silicon tip with a resonant frequency of ~300 kHz for tapping mode). Engage the probe and set initial scan parameters.

- Broad Area Scan: Perform a relatively large scan (e.g., 20 μm x 20 μm) in Tapping Mode to identify potential defect sites. Set a moderate resolution (512 x 512 pixels).

- Defect Registration: Note the XY coordinates of any candidate defects (particles, scratches, etc.).

- High-Resolution Imaging: For each defect, perform a higher-resolution scan (e.g., 2 μm x 2 μm at 1024 x 1024 pixels) to obtain detailed topographical data.

- Data Acquisition: Capture height, amplitude, and phase images for each defect site.

- Initial Classification: Based on the 2D/3D topographical renderings, perform a preliminary classification (e.g., particle vs. pit).

Protocol 2: Quantitative Metrology of Defects

Objective: To extract quantitative dimensional data from identified defects. Materials: AFM system with completed scans from Protocol 1, AFM analysis software (e.g., Gwyddion, Bruker NanoScope Analysis). Procedure:

- Image Flattening: Apply a 1st or 2nd order flattening algorithm to the height image to remove sample tilt.

- Particle Analysis:

- Use a "Grain Analysis" or "Particle Analysis" tool. Set a threshold height to isolate the particle.

- Record the base diameter (at Full Width at Half Maximum, FWHM), maximum height, and volume.

- Scratch/Pit Analysis:

- Draw a perpendicular line profile across the defect.

- From the profile plot, measure: Maximum depth, Full Width at Half Maximum (FWHM) or width at top surface, and sidewall angle (using tangent fit).

- Pattern Discrepancy Analysis (for patterned wafers):

- Align a line profile along the feature edge.

- Use "Line Roughness" analysis to calculate Line Edge Roughness (LER) over a specified evaluation length, typically reported as 3σ (three times the standard deviation).

- Use "Step Analysis" to measure the Critical Dimension (CD) at multiple points along a line.

- Statistical Reporting: Compile measurements from multiple identical defects across the sample to calculate mean, standard deviation, and density (defects/cm²).

Diagram: AFM Defect Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for AFM-Based Semiconductor Defect Analysis

| Item | Function/Application | Key Considerations |

|---|---|---|

| AFM Probes (Tapping Mode) | Silicon tips for high-resolution topographical imaging of delicate surfaces. | High resonance frequency (~300 kHz), sharp tip radius (<10 nm), consistent spring constant. |

| Conductive AFM Probes | For simultaneous topographical and electrical characterization (e.g., identifying conductive particles). | Pt/Ir or doped diamond-coated tips, low resistance. |

| Wafer Handling Tweezers | For cleaving and mounting wafer fragments without introducing contamination or damage. | Vacuum or smooth, non-marring tips. Cleanroom compatible. |

| Conductive Adhesive Tabs | To securely mount semiconductor samples to the AFM metal puck, ensuring electrical contact if needed. | Low outgassing, stable adhesion. |

| Cleanroom Wipes & Swabs | For gentle cleaning of the sample stage and puck to prevent particulate contamination. | Lint-free, solvent-compatible (e.g., IPA). |

| Vibration Isolation Table | Critical infrastructure to decouple the AFM from ambient floor vibrations for stable imaging. | Active or passive isolation system. |

| Reference Sample Gratings | Calibration artifacts (e.g., pitch, step height) for verifying the AFM's lateral and vertical scanner accuracy. | Traceable standards (e.g., from NIST). |

| Data Analysis Software | For image processing, quantitative measurement, and 3D visualization of AFM data. | Capabilities for grain, roughness, and statistical analysis. |

The Critical Role of Surface Roughness (Ra, Rq) and Step Height Measurements.

This application note is framed within a doctoral thesis investigating the use of Atomic Force Microscopy (AFM) for the analysis of surface defects in advanced semiconductor devices. As feature sizes shrink to the atomic scale, traditional optical inspection tools reach their limits. Surface roughness (quantified by parameters like Ra and Rq) and step height are no longer mere cosmetic metrics; they are critical indicators of process fidelity, directly influencing device performance, yield, and reliability. Precise measurement of these topographical features via AFM is essential for identifying defect origins in deposition, etching, and chemical-mechanical polishing (CMP) processes.

Quantitative Data: Impact of Roughness on Device Parameters

The following table summarizes key findings from recent literature on the relationship between surface topography and semiconductor device characteristics.

Table 1: Impact of Surface Roughness & Step Height on Semiconductor Properties

| Device/Structure | Topography Parameter | Measured Value Range | Impact on Device Performance | Primary Measurement Tool |

|---|---|---|---|---|

| High-k Metal Gate Stack | Ra (Interface) | 0.2 nm vs. 0.5 nm | ~15% change in effective oxide thickness (EOT); increased gate leakage current. | Tapping Mode AFM, TEM cross-section. |

| FinFET Sidewall | Rq (Line Edge Roughness) | < 1.0 nm (target) | Rq > 1.2 nm leads to significant variability in threshold voltage (Vt) and drive current. | High-resolution Tapping Mode AFM. |

| Cu Interconnects (post-CMP) | Ra (Field Region) | 0.3 - 1.0 nm | Ra > 0.7 nm correlates with increased scattering, leading to >10% rise in line resistance. | ScanAsyst or Contact Mode AFM. |

| Epitaxial SiGe Layer | Step Height (Terrace) | Target: 0.314 nm (monolayer) | Step height deviation > ±0.05 nm indicates misfit dislocation or poor epitaxial quality. | Atomic-resolution AFM in Contact Mode. |

| Photoresist Pattern | Sidewall Angle & Roughness | Rq < 2 nm (sidewall) | High sidewall Rq causes line-width roughness (LWR), degrading pattern transfer fidelity. | Tilt-compensated 3D-AFM. |

Experimental Protocols

Protocol 3.1: AFM Measurement of Ra and Rq for a CMP Wafer

Objective: To quantitatively assess the global and local roughness of a silicon oxide surface after chemical-mechanical polishing. Materials: See "The Scientist's Toolkit" (Section 5). Method:

- Sample Preparation: Cleave a 1cm x 1cm sample from the wafer. Use a filtered nitrogen gun to remove particulate contaminants. Mount securely on a magnetic or adhesive AFM sample disc.

- AFM Calibration: Calibrate the AFM scanner's lateral (XY) and vertical (Z) piezos using a traceable grating standard (e.g., 1μm pitch, 180nm step height).

- Image Acquisition:

- Mode: Tapping Mode (Air) or ScanAsyst Mode.

- Probe: Use a high-frequency silicon tip (e.g., 300 kHz).

- Scan Area: Acquire images at multiple scales: 10μm x 10μm (global), 1μm x 1μm (local).

- Resolution: Set to 512 samples/line for the 1μm scan.

- Scan Rate: 0.5 - 1.0 Hz.

- Data Processing (First-Order Plane Fit):

- Apply a first-order (linear) plane fit to the raw data to remove sample tilt.

- Apply no additional filtering for Ra/Rq calculation.

- Analysis:

- Select a representative, defect-free region.

- Calculate Ra (Arithmetic Average Roughness): Ra = (1/L) ∫\|Z(x)\| dx

- Calculate Rq (Root Mean Square Roughness): Rq = √[ (1/L) ∫ Z(x)² dx ]

- Report both values with scan size and analysis area noted.

Protocol 3.2: Step Height Measurement for a Shallow Trench Isolation (STI) Structure

Objective: To precisely measure the depth of an STI structure, critical for device isolation. Method:

- Sample & Tool Prep: As per Protocol 3.1. Use a sharp, high-aspect-ratio tip for accurate sidewall profiling.

- Image Acquisition:

- Mode: Tapping Mode.

- Scan Area: Orient the scan perpendicular to the trench. Use a 5μm x 5μm area encompassing several trenches.

- Resolution: Increase to 1024 samples/line for precise edge definition.

- Data Processing (Leveling):

- Apply a first-order plane fit.

- Use a "Line-by-Line" leveling function to correct for bow.

- Analysis (Step Height):

- Draw multiple cross-sectional line profiles (≥10) across the trench.

- For each profile, use the AFM software's step height tool. Manually define upper and lower plateau regions, ensuring they are free of artifacts.

- The software calculates the vertical distance between the average heights of the two plateaus.

- Report the average step height and standard deviation across all measurements.

Visualizations: AFM Defect Analysis Workflow

Title: AFM Surface Metrology Feedback Loop for Defect Analysis

Title: Correlation Chain: AFM Metrics to Device Failure

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for AFM-Based Semiconductor Surface Analysis

| Item Name / Solution | Function / Purpose | Critical Specifications |

|---|---|---|

| Silicon AFM Probes (Tapping Mode) | High-resolution imaging of delicate surfaces without damage. | Frequency: 250-400 kHz; Force Constant: 20-80 N/m; Tip Radius: <10 nm. |

| Diamond-Like Carbon (DLC) Coated Probes | For scanning abrasive or hard materials (e.g., SiC, hardened films) to prolong tip life. | Extremely high wear resistance. |

| Scanner Calibration Gratings | Traceable calibration of AFM scanner in X, Y, and Z axes. Essential for quantitative data. | Certified pitch (e.g., 1.0 ± 0.01 μm) and step height (e.g., 180 ± 5 nm). |

| Particle-Free Nitrogen Gas Gun | Safe sample cleaning to remove ambient particulates prior to AFM scan. | 0.1 μm filtered, regulated pressure. |

| Vibration Isolation Platform | Mitigates environmental noise (floor vibration, acoustic) to achieve atomic-level resolution. | Resonance frequency < 1.0 Hz. |

| Sample Mounting Adhesive | Securely fixes small wafer fragments to the AFM sample disk without introducing topography. | Double-sided, low-outgassing, non-creeping adhesive. |

| Antistatic Gun / Source | Neutralizes static charge on insulating samples (e.g., oxides) that can attract particles or destabilize the AFM cantilever. | Ionizing, non-contaminating. |

| UV-Ozone Cleaner | For advanced sample prep to remove trace organic contaminants from surfaces. | Produces atomic-level clean surfaces for fundamental studies. |

This application note is framed within a thesis focused on leveraging Atomic Force Microscopy (AFM) for the comprehensive analysis of semiconductor surface defects. A core challenge in this field is balancing the need for ultra-high-resolution imaging with operational practicality. Traditional vacuum-based techniques, such as Scanning Electron Microscopy (SEM) or Transmission Electron Microscopy (TEM), offer high resolution but impose significant sample environment limitations. In contrast, modern AFM enables sub-nanometer resolution imaging under ambient conditions (or even in liquid), providing a unique and critical advantage for studying real-world semiconductor surfaces, organic contaminants, and thin film morphologies without complex sample preparation.

Comparative Quantitative Data: AFM vs. Vacuum Techniques

Table 1: Performance Comparison of Surface Analysis Techniques

| Feature / Parameter | Ambient AFM (e.g., Tapping Mode) | Vacuum SEM | Vacuum TEM | High-Vacuum AFM |

|---|---|---|---|---|

| Best Resolution (Vertical) | < 0.1 nm | ~ 0.5 nm | < 0.05 nm | < 0.05 nm |

| Best Resolution (Lateral) | ~ 0.5 nm | 0.4 - 1 nm | < 0.1 nm | ~ 0.2 nm |

| Operational Environment | Ambient, Liquid, Gas | High Vacuum (~10⁻⁶ mbar) | Ultra-High Vacuum (~10⁻¹⁰ mbar) | High Vacuum (~10⁻⁶ mbar) |

| Sample Preparation Complexity | Minimal | Moderate (conductive coating often required) | High (ultra-thin sectioning) | Moderate (cleaning, drying) |

| Measurement Throughput | Medium (min-hr/scan) | High (sec-min/scan) | Low (hrs for prep+imaging) | Low-Medium (min-hr/scan) |

| 3D Topography Data | Yes (Direct) | No (Inferred) | No | Yes (Direct) |

| Quantitative Mechanical Data | Yes (Modulus, Adhesion) | No | Limited | Yes (Modulus, Adhesion) |

| Electrical Characterization | Yes (SSRM, KPFM) | Limited (EDS) | Yes (EELS) | Yes (SSRM, KPFM) |

Detailed Application Notes

Application Note AN-1: In-situ Analysis of Post-CMP Wafer Defects

Objective: To identify and classify sub-nanometer haze and residual particles on a silicon wafer post-chemical mechanical planarization (CMP) without introducing vacuum-induced artifacts. Challenge in Vacuum: SEM may cause charging on insulating residues and cannot reliably measure step heights of shallow scratches (<1 nm). AFM Advantage: Operates in ambient air, allowing immediate analysis of wet wafers after a nitrogen dry. Tapping mode AFM provides true 3D topography, distinguishing between a 0.3-nm high adsorbed organic layer and a 0.8-nm deep scratch with clarity. Protocol: See Section 4.1.

Application Note AN-2: Characterization of Organic Photoresist Sidewall Roughness

Objective: Measure Line Edge Roughness (LER) and sidewall nanoscale imperfections of a 10-nm photoresist feature. Challenge in Vacuum: SEM electron beam can alter or damage organic resist materials, leading to inaccurate measurements. AFM Advantage: Ambient operation with a super-sharp tip (tip radius < 5 nm) enables non-destructive, high-resolution profiling of sensitive organic structures. PeakForce Tapping mode quantifies nanomechanical variation (elastic modulus) along the sidewall, correlating roughness with local material properties.

Experimental Protocols

Protocol P-1: Ambient AFM for Sub-nm Wafer Defect Mapping

Title: Protocol for Ambient Tapping Mode AFM Analysis of Semiconductor Wafers. Objective: To image and quantify topographical defects with sub-nanometer vertical resolution on a 300mm Si wafer.

I. Materials & Pre-imaging Sample Prep

- Sample: 300mm silicon wafer, post-CMP, stored in ISO Class 3 cleanroom.

- Cleaning: Use a critical point dryer or a gentle nitrogen gas stream to remove airborne particulates. Avoid touching the active surface.

- Mounting: Affix the wafer to a 200mm AFM puck using a double-sided carbon tab or a custom wafer holder. Ensure secure, vibration-free mounting.

II. Instrument Setup (Bruker Dimension Icon used as example)

- Scanner Calibration: Perform thermal and linearity calibration using a traceable pitch standard (e.g., 180 nm grating).

- Probe Selection: Install a high-resolution silicon tip (e.g., Bruker RTESPA-300, nominal tip radius < 8 nm, resonance frequency ~300 kHz).

- Environment: Conduct experiment on an active vibration isolation table within a cleanroom or acoustic enclosure. Record ambient temperature and humidity.

III. Imaging Parameters

- Mode: Tapping Mode in air.

- Scan Area: Start with a 50µm x 50µm scan to locate defects, then zoom to 5µm x 5µm and 1µm x 1µm regions of interest.

- Resolution: Set to 1024 x 1024 pixels for the 1µm scan, yielding a pixel resolution of ~1 nm.

- Scan Rate: 0.5 - 1.0 Hz.

- Setpoint: Adjust amplitude setpoint to ~80% of the free air amplitude for optimal engagement.

- Feedback Gains: Optimize Proportional (P) and Integral (I) gains to minimize image artifacts while tracking topography.

IV. Data Acquisition & Analysis

- Acquire both height and phase images.

- Flattening: Apply a 0th or 1st order flattening algorithm to the height image.

- Defect Analysis: Use particle analysis software to identify and count defects. Use cross-sectional analysis to measure scratch depth/particle height with sub-nm precision.

- Roughness Metrics: Calculate RMS (Rq) and Average (Ra) roughness over defect-free areas.

Protocol P-2: Correlative SEM-AFM Analysis for Deep Defect Investigation

Title: Protocol for Sequential Vacuum SEM and Ambient AFM on the Same Defect. Objective: To leverage SEM for rapid defect location and AFM for high-resolution 3D metrology and nanomechanical mapping.

- Initial SEM (Vacuum) Imaging:

- Load sample into FE-SEM.

- Locate region of interest (ROI) using low-dose imaging conditions.

- Capture secondary electron image and note stage coordinates or use navigational marks.

- Sample Transfer:

- Vent the SEM chamber and carefully unload the sample.

- Minimize exposure to ambient contaminants. Transfer directly to AFM.

- AFM (Ambient) Imaging:

- Mount sample on AFM stage.

- Use optical microscope or stage coordinates to relocate the exact SEM ROI.

- Perform high-resolution PeakForce Quantitative Nanomechanical Mapping (QNM) scan over the defect.

- QNM Parameters: Engage in PeakForce Tapping mode. Calibrate tip sensitivity and spring constant. Set PeakForce amplitude to 50-100 pN. Map DMT modulus and adhesion simultaneously with topography.

- Data Correlation: Overlay AFM topography and modulus maps with the SEM micrograph using software alignment tools to create a comprehensive defect profile.

Diagrams

Decision Workflow for Surface Defect Analysis

Ambient AFM Wafer Defect Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Ambient AFM Semiconductor Defect Studies

| Item / Reagent | Function & Relevance |

|---|---|

| High-Resolution AFM Probes (e.g., Si tip, < 8 nm radius) | Core sensor for achieving sub-nanometer lateral resolution. Coated (Pt/Ir) variants enable electrical modes. |

| Vibration Isolation Platform | Critical for stabilizing measurements to the sub-nm level in ambient environments with acoustic and floor vibrations. |

| Acoustic Enclosure | Further dampens airborne noise that can couple into the AFM head, reducing imaging artifacts. |

| Calibration Gratings (TGZ, PG, HS) | Traceable pitch and height standards (e.g., 180 nm pitch, 7 nm step) for daily verification of scanner and z-axis accuracy. |

| Critical Point Dryer | Prepares wet or rinsed samples without inducing surface tension artifacts (e.g., water marks) that mimic defects. |

| Particle/Nanoindentation Reference Samples (e.g., nanoparticles on Si) | Used to verify tip shape, particle analysis algorithms, and nanomechanical calibration. |

| Cleanroom Supplies (N2 gun, anti-static tweezers, carbon tabs) | Minimizes introduction of new contaminants during sample handling and mounting. |

| PeakForce QNM Calibration Kit | Includes a polystyrene/low-density polyethylene sample for calibrating the nanomechanical properties mapping (DMT modulus). |

AFM Operational Workflow: Step-by-Step Protocol for Semiconductor Defect Characterization

Sample Preparation Best Practices for Wafers and Processed Semiconductor Surfaces

This application note outlines critical sample preparation protocols for Atomic Force Microscopy (AFM) analysis within semiconductor defect research. Proper preparation is paramount to obtaining artifact-free, high-resolution data that accurately reflects surface topography and electronic properties.

Foundational Cleaning Protocols

Contaminants (particles, organic residues, native oxides) are the primary source of measurement artifacts. The following sequential cleaning procedures are recommended prior to AFM analysis.

Table 1: Standardized Cleaning Sequences for Various Surfaces

| Wafer/ Surface Type | Primary Contaminant Target | Recommended Protocol Sequence | Key Parameters & Notes |

|---|---|---|---|

| Virgin Silicon (Si) | Particles, organic films | 1. Piranha (H₂SO₄:H₂O₂ 3:1) soak2. SC-1 (NH₄OH:H₂O₂:H₂O 1:1:5) dip3. HF (1-2%) dip4. DI water rinse & N₂ dry | CAUTION: Piranha is highly exothermic. HF requires proper PPE. HF step removes native oxide. |

| Processed Wafers (with films) | Particles, light organics | 1. Modified SC-1 (diluted 1:1:50) or surfactant clean2. IPA rinse3. DI water megasonic rinse4. Spin-rinse-dry | Use diluted SC-1 to minimize attack on metal lines or porous low-κ dielectrics. Megasonic energy <100W. |

| III-V Compounds (GaAs, InP) | Native oxides, carbon | 1. Acetone soak (ultrasonic)2. Isopropanol (IPA) rinse3. HCl (36%) dip (e.g., 1 min for GaAs)4. DI water rinse & N₂ dry | HCl selectively removes oxide. Avoid basic solutions (NH₄OH) which can roughen surfaces. |

| Post-CMP Surfaces | Slurry particles, residues | 1. Alkaline surfactant clean (pH~10)2. Citric acid (1-5%) dip3. DI water megasonic rinse4. Marangoni drying | Citric acid chelates metal ions. Marangoni drying prevents watermarks. |

Protocol 1.1: Standard RCA-Based Clean for Si Surfaces

- Materials: Fume hood, PTFE wafer carriers, DI water supply, N₂ gun.

- SC-1 Solution: Prepare fresh by mixing NH₄OH (29%): H₂O₂ (30%): H₂O at 1:1:5 ratio at 70-80°C.

- Procedure:

- Piranha Clean: Immerse wafer in piranha solution for 10-15 minutes. Remove, rinse thoroughly with DI water.

- SC-1 Clean: Immerse wafer in SC-1 solution for 10 minutes to remove organic residues and particles. Rinse in flowing DI water for >2 minutes.

- Oxide Strip: Dip wafer in 2% Hydrofluoric Acid (HF) for 60 seconds to achieve a hydrophobic, hydrogen-terminated surface.

- Final Rinse & Dry: Rinse in DI water for 1 minute and dry immediately with a filtered, high-purity N₂ jet. Analyze promptly.

Protocol for Cross-Sectional AFM Sample Preparation

Analyzing cross-sections is essential for defect analysis in multilayer stacks and for measuring layer thickness/roughness.

Protocol 2.1: Cleaving and Mounting for Cross-Sectional AFM

- Materials: Precision wafer scribe, cleaving tool (for brittle materials), cyanoacrylate adhesive or crystal bond, low-outgassing metal specimen puck, optical microscope.

- Procedure:

- Scribing: Using a diamond scribe under a microscope, create a shallow, straight scribe line on the backside of the wafer along the desired cleave direction (e.g., <110> for Si).

- Cleaving: Place the wafer on a clean, flat surface with the scribe line aligned over a straight edge. Apply quick, downward pressure on the overhang to cleave. For delicate processed wafers, use a precision cleaving tool.

- Mounting: Affix the cleaved cross-section sample vertically to a metal puck using a minimal amount of adhesive (e.g., a tiny dot of cyanoacrylate at the base). Ensure the region of interest is at the top and unobstructed.

- Cure: Allow adhesive to fully cure. Inspect under an optical microscope to ensure the cross-section edge is clean and protruding sufficiently for AFM tip access.

Handling and Storage Best Practices

- Immediate Analysis: Ideally, prepared samples should be analyzed within hours to minimize recontamination or re-oxidation.

- Storage: If storage is necessary, place samples in a clean, dry nitrogen-purged desiccator or in a vacuum load-lock chamber (<10⁻³ Torr).

- Handling: Always use powder-free nitrile gloves and cleanroom tweezers with smooth, non-scratching tips. Handle wafers by the edges only.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for Semiconductor Surface Preparation

| Reagent Solution | Typical Composition/Example | Primary Function in Preparation |

|---|---|---|

| Piranha (aka SPM) | H₂SO₄ : H₂O₂ (3:1 to 4:1) | Removes heavy organic contaminants and photoresist via powerful oxidation. |

| SC-1 (RCA-1) | NH₄OH : H₂O₂ : H₂O (1:1:5 to 1:2:7) | Removes organic films and lifts off particles through under-etching and electrostatic repulsion. |

| SC-2 (RCA-2) | HCl : H₂O₂ : H₂O (1:1:6 to 1:2:8) | Removes metallic ions and contaminants from the surface. |

| Diluted Hydrofluoric Acid (dHF) | HF : H₂O (1:50 to 1:100) | Selectively etches silicon dioxide and other metal oxides, creating a hydrophobic, passivated surface. |

| Semiconductor-Grade Solvents | Acetone, IPA, Methanol (ultra-high purity) | Dissolves and rinses away organic solvents and grease in initial cleaning steps. |

| Surfactant-based Cleaners | Tetramethylammonium hydroxide (TMAH) or proprietary formulations | Reduces surface tension and enhances particle removal, especially for post-CMP and patterned wafers. |

Visualization of Protocols and Relationships

Diagram Title: AFM Sample Prep Decision & Workflow for Semiconductor Defect Analysis

Diagram Title: Chemical Cleaning Target-Action-Result Pathway for AFM Prep

This application note provides a targeted guide for selecting Atomic Force Microscopy (AFM) probes to characterize common nanoscale defects on semiconductor surfaces. The selection is contextualized within a thesis focused on correlating surface defect morphology and electronic properties with device performance degradation. Optimal probe choice is critical for accurate topographical measurement, minimizing tip convolution, and enabling advanced electrical or mechanical property mapping.

Probe Parameter Selection Table

The following table summarizes the recommended probe characteristics for imaging and analyzing specific defect types prevalent in semiconductor manufacturing.

Table 1: AFM Probe Selection Guide for Semiconductor Surface Defects

| Defect Type | Key Measurable | Recommended Tip Radius | Recommended Coating | Recommended Resonance Frequency (in air) | Primary Imaging Mode |

|---|---|---|---|---|---|

| Gate Oxide Pinholes / Pits | Depth, sidewall angle, lateral dimensions. | Ultra-sharp (<10 nm) | Conductive Diamond-like Carbon (DLC) or PtIr | High (>300 kHz) | Tapping Mode, TUNA (for conductivity) |

| Chemical-Mechanical Polishing (CMP) Scratches | Depth profile, cross-sectional shape, roughness. | Medium (15-25 nm) Si or SiN | None (uncoated Si) or Al reflective | Medium-High (150-320 kHz) | Tapping Mode, Non-Contact Mode |

| Epitaxial Stacking Faults & Dislocations | Surface step height, strain-induced topography. | Ultra-sharp (<10 nm) | None (uncoated Si) for high resolution | Very High (>400 kHz) | Tapping Mode, PeakForce Tapping |

| Metal Contamination & Nanoparticles | Particle height, distribution, adhesion forces. | Medium-Sharp (~10-15 nm) | Conductive (PtIr) for identification | Medium (70-150 kHz) | Tapping Mode, Lift Mode (EFM/KPFM) |

| Lithography Line Edge Roughness (LER) | Sidewall profile, 3D roughness parameters. | High-Aspect Ratio, sharp tip (<10 nm radius) | Conductive Diamond or PtIr | High (>300 kHz) | Tapping Mode, 3D-AFM |

| Charge Trapping in Dielectrics | Surface potential variation, charge distribution. | Conductive tip (any radius, as needed for topography) | Doped Diamond or PtIr | Tuned to application (70-350 kHz) | Kelvin Probe Force Microscopy (KPFM) |

Experimental Protocols

Protocol 1: Imaging and Electrical Analysis of Gate Oxide Pinholes

Objective: To locate, topographically characterize, and assess the local conductivity of pinhole defects in a thin gate oxide layer. Materials: Conductive DLC-coated AFM probe, p-type Si wafer with thermal oxide, conductive AFM holder. Procedure:

- Probe Calibration: Perform thermal tuning to determine the exact resonance frequency and spring constant of the conductive probe.

- Topographic Survey: Engage in Tapping Mode at a scan rate of 0.5-1 Hz over a 5 µm x 5 µm area to identify defect locations.

- High-Resolution Imaging: Zoom into a region containing a suspected pinhole (1 µm x 1 µm). Optimize setpoint and drive amplitude for fine feature resolution.

- Conductive AFM (c-AFM) / TUNA Measurement: Switch to contact mode with a applied DC bias (e.g., +2V to sample). Scan the same area while measuring the current through the tip. Pinholes will show significantly higher current leakage.

- Data Correlation: Overlay the topography and current maps to confirm conductive spots correspond to topographical pits.

Protocol 2: Quantifying Lithography Line Edge Roughness (LER)

Objective: To obtain a three-dimensional profile of a photoresist line and calculate line edge roughness parameters (e.g., Ra, Rq). Materials: High-aspect ratio, conductive diamond-coated probe, semiconductor wafer with patterned photoresist lines. Procedure:

- Probe Alignment: Align the probe and scan axis precisely perpendicular to the line feature to ensure accurate sidewall tracking.

- 3D-AFM Scanning: Use Tapping Mode with a high-resolution scan (512 x 512 pixels) over a line segment (e.g., 2 µm length). Ensure the z-range is sufficient for the line height.

- Image Processing: Flatten the raw data using a first-order plane fit. Extract a cross-sectional profile at multiple points along the line.

- Edge Detection & Analysis: Use dedicated LER analysis software. For each profile, define the top and bottom thresholds (e.g., 10% and 90% of line height). The software extracts the edge points and calculates roughness statistics per industry standards (e.g., SEMI P49).

Visualization of Probe Selection Logic

Title: Decision Logic for AFM Probe Selection

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for AFM-Based Defect Analysis

| Item | Function in Research |

|---|---|

| Conductive DLC-Coated Probe | Enables simultaneous topography and nanoscale electrical measurements (c-AFM, KPFM) on insulating layers. |

| Ultra-Sharp Silicon Probe (TIP <10 nm) | Minimizes tip convolution for accurate imaging of step edges, dislocations, and fine roughness. |

| High-Aspect Ratio Diamond Tip | Faithfully traces steep sidewalls of trenches and lines for 3D metrology and LER analysis. |

| Vibration Isolation Enclosure | Critical for achieving atomic-scale resolution by isolating the AFM from ambient acoustic and floor vibrations. |

| Sample Cleaning Kit (e.g., UV-Ozone, Solvents) | Ensures contamination-free surfaces to prevent artefactual defects and probe contamination. |

| Calibration Grating (e.g., TGZ1, PG) | Provides traceable standards for verifying lateral (X,Y) and vertical (Z) scanner accuracy and tip integrity. |

| Conductive Sample Mounting Tape | Provides electrical grounding for the sample during electrical modes (KPFM, EFM, c-AFM). |

| Anti-Static Gun | Neutralizes static charge on samples and equipment to prevent electrostatic attraction artefacts. |

Within the broader thesis on Atomic Force Microscopy (AFM) for semiconductor surface defects analysis, achieving high-fidelity imaging is paramount. The reliable identification and characterization of nanoscale defects—such as pits, particles, and pattern irregularities—directly depend on the precise optimization of three core operational parameters: scan rate, resolution (pixels per line), and setpoint (feedback force). Misconfiguration leads to artifacts, tip degradation, or missed critical data, compromising research on device failure mechanisms. This application note provides a current, detailed protocol for establishing optimal parameters for contact mode AFM imaging of semiconductor surfaces.

| Parameter | Typical Range for Semiconductor Imaging | Optimal Starting Point | Primary Effect on Image Quality | Risk if Too High | Risk if Too Low |

|---|---|---|---|---|---|

| Scan Rate (Hz) | 0.5 - 2.0 Hz | 1.0 Hz | Controls temporal resolution & tracking. | Tip drag, surface damage, distortion. | Thermal drift effects, long scan times. |

| Resolution (pixels) | 256 - 1024 px/line | 512 x 512 px | Defines spatial sampling density. | Very large files, slow scanning. | Loss of critical defect detail. |

| Setpoint (nN or V) | 0.5 - 10 nN (varies by mode) | 1-2 nN (Contact); 80-90% Amplitude (Tapping) | Controls tip-sample interaction force. | Surface/tip damage, compressed features. | Poor tracking, noise, tip instability. |

Experimental Protocol: Iterative Optimization for Defect Analysis

Protocol 1: Baseline Calibration on Reference Sample

Objective: Establish a damage-free, stable imaging baseline.

- Sample: Use a standardized grating (e.g., TGZ1 or TGX1) with known pitch (e.g., 3 µm).

- Cantilever Selection: Install a silicon nitride tip for contact mode (nominal k ~ 0.1 N/m) or silicon tip for tapping mode (nominal k ~ 40 N/m). Record the resonant frequency and spring constant.

- Initial Parameters:

- Setpoint: Engage at a very low force (setpoint voltage near free-air deflection).

- Scan Rate: 0.5 Hz.

- Resolution: 256 x 256 pixels.

- Scan Size: 5 µm x 5 µm.

- Optimization Sequence: a. Adjust Setpoint: Incrementally increase the force (lower setpoint voltage) until a stable trace/retrace loop is observed with minimal error signal. Target < 10% RMS error. b. Optimize Resolution: Increase to 512 x 512 pixels. Ensure the known feature dimensions are accurately reproduced. c. Adjust Scan Rate: Gradually increase the rate until the error signal shows signs of increase or image distortion appears. Use this as the maximum allowable rate.

- Validation: Measure the pitch of the grating. The value must be within ±2% of the certified value.

Protocol 2: Defect Imaging on Semiconductor Wafer

Objective: Image unknown defects with high fidelity and minimal artifact introduction.

- Locate Region of Interest (ROI): Use optical or integrated video microscopy to navigate to a pre-marked defect area.

- Perform Large-Area Survey:

- Use the Optimal Starting Point parameters from the table on a 20 µm x 20 µm area.

- Analyze for defect location and type.

- High-Resolution Defect Scan:

- Center the defect and reduce scan size to 2 µm x 2 µm.

- Increase Resolution to 1024 x 1024 pixels.

- Reduce Scan Rate by 50% (e.g., to 0.5 Hz) to ensure accurate tracking over steep defect edges.

- Fine-tune Setpoint: Slightly reduce the force (increase setpoint) if the defect appears "smeared," or increase it if the tip is losing contact.

- Data Acquisition: Capture both height and deflection/error signal images. The error signal often highlights defect edges with enhanced contrast.

Logical Workflow for Parameter Optimization

Diagram Title: AFM Parameter Optimization Workflow for Defect Imaging

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Semiconductor AFM Analysis |

|---|---|

| Standard Calibration Gratings (TGZ/TGX Series) | Provides traceable vertical and lateral dimensional references for scanner calibration and parameter validation. |

| SiO₂/Si Wafers with Patterned Features | Used as control samples with known topography to test parameter sets before analyzing unknown defect wafers. |

| Particle Contamination Reference Samples | Samples with monodisperse polystyrene or silica spheres of known size (e.g., 100nm) for assessing imaging fidelity on particulate defects. |

| Deionized Water & Isopropyl Alcohol (IPA) | For safe sample cleaning to remove ambient contaminants without damaging semiconductor structures. |

| PFPE-Based Lubricant (for Tribology Studies) | Applied in controlled studies to simulate the effect of chemical-mechanical planarization (CMP) residues on surface imaging. |

| Soft Contact Mode Cantilevers (k ~ 0.1 N/m) | Minimize surface deformation during contact mode imaging of delicate structures or soft contamination. |

| High-Resonant Frequency Tapping Mode Tips (f > 300 kHz) | Enable stable imaging of steep, high-aspect-ratio semiconductor features with minimal lateral force. |

Atomic Force Microscopy (AFM) has evolved from a pure topographic imaging tool to a multifunctional platform for nanoscale characterization. Within semiconductor defect analysis, correlating a defect's topography with its electrical and mechanical properties is critical for understanding failure mechanisms, strain effects, and local performance variations. This application note details the integration of Conductive AFM (CAFM), Kelvin Probe Force Microscopy (KPFM), and nanoindentation for comprehensive defect analysis, framed within a thesis on advanced AFM methodologies for semiconductor surfaces.

Table 1: Comparison of Key AFM-Based Techniques for Defect Analysis

| Technique | Primary Measurand | Lateral Resolution | Key Output on Defects | Typical Application on Semiconductors |

|---|---|---|---|---|

| Conductive AFM (CAFM) | Local current (I) vs. voltage (V) | 5-20 nm | Defect conductivity, leakage current sites, I-V curves at nanoscale. | Mapping conductive filaments, oxide breakdown spots, dislocation conductivity. |

| Kelvin Probe Force Microscopy (KPFM) | Contact Potential Difference (CPD) | 20-50 nm | Surface potential, work function variation, trapped charge. | Imaging charge trapping at grain boundaries, doping variations, defect charge states. |

| Nanoindentation | Force (F) vs. displacement (δ) | 100-500 nm (tip radius dependent) | Reduced elastic modulus (Er), hardness (H), plasticity onset. | Measuring strain fields around dislocations, mechanical degradation of low-k dielectrics. |

Table 2: Typical Quantitative Data from Defect Measurements

| Defect Type | CAFM Current Range | KPFM ΔCPD Range | Nanoindentation Modulus Change | Implied Property |

|---|---|---|---|---|

| Single Dislocation (Si) | 1-10 pA (enhanced) | +20 to +100 mV | -5% to -15% (local softening) | Strain-induced band gap narrowing, local plasticity. |

| Grain Boundary (Perovskite) | 10 pA - 1 nA (leakage) | -50 to -300 mV | Not Typically Measured | Enhanced ion migration, non-radiative recombination. |

| Oxide Pinhole Defect | 10 nA - 1 µA (high) | +100 to +500 mV | -20% to -40% (void) | Direct conductive short, localized dielectric failure. |

| Ion Implantation Damage | Variable (dopant dependent) | -200 to +200 mV | +10% to +30% (hardening) | Amorphization, compressive/tensile strain, doping activation. |

Experimental Protocols

Protocol 3.1: Correlative CAFM and KPFM on Electronic Defects

Objective: To simultaneously map the topography, conductivity, and surface potential of a defect site (e.g., a stacking fault or grain boundary) on a semiconductor surface.

Materials & Sample Prep:

- Sample: Patterned semiconductor wafer (e.g., Si, GaN) or thin-film device (e.g., perovskite solar cell).

- Substrate Preparation: Clean via standard RCA protocol. For air-sensitive samples, use glovebox transfer.

- AFM Probe Selection:

- CAFM/KPFM: Pt/Ir-coated conductive probe (e.g., BudgetSensor ContE-G), force constant ~0.2-5 N/m, resonance frequency ~13-75 kHz.

- Calibrate deflection sensitivity and spring constant prior to measurement.

Procedure:

- Mounting: Secure sample on a grounded metal puck using conductive tape.

- Topography: Engage in intermittent contact (tapping) mode to obtain a high-resolution topographic image of the region of interest.

- Electrical Setup:

- Connect the conductive probe to a current amplifier (sensitivity: 1 pA - 100 nA).

- Connect the sample back-contact to a bias source. For KPFM, this is also the feedback input.

- Lift-Mode KPFM:

- Perform a primary topographic line scan.

- On the second pass (lift height: 10-50 nm), the probe follows the stored topography.

- Apply an AC voltage (ω, ~1-10 V) to the probe and use a lock-in amplifier to nullify the electrostatic force by applying a DC bias (VDC). This VDC equals the CPD.

- CAFM Measurement:

- Switch to contact mode with a low applied force (~10 nN) to maintain electrical contact and minimize tip wear.

- Apply a DC bias (e.g., ±1-5 V) to the sample.

- Map the local current simultaneously with topography. For I-V spectroscopy, position the tip over the defect and sweep bias.

- Data Correlation: Overlay CAFM current and KPFM CPD maps onto the topography using analysis software to pinpoint defect coordinates and properties.

Protocol 3.2: Nanoindentation on and around Mechanical Defects

Objective: To quantify the local elastic modulus and hardness at a strain field defect (e.g., dislocation cluster, edge of a trench structure).

Materials & Sample Prep:

- Sample: Prepared semiconductor surface. Must be ultra-clean to avoid tip contamination.

- AFM Probe Selection: Diamond-tipped nanoindentation probe (e.g., Berkovich or cube-corner geometry) mounted on a stiff cantilever (k > 100 N/m).

Procedure:

- Calibration:

- Perform indentation on a standard reference sample (e.g., fused silica) to calibrate tip area function and machine compliance.

- Site Selection:

- Use prior AFM topography to identify the defect and a reference "pristine" area.

- Indentation Matrix:

- Program a grid of indents (e.g., 5x5) covering the defect and surrounding material.

- Ensure sufficient spacing (≥ 20x indent depth) to avoid strain field overlap.

- Loading Protocol:

- Approach surface at a controlled rate (e.g., 10 nm/s).

- Execute a load function: linear load to a peak force (e.g., 100 µN) in 5s, hold for 2s to assess creep, unload in 5s.

- Record full load (P) vs. depth (h) curve.

- Analysis (Oliver-Pharr Method):

- Fit the unloading curve's initial portion to a power law: P = α (h - hf)m.

- Calculate contact stiffness S = dP/dh at maximum load.

- Determine contact depth hc.

- Compute reduced modulus (Er) and hardness (H) using calibrated area function.

- Mapping: Plot Er and H values spatially to visualize the mechanical property perturbation caused by the defect.

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function / Explanation |

|---|---|

| Pt/Ir-coated Si AFM Probes | Standard conductive probes for CAFM/KPFM. Coating provides electrical conductivity while maintaining sharpness. |

| Diamond-coated/Cube-Corner Probes | Essential for nanoindentation. Diamond ensures minimal wear during high-force contact on hard semiconductor surfaces. |

| Conductive Sample Mounting Tape | Provides electrical grounding path from sample back-contact to the AFM stage for CAFM/KPFM. |

| Fused Silica Reference Sample | Calibration standard for nanoindentation. Its well-defined modulus and hardness are used to calibrate the tip area function. |

| Current Amplifier (pA - nA range) | Converts the tiny currents measured in CAFM (pA to µA) into a measurable voltage signal. |

| Lock-in Amplifier | Core component for KPFM. Detects the first harmonic of the electrostatic force at frequency ω to determine the CPD with high sensitivity. |

| Vibration Isolation Enclosure | Critical for all high-resolution AFM measurements. Minimizes acoustic and floor vibrations to achieve stable tip-sample contact. |

| Glovebox Integration Kit | For measurement of air-sensitive samples (e.g., halide perovskites). Enables sample transfer from fabrication to AFM without air exposure. |

Visualized Workflows and Relationships

Title: Correlative AFM Defect Analysis Workflow

Title: Relationship of Techniques within Thesis Core

Within the broader thesis on Atomic Force Microscopy (AFM) for semiconductor surface defects analysis, this application note details protocols for investigating three critical failure modes: CMP residue, etch pits, and gate oxide integrity. These nanoscale defects directly impact device performance, yield, and reliability. AFM provides unparalleled 3D topography and electrical characterization essential for root-cause analysis.

Application Notes & Protocols

Case Study 1: CMP Residue Analysis

CMP residues—slurry particles, organic contaminants, and precipitates—cause electrical shorts and increase contact resistance. AFM morphological and electrical mapping is key for identification.

Quantitative Data Summary: CMP Residue Characterization

| Defect Type | Typical Size Range | AFM Mode Used | Key Measured Parameter | Impact on Device |

|---|---|---|---|---|

| Slurry Particles (e.g., SiO₂, CeO₂) | 50 nm - 200 nm | Tapping Mode, PeakForce Tapping | Height, Adhesion Force | Interlevel Shorts, High Contact Resistance |

| Organic Residue (Buffers, Inhibitors) | Monolayer - 50 nm | Contact Mode, Scanning Kelvin Probe Force Microscopy (SKPFM) | Surface Potential, Adhesion, Roughness (Rq) | Altered Work Function, Poor Epitaxial Growth |

| Metallic Contaminants (e.g., Cu, Al) | Nanoparticles - 100 nm | Torsional Resonance Mode (TR-TUNA), SKPFM | Conductivity, Corrosion Potential | Junction Leakage, Reduced Minority Carrier Lifetime |

Experimental Protocol: SKPFM for CMP Residue Identification

- Sample Preparation: Cleave a 1cm x 1cm sample from the wafer. Perform a standard SCI (NH₄OH/H₂O₂/H₂O) clean for 10 minutes at 65°C to remove adventitious carbon, then rinse in deionized water and dry with N₂. Do not use ultrasonic agitation.

- AFM Mounting: Secure the sample to a 15mm magnetic stainless steel puck using a double-sided carbon tab.

- Probe Selection: Use a conductive, Pt/Ir-coated cantilever (e.g., BudgetSensor Multi75E-G). Confirm resonance frequency (~75 kHz) and force constant (~3 N/m) via thermal tune.

- Topography Scan: Engage in PeakForce Tapping mode in air. Scan a 5µm x 5µm area at 512 samples/line resolution. Optimize PeakForce setpoint to minimize tip wear.

- SKPFM Measurement: On the same area, engage two-pass lift mode.

- First Pass: Record topography trace at a scan rate of 0.8 Hz.

- Second Pass: Retrace the topography at a lift height of 50 nm. Apply an AC voltage (V_ac = 2V, frequency ~10 kHz below resonance) and a DC bias to the tip. Use a lock-in amplifier to nullify the first harmonic, mapping the contact potential difference (CPD).

- Data Analysis: Correlate CPD maps with topography. Regions with differing CPD indicate residue composition variation (e.g., metallic vs. organic).

Case Study 2: Etch Pit Analysis

Etch pits are localized surface depressions caused by non-uniform wet or dry etching, leading to stress concentration and potential gate leakage.

Experimental Protocol: Tapping Mode AFM for Etch Pit Statistics

- Sample Preparation: Use as-received wafer. Optionally, perform a brief HF vapor etch (30 sec) to remove native oxide and enhance pit contrast.

- AFM Setup: Use a high-aspect-ratio silicon tip (e.g., Olympus AC160TS) in Tapping Mode. Set drive frequency to ~300 kHz.

- Image Acquisition: Scan multiple 10µm x 10µm and 2µm x 2µm areas across the wafer at 1024x1024 resolution. Maintain a scan rate ≤ 0.5 Hz for high fidelity.

- Quantitative Analysis: Use grain analysis software. Set threshold to isolate depressions >5nm in depth. Export data for each pit: X/Y location, Planar Area, Max Depth, Volume, and Full Width at Half Max (FWHM).

- Statistical Reporting: Compile data into a histogram distribution for pit depth and diameter. Calculate areal density (pits/cm²).

Case Study 3: Gate Oxide Integrity Assessment

Gate oxide integrity is compromised by local thinning, pinholes, and charge trapping sites. Conductive AFM (C-AFM) and Tunneling AFM (TUNA) are used for nanoscale electrical breakdown testing.

Quantitative Data Summary: C-AFM Oxide Breakdown Metrics

| Oxide Type (Thickness) | Typical Breakdown Voltage (C-AFM) | Breakdown Field (MV/cm) | Leakage Current Pre-BD | C-AFM Tip Bias Polarity |

|---|---|---|---|---|

| Thermal SiO₂ (2 nm) | 4 - 6 V | 20 - 30 | 1 - 10 pA | Substrate Grounded, Tip Negative |

| HfO₂ High-κ (5 nm) | 2 - 3 V | 4 - 6 | 10 - 100 pA | Substrate Grounded, Tip Negative |

Experimental Protocol: C-AFM for Localized Oxide Breakdown

- Sample & Probe Prep: Use a metal-oxide-semiconductor (MOS) capacitor test structure. Use a diamond-coated conductive probe (e.g., AD-2.8-AS) for durability. Clean the tip via sequential sonication in acetone, isopropanol, and DI water.

- System Configuration: Place the sample on a grounded metal chuck. Connect the tip to a source measurement unit (SMU) within the AFM. Ensure a Faraday cage is engaged.

- I-V Spectroscopy: Position the tip over a featureless oxide region. Disengage feedback. Ramp the tip bias from 0V to -8V (for SiO₂) at a rate of 0.5 V/s while recording current with a compliance set to 1 µA.

- Breakdown Point Detection: A sudden current jump (>3 decades) indicates dielectric breakdown. The SMU triggers immediately to compliance to prevent tip damage.

- Topographic Verification: Re-engage feedback in tapping mode and image the breakdown location to check for physical crater formation (typically 20-50 nm in diameter).

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in Experiment |

|---|---|

| SC1 Cleaning Solution (Standard Clean 1: NH₄OH:H₂O₂:H₂O, 1:1:5) | Removes organic residues and particles from silicon surfaces prior to AFM analysis without etching the substrate. |

| Dilute Hydrofluoric Acid (HF, 0.5% vol.) or HF Vapor | Selectively removes native silicon dioxide to enhance topographic contrast of etch pits and sub-surface defects. |

| Conductive AFM Probes (Pt/Ir or Diamond-coated, Force Constant ~1-5 N/m) | Enables simultaneous topographic imaging and localized current measurement for SKPFM and C-AFM/TUNA. |

| Calibration Gratings (e.g., TGZ1, PG, HS-100MG) | Verifies scanner calibration in X, Y, and Z dimensions, and tip sharpness for accurate defect sizing. |

| Vibration Isolation Platform | Mitigates environmental acoustic and floor vibrations critical for achieving sub-nanometer resolution in AFM imaging. |

| Conductive Sample Mounting Tape (Carbon Tape) | Provides a secure, electrically grounded connection between the sample and the AFM puck for electrical measurements. |

Diagrams

AFM-SKPFM Workflow for CMP Residue

Defect Analysis Decision Logic

Solving AFM Challenges: Troubleshooting and Optimizing Measurements for Reliable Defect Data

This application note, framed within a broader thesis on Atomic Force Microscopy (AFM) for semiconductor surface defects analysis research, addresses three prevalent imaging artifacts. Accurate nanoscale metrology is critical for semiconductor process control and failure analysis, as well as for characterizing biomolecular interactions in drug development. We detail the identification, quantitative impact, and standardized protocols for mitigating double-tip effects, scanner hysteresis, and thermal drift.

Artifact Analysis and Quantitative Data

Table 1: Summary of Common AFM Artifacts and Their Impacts

| Artifact | Primary Cause | Key Symptom in Semiconductor Imaging | Typical Dimensional Error | Criticality for Defect Analysis |

|---|---|---|---|---|

| Double Tip | Contaminated or damaged probe with multiple effective tips. | Repeating "ghost" features, asymmetrical line edges. | Feature width overestimation by 20-50%; false defect counts. | High - leads to misclassification of dense nanostructures. |

| Scanner Hysteresis | Piezoelectric material nonlinearity and history-dependent motion. | Distortion in fast-scan direction, skewed features. | Lateral: Up to 10-15% of scan size; Vertical: 1-5% error. | Medium-High - compromises critical dimension (CD) measurement. |

| Thermal Drift | System temperature changes causing probe/sample displacement. | Image stretching/compression over time; unstable tracking. | Drift rates of 0.5-5 nm/min initially, stabilizing after 1-2 hours. | High - for long-duration scans (e.g., conductivity mapping). |

Experimental Protocols

Protocol 3.1: Identification and Verification of Double-Tip Artifacts

Objective: To confirm probe integrity and distinguish true nanoscale features from artifacts. Materials: AFM with standard tapping mode, Reference Sample (e.g., TGZ1 or TGX1 calibrant with sharp, isolated spikes), new/unused probe of known radius. Procedure:

- Initial Scan: Image the reference sample using standard tapping mode parameters (set point ~0.7V, drive frequency near resonance).

- Feature Symmetry Analysis: Scan a known isolated, sharp feature (e.g., a single spike on TGZ1) in both the forward and reverse fast-scan directions.

- Tip Characterization: If a double tip is suspected, perform a blind tip reconstruction using dedicated software (e.g., SPIP, Gwyddion) or scan a tip characterization sample with features sharper than the probe.

- Validation: Compare the image of an isolated feature with its mirror image in the fast-scan axis. Asymmetry indicates a damaged tip.

- Action: If a double tip is confirmed, immediately replace the probe. Routine verification should be performed at the start of each imaging session.

Protocol 3.2: Minimizing Scanner Hysteresis with Closed-Loop Control and Linearization

Objective: To achieve linear scanner motion for accurate dimensional metrology. Materials: AFM system equipped with closed-loop scanner (capacitive sensors) or open-loop scanner with linearization algorithms. Procedure:

- System Setup: Allow the AFM electronics and scanner to thermally equilibrate for 60 minutes.

- Scanner Calibration: Perform a vendor-specified calibration routine using a pitch standard (e.g., 1µm or 10µm grid).

- Open-Loop Mitigation: For systems without closed-loop sensors:

- Use a slow scan rate (e.g., 0.5-1 Hz) to reduce dynamic hysteresis.

- Implement a bidirectional scan and use the trace and retrace signals to assess hysteresis error.

- Apply a polynomial linearization model based on prior characterization data.

- Closed-Loop Operation: For equipped systems, always enable the closed-loop feedback during final data acquisition.

- Verification: Image a known 2D grating. Measure pitch in both X and Y axes at multiple locations. Variation should be <1%.

Protocol 3.3: Compensation for Thermal Drift

Objective: To stabilize the probe-sample position for long-term measurements. Materials: Vibration isolation table, acoustic enclosure, environmental chamber (optional but recommended), sample stage with thermal mass. Procedure:

- Initial Stabilization: Load the sample and probe, then allow the entire system to settle in the measurement environment for a minimum of 90 minutes.

- Drift Rate Measurement: Engage on a stable, identifiable feature. Use the "point spectroscopy" mode to track the (X, Y) position of this feature over 30 minutes, recording every 60 seconds.

- Modeling: Calculate the drift rate in nm/min for X and Y axes. Most software can use this to apply a compensatory scan offset.

- Optimal Scan Strategy: For high-resolution imaging, set the slow-scan direction to be opposite the primary drift direction. Use a moderate scan rate (~1 Hz) to average out low-frequency drift.

- Environmental Control: For drug development research (e.g., protein aggregation studies), use a temperature-controlled fluid cell or environmental chamber to minimize bulk thermal changes.

Visualization of Workflows

Diagram Title: Pre-Imaging Setup and Calibration Workflow for AFM Defect Analysis

Diagram Title: Diagnostic Decision Tree for Common AFM Artifacts

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Artifact-Free AFM Semiconductor Analysis

| Item | Function in Mitigating Artifacts | Example Product/ Specification |

|---|---|---|

| High-Aspect Ratio, Single-Crystal Silicon Probes | Minimizes double-tip risk, provides consistent geometry for defect sizing. | BudgetSensors Tap300GD-G (tip radius <10nm, resonant freq ~300 kHz). |

| Traceable Pitch Calibration Samples | Calibrates scanner linearity, verifies XY dimensions, identifies hysteresis. | NT-MDT TGZ1 (1µm pitch), TGX1 (10µm pitch), or NIST-traceable standards. |

| Tip Characterization Sample | Directly images probe shape to confirm single-tip condition. | NT-MDT TGG01 (sharp spikes) or Nanosensors SSS-SHR. |

| Acoustic and Vibration Enclosure | Reduces environmental noise, a contributor to both drift and image distortion. | Custom or manufacturer-provided passive isolation hood. |

| Active Temperature Control Stage | Actively stabilizes sample temperature to sub-°C level, drastically reducing thermal drift. | JPK BioCell, or stages with Peltier elements. |

| Closed-Loop Scanner AFM | Uses internal capacitive sensors to correct hysteresis and creep in real-time. | Bruker Dimension FastScan, Oxford Instruments Cypher ES. |

| Linearization Software | Applies mathematical correction to open-loop scanner data post-acquisition. | Gwyddion (open-source), SPIP, or vendor-specific packages. |

This application note is framed within a doctoral thesis investigating Atomic Force Microscopy (AFM) methodologies for high-resolution analysis of surface defects in next-generation, low-k dielectric and organic semiconductor films. A central challenge in this research is the unintentional induction of surface damage (scratching, deformation, material transfer) during imaging, which corrupts defect characterization data and hinders reliable material evaluation. This protocol details a systematic approach to optimize the critical AFM feedback parameters—setpoint and feedback gains (proportional, integral)—to enable nondestructive imaging of soft, adhesive surfaces prevalent in advanced semiconductor and biopharmaceutical thin-film applications.

Core Principles & Parameter Definitions

Successful AFM operation in intermittent contact (tapping) mode relies on a feedback loop that maintains constant oscillation amplitude. The optimization of this loop is paramount for soft film integrity.

- Setpoint Ratio (rsp): The ratio of the operational oscillation amplitude (Asp) to the free-air amplitude (A0). It directly controls the time-averaged tip-sample interaction force.

- Proportional Gain (P): Determines the immediate response of the z-piezo to an error signal (difference between Asp and actual amplitude). High P values can cause instability (ringing).

- Integral Gain (I): Corrects for persistent, steady-state error. High I values can cause overshoot and low-frequency oscillations.

- Damage Threshold: The critical combination of rsp and gains below which no permanent topographic alteration occurs. This is material-dependent.

Table 1: Empirical Damage Thresholds for Representative Soft Films

| Material System | Typical Elastic Modulus (MPa) | Recommended Max Setpoint Ratio (rsp) | Optimized Gain Range (P / I) | Primary Damage Mode Observed |

|---|---|---|---|---|

| PS-b-PMMA Block Copolymer | 2000 - 3000 | 0.85 - 0.90 | 0.4 - 0.6 / 4 - 6 | Layer Delamination |

| Spin-On Low-k Dielectric (porous SiCOH) | 5000 - 8000 | 0.75 - 0.82 | 0.3 - 0.5 / 3 - 5 | Pore Collapse |

| Amorphous Organic Semiconductor (e.g., TIPS-pentacene) | 1000 - 2000 | 0.90 - 0.95 | 0.5 - 0.7 / 5 - 8 | Molecular Displacement |

| Pharmaceutical Polymer Film (HPMC) | 100 - 1000 | 0.95 - 0.98 | 0.6 - 0.8 / 6 - 10 | Viscoelastic Grooving |