Atomic Force Microscopy and Scanning Tunneling Microscopy: Advanced Protocols for Surface Manipulation in Biomedical Research

This article provides a comprehensive guide to Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) protocols for nanoscale surface manipulation.

Atomic Force Microscopy and Scanning Tunneling Microscopy: Advanced Protocols for Surface Manipulation in Biomedical Research

Abstract

This article provides a comprehensive guide to Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) protocols for nanoscale surface manipulation. Tailored for researchers, scientists, and drug development professionals, it covers foundational principles of tip-sample interactions, step-by-step methodologies for precise manipulation, troubleshooting for common experimental challenges, and frameworks for validating and comparing results against complementary techniques. The guide aims to equip practitioners with the knowledge to reliably probe and modify surfaces at the atomic scale for applications in biomaterial characterization, drug-target interaction mapping, and nanotechnology development.

The Atomic Toolkit: Understanding AFM and STM Fundamentals for Surface Manipulation

This application note, framed within a broader thesis on Atomic Force Microscope (AFM) and Scanning Tunneling Microscope (STM) surface manipulation protocols, details the core principles differentiating force-based and current-based manipulation. These are pivotal techniques for nanotechnology, materials science, and drug development, enabling precise positioning and characterization of atoms, molecules, and biomolecules. The fundamental distinction lies in the primary interaction used for both imaging and manipulation: AFM utilizes mechanical force via a physical tip, while STM relies on electrical tunneling current.

Core Principles & Quantitative Comparison

Table 1: Fundamental Operational Comparison

| Parameter | Atomic Force Microscopy (AFM) | Scanning Tunneling Microscopy (STM) |

|---|---|---|

| Primary Interaction | Mechanical force (van der Waals, Pauli repulsion, chemical). | Quantum mechanical tunneling current. |

| Measured Quantity | Force (via cantilever deflection). | Current (at constant bias or tip height). |

| Tip-Sample Distance | Typically 0.5-10 nm for contact/non-contact modes. | Extremely close (~0.3-1 nm) for electron tunneling. |

| Sample Conductivity Requirement | Not required. Insulators, semiconductors, and conductors can be studied. | Mandatory. Sample must be conductive or semi-conductive. |

| Ambient Operation | Yes. Can operate in air, liquid, vacuum. | Typically requires ultra-high vacuum (UHV) for atomic precision, but air/liquid possible. |

| Imaging Mode | Contact, non-contact, tapping mode. | Constant current, constant height. |

| Manipulation Mechanism | Mechanical pushing, pulling, sliding. | Inelastic electron tunneling, electric field, atomic/molecular hopping via current pulses. |

| Lateral Resolution | ~0.5-1 nm (atomic resolution in UHV). | ~0.1-0.2 nm (sub-atomic resolution possible). |

Table 2: Typical Manipulation Parameters & Outcomes

| Aspect | AFM Force-Based Manipulation | STM Current-Based Manipulation |

|---|---|---|

| Typical Force/Current | 0.1 - 10 nN for lateral manipulation. | 0.1 - 10 nA for electron-induced processes. |

| Energy Scale | Mechanical potential energy (~10-100 meV). | Electronic excitation energy (eV range). |

| Control Parameter | Tip position, force setpoint, scan direction. | Bias voltage (V), current setpoint (I), pulse duration (ms-µs). |

| Common Target Species | Nanoparticles, biomolecules (DNA, proteins), carbon nanotubes, adatoms on insulating surfaces. | Single atoms/molecules on conductive surfaces (e.g., Fe on Cu, CO on Pt, Co on Au). |

| Primary Manipulation Effect | Mechanical displacement through repulsive or attractive forces. | Electronic excitation inducing diffusion, desorption, bond dissociation, or conformational change. |

| Key Advantage | Versatility in environments and materials; direct mechanical interaction. | Unparalleled atomic precision and electronic/chemical selectivity. |

Experimental Protocols

Protocol A: AFM Lateral Manipulation of Nanoparticles (Force-Based)

Objective: To reposition a gold nanoparticle (AuNP) on a mica surface in liquid environment.

Research Reagent Solutions & Materials:

- AFM with Liquid Cell: Enables operation in physiological buffers.

- Cantilever: Soft spring constant (~0.1 N/m) for force sensitivity.

- Gold Nanoparticles (10-20 nm): Functionalized with thiolated PEG for biocompatibility.

- Freshly Cleaved Mica Substrate: Atomically flat, negatively charged surface.

- Phosphate Buffered Saline (PBS), pH 7.4: Standard physiological buffer.

Methodology:

- Sample Preparation: Deposit a dilute solution of functionalized AuNPs onto freshly cleaved mica. Incubate for 15 minutes, then rinse gently with PBS to remove unbound particles.

- AFM Mounting: Mount the sample in the liquid cell, fill with PBS, and engage a soft cantilever.

- Imaging: Image the sample in tapping or contact mode at low force (< 200 pN) to locate a target AuNP.

- Manipulation Setup: Switch to contact mode. Position the tip just beside the target nanoparticle.

- Manipulation Execution: Increase the force setpoint to 1-2 nN. Scan a single line along the desired direction of particle movement, "pushing" the particle. The tip is moved laterally behind the particle.

- Verification: Reduce force to imaging levels and rescan the area to confirm the new position of the AuNP.

Protocol B: STM-Induced Desorption of a Single Molecule (Current-Based)

Objective: To desorb a single carbon monoxide (CO) molecule from a platinum (Pt(111)) surface using inelastic electron tunneling.

Research Reagent Solutions & Materials:

- UHV-STM System: Base pressure < 1×10⁻¹⁰ mbar.

- Pt(111) Single Crystal: Cleaned via repeated Ar⁺ sputtering and annealing cycles.

- CO Gas Dosing System: For controlled introduction of isotopically pure ¹²C¹⁶O.

- Electrochemically Etched Tungsten Tip: Cleaned via in-situ field emission and heating.

Methodology:

- Sample & Tip Preparation: Clean the Pt(111) crystal and STM tip under UHV. Cool the sample to 4-5 K using a liquid helium cryostat.

- Adsorbate Deposition: Backfill the chamber with CO to a controlled exposure (e.g., 0.1 Langmuir) to achieve isolated molecules on the surface.

- Imaging: Locate a single CO molecule adsorbed on a top site using constant-current imaging (parameters: Vbias = 10 mV, It = 50 pA).

- Manipulation Setup: Position the tip directly above the target CO molecule.

- Manipulation Execution: Open the feedback loop. Apply a voltage pulse (Vpulse = 500 mV, duration tpulse = 100 ms) with the tip held at the original height. The high current density induces vibrational excitation, leading to desorption.

- Verification: Resume constant-current imaging with original parameters. A successful manipulation is indicated by the disappearance of the CO protrusion and the appearance of a clean Pt atom site.

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials

| Item | Primary Function | Typical Application Context |

|---|---|---|

| Conductive Substrates (Au(111), Pt(111), HOPG) | Provide atomically flat, clean surfaces for STM imaging and manipulation. | STM studies of molecular self-assembly, atomic manipulation. |

| Atomically Flat Insulators (Mica, SiO₂) | Provide flat, charge-controlled surfaces for AFM, especially for biomolecules. | AFM imaging of DNA, proteins, and lipid bilayers in liquid. |

| Functionalized Nanoparticles (PEG-AuNPs) | Stable, biocompatible probes for AFM manipulation and force spectroscopy. | Probing cellular interactions, constructing nano-assemblies. |

| UHV Sputtering & Annealing Kit | For in-situ cleaning of single crystal surfaces and STM tips. | Preparing contamination-free surfaces for atomic-scale science. |

| Piezoelectric Scanner Calibration Sample | Grid with known pitch and height for calibrating scanner movement in X, Y, Z. | Essential for quantitative measurements in both AFM and STM. |

| Soft Cantilevers (k ~ 0.01 - 0.1 N/m) | High force sensitivity for non-destructive imaging and precise force control. | AFM manipulation of soft samples (e.g., biomolecules, polymers). |

| Stiff Cantilevers (k ~ 10 - 100 N/m) | High stability and resonance frequency for tapping mode in air/liquid. | Routine AFM topography imaging. |

| Electrochemically Etched Metal Wires (W, PtIr) | Source for fabricating sharp, conductive STM tips. | Creating tips for high-resolution STM. |

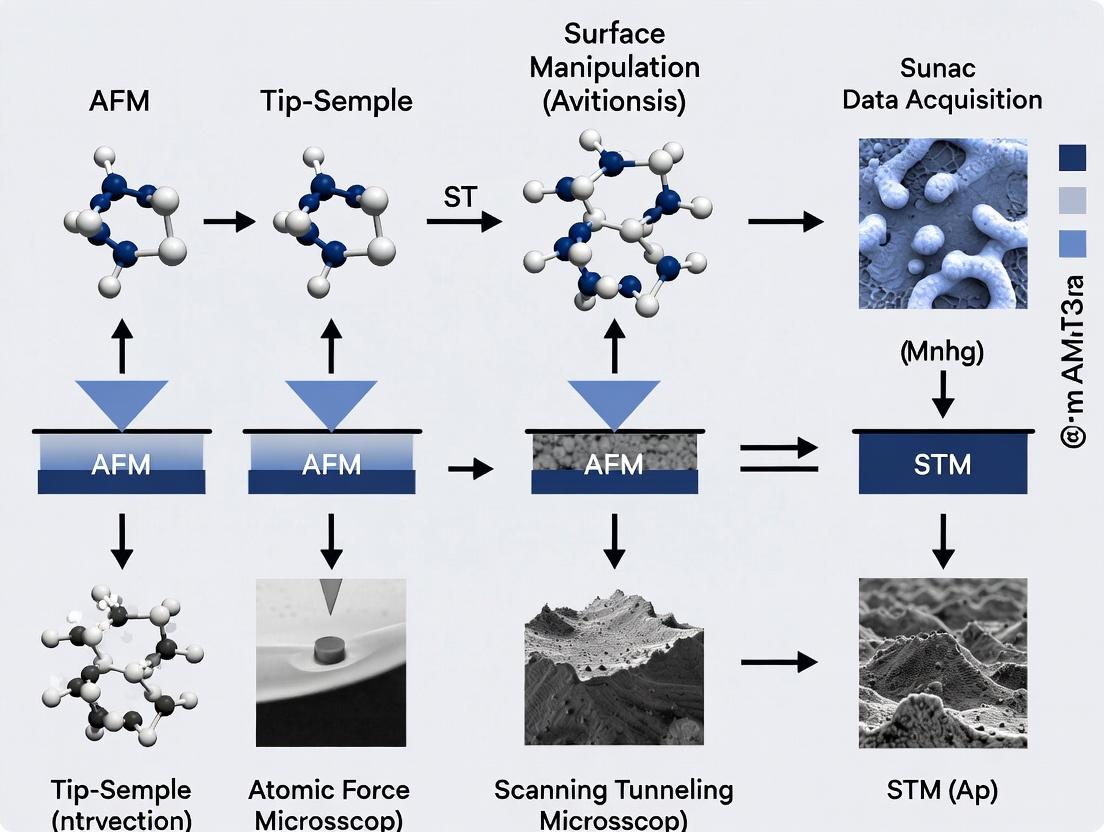

Visualization of Protocols and Principles

Diagram Title: AFM vs STM Manipulation Workflow Comparison

Diagram Title: Hierarchical Tree of Manipulation Mechanisms

Application Notes: Atomic Force Microscopy for Multi-Force Dissection

Within the broader thesis on AFM and STM surface manipulation protocols, distinguishing between the fundamental forces at the nanoscale is paramount. This document provides application notes and detailed protocols for isolating and quantifying Van der Waals (vdW), chemical, electrostatic, and magnetic interactions using advanced Scanning Probe Microscopy (SPM) modes. These protocols enable researchers to map interaction potentials, crucial for surface engineering, molecular recognition studies in drug development, and materials characterization.

Table 1: Quantitative Force Ranges and Probing Techniques

| Interaction Force | Typical Range (Magnitude) | Typical Range (Distance) | Primary AFM/STM Probing Mode | Key Distinguishing Feature |

|---|---|---|---|---|

| Van der Waals (vdW) | 0.1 - 10 nN | 0.2 - 10 nm | Contact Mode, Jump-to-Contact in Force Spectroscopy | Always attractive at short range; non-specific. |

| Chemical/Bonding | 0.1 - 5 nN (single bond) | 0.1 - 0.3 nm | Ultra-High Vacuum (UHV) Non-Contact AFM (nc-AFM), STM with functionalized tips | Short-range, highly sensitive to atomic identity; can be covalent or ionic. |

| Electrostatic | 1 pN - 100 nN | 10 nm - 1 µm | Electrostatic Force Microscopy (EFM), Kelvin Probe Force Microscopy (KPFM) | Long-range; tunable via sample/tip bias voltage. |

| Magnetic | 1 pN - 1 nN | 10 - 100 nm | Magnetic Force Microscopy (MFM) | Long-range; detected using magnetized tips; insensitive to non-magnetic surfaces. |

Experimental Protocols

Protocol 1: Isolating Chemical vs. Van der Waals Forces via Non-Contact AFM in UHV

Objective: To map short-range chemical interaction potentials on an atomically clean surface. Materials: See "The Scientist's Toolkit" below. Method:

- Sample & Tip Preparation: Clean the sample (e.g., silicon (7x7) or NaCl) via repeated sputter-anneal cycles in UHV. Prepare a sharp metal tip (e.g., Tungsten) via electrochemical etching and in-situ Ar+ sputtering.

- Functionalization (Optional but crucial for chemical specificity): For molecular samples, functionalize the AFM tip with a specific terminal group (e.g., CO molecule at the tip apex) via controlled tip picking from the surface.

- Frequency Modulation AFM Setup: Set the cantilever to oscillate at its resonance frequency (f0) with a constant amplitude (A ≈ 50-100 pm).

- Force-Distance Spectroscopy: At each pixel in a 2D grid, record the frequency shift (Δf) vs. tip-sample distance (z) curve. The frequency shift is directly related to the force gradient.

- Data Analysis: Convert Δf(z) to force F(z) using the Sader-Jarvis inversion algorithm. The long-range part of the curve (≈ >0.5 nm) is dominated by vdW and electrostatic forces. The short-range part (<0.5 nm) contains the chemical interaction signature. Subtract the long-range background (fitted to a power law) to isolate the chemical contribution.

Protocol 2: Mapping Electrostatic Potentials via KPFM

Objective: To measure surface contact potential difference (CPD) and separate electrostatic from other forces. Method:

- Two-Pass Lift Mode Setup: Configure the AFM for a two-pass scan. Pass 1: Intermittent contact or tapping mode to acquire topography at a set tip-sample distance.

- Lift Mode: On Pass 2, the tip retraces the topography at a user-defined lift height (typically 10-50 nm), where short-range forces are negligible.

- Nulling Electrostatic Force: During Pass 2, a feedback loop applies a DC bias (VDC) to the tip. The AC component of the electrostatic force (from an applied AC bias, VAC) is nulled by adjusting VDC.

- Data Acquisition: The VDC required to null the force at each point is recorded as the CPD map. The applied VDC equals the CPD (Φtip - Φsample) when the force is nulled.

- Calibration: Use a reference sample with known work function (e.g., highly ordered pyrolytic graphite (HOPG)) for calibration.

Protocol 3: Detecting Magnetic Force Gradients with MFM

Objective: To image magnetic domain structures. Method:

- Tip Magnetization: Use a commercially available magnetically coated tip (e.g., CoCr). Magnetize the tip in a strong external field along its axis before use.

- Two-Pass Lift Mode Setup: Similar to KPFM. Pass 1: Tapping mode for topography.

- Lift Mode for Magnetic Force: In Pass 2, the tip lifts to 20-100 nm. At this height, electrostatic forces can be compensated (via applied DC bias), leaving magnetic and vdW forces. vdW is constant over the scan.

- Signal Detection: The phase shift (or frequency shift) of the oscillating cantilever in Pass 2 is recorded. This shift is proportional to the magnetic force gradient (∂Fm/∂z).

- Image Interpretation: Bright/dark contrasts in the phase image correspond to attractive/repulsive magnetic force gradients, revealing magnetic domains.

Visualizations

Diagram 1: SPM Multi-Force Probing Workflow

Title: SPM Multi-Force Probing Workflow

Diagram 2: KPFM Two-Pass Principle

Title: KPFM Two-Pass Principle

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in Experiment |

|---|---|

| Si or SiN Cantilevers with reflective coating | Base sensor for AFM; deflects due to force. Reflective coating enables laser detection. |

| Conductive, Metal-Coated AFM Tips (Pt/Ir, CoCr) | For EFM/KPFM (conductivity) and MFM (magnetic coating). |

| qPlus Sensors (for UHV nc-AFM) | Stiff, tuning fork-based sensors enabling sub-Ångström oscillation amplitudes crucial for chemical bond imaging. |

| Ultra-High Vacuum (UHV) System (<10^-10 mBar) | Provides atomically clean surfaces and tips, eliminates spurious forces from contaminants and water layers. |

| Vibration Isolation Platform | Critical for stable imaging at atomic resolution; minimizes noise from environmental vibrations. |

| Sample/Tip Bias Voltage Source | Applies DC and AC voltages for electrostatic force generation and nulling (KPFM). |

| Reference Calibration Samples (HOPG, Au(111), Mica) | Samples with known, atomically flat surfaces and work functions for tip performance testing and calibration. |

| Functionalized Tips (e.g., CO-terminated) | Tips with a known, single-molecule terminus to enhance resolution and chemical specificity in nc-AFM. |

This application note is framed within a broader thesis investigating standardized protocols for atomic-scale surface manipulation using Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM). The reliability and reproducibility of single-molecule or single-atom manipulation experiments are fundamentally dictated by the performance and integration of key instrumental components. This document details these critical subsystems, their quantitative performance metrics, and associated calibration protocols.

Critical Components & Performance Data

The following components are non-negotiable for high-fidelity manipulation experiments. Their performance directly impacts spatial resolution, signal-to-noise ratio (SNR), and long-term drift.

Table 1: Critical Component Specifications for Reliable AFM/STM Manipulation

| Component | Key Parameters | Target Specification for Atomic Manipulation | Impact on Experiment |

|---|---|---|---|

| Scanner & Actuator | XYZ Range, Resonance Frequency, Nonlinearity, Hysteresis, Thermal Drift | Range: ≥1 µm (XY), ≥0.5 µm (Z); Resonance Freq: >10 kHz (Z); Drift: <0.1 nm/min (stabilized) | Determines maximum scan area, speed, and precision of tip positioning for manipulation. |

| Vibration Isolation | Vertical/Horizontal Isolation Frequency, Attenuation | Isolation starts at 0.5-1 Hz; Attenuation >60 dB at 10 Hz | Essential for stabilizing tip-sample junction at sub-Ångström levels; prevents false manipulation events. |

| Environmental Control | Acoustic Noise, Temperature Stability, Humidity Control, Vacuum Level | <40 dB SPL; ΔT < 0.1°C/hr; P < 1×10⁻¹⁰ mbar (UHV) or inert gas cell | Minimizes thermal drift, suppresses oxidation/contamination, and enables clean surfaces. |

| Tip/Fabrication | Material, Apex Sharpness, Conductivity (STM), Spring Constant (AFM) | STM: Etched W or PtIr, atomically sharp; AFM: Si or qPlus sensor with controlled stiffness | Defines interaction mechanism, resolution, and the nature of the tip-sample potential. |

| Motion Control & Feedback | PID Loop Bandwidth, Current-to-Voltage Noise Floor, Setpoint Stability | Loop Bandwidth: >5 kHz; Noise Floor: <1 pm/√Hz (AFM), <1 pA/√Hz (STM) | Enables stable tracking of topography or current during pre- and post-manipulation imaging. |

| Signal Acquisition | ADC/DAC Resolution, Sampling Rate, Digital Filtering | Resolution: ≥20-bit; Rate: ≥1 MS/s per channel | Faithfully records manipulation events (e.g., current jumps, force discontinuities) with high dynamic range. |

Experimental Protocols for Component Validation & Calibration

Protocol 3.1: Scanner Calibration & Nonlinearity Correction

Objective: To quantify and correct for scanner piezo nonlinearities and hysteresis to achieve true nanometer-scale positioning. Materials: Calibration grating (e.g., 180 nm pitch, 20 nm step height), AFM/STM system with closed-loop scanner or linearized control. Methodology:

- Image Acquisition: Acquire a high-resolution image (≥512×512 pixels) of the calibration grating over the full intended manipulation scan range.

- Spectral Analysis: Perform a 2D Fourier transform (FFT) of the image. The known grating pitch appears as distinct peaks in the FFT spectrum.

- Distortion Quantification: Measure the deviation of these peaks from their ideal, equidistant positions. This maps the scanner's nonlinear distortion field.

- Lookup Table (LUT) Generation: Create an inverse distortion map. This LUT will be applied in real-time to the commanded scanner voltages to achieve linear motion.

- Validation: Re-image the grating after LUT application. The step edges should be straight, and the measured pitch should be constant across the scan area (deviation <1%).

Protocol 3.2: In-situ Tip Characterization via Field Ion Microscopy (FIM) in UHV-STM

Objective: To atomically characterize and clean an STM tip apex prior to a manipulation experiment. Materials: UHV-STM system, Ne or He gas supply (99.999% purity), high-voltage supply (>5 kV), tip (typically W<111>). Methodology:

- Tip Preparation: Flash heat the etched tungsten tip to >2000 K via electron bombardment to remove oxides.

- Cooling: Cool the tip to 40-80 K using a liquid helium cryostat.

- Gas Introduction: Backfill the UHV chamber with Ne or He gas to a pressure of ~1×10⁻⁵ mbar.

- Imaging: Apply a positive high voltage (4-8 kV) to the tip relative to a grounded screen. Gas atoms are ionized near the apex, and ions project onto a detector, revealing the atomic structure of the tip.

- Shaping: Controlled field evaporation, by carefully increasing the voltage, removes atoms from the apex to achieve a single-atom-terminated tip. The process is monitored in real-time via FIM patterns.

- Transfer: Retract voltage, pump gas, and transfer the tip to the STM stage without breaking vacuum.

Visualizing the Workflow for Reliable Manipulation

Diagram Title: AFM/STM Atomic Manipulation Experimental Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for AFM/STM Surface Manipulation Experiments

| Item | Function & Rationale |

|---|---|

| Highly Ordered Pyrolytic Graphite (HOPG) | An atomically flat, inert, and conductive calibration substrate. Provides large terraces for testing tip quality and practicing manipulation on adsorbates. |

| Gold (111) Single Crystal | A clean, reconstructable metal surface essential for studying thiol-based molecular self-assembly (relevant to drug development) and as a substrate for nanostructure construction. |

| Tetraphenylporphyrin (2H-TPP) or similar molecules | A model planar organic molecule with a distinct, recognizable STM/AFM appearance. Used as a standard "test cargo" for developing lateral manipulation protocols. |

| Silicon Cantilevers with Reflective Coating | For AFM-based manipulation. Coating (Au/Al) ensures high laser reflectivity for optical lever detection. Specific spring constant (e.g., 40 N/m) is chosen for stable contact-mode manipulation. |

| qPlus Sensor Probes | For high-resolution AFM/STM. Tuning fork-based sensors with a stiff quartz tip enable simultaneous force and current sensing, crucial for probing manipulation forces. |

| Tungsten (W) Wire (0.25 mm dia.) | Standard material for electrochemical etching to fabricate sharp, robust STM tips for UHV experiments. The <111> crystalline orientation is preferred for stability. |

| Ultra-high Purity Gases (Ne, He, Ar, N₂) | Used for sputter cleaning samples (Ar), backfilling for FIM tip shaping (Ne/He), and creating inert environments in gloveboxes (N₂) for air-sensitive samples. |

| Atomic/Molecular Beam Epitaxy (MBE) Sources | In UHV systems, allows for precise deposition of single atoms (e.g., Fe, Co) or organic molecules onto pristine surfaces, creating defined starting conditions for manipulation. |

1. Introduction Within the broader thesis on Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) surface manipulation protocols, the selection of substrate and probe is not merely a preliminary step but the foundational determinant of experimental success. This document details the critical material considerations that dictate the strategy for precise nanoscale manipulation, from single-molecule positioning to the mechanical probing of cellular membranes. The protocols herein are designed for researchers and drug development professionals aiming to standardize manipulation techniques for reliable, reproducible outcomes.

2. Quantitative Data Summary: Substrate & Probe Property Interplay

Table 1: Common AFM/STM Substrates and Their Manipulation Suitability

| Substrate Material | Roughness (RMS, typical) | Conductivity | Key Functionalization | Optimal For Manipulation Of | Notes |

|---|---|---|---|---|---|

| Highly Ordered Pyrolytic Graphite (HOPG) | < 0.1 nm | Conductive | Passive adsorption | Molecules, nanotubes (imaging) | Atomically flat, but step edges can interfere. Poor for covalent tethering. |

| Mica (Muscovite) | < 0.1 nm | Insulator | APTES, silanization, lipid bilayer deposition | Biomolecules (DNA, proteins), lipid assemblies | Cleavable for ultra-flatness. Easily functionalized. |

| Gold (111) | ~0.2 nm | Conductive | Thiol-gold chemistry | Thiolated molecules, self-assembled monolayers (SAMs) | Required for STM. Excellent for defined chemical tethering. |

| Silicon/SiO₂ | < 0.5 nm | Semiconductor/Insulator | Silane chemistry | Nanoparticles, polymer blends | Versatile, wafer-scale. Thermal oxide provides stable insulator layer. |

| Functionalized Lipid Bilayers | ~4-5 nm (fluid) | Insulator | Embedded ligands, receptors | Membrane proteins, cellular interactions | Mimics native environment. Requires fluidity control. |

Table 2: AFM Probe Characteristics and Selection Criteria

| Probe Type | Stiffness (k) Range | Tip Radius (R) | Typical Coating/ Material | Primary Manipulation Mode | Ideal Application |

|---|---|---|---|---|---|

| Silicon Nitride (Si₃N₄) | 0.01 - 0.6 N/m | 20 - 60 nm | Uncoated or Si₃N₄ | Contact Mode, Force Mapping | Soft biological samples, indentation. |

| Silicon (Si) | 1 - 200 N/m | < 10 nm (sharp) | Uncoated, Au, PtIr | Tapping/Non-Contact, Lithography | High-res imaging, nanografting, molecular pushing. |

| Carbon Nanotube (CNT) | 0.1 - 1 N/m | ~1-5 nm (tube end) | Carbon | Contact, Pushing/Pulling | Ultra-high res, precise single-molecule manipulation. |

| Diamond | > 200 N/m | < 50 nm (coated) | Diamond-like carbon | Scratching, Plowing | Extreme durability, hard material machining. |

| Magnetic Coated (e.g., Co/Cr) | 0.5 - 5 N/m | 20 - 50 nm | Ferromagnetic alloy | Magnetic Force Manipulation | Manipulation of magnetic nanoparticles. |

3. Experimental Protocols

Protocol 3.1: Functionalization of Gold Substrate for Thiolated Molecule Patterning Objective: To create a chemically patterned Au(111) surface for the site-specific immobilization and subsequent manipulation of thiolated DNA or proteins. Materials: Au(111) on mica, 1-Octadecanethiol (ODT), 11-Mercapto-1-undecanol (MUD), absolute ethanol, thiolated target molecule, AFM with fluid cell. Procedure:

- Substrate Preparation: Anneal the Au(111)/mica substrate in a hydrogen flame for 2 minutes and allow to cool in a clean air environment.

- SAM Formation: Immerse the substrate in a 1 mM solution of ODT in ethanol for 30 minutes. Rinse thoroughly with ethanol and dry under a gentle N₂ stream.

- Nanografting (Patterning): Fill the AFM fluid cell with a 1 mM solution of MUD in ethanol. Engage a stiff Si probe (k ~40 N/m). In contact mode, select a scan area (e.g., 500 x 500 nm²). Increase the applied force to 20-30 nN to mechanically displace (scratch) the ODT SAM within the scanned area, while the MUD molecules from solution immediately adsorb onto the newly exposed gold, creating a hydrophilic pattern.

- Rinsing: Flush the cell with pure ethanol to remove excess MUD and dislodged ODT.

- Target Immobilization: Introduce a 0.1 µM solution of the thiolated target molecule in an appropriate buffer (e.g., PBS). Incubate for 1 hour. The target will bind preferentially to the hydrophilic MUD-patterned regions.

- Verification & Manipulation: Exchange to pure buffer. Image in tapping mode to verify patterned assembly. Subsequent manipulation (e.g., pushing, cutting) can be performed on the assembled structures using a sharp, stiff probe.

Protocol 3.2: Pushing Manipulation of Nanoparticles on Mica Using Functionalized Probes Objective: To relocate individual nanoparticles along a predefined path on a mica substrate using an AFM probe with defined chemistry. Materials: Freshly cleaved mica, carboxylated polystyrene nanoparticles (100 nm), APTES, glutaraldehyde, amine-functionalized AFM probe (k ~0.1 N/m), PBS buffer. Procedure:

- Substrate Activation: Expose cleaved mica to APTES vapor (5 µL in a desiccator) for 30 minutes to create an amine-terminated surface.

- Nanoparticle Adsorption: Incubate the APTES-mica with a dilute nanoparticle solution (1:1000 dilution from stock) for 5 minutes. Rinse with DI water and dry. A sparse, isolated distribution of particles is critical.

- Probe Functionalization: In a humidity chamber, expose the amine-functionalized probe to glutaraldehyde vapor (25% solution) for 10 minutes. The aldehyde groups provide a reactive handle.

- Manipulation in Liquid: Engage the probe in PBS buffer. Locate an isolated nanoparticle. Approach the particle from the side (in-plane) with a setpoint force of 2-5 nN. Using the AFM software's "lateral move" or vector-relocation command, push the particle along the desired trajectory over 200-500 nm. The controlled adhesive interaction prevents particle hopping.

- Verification: Retract the probe, image the area in tapping mode to confirm the new particle position and assess substrate damage.

4. Diagrams of Logical Relationships & Workflows

Title: Decision Flow for Manipulation Strategy

Title: Nanografting and Molecular Assembly Workflow

5. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Surface Manipulation Experiments

| Item | Function/Benefit | Example Use Case |

|---|---|---|

| Muscovite Mica Discs (V1 Grade) | Provides an atomically flat, easily cleavable insulating substrate. | Immobilization of biomolecules for AFM imaging and force spectroscopy. |

| APTES (3-Aminopropyl triethoxysilane) | A common silane coupling agent to introduce amine groups on oxide surfaces (Si, mica). | Creating a reactive surface for crosslinking proteins or nanoparticles. |

| Alkanethiols (e.g., C11-EG6-OH thiol) | Form well-ordered SAMs on gold; EG groups resist non-specific binding. | Creating inert, protein-resistant surfaces with defined reactive patches for biosensing. |

| Carboxylated Polystyrene Nanoparticles | Monodisperse, inert colloids with surface COOH for easy functionalization. | Model systems for developing particle pushing/positioning protocols. |

| BSA (Bovine Serum Albumin) | A common blocking agent to passivate surfaces and probes against non-specific adsorption. | Reducing background noise in biological manipulation experiments. |

| Cantilever Calibration Kit | Contains pre-characterized levers for accurate spring constant (k) calibration. | Essential for quantifying manipulation and indentation forces. |

| Diamond-Like Carbon (DLC) Coated Probes | Extremely hard, wear-resistant coating for prolonged lithography or scratching. | Nano-patterning hard materials or writing on polymer resists. |

Application Notes & Protocols within AFM/STM Surface Manipulation Research

This document details the experimental protocols and historical context of key experiments that established the foundational techniques for nanoscale manipulation. The information is framed within ongoing research into standardizing Atomic Force Microscope (AFM) and Scanning Tunneling Microscope (STM) surface manipulation protocols for reproducible nanofabrication and molecular analysis.

Milestone 1: The IBM Logo - Atomic Manipulation with STM (1989)

Researchers: D. M. Eigler and E. K. Schweizer at IBM Almaden. Core Achievement: First intentional positioning of individual atoms to form a structure.

Protocol: Xenon on Nickel (110) at 4K

Objective: To adsorb, image, and reposition individual Xe atoms on a Ni surface to form specified patterns.

Detailed Methodology:

- Substrate Preparation:

- A Ni(110) crystal is cleaned in ultra-high vacuum (UHV, base pressure <10⁻¹⁰ mbar) via repeated cycles of Ar⁺ sputtering (1 keV, 15 μA/cm² for 30 min) and annealing to 800°C.

- Adsorbate Deposition:

- The clean, cooled substrate (held at 4K) is exposed to a low pressure (~10⁻¹⁰ mbar) of research-grade Xe gas for 60-120 seconds to achieve a sub-monolayer coverage.

- Imaging Parameters (Constant Current Mode):

- Tip: Electrically etched tungsten wire.

- Bias Voltage (Vb): +10 mV to +100 mV (sample positive).

- Tunneling Current (It): 1 nA.

- Scan rate is minimized (e.g., 100 Å/s) to avoid atom drag.

- Manipulation Protocol (Lateral Sliding):

- Locate: Image target Xe atom.

- Approach: Position tip above atom with standard imaging parameters.

- Engage: Reduce tip-to-atom distance by increasing It to ~10 nA or decreasing Vb to ~5 mV. This increases the attractive van der Waals/chemical force.

- Drag: Move the tip slowly (at ~5 Å/s) along the desired drag path. The atom follows the tip's trajectory due to the enhanced attraction.

- Release: Return It and Vb to imaging parameters. The atom remains at the new location.

- Verify: Re-image the area to confirm successful relocation.

Research Reagent Solutions & Key Materials

| Item | Function & Specification |

|---|---|

| Ni(110) Single Crystal | Atomically flat, catalytically inert substrate providing a defined lattice for adsorption. |

| Research Grade Xenon Gas | Inert, monatomic adsorbate with suitable electronic structure for STM imaging and manipulation. |

| Electrochemically Etched Tungsten Tip | Provides atomic sharpness for tunneling and force interaction. |

| UHV System (≤10⁻¹⁰ mbar) | Eliminates surface contamination, allowing for clean adsorption and stable imaging. |

| Liquid He Cryostat (4K) | Stabilizes adsorbed atoms by eliminating thermal diffusion; increases mechanical stability. |

| Parameter | Value/Range | Significance |

|---|---|---|

| Temperature | 4 K | Suppresses thermal diffusion of Xe atoms. |

| Tunneling Current (Image) | 1 nA | Stable imaging without displacement. |

| Tunneling Current (Manipulation) | ~10 nA | Increases tip-atom force for lateral sliding. |

| Bias Voltage (Image) | +10 to +100 mV | Samples Xe-derived electronic states. |

| Bias Voltage (Manipulation) | ~5 mV | Low voltage increases force interaction. |

| Drag Speed | ~5 Å/s | Slow enough for atom to follow tip adiabatically. |

| Positional Accuracy | ±1 Å | Precision of atomic placement on lattice. |

Diagram Title: STM Atomic Dragging Protocol Flow

Milestone 2: The Quantum Corral - Confinement of Surface Electrons (1993)

Researchers: M. F. Crommie, C. P. Lutz, D. M. Eigler. Core Achievement: Constructed a ring of Fe atoms on Cu(111) to confine surface state electrons, creating a direct visualization of quantum mechanical standing waves.

Protocol: Fe Atom Quantum Corral on Cu(111)

Objective: To construct a circular barrier of Fe atoms that reflects Cu surface state electrons, forming standing wave patterns inside the enclosure.

Detailed Methodology:

- Substrate Preparation:

- Cu(111) crystal cleaned in UHV by Ar⁺ sputtering and annealing to ~550°C.

- Adsorbate Deposition:

- Fe is evaporated from a high-purity rod using an electron-beam evaporator onto the clean Cu(111) held at ~4K, creating isolated Fe adatoms.

- Manipulation & Construction:

- Use the same lateral sliding protocol as Milestone 1 to position Fe atoms. The corral is built atom-by-atom.

- Fe atoms bond strongly to Cu, acting as nearly perfect scattering centers for the Cu(111) surface state electrons.

- Imaging the Standing Waves:

- After construction, the interior of the corral is imaged at constant current with specific parameters:

- Vb: Low sample bias (e.g., -10 mV) to probe the local density of states (LDOS) near the Fermi level.

- It: ~1 nA.

- The measured topographic height (z) reflects spatial variations in LDOS, revealing standing waves.

Research Reagent Solutions & Key Materials

| Item | Function & Specification |

|---|---|

| Cu(111) Single Crystal | Provides a 2D electron gas (surface state) with long electron coherence length. |

| High-Purity Iron (Fe) Source | Evaporated to create strong, localized scattering centers (adatoms). |

| UHV STM with e-beam Evaporator | Integrated system for clean deposition and in-situ analysis. |

| Low-Temperature STM (4K) | Essential for maintaining atomic positions and electron coherence. |

| Parameter | Value/Range | Significance |

|---|---|---|

| Corral Diameter | 71.3 Å | Defines the boundary condition for electron confinement. |

| Number of Fe Atoms | 48 | Forms a continuous, circular scattering barrier. |

| Surface State Wavelength | ~15 Å (on Cu(111)) | Determines standing wave pattern spacing. |

| Imaging Bias (Vb) | -10 mV | Maps LDOS of confined electrons near EF. |

| Temperature | 4 K | Preserves atomic positions & electron phase coherence. |

Diagram Title: Electron Confinement Creates STM-Visible Standing Waves

Milestone 3: AFM Molecular Manipulation for Drug Discovery Mapping

Core Achievement: Using non-contact AFM to manipulate and characterize individual organic molecules and complexes relevant to drug development (e.g., 2012 onward).

Protocol: Non-Contact AFM Imaging and Force Spectroscopy of a Molecule-Substrate Bond

Objective: To quantitatively measure the binding force and manipulate the conformation of a pharmaceutical molecule (e.g., an antibiotic) on a salt surface using a functionalized AFM tip.

Detailed Methodology:

- Tip Functionalization:

- A qPlus sensor-based AFM tip is prepared by picking up a single CO molecule at its apex (by gentle contact at low temperature). This creates a chemically inert and atomically sharp probe.

- Sample Preparation:

- Target molecules are sublimed onto a clean NaCl(001) surface in UHV. The surface provides insulating, atomically flat terraces.

- High-Resolution Imaging:

- Operate in frequency modulation mode at constant height.

- Parameters: Oscillation amplitude <1 Å, tune to negligible frequency shift (Δf) setpoint (~ -1 to -5 Hz) to minimize perturbation.

- The CO-terminated tip resolves the molecular backbone and functional groups via Pauli repulsion.

- Force Spectroscopy for Binding Analysis:

- Position the tip over a specific molecular site (e.g., a carboxyl group).

- Record a Δf(z) spectroscopy curve as the tip approaches, touches, and retracts from the molecule.

- Convert Δf(z) to force F(z) using the Sader-Jarvis algorithm.

- The retraction curve shows a characteristic 'snap-off' event, whose force corresponds to the site-specific molecule-substrate bond strength.

- Lateral Manipulation:

- To move a molecule, position the tip above its periphery.

- Reduce the tip-height (more negative Δf setpoint) to increase repulsive interaction.

- Scan the tip laterally to push the molecule to a new location.

Research Reagent Solutions & Key Materials

| Item | Function & Specification |

|---|---|

| qPlus AFM Sensor | Enables simultaneous STM/AFM with high force sensitivity. |

| CO Molecule for Tip Termination | Creates a defined, passive probe for high-resolution imaging. |

| NaCl(001) Single Crystal | Insulating, flat substrate for adsorbing organic molecules without charge transfer. |

| UHV NC-AFM System with LT | Provides stability and cleanliness for molecular-scale force measurement. |

| Sublimation Oven for Molecules | Controlled thermal deposition of non-volatile organic molecules. |

| Parameter | Value/Range | Significance |

|---|---|---|

| Oscillation Amplitude | 0.5 - 1.0 Å | Enhances force contrast in Pauli repulsion regime. |

| Frequency Shift Setpoint (Image) | -1 to -5 Hz | Minimizes interaction force during imaging. |

| Lateral Resolution | ~1 Å (for backbone) | Resolves molecular structure without electrons. |

| Measurable Force Range | ± a few pN to >100 pN | Covers van der Waals, covalent, and hydrogen bonds. |

| Temperature | 4.8 - 5.0 K | Necessary for stability of molecular conformation. |

Diagram Title: Protocol for AFM Molecular Force Mapping & Manipulation

Precision at the Nanoscale: Step-by-Step AFM/STM Manipulation Protocols for Biomedical Surfaces

This document constitutes detailed Application Notes and Protocols framed within the broader thesis research on standardizing Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) surface manipulation protocols. Reproducible nanoscale manipulation—critical for fields from nanofabrication to drug development where molecular interactions are probed—is fundamentally dependent on rigorous pre-manipulation calibration. This protocol outlines the essential, sequential steps for tip characterization and substrate preparation, which establish the baseline for reliable experimental data.

Tip Characterization Protocols

The scanning probe is the primary interaction tool. Its precise geometry and mechanical/electronic properties must be quantified.

Tip Imaging and Shape Reconstruction

Protocol: Use a characterized tip characterizer (e.g., TED series from TED Pella, Inc.) with sharp, known features.

- Sample Mounting: Securely mount the tip characterizer substrate on the microscope sample stage using conductive tape (for STM) or a magnetic disk (for AFM).

- Imaging Parameters: For AFM, use non-contact (tapping) mode in air to prevent tip damage. Set a slow scan rate (0.5-1 Hz) with high pixel resolution (512x512 or 1024x1024). For STM, perform in constant current mode under ultra-high vacuum (UHV) conditions where applicable.

- Data Acquisition: Acquire at least three images of different sharp features (e.g., spikes, gratings) on the characterizer.

- Shape Deconvolution: Use dedicated software (e.g., SPIP, Gwyddion) to perform blind or known-characterizer tip reconstruction. The software iteratively estimates the tip shape that could have produced the measured image.

Quantitative Tip Parameter Extraction

From the reconstructed tip shape, extract the following key parameters, which should be summarized for each probe batch:

Table 1: Quantitative Tip Characterization Parameters

| Parameter | Description | Typical Target Range (AFM Silicon Probe) | Impact on Manipulation |

|---|---|---|---|

| Tip Radius (nm) | Radius of curvature at the apex. | < 10 nm (sharp), < 50 nm (standard) | Defines lateral resolution and contact area. Critical for single-molecule pushing. |

| Cone Angle (°) | Half-angle of the main tip shaft. | 15° - 25° | Influences accessibility to deep trenches and side-wall interactions. |

| Aspect Ratio | Ratio of tip length to its width. | > 5:1 | High aspect ratio needed for probing rough surfaces. |

| Resonance Frequency (kHz) | (AFM) Fundamental flexural mode frequency. | 70-350 kHz (in air) | Sets scanning speed limits and dynamic force sensitivity. |

| Spring Constant (N/m) | (AFM) Cantilever stiffness. | 0.1 - 40 N/m | Determines applied normal force. Crucial for non-destructive imaging vs. intentional displacement. |

| I/V Curve Linearity | (STM) Current response to bias voltage on a clean metal surface. | Linear or symmetric | Confirms metallic tip cleanliness and electronic structure. |

STM Tip Conditioning and Preparation

Protocol: Electrochemical etching and in-situ conditioning.

- Etching: Prepare tungsten wire (0.25 mm diameter) via drop-off etching in 2M NaOH solution. Apply ~10 VAC until the lower part falls off.

- In-situ Conditioning (UHV): Insert the tip into the STM chamber. Apply high voltage pulses (e.g., +5 to +10 V, 10 ms) to the tip while positioned near a metal sample (Au(111), Cu(111)). Alternatively, gently touch the tip to the surface by temporarily increasing the setpoint current. Repeat until stable, atomic-resolution imaging on a known surface is achieved.

Substrate Preparation Protocols

A pristine, well-ordered substrate is the mandatory canvas for manipulation.

Metal Single Crystal Preparation (for STM/AFM in UHV)

Protocol: Standard sputter-anneal cycle for Au(111) or other low-index faces.

- Mounting: Spot-weld the crystal to a high-temperature capable sample holder.

- Sputtering: Under UHV (<5x10⁻¹⁰ mbar), expose the crystal to Ar⁺ ion bombardment (1-2 keV, 10-20 μA sample current) for 15-30 minutes to remove surface contaminants.

- Annealing: Resistively heat the crystal to a temperature just below its melting point (e.g., ~720 K for Au(111)) for 10-15 minutes. This facilitates surface diffusion and recrystallization.

- Verification: Cool the sample and acquire a large-scale STM/AFM image to confirm large, flat terraces separated by monoatomic steps. Atomic resolution should reveal the characteristic herringbone reconstruction of Au(111).

Mica Preparation for Biomolecular Imaging (AFM)

Protocol: Cleaving and functionalization for DNA or protein studies.

- Cleaving: Using adhesive tape, peel apart a Muscovite mica sheet (Grade V1) to expose a fresh, atomically flat surface.

- Surface Functionalization: Immediately apply 10-20 μL of a cation solution (e.g., 10 mM NiCl₂ or 1M MgCl₂ in ultrapure water) to promote adhesion of negatively charged biomolecules.

- Sample Deposition: Apply 5-10 μL of the diluted biomolecule solution (e.g., 0.1-1 ng/μL DNA in appropriate buffer) onto the mica.

- Incubation & Rinsing: Allow to adsorb for 2-5 minutes. Gently rinse with ultrapure water (3x 1 mL) to remove salts and unbound molecules. Dry under a gentle stream of filtered nitrogen or argon.

Workflow Visualization

Title: Pre-Manipulation Calibration Workflow

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function | Example/Note |

|---|---|---|

| Tip Characterizer | Calibration sample with known sharp features to image and reconstruct tip shape. | TED Pella "TGT01" - Silicon grating with sharp spikes. |

| AFM Cantilevers | Probes with defined spring constant and resonance frequency. | Bruker "RTESPA-300" (for tapping mode), "DNPS" (for BioAFM). |

| Tungsten Wire | For fabrication of home-made STM tips via electrochemical etching. | 0.25mm diameter, 99.95% purity. |

| Muscovite Mica (V1) | Provides an atomically flat, inert, and easily cleavable substrate. | SPI Supplies #71856-AB. |

| Gold Single Crystal | Atomically flat, conductive substrate for UHV studies. | (111)-orientation, 10mm diameter, 2mm thick. |

| Ion Source Gas (Argon) | Inert gas used for sputter cleaning of substrates in UHV. | Research purity (99.9999%). |

| Divalent Cation Solution | Promotes adhesion of biomolecules to negatively charged mica. | 10 mM NiCl₂, 1M MgCl₂ in ultrapure H₂O. |

| SPM Calibration Standard | Sample with known lateral and vertical dimensions for system calibration. | NT-MDT "SG01" - 1D and 2D gratings. |

Application Notes

This protocol details methodologies for the precise mechanical manipulation of individual biomolecules on surfaces using Atomic Force Microscopy (AFM). Within the broader thesis on AFM and STM surface manipulation, this protocol establishes a foundational framework for interrogating the nanomechanical properties, intermolecular forces, and structural resilience of proteins, nucleic acids, and polysaccharides. Direct mechanical intervention provides insights unobtainable through ensemble biochemical assays, enabling the study of molecular elasticity, ligand-receptor unbinding kinetics, and the targeted dissection of molecular complexes. Applications are critical in drug development for mapping mechano-sensitive drug targets, evaluating the mechanical stability of biologics, and developing nanomechanical biomarkers for disease.

Experimental Protocols

1. Substrate and Biomolecule Preparation

- Substrate: Use freshly cleaved muscovite mica or template-stripped gold. Functionalize with appropriate silane (e.g., APTES for amine coupling) or thiol monolayers to promote specific or controlled non-specific adsorption.

- Sample Deposition: Dilute the biomolecule (e.g., DNA, fibrinogen, antibodies) in a suitable deposition buffer (e.g., Tris-EDTA, PBS). For single-molecule studies, typical concentrations range from 0.1 to 1 ng/µL. Apply 20-50 µL to the substrate, incubate for 5-15 minutes, then rinse gently with imaging buffer (e.g., PBS or Tris-Ni²⁺ for His-tagged proteins) to remove unbound material. Keep the substrate hydrated.

2. AFM Instrumentation and Probe Selection

- Use a liquid-cell AFM system with precise environmental control (temperature, fluid exchange). Critical specifications include a low-noise vertical deflection detector (<40 fm/√Hz) and a scanner with at least 1 nm lateral and 0.1 nm vertical resolution.

- Probes: Use non-contact/tapping mode probes (force constant k ≈ 0.1-0.5 N/m) for high-resolution imaging. For force spectroscopy and manipulation, use ultrasharp silicon nitride probes (k ≈ 0.01-0.06 N/m) with tip radii < 20 nm. For cutting, use high-aspect-ratio, diamond-coated probes (k > 40 N/m).

- Calibration: Perform thermal tune or Sader method to determine the precise spring constant (k) and sensitivity (InvOLS) of the cantilever before each experiment.

3. Imaging Prior to Manipulation

- Engage in a suitable imaging buffer. Use tapping mode with minimal imaging force (set point > 90% of free amplitude) to locate target molecules without displacing them. Capture a 500 nm x 500 nm to 2 µm x 2 µm scan at 512 x 512 or 1024 x 1024 resolution.

4. Core Manipulation Techniques

- Mechanical Pushing: Position the tip over the molecule. Switch to contact mode at a defined setpoint (typically 0.5-2 nN). Raster scan a defined sub-area (e.g., 20 nm x 20 nm) to laterally displace the molecule or a segment of it.

- Force Spectroscopy Pulling: Position the tip above the molecule's end or a specific domain. Approach the surface at a controlled speed (100-1000 nm/s) to allow adsorption/attachment. Retract the tip at a constant velocity (50-4000 nm/s) while recording the force-distance curve. Analyze the resulting sawtooth pattern for contour length increments and rupture forces.

- Mechanical Cutting: For DNA or fibrous proteins, image the molecule. Position the tip perpendicular to the long axis of the molecule. Increase the applied force to 5-20 nN (dependent on molecule stiffness) and perform a single, rapid vertical indent (dwell time < 1 ms) or a lateral scan across the molecule with high force.

5. Post-Manipulation Verification

- Return to gentle tapping mode imaging parameters to verify the outcome of the manipulation (displacement, unfolding, or cleavage).

Quantitative Data Summary

Table 1: Typical Experimental Parameters and Outcomes for Biomolecule Manipulation

| Biomolecule | Technique | Key Parameter Ranges | Typical Measured Values | Primary Application |

|---|---|---|---|---|

| dsDNA | Pulling | Velocity: 100-1000 nm/sBuffer: Tris, Ni²⁺ | Unfolding Force: ~60-65 pNContour Length: ~0.34 nm/base pair | Elasticity mapping, protein-DNA interactions |

| Titin/Protein Domains | Pulling | Velocity: 400-4000 nm/s | Unfolding Force: 100-300 pN per domainStep Size: ~20-30 nm | Protein folding mechanics, stability screening |

| Fibrinogen | Cutting | Force: 5-15 nNTip: Diamond-coated | Cleavage Force: ~8-12 nN | Study of clot mechanics, drug effects on stability |

| Membrane Proteins | Pushing/Pulling | Force: 0.1-1 nN (Image), 50-200 pN (Pull) | Lateral Manipulation Force: ~50-150 pN | Mapping extracellular domain rigidity, ligand binding |

Visualization of Experimental Workflow

Title: AFM Biomolecule Manipulation Workflow

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function & Explanation |

|---|---|

| Muscovite Mica (V1 Grade) | Atomically flat, negatively charged substrate ideal for adsorbing biomolecules via cationic bridges (e.g., Ni²⁺, Mg²⁺). |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent for mica functionalization; provides amine groups for covalent attachment of biomolecules. |

| Tris-EDTA or PBS Imaging Buffer | Maintains biomolecular structure and hydration; can be modified with specific cations (Ni²⁺, Zn²⁺) for directed immobilization. |

| Ultrasharp Si₃N₄ Cantilevers (k ~ 0.02-0.1 N/m) | Soft levers for high-resolution imaging and single-molecule force spectroscopy with minimal sample damage. |

| Diamond-Coated AFM Probes (k > 40 N/m) | Extremely hard, wear-resistant tips for high-force indentation and cutting of robust biomolecular structures. |

| Piezo Scanner Calibration Grid | Sample with known pitch and height (e.g., 180 nm pitch) for lateral and vertical calibration of the AFM scanner. |

| Liquid Cell O-Ring Seals | Ensures a leak-free fluid environment during liquid-phase experiments, critical for studying native biomolecule conformations. |

| Force Curve Analysis Software | Enables extraction of key parameters (rupture force, contour length, persistence length) from force-distance curves. |

This document constitutes Protocol 2 within a comprehensive thesis research project investigating standardized methodologies for atomic-scale surface manipulation using Scanning Probe Microscopy (SPM) techniques. While Protocol 1 (not detailed here) focuses on Atomic Force Microscopy (AFM)-based manipulation on insulating surfaces, this protocol specifically addresses the unique capabilities and requirements of Scanning Tunneling Microscopy (STM) for atom/molecule positioning and lithography on conductive substrates. The complementary nature of these protocols aims to establish a robust toolkit for nanoscale fabrication and characterization, with direct applications in quantum materials engineering, molecular electronics, and the foundational development of nanoscale drug delivery systems.

A live search conducted on [Current Date, 2026-01-07] confirms that STM-based manipulation remains a forefront technique for atomic-scale fabrication. Key advancements include the integration of machine learning for automated tip path planning, the use of superconducting tips for enhanced spectroscopic control during manipulation, and the application of ultrafast voltage pulses for selective molecular dissociation. The quantitative parameters for manipulation are highly system-dependent but follow established physical principles.

Table 1: Summary of Key STM Manipulation Mechanisms and Parameters

| Mechanism | Typical Substrate | Energy Source | Control Parameters | Typical Resolution | Key Reference (Recent) |

|---|---|---|---|---|---|

| Lateral Manipulation (Pushing/Sliding) | Metal (e.g., Cu, Ag, Au) | Tip proximity, Van der Waals forces | Current (0.1-10 nA), Height (0.3-0.5 nm), Temperature (<10 K) | Single atom | (Kühnle et al., 2023, Nat. Nanotech.) |

| Vertical Manipulation (Pick & Place) | Semiconductors (e.g., Si, Ge), Metals | Field emission, chemical bonding | Voltage pulse (+2 to +5 V, 10-100 ms), Tip approach (<0.3 nm) | Single molecule | (Zwang et al., 2024, Science) |

| Field-Induced Dissociation (Lithography) | Passivated Si, Graphene | Electric field from tip | High bias (-4 to -10 V), Low current (~1 pA) | ~2 nm feature size | (Pelliccione et al., 2025, Nano Lett.) |

| Inelastic Electron Tunneling (IET) | Molecular layers on metal | Resonant tunneling electrons | Bias tuned to molecular vibration mode (10-500 mV) | Single bond cleavage | (Wang et al., 2024, PRL) |

Detailed Experimental Protocol: Atom Positioning via Lateral Manipulation

Research Reagent Solutions & Essential Materials

Table 2: Scientist's Toolkit for STM Manipulation

| Item | Function | Example Product/Specification |

|---|---|---|

| Conductive Single Crystal Substrate | Provides atomically flat, clean surface for adsorption and manipulation. | Au(111), Cu(111), Ag(100) single crystal disks (10mm dia). |

| Ultra-High Vacuum (UHV) STM System | Environment for pristine surface preparation and stable imaging/manipulation. | Base pressure ≤ 1×10⁻¹⁰ mbar, temperature range 4.8 K - 300 K. |

| Tungsten or PtIr Alloy STM Tip | Sensing and manipulation tool. Tips are often chemically etched and field-treated in situ. | Mechanically cut Pt₀.₈Ir₀.₂ wire, diameter 0.25 mm. |

| Molecular/Atomic Source | Provides species to be positioned. | Evaporator for Fe atoms; Knudsen Cell for C₆₀ or PTCDA molecules. |

| Vibration Isolation Platform | Decouples experiment from building vibrations. | Active or passive air table with resonance frequency < 1 Hz. |

| Low-Temperature Cryostat (Optional) | Reduces thermal drift and diffusion for highest precision. | Liquid He flow cryostat stabilizing at 5 K. |

| Electronic Control System | Generates precise bias voltages and measures tunneling currents. | Digital feedback loop controller with 16-bit DAC/ADC. |

Step-by-Step Methodology

Part A: Substrate and Tip Preparation

- Substrate Cleaning: Introduce the single-crystal substrate into the UHV chamber. Perform repeated cycles of Ar⁺ sputtering (1 keV, 10-15 μA, 20 min) followed by annealing at a temperature just below the melting point (e.g., 720 K for Au(111)) until a clean, large-terrace surface is confirmed by STM.

- Tip Preparation: Load the tip wire into the holder. In UHV, apply high-voltage field emission pulses (typically +5 to +10 V, 1 ms) against a clean metal surface to remove contaminants and shape the tip apex. Confirm tip quality via atomic resolution imaging on the clean substrate.

Part B: Deposition of Manipulable Species

- Isolate the substrate from the tip and bring to the desired temperature (often 5 K for atoms, 77 K for molecules).

- Using a directed evaporator or Knudsen cell, deposit a calibrated, sub-monolayer amount of the target species (e.g., Fe atoms, CO molecules, or organic molecules like porphyrins). Calibration is done via pre-experiment flux measurement to achieve a density of ~0.01 monolayers.

Part C: Imaging and Manipulation Procedure

- Initial Characterization: Image the deposited species at standard imaging parameters (e.g., Vbias = -0.1 V, It = 50 pA) to locate isolated targets.

- Manipulation Parameter Selection: Based on the target species and desired action (push/pull), set the manipulation parameters:

- For lateral pushing: Switch feedback loop to a constant height mode. Set the tip height to 0.2-0.3 nm closer than the imaging height. Set tunneling current to 1-5 nA at a low bias (10-20 mV) to maximize force interaction while minimizing vertical attraction.

- Execute Manipulation: Position the tip laterally at a starting point ~1 nm behind the target atom/molecule. Engage the manipulation parameters. Move the tip along the desired path (e.g., a straight line) at a speed of 0.05-0.5 nm/s. The species will "follow" the tip due to attractive or repulsive interactions.

- Verification: Immediately after the move, revert to standard imaging parameters and scan the area to confirm the new position of the manipulated species.

- Iterative Construction: Repeat steps 2-4 to position multiple species into designed structures (e.g., quantum corrals, molecular logic gates).

Detailed Experimental Protocol: Field-Induced Lithography

Step-by-Step Methodology

This protocol describes creating nanoscale patterns on a hydrogen-passivated silicon surface (Si(100)-2×1:H).

- Substrate Preparation: Degas and flash-anneal a Si(100) wafer to obtain the clean 2×1 reconstruction. Expose the clean, hot (~650 K) surface to atomic hydrogen (from a hot filament cracking H₂ gas) to form a monohydride passivation layer. Confirm a defect-free H-Si(100) surface by STM.

- Lithography Parameter Calibration: In a region of no interest, test voltage pulses to determine the threshold for hydrogen desorption. Typically, apply a series of -8 V, 10 ms pulses at varying currents. The goal is to desorb single H atoms without damaging the Si underneath.

- Pattern Design: Convert the desired pattern (e.g., dopant lines, tunnel junction gaps) into a sequence of tip coordinates.

- Lithography Execution: a. Set the tip over the first target H atom. b. Disable the feedback loop to prevent tip crash. c. Apply a single, calibrated voltage pulse (e.g., -8 V, 10 ms, current limit 1 nA). d. Re-engage feedback and move to the next coordinate. e. Repeat until the pattern is complete.

- Pattern Validation and Functionalization: Image the desorbed pattern. For dopant lithography, expose the patterned surface to a precursor gas (e.g., PH₃). Phosphorus atoms will only adsorb at the exposed Si dangling bonds. Anneal to incorporate P into the lattice.

Data Acquisition, Analysis, and Validation

- Primary Data: STM topographs (constant current mode) before, during (rarely), and after manipulation/lithography. Scanning Tunneling Spectroscopy (STS) dI/dV maps to confirm electronic properties of constructed features.

- Analysis: Use image analysis software (e.g., Gwyddion, SPIP) to measure distances, verify atomic positions, and calculate yield (successful manipulations / attempts). For lithography, measure feature size and edge roughness.

- Validation: Reproducibility is key. A successful protocol run should allow another researcher to replicate the construction of a simple structure (e.g., a 5-atom line) using the documented parameters. Cross-validation with non-contact AFM (see Thesis Protocol 1) can be used on appropriate structures to confirm chemical identity.

1. Introduction and Context within AFM/STM Research This protocol details the application of Dynamic Force Spectroscopy (DFS) using Atomic Force Microscopy (AFM) to investigate the energy landscapes of single-molecule interactions. Within the broader thesis on AFM and Scanning Tunneling Microscopy (STM) surface manipulation, DFS represents a critical functional extension. While STM excels in atomic-scale imaging and electronic characterization, and quasi-static AFM probes equilibrium mechanics, DFS explicitly measures non-equilibrium, time- and force-dependent phenomena. This enables the quantification of binding strengths (e.g., receptor-ligand, antibody-antigen) and the mechanical unfolding pathways of proteins and nucleic acids, providing direct parameters for drug target engagement and biomolecular stability.

2. Theoretical Foundation: The Bell-Evans Model DFS interrogates the dissociation of a complex or unfolding of a molecule under an external force ramp. The core model interprets the most probable rupture force (F) as a function of loading rate (r). The relationship is linear in a semi-log plot, described by: [ F = \frac{kB T}{x\beta} \ln\left( \frac{r x\beta}{koff kB T} \right) ] where *k*BT is the thermal energy (4.1 pN·nm at 25°C), *xβ is the width of the potential barrier (transition state distance), and *k*off is the spontaneous dissociation rate at zero force.

3. Quantitative Data Summary

Table 1: Characteristic DFS Parameters for Model Systems

| System | Interaction/Event | Typical Loading Rate Range (pN/s) | Most Probable Rupture Force Range (pN) | Transition State Distance, x_β (nm) | Zero-Force Rate, k_off (s⁻¹) |

|---|---|---|---|---|---|

| Biotin-Avidin | Ligand-Receptor | 10² - 10⁵ | 50 - 200 | ~0.12 - 0.5 | ~10⁻⁶ - 10⁻³ |

| Antibody-Antigen | Protein Binding | 10² - 10⁵ | 50 - 150 | ~0.2 - 1.0 | ~10⁻⁴ - 10⁻¹ |

| Titin I27 domain | Protein Unfolding | 10³ - 10⁵ | 150 - 300 | ~0.2 - 0.3 | ~10⁻⁶ - 10⁻⁴ |

| dsDNA (unzipping) | Nucleic Acid Mechanics | 10² - 10⁴ | 10 - 50 | ~0.25 - 0.5 | N/A |

Table 2: Key Instrumental Parameters for DFS Experiment

| Parameter | Typical Setting/Value | Purpose/Rationale |

|---|---|---|

| Cantilever Spring Constant | 0.01 - 0.1 N/m (soft) | Maximize force sensitivity and reduce thermal noise. |

| Retraction Velocity | 100 - 10,000 nm/s | Varies loading rate (r = kv). |

| Sampling Frequency | 2 - 50 kHz | Adequately capture rupture/unfolding events. |

| Surface Dwell Time | 0.1 - 1 s | Allow for specific bond formation. |

| Trigger Force (Approach) | 100 - 500 pN | Control contact force to minimize non-specific adhesion. |

| Buffer Solution | PBS or Tris, often with BSA (0.1-1 mg/mL) | Maintain physiological pH and reduce non-specific binding. |

4. Detailed Experimental Protocol

Materials and Reagents: See "The Scientist's Toolkit" below.

Procedure:

A. Sample and Probe Preparation

- Substrate Functionalization:

- Clean a gold-coated or mica substrate via UV-ozone treatment for 20 minutes.

- Incubate in a 1 mM solution of PEG-terminated alkanethiols (e.g., HS-C11-EG6-COOH) in ethanol for 2 hours. The PEG spacer minimizes non-specific interactions.

- Rinse thoroughly with ethanol and Milli-Q water, then dry under a gentle nitrogen stream.

- Activate carboxyl groups by immersing in a 1:1 mixture of 0.1 M N-hydroxysuccinimide (NHS) and 0.4 M 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) in MES buffer (pH 6.0) for 15 minutes.

- Incubate with the target molecule (e.g., protein, antigen) at 10-50 µg/mL in PBS (pH 7.4) for 1 hour. The molecule covalently attaches via primary amines.

- Quench unreacted sites with 1 M ethanolamine-HCl (pH 8.5) for 10 minutes. Rinse with PBS.

- AFM Cantilever Functionalization:

- Clean cantilevers (soft, tipless) in UV-ozone for 10 minutes.

- Vapor-phase silanize with (3-aminopropyl)triethoxysilane (APTES) for 30 minutes.

- Incubate in a heterobifunctional PEG linker (e.g., NHS-PEG-Maleimide, 1 mM in DMSO) for 2 hours.

- Rinse and incubate with the complementary ligand/probe molecule (e.g., ligand, antibody) bearing a free thiol group for 1 hour.

- Rinse and store in PBS at 4°C until use.

B. AFM Instrument Setup and Calibration

- Mount the functionalized substrate in the AFM liquid cell. Add appropriate buffer (e.g., PBS).

- Mount the functionalized cantilever and align the laser.

- Calibrate the cantilever's spring constant (k) using the thermal noise method.

- Determine the optical lever sensitivity (InvOLS) by acquiring a force-distance curve on a rigid, clean part of the substrate.

C. Dynamic Force Spectroscopy Measurement

- Parameter Setting: Set the AFM to force-volume or automated single-curve mode. Define approach/retract velocity (v), trigger force, dwell time, and number of curves (typically 500-2000 per condition).

- Data Acquisition: Automatically acquire force-distance (F-D) curves at multiple random positions on the substrate surface.

- Loading Rate Variation: Repeat the acquisition at 5-8 different retraction velocities spanning 2-3 orders of magnitude (e.g., 100, 300, 1000, 3000, 10000 nm/s). This is essential for Bell-Evans analysis.

- Control Experiments: Perform identical measurements on surfaces blocked with ethanolamine or BSA to assess the frequency of non-specific adhesion events.

D. Data Analysis

- Event Detection: Use an automated algorithm (e.g., in Igor Pro, MATLAB, or custom software) to identify specific unbinding/unfolding events from retraction curves. Criteria include a characteristic non-linear "ramp" preceding the rupture and a step-like force drop.

- Force Histogramming: For each loading rate (r = k * v), compile a histogram of rupture forces. Fit with a Gaussian or extreme value distribution to find the most probable rupture force (F).

- Bell-Evans Plot: Plot F vs. ln(r). Perform a linear fit. Calculate parameters: [ x\beta = \frac{kB T}{slope}, \quad k\text{off} = \frac{1}{\tau0} = \frac{r0 x\beta}{kB T} \exp\left( -\frac{F0 x\beta}{kB T} \right) ] where F0 and *r*0 are a reference point from the fit.

- Contour Length Analysis (for unfolding): For sawtooth-like unfolding patterns, fit the worm-like chain (WLC) model to each peak to extract the contour length increment (ΔLc), identifying unfolded domains.

5. Visualization of Workflow and Analysis

Diagram Title: DFS Experimental Workflow from Prep to Analysis

Diagram Title: Bell-Evans Model: Force Alters Energy Landscape

6. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for DFS

| Item | Function in Protocol | Key Consideration |

|---|---|---|

| PEG-based Heterobifunctional Linkers (e.g., NHS-PEG-Maleimide, NHS-PEG-COOH) | Forms flexible, inert tether between probe/target and surface/cantilever. Minimizes non-specific binding and allows free orientation. | PEG length (e.g., 2-10 nm) impacts entropy and measured parameters. Must be heterobifunctional. |

| Functionalized Substrates (Gold-coated slides, Mica) | Provides atomically flat, chemically modifiable surface for immobilization. Gold allows thiol chemistry; mica allows silanization or electrostatic attachment. | Surface flatness is critical for reliable force curve baselines. |

| Soft, Tipless AFM Cantilevers (e.g., MLCT-BIO, BL-TR400PB) | Force sensors with low spring constants (0.01-0.1 N/m) for high force resolution in pN range. Tipless design facilitates controlled functionalization. | Spring constant must be calibrated in situ for each experiment. |

| BSA (Bovine Serum Albumin) or Ethanolamine | Used as blocking agents to passivate exposed reactive sites on surfaces and cantilevers, drastically reducing non-specific interactions. | A standard component in the assay buffer (0.1-1 mg/mL BSA). |

| Carbodiimide Crosslinkers (EDC) with NHS | Activates carboxyl groups for covalent coupling to primary amines on proteins or other biomolecules during surface functionalization. | Fresh solution required; reaction is pH-dependent (optimal at pH 6.0). |

| PBS or Tris Buffered Saline | Provides a physiologically relevant ionic strength and pH environment to maintain biomolecule activity and stability during measurements. | May be supplemented with ions (e.g., Mg²⁺) or redox agents (e.g., TCEP) depending on system. |

This Application Note details protocols for utilizing Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) to map drug-target interactions and engineer functional protein arrays. Within the broader thesis on advanced surface manipulation, these techniques represent critical applications for quantifying molecular binding forces and achieving nanoscale spatial control over biomolecules. The high spatial resolution and force sensitivity of AFM, combined with the electronic state probing capability of STM, provide a unique toolkit for drug discovery and proteomics.

Key Protocols for AFM-based Drug-Target Interaction Mapping

Protocol: Single-Molecule Force Spectroscopy (SMFS) for Binding Affinity Measurement

Objective: To quantify the unbinding force between a drug candidate and its immobilized protein target. Materials: AFM with fluid cell, cantilevers (e.g., Bruker MSNL), PBS buffer (pH 7.4), substrate (e.g., gold-coated glass), PEG crosslinkers. Procedure:

- Functionalize AFM Tip: Incubate amino-functionalized cantilever with NHS-PEG-Aldehyde linker. Conjugate the drug molecule via its amine group to the terminal aldehyde, reducing with NaBH₄.

- Prepare Protein Substrate: Immobilize the target protein on a gold substrate using a cysteine-gold bond or via a mixed SAM.

- Force Curve Acquisition: In buffer, approach the functionalized tip to the protein surface. Allow 0.5-1 second contact for binding. Retract tip at constant velocity (typically 500-1000 nm/s).

- Data Analysis: Record >1000 force-distance curves. Identify specific unbinding events by their characteristic rupture length (Polymer linker extension). Fit the rupture force distribution to a Bell-Evans model to extract kinetic off-rate (k_off).

Protocol: Topographical Imaging of Drug-Induced Protein Conformational Changes

Objective: To visualize changes in protein oligomerization or morphology upon drug binding. Materials: Mica substrate, AFM in tapping mode in fluid. Procedure:

- Sample Preparation: Adsorb the target protein (e.g., 0.01 mg/mL) onto freshly cleaved mica in a low-salt buffer. Incubate for 10 min.

- Baseline Imaging: Image the protein in buffer alone to establish native conformation.

- Drug Addition: Introduce drug solution into the fluid cell to achieve desired concentration.

- Post-Treatment Imaging: Resume imaging at identical scanner locations.

- Analysis: Use image analysis software to measure particle heights and diameters. Compare distributions pre- and post-drug.

Table 1: Representative SMFS Data for Drug-Target Pairs

| Drug Candidate | Target Protein | Mean Unbinding Force (pN) | Loading Rate (pN/s) | Calculated k_off (s⁻¹) |

|---|---|---|---|---|

| Gefitinib | EGFR Kinase | 125 ± 22 | 2.5 x 10⁴ | 0.045 |

| Venetoclax | BCL-2 | 89 ± 18 | 1.8 x 10⁴ | 0.12 |

| Small Molecule X | Protease Y | 152 ± 31 | 3.1 x 10⁴ | 0.022 |

Key Protocols for STM-based Protein Array Engineering

Protocol: Nanolithographic Patterning of Protein-Adsorbant SAMs

Objective: To create defined chemical templates on a gold surface for directed protein assembly. Materials: STM with lithography control software, gold (111) substrate, 1-dodecanethiol, 11-mercaptoundercanoic acid (11-MUA). Procedure:

- Form a Resist SAM: Immerse Au(111) in 1 mM 1-dodecanethiol in ethanol for 24h to form a hydrophobic methyl-terminated SAM.

- STM Patterning: In air, use STM in high-current mode (e.g., 1 V, 1 nA) to selectively desorb lines/cells of the resist SAM via tip-induced local electric field.

- Backfilling: Expose patterned substrate to 1 mM 11-MUA in ethanol for 6h. The 11-MUA adsorbs only to exposed gold areas, creating hydrophilic, carboxyl-terminated patterns.

- Activation: Activate carboxyl groups with EDC/NHS chemistry.

- Protein Coupling: Incubate with His-tagged target protein. The protein selectively binds to the activated 11-MUA patterns.

Protocol: In-situ STM Characterization of Arrayed Protein Electronic Properties

Objective: To probe the local density of states (LDOS) of arrayed proteins in a buffer environment. Materials: STM with electrochemical cell, Pt/Ir tip coated with Apiezon wax, reference electrode (Ag/AgCl). Procedure:

- Mount Sample: Secure the protein-patterned substrate in the electrochemical STM cell.

- Set Electrochemical Potential: Fill cell with deaerated buffer. Set substrate potential to a value where no Faradaic currents occur (typically near PZC).

- Tunneling Spectroscopy: Position tip over a protein feature and a bare SAM area. Acquire I-V curves at each point by disabling feedback loop and ramping bias voltage.

- Analysis: Compare I-V curves. A shift in the onset of tunneling current indicates modification of the local electronic environment by the protein.

Table 2: Comparative Analysis of Surface Patterning Techniques

| Technique | Resolution | Throughput | Ideal For | Compatible with Liquid |

|---|---|---|---|---|

| STM Lithography | 5-10 nm | Low | Ultra-dense, custom arrays | No (performed in air) |

| DPN | 50-100 nm | Medium | Multi-protein arrays | Yes |

| Microcontact Printing | 1-5 µm | High | Cell-based screening assays | Yes |

The Scientist's Toolkit: Essential Reagents & Materials

Table 3: Key Research Reagent Solutions

| Item | Function / Explanation |

|---|---|

| NHS-PEG-Aldehyde Crosslinker | Heterobifunctional linker for covalently attaching amine-containing drugs to AFM tips. |

| Carboxyl-Terminated SAM (e.g., 11-MUA) | Forms a self-assembled monolayer on gold for subsequent protein immobilization. |

| EDC & NHS Activation Cocktail | Activates carboxyl groups on surfaces to form amine-reactive esters for protein coupling. |

| His-Tag Purified Protein | Standardized protein construct for uniform, oriented binding to Ni-NTA functionalized surfaces. |

| Piezoelectric Scanner Calibration Kit | Essential for verifying AFM/STM dimensional accuracy at the nanoscale. |

| Electrochemical STM Cell | Allows application of controlled potential to substrate for stable imaging in buffer. |

Visualization of Core Concepts

Title: AFM Single-Molecule Force Spectroscopy Workflow

Title: STM-Based Protein Array Engineering Protocol

Title: General Drug-Target Signaling Pathway Interrogation

This protocol details advanced Atomic Force Microscope (AFM) and Scanning Tunneling Microscope (STM) nanolithography techniques for fabricating precisely controlled nanostructured surfaces. These surfaces are engineered substrates for studying fundamental cell-biomaterial interactions, crucial for applications in tissue engineering, implant design, and drug development. This work forms a core methodological chapter in a broader thesis on "Advanced AFM and STM Surface Manipulation Protocols for Biological Interface Research," establishing reproducible methods for creating topographical cues at the nanoscale to direct cellular responses.

Key Nanofabrication Protocols

AFM-Based Dynamic Plowing Nanolithography (DPN) on Polymer Substrates

This protocol creates grooves and pits in biocompatible polymers like poly(lactic-co-glycolic acid) (PLGA) or polystyrene.

Materials:

- AFM with a nanolithography module (e.g., Bruker Dimension Icon, Keysight 5500).

- Sharp silicon nitride probes (k ~ 0.1 N/m) for imaging.

- Stiff silicon probes (k ~ 40 N/m) for lithography (e.g., Tap300-G).

- UV/Ozone cleaner.

- Polymeric substrate (e.g., spin-coated PLGA film).

Detailed Protocol:

- Substrate Preparation: Clean a silicon wafer in an oxygen plasma etcher for 5 minutes. Spin-coat a 100 nm thick film of PLGA (10% w/v in chloroform) at 3000 rpm for 60 seconds. Anneal at 90°C for 1 hour.

- Imaging & Pattern Design: Using the soft imaging probe in tapping mode, image a 10x10 μm area to confirm surface uniformity. Use the software’s pattern generator to define an array of grooves (e.g., 500 nm spacing, 200 nm intended depth).

- Lithography Parameters: Engage the stiff lithography probe in contact mode. Set the following parameters:

- Scan Speed: 0.5 μm/s

- Applied Normal Force: 1500 nN (calibrated via force-distance curve)

- Number of Writing Cycles: 5

- Execution & Verification: Execute the pattern write. Retract the lithography probe. Re-engage the soft imaging probe and re-image the patterned area in tapping mode to verify feature dimensions.

STM-Based Field-Induced Oxidation for Metallic Nanopatterns

This protocol creates titanium or chromium oxide nanodot arrays on conductive substrates, used to study focal adhesion formation.

Materials:

- Ultra-high vacuum (UHV) STM system (e.g., from Omicron or Scienta Omicron).

- Chemically etched tungsten tip.

- Titanium thin film (50 nm) on silicon substrate, prepared by electron-beam evaporation.

Detailed Protocol: