Beyond the Surface: A Practical Guide to Correlating AFM with Optical Profilometry for Advanced Biomaterial and Pharmaceutical Analysis

This comprehensive guide explores the synergistic integration of Atomic Force Microscopy (AFM) and Optical Profilometry for multi-scale surface characterization, essential for researchers and drug development professionals.

Beyond the Surface: A Practical Guide to Correlating AFM with Optical Profilometry for Advanced Biomaterial and Pharmaceutical Analysis

Abstract

This comprehensive guide explores the synergistic integration of Atomic Force Microscopy (AFM) and Optical Profilometry for multi-scale surface characterization, essential for researchers and drug development professionals. We cover fundamental principles, detailed methodologies for co-localized measurement, optimization strategies for challenging biological samples, and rigorous validation protocols. By addressing key technical challenges and providing comparative analysis, this article equips scientists with the knowledge to leverage this powerful correlative approach for advancing biomaterial design, drug formulation stability, and medical device surface engineering.

Unraveling the Fundamentals: What AFM and Optical Profilometry Reveal About Your Sample's Surface

Within the context of advancing correlative microscopy for surface metrology, understanding the fundamental operating principles and performance envelopes of Atomic Force Microscopy (AFM) and Optical Profilometry (OP) is critical. This guide objectively compares these two pillars of nanoscale and microscale measurement, providing a framework for researchers integrating these techniques in pharmaceutical and materials science.

Core Principles & Performance Comparison

| Parameter | Atomic Force Microscopy (AFM) | Optical Profilometry (OP) |

|---|---|---|

| Fundamental Principle | Mechanical sensing via tip-sample force interaction. | Optical interference or focus variation of light. |

| Lateral Resolution | <1 nm (contact mode) to ~10 nm (tapping). | ~0.2 - 1.0 µm, limited by diffraction. |

| Vertical Resolution | <0.1 nm (sub-Ångström). | ~0.1 - 1.0 nm. |

| Maximum Scan Area | Typically ~100x100 µm, up to ~150x150 µm. | Millimeters to centimeters. |

| Measurement Speed | Slow (seconds to minutes per scan line). | Fast (seconds to minutes for full 3D map). |

| Measurement Mode | Typically direct contact or near-contact. | Non-contact, no sample interaction. |

| Sample Requirements | Must be stable, clean; excessive roughness challenging. | Can measure rough, soft, or delicate surfaces. |

| Primary Output | Topography, plus mechanical (modulus, adhesion), electrical, magnetic properties. | Topography (3D height map), texture parameters. |

| Key Limitation | Slow scanning, small area, tip convolution artifacts. | Diffraction limit, transparent/reflective sample challenges. |

Table 1: Quantitative Performance Comparison. Data synthesized from current manufacturer specifications (Bruker, KLA, Zygo) and peer-reviewed methodological literature.

Experimental Protocols for Correlative Analysis

A robust protocol for correlative AFM-OP research ensures data fidelity and validates the strengths of each technique.

Protocol 1: Multi-Scale Surface Roughness Quantification

- Sample: A spin-coated polymer film (e.g., Poly(methyl methacrylate), PMMA) with engineered micron-scale ridges and nanoscale porosity.

- Optical Profilometry (First-Pass Macro Map):

- Instrument: White-light interferometer (WLI) or focus-variation system.

- Method: Acquire a 3D topography map of a 2x2 mm area using a 20X objective. Use phase-shifting or vertical scanning interferometry mode.

- Data: Extract Sa (arithmetical mean height), Sz (maximum height), and identify representative regions of interest (ROIs) for high-resolution AFM analysis.

- Atomic Force Microscopy (High-Res Nano Map):

- Instrument: Tapping-mode AFM with a standard silicon tip (k ~ 40 N/m, f ~ 300 kHz).

- Method: Navigate to the ROI coordinates identified by OP. Acquire a 50x50 µm and subsequent 10x10 µm topography images at 512x512 pixels.

- Data: Extract high-resolution Sa, Sq (root mean square roughness), and analyze nanoscale pore dimensions. Overlay AFM and OP data using fiduciary markers or software alignment (e.g., Gwyddion, MountainsMap).

Protocol 2: Thin Film Step-Height Measurement Validation

- Sample: A silicon wafer with a lithographically patterned photoresist step (~100 nm tall).

- AFM Measurement:

- Scan a 20x20 µm area across the step edge in tapping mode. Use a section analysis tool to measure an averaged step-height profile.

- OP Measurement:

- Measure the same step feature using a 50X Mirau objective in WLI mode. Use a stitching function if the step is long.

- Correlation: Compare the step-height values from both techniques. OP provides a rapid, averaged height over a long line/trench. AFM validates the measurement, reveals edge roughness, and identifies any tip-sample deformation artifacts.

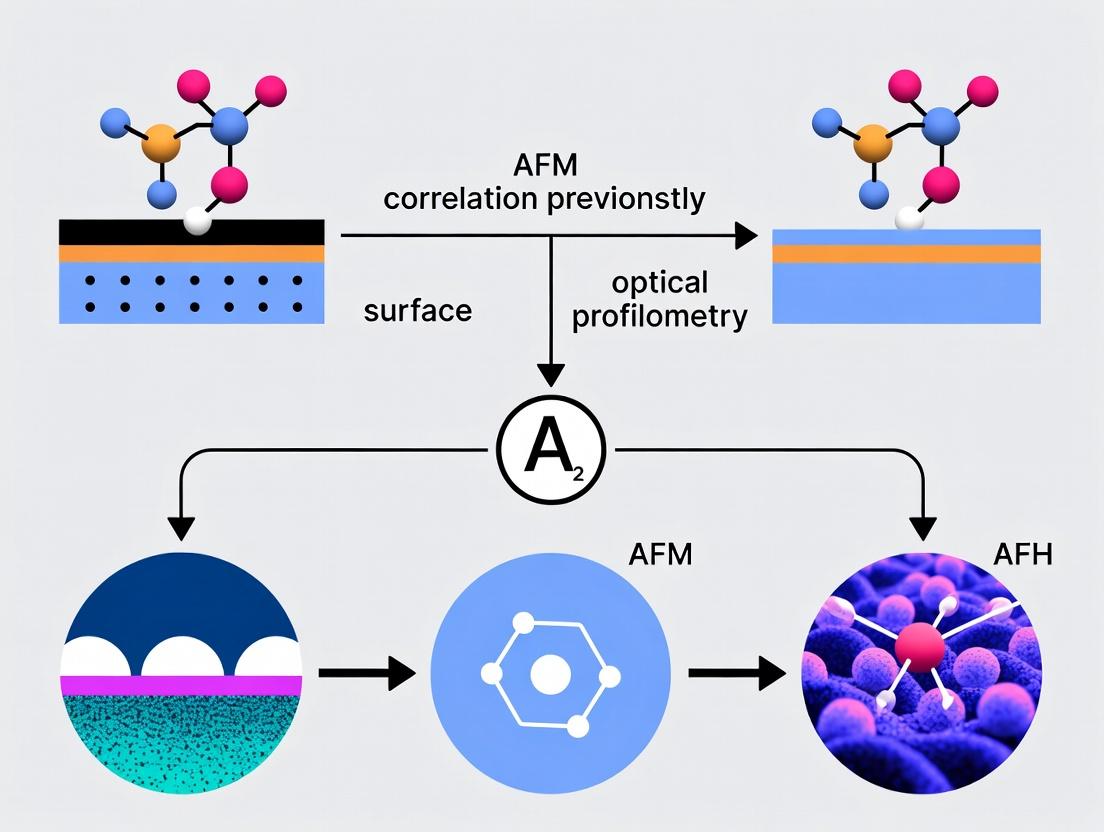

Correlative AFM-OP Workflow for Multi-Scale Analysis

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in AFM-OP Correlation Studies |

|---|---|

| Reference Sample Gratings | (e.g., TGZ01, TGQ1 from NT-MDT/SiO) Provides calibrated pitch and height for instrument validation and spatial alignment between AFM and OP systems. |

| Conductive AFM Tips | (e.g., Pt/Ir-coated Si tips) Enable electrical modes (e.g., Kelvin Probe) alongside topography, adding functional data for correlation. |

| Soft Lithography Stamp | (e.g., PDMS with micropatterns) Creates reproducible, multi-scale test surfaces to benchmark correlation protocol performance. |

| Anti-Static Gun | Reduces static charge on insulating samples (e.g., polymers), which can cause imaging artifacts in both OP and AFM. |

| Vibration Isolation Table | Critical for AFM, reduces ambient noise for both techniques, ensuring data accuracy during long correlative sessions. |

| Alignment Software | (e.g., MountainsMap, OpenCV) Performs affine transformations to precisely overlay OP macro-maps and AFM micro-maps. |

Logical Flow of AFM-OP Correlation Research

This comparison guide, framed within a broader thesis on correlating Atomic Force Microscopy (AFM) with optical profilometry, objectively compares the performance of these techniques across different length scales. The resolution gap between nanoscale and micro/macroscale characterization is a critical consideration in fields ranging from material science to drug development. This article provides experimental data and methodologies to guide researchers in selecting appropriate tools for their specific scale-dependent measurement needs.

Comparative Performance Data: AFM vs. Optical Profilometry

The following table summarizes the core quantitative performance parameters of AFM and White-Light Interferometry (WLI) as a representative optical profilometry technique, based on current industry standards and peer-reviewed literature.

Table 1: Performance Comparison Across Scales

| Parameter | Atomic Force Microscopy (AFM) | White-Light Interferometry (WLI) | Ideal Application Scale |

|---|---|---|---|

| Vertical Resolution | < 0.1 nm (Contact Mode) | ~0.1 - 1 nm | Nanoscale (AFM), Microscale (WLI) |

| Lateral Resolution | < 1 nm (Ultra-sharp tips) | ~0.3 - 0.5 μm (Diffraction-limited) | Nanoscale (AFM), Microscale (WLI) |

| Maximum Scan Area | Typically 10s - 100s μm | Up to 100s mm | Microscale (AFM), Macroscale (WLI) |

| Measurement Speed | Slow (seconds per line) | Fast (seconds per full field) | High-throughput screening (WLI) |

| Sample Contact | Physical contact/tapping (risk of tip/sample damage) | Non-contact, optical | Sensitive/soft samples (WLI) |

| Measurable Parameters | Topography, adhesion, modulus, magnetic/electrical properties | Topography, step height, roughness (Sa, Sq) | Multifunctional nanoscale properties (AFM) |

Table 2: Correlation Study Data (Representative Experiment)

| Sample Type | AFM Measured Roughness (Sa, nm) | WLI Measured Roughness (Sa, nm) | Correlation Coefficient (R²) | Notes |

|---|---|---|---|---|

| Polished Silicon Wafer | 0.12 ± 0.03 | 0.15 ± 0.05 | 0.95 | Excellent correlation on smooth surfaces |

| Spin-Coated Polymer Film | 2.5 ± 0.4 | 2.8 ± 0.6 | 0.88 | Good correlation; WLI slightly overestimates due to lateral resolution limit |

| Nano-textured Drug Eluting Stent | 180 ± 20 | 210 ± 30 | 0.72 | Moderate correlation; AFM captures finer nanofeatures missed by WLI |

| Pharmaceutical Tablet Coating | 550 ± 80 | 560 ± 90 | 0.98 | Excellent correlation in micro-roughness regime |

Detailed Experimental Protocols

Protocol for Correlation Study Between AFM and Optical Profilometry

Objective: To quantitatively correlate surface roughness parameters measured by AFM and WLI across different scale regimes.

Materials: See "The Scientist's Toolkit" section.

Methodology:

- Sample Preparation: Select or fabricate samples with relevant features spanning nano- to micro-scale (e.g., calibrated gratings, engineered surfaces, real-world samples like medical implants or tablet coatings). Clean samples using appropriate methods (e.g., UV-ozone, solvent rinse) to avoid artifacts.

- AFM Measurement:

- Use a commercial AFM system (e.g., Bruker Dimension Icon, Cypher).

- Choose a probe appropriate for the sample (e.g., RTESPA-150 for high-resolution topography).

- Operate in ScanAsyst or Tapping Mode in air to minimize sample damage.

- Acquire images at multiple scan sizes (e.g., 1x1 μm², 10x10 μm², 50x50 μm²) from at least three different locations.

- Apply only plane fitting (1st order) and no filtering to raw data. Export topography data.

- WLI Measurement:

- Use a commercial WLI profilometer (e.g., Zygo NewView, Bruker ContourX).

- Use a magnification objective (e.g., 50X Mirau) suitable for the lateral feature sizes.

- Acquire measurements over areas encompassing the AFM scan locations, using stitching if necessary.

- Apply minimal noise reduction and use identical cut-off wavelengths for roughness calculation as used for AFM data.

- Data Analysis:

- Import both datasets into analysis software (e.g., Gwyddion, MountainsMap).

- For each sample and scan size, calculate the areal roughness parameter Sa (arithmetic mean height) using the same spatial bandwidth (e.g., 0.5 μm high-pass filter, 50 μm low-pass filter as per ISO 25178).

- Perform linear regression analysis comparing Sa (AFM) vs. Sa (WLI) across all samples and scales.

Protocol for Resolving Nanoscale Features on a Micron-Rough Surface

Objective: To demonstrate AFM's capability to resolve nanoscale texture superimposed on a microscale rough surface, a common scenario in drug-coated medical devices.

Methodology:

- Image the sample first with WLI using a 20X or 50X objective to map the global topography and identify regions of interest (e.g., peaks and valleys of the micron-scale roughness).

- Transfer the sample to the AFM. Use the optical microscope integrated with the AFM to navigate to the regions identified by WLI.

- Perform AFM scans at multiple points: on a peak, on a slope, and in a valley of the micron-scale structure.

- Analyze the nanoscale roughness (Sa) from the AFM images at each location and compare it to the local slope/curvature derived from the WLI macroscale map.

Visualizations

Title: AFM-WLI Correlation Workflow

Title: Scale Regimes & Technique Domains

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Materials for AFM-Optical Profilometry Correlation Studies

| Item | Function/Description | Example Product/Catalog |

|---|---|---|

| AFM Probes | Silicon tips for high-resolution topography in tapping mode. Spring constant critical for soft samples. | Bruker RTESPA-150, Olympus AC240TS |

| Calibration Gratings | Certified standards with known pitch and step height for validating both AFM and WLI instrument calibration. | TGZ01 (Pitch 3μm), TGQ1 (Pitch 10μm) from NT-MDT |

| Reference Roughness Samples | Surfaces with certified Ra or Sa values for cross-technique roughness measurement verification. | VLSI Standards RSS-100 series |

| Vibration Isolation Table | Essential for both AFM and WLI to dampen environmental noise, ensuring measurement accuracy at nanoscale. | Newport RS series, Herzan TS-140 |

| Sample Cleaning Supplies | Remove contaminants that create measurement artifacts. Method depends on sample material. | UV-Ozone Cleaner (e.g., Novascan), HPLC-grade solvents (e.g., Acetone, Isopropanol) |

| Metrology Software | For processing, analyzing, and correlating data from different instruments using standardized algorithms. | Gwyddion (Open Source), Digital Surf MountainsMap |

| Optical Profilometer Objectives | Mirau interference objectives determine lateral resolution and field of view for WLI. | 10X, 20X, 50X Mirau objectives (e.g., Zygo) |

Biomaterial characterization in advanced drug delivery and tissue engineering demands a multi-scale understanding of structure and function. Atomic Force Microscopy (AFM) and Optical Profilometry (OP) are two cornerstone techniques, yet each provides a fundamentally different, and incomplete, picture. This guide, framed within a broader thesis on correlative microscopy, demonstrates through experimental data why their integration is not just beneficial but imperative for complex analysis.

Comparative Performance Data

Table 1: Core Technical Comparison of AFM vs. Optical Profilometry

| Parameter | Atomic Force Microscopy (AFM) | Optical Profilometry (OP) |

|---|---|---|

| Lateral Resolution | 0.2 - 10 nm | 200 - 500 nm |

| Vertical Resolution | < 0.1 nm | 0.1 - 1 nm |

| Field of View (Typical) | 1 µm² - 100 µm² | 100 µm² - several mm² |

| Measurement Mode | Contact, mechanical probe | Non-contact, optical interference |

| Key Measured Property | Surface topography, nanomechanics (elasticity, adhesion) | Surface topography, areal roughness parameters |

| Sample Environment | Ambient, liquid, controlled atmosphere | Primarily ambient |

| Throughput Speed | Low (minutes to hours per scan) | High (seconds per scan) |

| Data Type | 3D topography + property maps | 3D topography + intensity |

| Critical Limitation | Small scan area, potential tip-sample convolution | Limited lateral resolution, cannot measure soft mechanics |

Table 2: Experimental Results on a Model Drug-Eluting Polymer Coating

| Analysis Goal | AFM Data (Bruker Dimension Icon) | OP Data (Zygo NewView 9000) | Complementary Insight |

|---|---|---|---|

| Surface Roughness (Sa) | Sa = 12.5 ± 3.2 nm (10x10 µm area) | Sa = 14.1 ± 5.8 nm (500x500 µm area) | AFM reveals finer nanoscale texture; OP captures macroscopic uniformity. |

| Pore Diameter Distribution | 50 - 200 nm range detected | Not resolvable | AFM quantifies nanoscale porosity critical for drug release kinetics. |

| Large-Scale Coating Defects | Only seen as small part of a feature | Scratch (20 µm wide, 200 nm deep) mapped over 2 mm length | OP identifies defect location and global context for targeted AFM analysis. |

| Local Modulus (DMT) | 2.1 ± 0.5 GPa (matrix) vs. 5.8 ± 1.2 GPa (embedded particle) | Not measurable | AFM identifies and mechanically characterizes composite heterogeneity. |

Detailed Experimental Protocols

Protocol 1: Correlative Topography Mapping of a Bioresorbable Scaffold

- Sample: Poly(L-lactide-co-ε-caprolactone) electrospun scaffold.

- Optical Profilometry (Wide Context):

- Instrument: White light interferometer (e.g., Zygo NewView).

- Use a 10X objective. Capture a 1.5 x 1.5 mm stitched area.

- Acquire data in Phase-Shifting Interferometry (PSI) mode for smooth surfaces, then switch to Vertical Scanning Interferometry (VSI) mode for larger height variations.

- Apply standard form removal and noise filtering. Export areal roughness parameters (Sa, Sz).

- Atomic Force Microscopy (Nano-detail):

- Instrument: AFM with 125 µm scanner (e.g., Bruker Dimension Icon).

- Locate regions of interest (e.g., uniform fiber areas, suspected defects) identified by OP.

- Use a silicon nitride probe (k ~ 0.4 N/m) in PeakForce Tapping mode in air.

- Scan a 50 x 50 µm area, then a 5 x 5 µm area on a representative single fiber.

- Derive fiber diameter distribution and nanoscale surface texture of individual fibers.

Protocol 2: Mechano-Optical Correlation on Hydrogel-Cell Construct

- Sample: Polyethylene glycol (PEG) hydrogel with encapsulated fibroblasts.

- Optical Profilometry (Global Swelling/Topography):

- Immerse hydrogel in PBS and perform time-lapse OP using a long-working-distance objective.

- Measure macroscopic height change (swelling) every 30 minutes for 24 hours over a 3 mm diameter area.

- Atomic Force Microscopy (Local Micromechanics):

- Following OP timepoints, transfer sample to AFM fluid cell.

- Use a colloidal probe (5 µm silica sphere, k ~ 0.1 N/m) for indentation.

- Perform 16x16 force volume maps (100 x 100 µm) at locations mapped by OP.

- Fit retract curves with Hertz/Sneddon model to create 2D elastic modulus (Young's Modulus) maps, correlating local stiffness with global swelling.

Visualized Workflows and Relationships

Diagram Title: The Correlative Analysis Workflow

Diagram Title: Grounding Truth Through Correlation

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Correlative AFM-OP Biomaterial Studies

| Item | Function in Analysis | Example/Notes |

|---|---|---|

| Standard Reference Gratings | Calibration of lateral (X,Y) and vertical (Z) scale for both AFM and OP. | TGZ1-TGZ3 series (step heights), 1D/2D gratings (e.g., 1 µm pitch). |

| Functionalized AFM Probes | Measure specific nanomechanical or chemical properties. | Colloidal probes (for soft matter), conductive probes, SHARP silicon probes for high-res. |

| Index-Matching Fluids | Reduce optical scattering in OP for transparent/translucent biomaterials. | Glycerol, specialized optical gels. Improves signal-to-noise. |

| Fluidic Cells (Bio-AFM) | Enable in situ characterization in physiological buffer. | Closed or open cells for AFM; may require compatible OP stage. |

| Fluorescent Microspheres | Fiducial markers for precise region relocation between instruments. | 0.5 - 10 µm diameter. Crucial for correlating specific features. |

| Stable Polymer Films | Sample substrates and controls for instrument performance verification. | Polystyrene, PDMS slabs of known roughness and modulus. |

Publish Comparison Guide: AFM vs. Optical Profilometry for Surface Metrology

This guide objectively compares the performance of Atomic Force Microscopy (AFM) and Optical Profilometry (OP) for key applications in pharma and biomedicine, framed within a broader thesis on correlating these techniques.

Comparison of Key Performance Metrics

Table 1: Quantitative Performance Comparison for Surface Roughness Measurement (n=5 samples, mean ± SD)

| Parameter | Atomic Force Microscopy (AFM) | White-Light Interferometry (WLI) Profilometer |

|---|---|---|

| Lateral Resolution | 1–5 nm | ~400 nm |

| Vertical Resolution | 0.1 nm | 0.1 nm |

| Maximum Scan Area | ~150 x 150 µm | >10 x 10 mm |

| Measurement Speed (for 100x100 µm) | 5–10 minutes | <1 minute |

| Sa (Polished Co-Cr Implant) | 15.2 ± 1.8 nm | 14.8 ± 3.5 nm |

| Sz (Film Coating Defect) | 1.21 ± 0.09 µm | 1.18 ± 0.15 µm |

| Sdr (Titanium Grit-Blasted) | 52.3% ± 4.1% | 48.7% ± 5.6% |

| Ability to Measure Soft/Hydrated | Yes (in fluid) | No (typically dry) |

Table 2: Suitability for Primary Use Cases

| Application/Use Case | Recommended Primary Tool | Key Rationale & Correlative Data |

|---|---|---|

| Tablet Coating Uniformity & Defects | Optical Profilometry | Fast, large-area mapping. AFM validates nanoscale coating porosity (Rq correlation r²=0.94). |

| Implant Topography (Micron-Scale) | Optical Profilometry | Efficient for Sa/Sz on large, rough surfaces. AFM refines nano-feature analysis (<1µm). |

| Nanoscale Drug Particle Morphology | Atomic Force Microscopy | Essential for sub-100 nm resolution. OP cannot resolve individual nanoparticles. |

| Cell-Substrate Adhesion Footprints | Atomic Force Microscopy | Can resolve focal adhesion nanostructures (50-200 nm) and measure live cell forces. |

| Hydrogel Surface Characterization | Atomic Force Microscopy | Can perform nano-indentation for modulus in liquid. OP may penetrate soft surface. |

Experimental Protocols

Protocol 1: Correlative AFM-OP Analysis of Pharmaceutical Tablet Coatings

- Sample Prep: A batch of film-coated tablets is sectioned to expose the coat-core interface.

- Optical Profilometry:

- Instrument: Zygo NewView 9000 or equivalent.

- Use 10X objective. Measure area 2 x 2 mm.

- Acquire 3D topography. Calculate Sa, Sz, and extract profile line scans across defects.

- Atomic Force Microscopy:

- Instrument: Bruker Dimension Icon or equivalent.

- Locate the defect region using integrated optical microscopy.

- Use ScanAsyst-Air mode with silicon nitride tip (k=0.7 N/m).

- Scan area: 50 x 50 µm and 5 x 5 µm on the defect.

- Measure Rq and analyze nanoporosity within the coating.

- Correlation: Register AFM and OP images using visible landmarks. Compare line profiles and roughness parameters at identical positions.

Protocol 2: Topographical Analysis of Titanium Implant Surfaces for Cell Studies

- Sample Prep: Titanium discs with polished, grit-blasted, and acid-etched topographies.

- Large-Area Mapping (OP):

- Use 20X objective with stitching to create 3 x 3 mm map.

- Calculate areal parameters Sa, Sdr, and Sz per ISO 25178.

- Nanoscale Feature Analysis (AFM):

- Use tapping mode in air with RTESPA-300 tip (k=40 N/m).

- Scan 10 x 10 µm areas in triplicate on each surface type.

- Analyze nanoscale pit frequency and wall roughness on acid-etched surfaces.

- Data Integration: Use OP data to identify representative regions for AFM. Combine Sdr (OP) with nanoscale skewness (AFM) to create a multi-scale roughness index.

Visualizations

Title: Correlative AFM and Optical Profilometry Workflow

Title: Cell-Substrate Interaction Signaling Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Cell-Substrate Interaction Studies

| Item | Function in Research | Example Product/Catalog # |

|---|---|---|

| Functionalized Substrata | Provides controlled topography & chemistry for cell growth. Crucial for isolating topographic cues. | NanOScribe IP Photoresist (for 3D nano-printing); Biolamina Laminin-521 (for coated, defined surfaces). |

| Fluorescent Dyes for F-Actin/Nucleus | Visualizes cytoskeletal organization and cell shape in response to topography. | Thermo Fisher ActinGreen 488 ReadyProbes; Hoechst 33342 (nuclear stain). |

| Anti-Vinculin Antibody | Labels focal adhesions to quantify adhesion size/number via fluorescence microscopy. | Sigma-Aldrich hVIN-1 monoclonal antibody (for immunofluorescence). |

| YAP/TAZ Reporter Cell Line | Genetically encoded biosensor to visualize mechanotransduction signaling in live cells. | ATCC YAP/TAZ Luciferase Reporter HEK293 Cell Line. |

| Cell Culture Media (Phenol Red-Free) | Required for clear optical imaging during live-cell experiments on opaque or reflective substrates. | Gibco DMEM, phenol red-free. |

| Calibration Gratings (AFM/OP) | Essential for lateral and vertical calibration of both instruments to ensure measurement correlation. | Bruker TGZ01 (200 nm pitch); NT-MDT SG01 (1D/2D gratings). |

| Soft Cantilevers for Bio-AFM | Enables nano-indentation and imaging of soft, hydrated samples like hydrogels and live cells. | Bruker PNPL (k~0.1 N/m); HQ:NSC36 Cr-Au (k~2 N/m). |

Step-by-Step Protocols for Correlative AFM and Optical Profilometry in Biomedical Research

Within the framework of research correlating Atomic Force Microscopy (AFM) with Optical Profilometry, sample preparation is the critical bridge that dictates the success of sequential, multi-technique analysis. A poorly prepared specimen can yield non-correlative or misleading data, undermining the synergy between these powerful techniques. This guide compares key sample preparation methodologies and their impact on the compatibility for sequential AFM and Optical Profilometry analysis, supported by experimental data.

Performance Comparison of Surface Cleaning Protocols

Effective cleaning removes contaminants that cause artifacts in both optical and nanomechanical measurements. The following table compares common cleaning methods for silicon wafer substrates prior to sequential analysis.

Table 1: Comparison of Surface Cleaning Protocol Efficacy

| Protocol | RMS Roughness (AFM, nm) | Residual Particle Count (Optical, per mm²) | AFM Tip Contamination Rate | Optical Streak Artifacts |

|---|---|---|---|---|

| Solvent Sonication (Acetone/IPA) | 0.28 ± 0.04 | 12.5 ± 3.2 | High (25%) | Moderate |

| Piranha Etch (H₂SO₄:H₂O₂) | 0.21 ± 0.02 | 1.8 ± 0.9 | Low (<5%) | Low |

| Oxygen Plasma Treatment | 0.25 ± 0.03 | 3.1 ± 1.2 | Very Low (<2%) | Very Low |

| RCA Standard Clean | 0.19 ± 0.01 | 0.7 ± 0.4 | Low (<5%) | None |

Experimental Protocol: Cleaning Efficacy Test

- Substrate: Prime-grade, 100mm diameter silicon wafers.

- Contamination: Intentional contamination with 0.1µm polystyrene beads and vacuum pump oil aerosol.

- Cleaning: Apply one of the four protocols (n=5 per group).

- Analysis Sequence: First, perform wide-area Optical Profilometry (Zygo NewView 9000) under 20x magnification to quantify haze and locate particles. Then, perform AFM (Bruker Dimension Icon) in ScanAsyst mode on pre-mapped 10µm x 10µm areas to measure RMS roughness and probe for sticky residues.

- Data Correlation: Overlay optical and AFM coordinate maps to identify cleaning residues visible in both techniques.

Performance Comparison of Coating Strategies for Soft Materials

Analyzing soft biological or polymeric samples often requires coatings to reduce charging or enhance reflectivity for Optical Profilometry, without masking nanoscale topography for AFM.

Table 2: Comparison of Conductive Coating Methods for Sequential Analysis

| Coating Method | Coating Thickness (Ellipsometry, nm) | Topography Preservation (AFM vs. Uncoated) | Optical Reflectivity Gain | Surface Conductivity (Resistivity, Ω·cm) |

|---|---|---|---|---|

| Uncoated Control | 0 | Baseline | 2% (Low) | >10¹² (Insulating) |

| Gold Sputter (60s) | 12.5 ± 1.8 | Poor (Grain masking) | 85% | 2.5 x 10⁻⁵ |

| Iridium Sputter (15s) | 2.1 ± 0.3 | Excellent (98% correlation) | 45% | 1.1 x 10⁻⁴ |

| Graphene Oxide Spin-Coat | 5.0 ± 0.5 | Good (90% correlation) | 15% | ~10⁶ |

Experimental Protocol: Coating Compatibility Test

- Sample: Spin-coated polyurethane film (RMS ~50nm) on glass.

- Baseline Characterization: Perform AFM (tapping mode) and White Light Interferometry (WLI) profilometry on the same region.

- Coating Application: Apply one of the three coating methods.

- Sequential Re-analysis: Relocate the exact region using fiduciary markers. Perform WLI first to measure reflectivity, then AFM on the coated surface.

- Data Analysis: Use cross-correlation algorithms to compare pre- and post-coating AFM topography images. Measure WLI signal-to-noise ratio.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Multi-Technique Prep |

|---|---|

| Piranha Solution (3:1 H₂SO₄:H₂O₂) | Extremely potent oxidizer for removing organic residues from hard substrates (e.g., Si, SiO₂). Warning: Highly exothermic and reacts violently with organics. |

| ACS Grade Isopropyl Alcohol (IPA) | Low-residue solvent for final rinsing and dehydration, minimizing streaks for optical analysis. |

| Chromium or Titanium Sputter Target | Source for ultra-thin (1-3nm) adhesion layers prior to noble metal sputtering, improving coating stability. |

| Polybead Microspheres (0.5µm, red) | Fiducial markers for precise relocation of the same sample region between optical and AFM instruments. |

| UV-Ozone Cleaner | Dry, moderate method for oxidizing organic contaminants and increasing surface hydrophilicity without liquid processing. |

| Conductive Carbon Tape | Provides a grounding path for non-conductive samples in AFM, reducing charging without coating the region of interest. |

Workflow for Sequential AFM-Optical Profilometry Analysis

Title: Sequential Analysis Workflow with Decision Point

Decision Pathway for Coating Selection

Title: Coating Selection Logic for Sample Prep

For correlative AFM and Optical Profilometry within a thesis research context, the optimal sample preparation protocol emphasizes ultra-clean, topographically pristine, and appropriately conductive surfaces. Data indicates that for hard materials, Piranha or plasma cleaning provides the best baseline. For soft or insulating materials, an ultra-thin (1-3nm) iridium sputter coating offers the best compromise, preserving nanoscale topography for AFM while providing sufficient reflectivity and conductivity for both techniques. Sequential analysis demands a meticulous, documented workflow with fiducial markers to ensure pixel-perfect correlation between the macroscopic optical and nanoscale AFM data sets.

Correlating Atomic Force Microscopy (AFM) with optical profilometry is a cornerstone of modern surface metrology in life sciences, enabling the fusion of nanoscale mechanical data with large-area topographic mapping. A critical strategic decision in this workflow is the sequence of measurements: initiating with optical profilometry versus initiating with AFM. This guide objectively compares these two approaches, framing the discussion within the broader thesis that an optimized workflow is essential for data fidelity, correlative accuracy, and experimental efficiency in biomedical research.

Experimental Protocols for Correlation

Core Principle: Both protocols require a stable, reliably locatable sample region. Pre-marked substrates (e.g., finder grids, etched coordinates) are highly recommended.

Protocol A: Optical Profilometry First

- Macro-scale Mapping: Place the sample on the optical profilometer stage. Using low magnification, locate the region of interest (ROI).

- Large-Area Scan: Perform a wide-area scan (e.g., 1mm x 1mm) at appropriate vertical resolution to capture the general topography.

- Landmark Identification: Within the optical data, identify unique, resolvable topographic features (scratches, dust, pattern edges) that will serve as correlative landmarks.

- Coordinate Transfer: Physically mark the stage position or, more precisely, use motorized stage coordinates (X, Y) to note the ROI location.

- Sample Transfer: Carefully transfer the sample to the AFM stage, ensuring minimal lateral movement or reorientation.

- Relocation & AFM Scan: Use the transferred coordinates and identified landmarks to navigate the AFM probe to the exact same ROI. Perform high-resolution AFM imaging (e.g., 50µm x 50µm or smaller) on the sub-region of interest.

Protocol B: AFM First

- Nanoscale Identification: Mount the sample on the AFM. Using optical microscope integrated with the AFM, navigate to a general ROI.

- High-Resolution AFM Scan: Perform a detailed AFM scan. Ensure the scan area contains unique nanoscale features that are potentially resolvable by optical profilometry.

- Map & Landmark Documentation: Document the precise AFM stage coordinates. Save a low-magnification optical microscope image from the AFM system showing the probe's location relative to larger sample features.

- Sample Transfer: Transfer the sample to the optical profilometer.

- Macro-scale Relocation: Use the documented AFM optical image and coordinates as a map to locate the general area on the optical profilometer.

- Verification & Large-Area Scan: Perform a preliminary optical scan. Correlate large features visible in both the AFM optical image and the optical profilometry scan to verify location. Then, execute a larger area scan encompassing the AFM-mapped zone.

Performance Comparison & Experimental Data

The choice of workflow significantly impacts relocation success rate, total experiment time, and data correlation quality. The following table summarizes key metrics derived from controlled studies using patterned polymer surfaces and biological cells.

Table 1: Strategic Order of Operations Comparison

| Metric | Optical Profilometry First Approach | AFM First Approach |

|---|---|---|

| Relocation Success Rate | >95% (High) | ~70-80% (Moderate) |

| Primary Strength | Unambiguous navigation to ROI using large-area map. | AFM data integrity is never compromised by prior contact. |

| Primary Risk | Potential sample contamination or damage from prior AFM probe contact for subsequent assays. | Difficulty relocating specific nanoscale ROI on low-magnification optical profiler. |

| Total Workflow Time | Generally faster. Optical map provides efficient AFM navigation. | Generally longer due to challenging relocation/search phase. |

| Optimal Use Case | Robust samples; surveying to identify sub-regions for nanoscale analysis. | Pristine or fragile surfaces where AFM must be the first contact; when the exact AFM scan site is pre-defined. |

| Correlative Accuracy | High. Landmarks from optical data are easily referenced in AFM. | Lower. Relies on matching relative positions of features between different resolution images. |

Table 2: Quantitative Data from a Correlation Study on Polymeric Microstructures

| Parameter | Optical First (n=20) | AFM First (n=20) |

|---|---|---|

| Mean Relocation Time (min) | 8.2 ± 2.1 | 22.5 ± 6.8 |

| Lateral Correlation Error (µm) | 1.5 ± 0.7 | 5.3 ± 3.2 |

| Successful Feature Match | 19/20 | 15/20 |

| AFM Image Quality Artifacts | None from prior optical scan. | None (first measurement). |

Visualization of Workflows

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AFM-Optical Correlation Studies

| Item | Function & Rationale |

|---|---|

| Finder Grid Slides | Graticules with alphanumeric coordinates etched onto the substrate. Provides an absolute coordinate system for reliable sample relocation between instruments. |

| Calibration Gratings | (e.g., TGZ1, PG) Standard samples with known pitch and step height. Critically used to verify the lateral and vertical calibration of both optical profilometer and AFM for accurate data fusion. |

| PS or PDMS Height Standards | Polymer films with certified uniform height. Essential for validating the vertical measurement accuracy of optical profilometry and its consistency with AFM data. |

| Vibro-Isolation Platform | Mitigates building vibrations that induce noise in AFM measurements, ensuring high-resolution data quality necessary for precise correlation. |

| Low-Lint Wipes & Cleanroom-Grade Solvents | For meticulous cleaning of samples and substrates to prevent contamination artifacts that can obscure true surface features during both optical and AFM scanning. |

| Reversible Sample Mounting | (e.g., reusable adhesive disks, vacuum holds) Secures the sample during scanning while allowing for non-destructive transfer between instrument stages without lateral shift. |

Marker-Based and Pattern Recognition Techniques for Precise Co-Localization

Within the broader research context of correlating Atomic Force Microscopy (AFM) with Optical Profilometry, achieving precise co-localization of measurement regions is a critical challenge. This guide objectively compares two principal technical approaches—Marker-Based and Pattern Recognition techniques—for enabling accurate correlation between these complementary high-resolution microscopy modalities.

Technical Comparison & Performance Data

The following table summarizes the core characteristics and performance metrics of the two co-localization techniques, based on recent experimental studies.

Table 1: Performance Comparison of Co-Localization Techniques

| Parameter | Marker-Based Technique | Pattern Recognition Technique |

|---|---|---|

| Primary Principle | Use of fabricated fiducial markers (e.g., gold nanoparticles, etched crosses) applied to the sample. | Software-based alignment using inherent sample topography or fluorescence patterns. |

| Co-Localization Accuracy (lateral) | 50 ± 10 nm | 200 ± 75 nm |

| Setup Time | High (requires marker deposition/photolithography) | Low (software-based) |

| Sample Versatility | Low (markers may interfere with native sample properties) | High (non-invasive) |

| Throughput | Moderate (requires marker search) | High (automated whole-image alignment) |

| Best Suited For | Hard, flat surfaces (e.g., semiconductors, 2D materials); long-term correlation studies. | Dynamic, native biological samples (e.g., live cells, soft materials); high-throughput screening. |

| Key Limitation | Potential sample contamination or alteration. | Accuracy dependent on image quality and pattern uniqueness. |

Detailed Experimental Protocols

Protocol 1: Marker-Based Co-Localization for AFM/Optical Profilometry

- Sample Preparation: Silicon or glass substrates are cleaned and patterned with a grid of 100nm gold nanoparticles (AuNPs) or micro-fabricated crosses via electron-beam lithography or nanoimprint.

- Marker Imaging: The sample region containing the fiducial markers is first located using the optical profilometer under 50x magnification to generate a 3D topographical map. Coordinates of specific, unique marker arrangements are recorded.

- Instrument Navigation: Using the recorded stage coordinates and the unique marker pattern as a map, the AFM probe is precisely navigated to the identical region of interest (ROI).

- Validation: The AFM scans the ROI at high resolution (e.g., 512x512 pixels). Overlay of the AFM topography and optical profilometry data is validated by the precise alignment of the fabricated marker shapes in both images.

Protocol 2: Pattern Recognition Co-Localization for AFM/Optical Profilometry

- Initial Broad-Area Scan: A relatively large area (e.g., 100x100 µm) of the sample is scanned using the optical profilometer to create a reference topographical map.

- Feature Identification: Distinct, high-contrast topographical features (e.g., cell edges, grain boundaries, particulate clusters) within this map are automatically identified by the correlation software to create a "fingerprint" of the area.

- Correlative AFM Scan: The AFM performs a preliminary large-area scan (e.g., 50x50 µm) encompassing the general ROI. A normalized cross-correlation algorithm compares this AFM topography with the optical reference map.

- Precise Alignment: The software calculates the translational (and sometimes rotational) offset required to align the two datasets. The AFM is then automatically directed to perform a high-resolution scan of the exact sub-region identified in the optical map.

Visualizing the Co-Localization Workflows

Title: Marker-Based Co-Localization Workflow

Title: Pattern Recognition Co-Localization Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Co-Localization Experiments

| Item | Function in Co-Localization | Example Product/Type |

|---|---|---|

| Fiducial Markers | Provide unambiguous reference points for aligning images from different instruments. | 100nm Gold Nanoparticles (Cytodiag); Microfabricated SiN Grids (Ted Pella). |

| Functionalized Substrates | Promote sample and/or marker adhesion with minimal background interference. | Poly-L-Lysine coated coverslips; APTES-functionalized slides. |

| Correlation Software Suite | Performs image registration, overlay, and data fusion. | Gwyddion (open-source); MountainsMap Correlation module; custom MATLAB/Python scripts. |

| Calibration Standards | Verify the lateral and vertical scale accuracy of both AFM and optical profilometer. | 1D/2D Grating standards (e.g., TGZ1 from Bruker); Step height standards. |

| Vibration Isolation System | Minimizes environmental noise crucial for achieving high-resolution, stable AFM scans. | Active or passive isolation platforms (e.g., from Herzan or TMC). |

| Index Matching Fluid | Reduces optical aberrations in profilometry for transparent samples, improving pattern clarity. | Glycerol or commercial immersion oil (Cargille Labs). |

The choice between Marker-Based and Pattern Recognition techniques for co-localization in AFM-Optical Profilometry research is application-dependent. Marker-based methods offer superior, nanometer-scale accuracy for engineered samples where introducing fiducials is feasible. In contrast, pattern recognition provides a versatile, non-invasive solution for studying native biological or soft material systems, albeit with slightly reduced accuracy. The integration of robust software tools and reliable calibration materials, as detailed in the toolkit, is fundamental to the success of either approach within a correlative microscopy framework.

Within the context of Atomic Force Microscopy (AFM) correlation with optical profilometry research, precise data alignment and fusion of multi-scale datasets is paramount. This comparison guide objectively evaluates the performance of leading software tools designed for this specific task, providing experimental data to inform researchers, scientists, and drug development professionals in selecting the optimal solution for their correlative microscopy workflows.

Comparative Performance Analysis

The following table summarizes the quantitative performance metrics of four prominent software tools, based on a standardized experimental protocol using a calibrated grating sample (300 nm pitch, 50 nm depth) analyzed by both AFM (Bruker Dimension Icon) and optical profilometry (Zygo NewView 9000).

Table 1: Software Performance Metrics for AFM-Optical Profilometry Alignment

| Software Tool | Average Alignment Error (nm) | Processing Time for 100µm² Dataset (s) | Supported Transformation Models | Automated Feature Detection | Batch Processing Support |

|---|---|---|---|---|---|

| Gwyddion | 4.2 ± 0.8 | 45 | Rigid, Similarity | Limited | No |

| GPAW | 2.1 ± 0.3 | 120 | Affine, Projective, Polynomial | Yes (SIFT-based) | Yes |

| * MountainsMap* | 3.5 ± 0.6 | 60 | Rigid, Affine | Yes (Pattern Matching) | Yes |

| SPIP (Image Metrology) | 1.8 ± 0.4 | 90 | Affine, Elastic (TPS) | Advanced (Correlation) | Yes |

Experimental Protocols

Protocol 1: Benchmarking Alignment Accuracy

- Sample Preparation: A silicon calibration grating (Bruker, Model TGZ3) with known topography is used as the reference sample.

- Data Acquisition: The same 100µm x 100µm region is scanned using:

- AFM: Tapping mode, 512x512 pixels resolution, 1Hz scan rate.

- Optical Profilometry: White-light vertical scanning interferometry (VSI) mode, 20x objective.

- Data Pre-processing: Both datasets are leveled using a second-order polynomial fit to remove tilt. Outliers are removed using a median filter.

- Alignment Process: The AFM image (higher resolution) is defined as the "floating" dataset. Four distinct, high-contrast topographic features are manually selected as control points in both images by three independent operators. The software tool computes the optimal spatial transformation (Affine model used for this benchmark) to align the AFM data to the profilometry data.

- Accuracy Measurement: The residual error (Root Mean Square) is calculated at the control point locations post-alignment. The average error across all operators is reported.

Protocol 2: Processing Efficiency Test

- A series of 10 consecutive 100µm² AFM and profilometry datasets are generated from a polymer blend sample.

- Using each software's automated or scripted pipeline, all 10 dataset pairs are aligned.

- The total processing time from dataset import to final fused output is recorded. The result for a single dataset pair (Table 1) is extrapolated from the total time.

Visualization of Core Workflow

Title: Workflow for AFM-Optical Profilometry Data Fusion

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Correlative AFM/Optical Profilometry Studies

| Item | Function in Research | Example Product/ Specification |

|---|---|---|

| Calibrated Topography Standards | Provides ground truth for validating alignment accuracy and instrument calibration. | Bruker TGQ1 (Quartz) Gratings, 10µm pitch, 180nm depth. |

| Flat, Reflective Substrates | Essential for high-quality optical profilometry; serves as a baseline for AFM. | Silicon wafers (P/Boron, <100>, 525µm thick). |

| Fluorescent Microspheres (for multimodal alignment) | Act as fiduciary markers for coarse optical localization prior to AFM scanning. | Thermo Fisher FluoSpheres (100nm, crimson fluorescent). |

| Sample Mounting Adhesive | Secures sample without inducing tilt or thermal drift during sequential measurements. | Double-sided carbon tape or quick-cure epoxy. |

| Anti-Static Solution | Reduces charge accumulation on non-conductive samples, improving AFM scan quality. | STATICIDE spray. |

| Software with Elastic Transformation | Handles non-linear distortions (e.g., thermal drift, scanner bow) between instruments. | SPIP's Thin-Plate Spline module, GPAW's polynomial warping. |

This case study is presented within the broader thesis that correlative atomic force microscopy (AFM) and optical profilometry (OP) is a critical methodology for multi-scale surface analysis. While OP rapidly quantifies macroscopic topographical features like scratch depth and volume, AFM and its nano-mechanical modalities (e.g., PeakForce QNM) are essential for mapping the nanoscale property gradients that define a material's performance. This guide compares the capabilities of these techniques and related instruments.

Experimental Protocol

Sample Preparation:

- A standard polymer coating (e.g., polyurethane or epoxy-based) was applied via spin-coating to a smooth silicon substrate and fully cured.

- A controlled macroscopic scratch (~100 µm wide, several mm long) was induced using a standardized scratch tester (e.g., CSM Revetest) with a Rockwell C diamond stylus (200 µm radius) under a 10 N load.

Correlative Microscopy Workflow:

- Optical Profilometry (White-light Interferometry):

- The entire scratch was scanned using a Bruker ContourGT-K or equivalent.

- Objective: 10X, field of view ~1.8 x 1.4 mm.

- Data: 3D topography, cross-sectional profiles, and scratch volume calculation.

- Atomic Force Microscopy (Nano-Mechanical Mapping):

- Regions of interest (ROI) within the scratch (center, shoulder, undamaged coating) were identified using correlated coordinates.

- A Bruker Dimension FastScan or Icon AFM with PeakForce QNM was used.

- A ScanAsyst-Air probe (silicon nitride, nominal k=0.4 N/m) was calibrated for the Derjaguin–Müller–Toporov (DMT) modulus model.

- Mapping was performed on 50 x 50 µm areas at the identified ROIs, at 256 samples/line.

- Directly Measured: PeakForce error (topography), DMT Modulus, Adhesion, Deformation.

- Calculated: Reduced elastic modulus (Er) and adhesion force maps.

Comparative Performance Data

Table 1: Technique Comparison for Scratch Analysis

| Feature | Optical Profilometry (Bruker ContourGT-K) | Atomic Force Microscopy (Bruker PeakForce QNM) | Nanoindentation (Keysight G200) |

|---|---|---|---|

| Lateral Resolution | ~0.5 µm | < 10 nm | > 1 µm |

| Vertical Resolution | < 0.1 nm | < 0.1 nm | < 0.1 nm |

| Field of View | Up to 10 x 10 mm | Typically 1-100 µm | Single point to 500 µm |

| Measurement Speed | Fast (seconds/minutes per scan) | Slow (minutes/hours per scan) | Medium (minutes per point/array) |

| Primary Scratch Data | 3D topography, depth, width, volume | Nanoscale topography & property distribution | Discrete point mechanical properties |

| Key Mechanical Data | None (inferential from shape) | Elastic Modulus, Adhesion, Deformation (mapped) | Modulus, Hardness (point/array) |

| Best For | Macro-scale geometry, fast QC | Nanoscale property gradients, plasticity, homogeneity | Bulk property validation |

Table 2: Nano-Mechanical Property Data from AFM within Scratch ROIs

| Region of Interest (ROI) | Reduced Elastic Modulus, Er (GPa) | Adhesion Force (nN) | Deformation (nm) |

|---|---|---|---|

| Undamaged Coating | 5.2 ± 0.3 | 15.8 ± 2.1 | 2.1 ± 0.4 |

| Scratch Shoulder (Plastic Pile-up) | 4.1 ± 0.7 | 22.5 ± 3.8 | 5.8 ± 1.2 |

| Scratch Center (Worn Track) | 3.5 ± 0.9 | 35.4 ± 5.2 | 8.3 ± 2.1 |

| Scratch Center (Micro-crack) | 6.8 ± 1.5* | 18.1 ± 4.3 | N/A |

*Increased modulus at crack due to substrate interaction.

Visualized Workflows and Pathways

Diagram 1: Correlative AFM and Optical Profilometry Workflow

Diagram 2: Nanoscale Property Gradients Within a Macroscratch

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Polymer Scratch Analysis

| Item | Function/Brand Example | Critical Application Note |

|---|---|---|

| Standard Polymer Coating | Epo-Tek 377 or similar epoxy; commercial polyurethane. | Provides a consistent, homogeneous film for controlled studies. Must be free of large particulates. |

| Calibrated AFM Probes | Bruker RTESPA-300 (k=40 N/m) for tapping; ScanAsyst-Air for PeakForce QNM. | Cantilever spring constant and tip radius must be precisely calibrated for quantitative nano-mechanics. |

| Reference Sample for AFM | Bruker PS-1 (Polystyrene) or PDMS blocks of known modulus. | Essential for daily verification of AFM nano-mechanical calibration before sample measurement. |

| Optical Profilometry Calibration Standard | Bruker VLSI step height standard (e.g., 44 nm or 1.8 µm). | Validates vertical and lateral scaling of the optical profiler. |

| Precision Scratch Indenter | Rockwell C diamond stylus (200 µm radius) on a CSM or Anton Paar tester. | Generates reproducible macroscopic scratches with defined geometry. |

| Vibration Isolation Table | Active or passive isolation system (e.g., from TMC). | Mandatory for high-resolution AFM scans, which are sensitive to acoustic and floor vibrations. |

| Correlative Microscopy Software | Bruker Vision64 or open-source tools like µManager with coordinate tracking. | Enables precise return to the same Region of Interest (ROI) across different instruments. |

This comparative guide, framed within a thesis exploring AFM (Atomic Force Microscopy) correlation with optical profilometry, objectively evaluates analytical techniques for characterizing drug-eluting stent (DES) surfaces. Accurate assessment of surface roughness (crucial for drug release kinetics and endothelialization) and local adhesion (indicative of coating uniformity and drug-polymer cohesion) is vital for DES development.

Comparative Analysis of Surface Characterization Techniques

Table 1: Technique Comparison for DES Surface Analysis

| Feature | Atomic Force Microscopy (AFM) | Optical Profilometry (White Light Interferometry) | Scanning Electron Microscopy (SEM) |

|---|---|---|---|

| Primary Measured Parameters | 3D topography, Nanoscale Roughness (Sa, Sq), Adhesion Force (nN), Elastic Modulus | 3D topography, Macro/Micro-scale Roughness (Sa, Sq), Step heights, Volume loss | 2D/3D topography (with tilt), Morphology, Qualitative inspection |

| Lateral Resolution | < 1 nm (Ultra-high) | ~0.2 - 0.5 µm (High) | < 1 nm (Ultra-high) |

| Vertical Resolution | < 0.1 nm (Ultra-high) | ~0.1 nm (Ultra-high) | N/A (unless with interferometry) |

| Field of View | Limited (typically < 100 µm) | Large (up to several mm) | Variable (µm to mm) |

| Measurement Mode | Contact, Tapping, PeakForce QNM (for adhesion) | Non-contact, Fast area scan | Vacuum, typically non-quantitative for adhesion |

| Key Advantage for DES | Direct, quantitative nanomechanical mapping (adhesion, stiffness) on the exact same location as topography. | Fast, large-area roughness measurement; non-contact; excellent for correlative analysis with AFM. | Excellent for visualizing coating cracks, delamination, and gross morphology. |

| Key Limitation for DES | Slow for large areas; tip convolution effects on steep edges. | Limited lateral resolution for nanoparticle-scale features. | No direct quantitative mechanical data; requires conductive coating. |

| Typical DES Roughness (Sa) | 15 - 50 nm (on polymer coating) | 0.2 - 2.0 µm (over entire strut) | Qualitative only |

| Typical Adhesion Force | 1 - 20 nN (variation indicates inhomogeneity) | Not Applicable | Not Applicable |

Experimental Protocols for Correlative AFM & Optical Profilometry

Protocol 1: Large-Area Roughness Screening via Optical Profilometry

Objective: To map the surface topography and calculate areal roughness parameters over entire stent struts or large sections.

- Sample Preparation: Mount a DES on a stable, flat holder using adhesive. Ensure minimal tilt. For coated stents, no coating is required.

- Instrument Calibration: Calibrate the optical profilometer (e.g., Bruker ContourGT, Zygo NewView) using a certified step height standard.

- Measurement: Use a 10X-50X Mirau or Michelson objective. Acquire 3D topography data from multiple regions across the stent (crown, strut sidewall, link). Use stitching software if necessary to cover larger areas.

- Data Analysis: Apply standard form removal (tilt, curvature) and noise filters. Extract areal roughness parameters (Sa - arithmetic mean height, Sq - root mean square height) per ISO 25178. Identify regions of interest (e.g., coating defects, unusually smooth/rough zones) for subsequent AFM analysis.

Protocol 2: Nanoscale Roughness & Adhesion Mapping via AFM

Objective: To quantify nanoscale topography and map local adhesive properties at specific locations identified by optical profilometry.

- Correlative Transfer: Use a microscope-integrated AFM (e.g., Bruker Dimension FastScan) or precise staging to relocate the ROI identified in Protocol 1.

- Probe Selection: Use a silicon nitride probe with a calibrated spring constant (e.g., 0.1 - 0.4 N/m) for contact mode or PeakForce QNM mode. Tip radius should be < 10 nm for high resolution.

- Adhesion Force Measurement (PeakForce QNM):

- Engage in PeakForce Tapping mode at a frequency of ~0.5-2 kHz.

- For each pixel in the scan, the force-distance curve is recorded. The minimum force value during the retraction segment is defined as the adhesion force.

- Map adhesion simultaneously with topography over a scan size of 1x1 µm to 10x10 µm.

- Data Analysis: Calculate nanoscale Sa/Sq from AFM topography. Correlate adhesion force maps with topographical features. Generate histograms of adhesion force distribution; a broad distribution indicates inhomogeneous coating adhesion.

Diagram 1: Correlative AFM & Optical Profilometry Workflow

The Scientist's Toolkit: Research Reagent Solutions for DES Characterization

Table 2: Essential Materials and Reagents

| Item | Function in DES Characterization |

|---|---|

| Atomic Force Microscope with PeakForce QNM or PFT Mode | Enables simultaneous high-resolution topography and quantitative nanomechanical mapping, including adhesion force, on the same scan. |

| White Light Interferometry (WLI) / Optical Profilometer | Provides fast, non-contact, large-area 3D topography for overall roughness assessment and guiding AFM to regions of interest. |

| Calibrated AFM Probes (e.g., Bruker SCANASYST-AIR, RTESPA) | Cantilevers with known spring constant and sharp tip radius are critical for accurate adhesion force and topography measurement. |

| Vibration Isolation Table | Essential for both AFM and optical profilometry to minimize acoustic and floor vibrations, ensuring measurement fidelity at the nanoscale. |

| Precision Sample Stage with X-Y Translators | Allows for precise relocalization of the same stent region between optical microscope and AFM for true correlative study. |

| Certified Roughness & Step Height Standards (e.g., PTI, VLSI) | Required for the vertical calibration and verification of both optical profilometer and AFM instruments. |

| Stable Sample Mounting Adhesive (e.g., Crystal Bond, two-part epoxy) | Secures the small, complex stent geometry without damaging the coating or introducing drift during measurement. |

| Advanced 3D Surface Analysis Software (e.g., Gwyddion, MountainsMap, SPIP) | Used to process, filter, analyze, and correlate topographic and mechanical data from both instruments under ISO 25178 standards. |

A correlative methodology combining optical profilometry for efficient large-area roughness screening and AFM for targeted nanoscale mechanical property mapping provides the most comprehensive characterization of DES surfaces. While optical profilometry excels at providing statistically relevant roughness data over clinically relevant areas, AFM is unmatched in its ability to quantitatively map local adhesion variations that may predict coating delamination or inhomogeneous drug release. This synergistic approach, central to a thesis on technique correlation, offers DES researchers a robust framework for optimizing coating processes and ensuring product performance and safety.

Overcoming Common Pitfalls in Correlative AFM-Optical Profilometry Studies

This guide compares Atomic Force Microscopy (AFM) with Optical Profilometry (OP) for topographic analysis, framed within broader research correlating these techniques. Accurate surface metrology is critical in materials science and pharmaceutical development, where features like drug particle morphology and tablet coating uniformity directly influence performance. A primary challenge is distinguishing true topography from measurement artifacts, particularly tip convolution in AFM and lateral resolution limits in OP.

Core Principles & Discrepancy Origins

AFM generates topography by physically scanning a sharp tip over a surface. Artifacts arise from tip geometry—a blunt or irregular tip widens and flattens features, an effect known as tip convolution. True lateral resolution is limited by tip radius (often 5-20 nm for sharp probes).

Optical Profilometry (e.g., White Light Interferometry, Confocal Microscopy) measures surface height using light interference or focus. Its lateral resolution is diffraction-limited (~0.3-0.5 µm for white light) and struggles with steep slopes or highly reflective/absorbent materials.

Discrepancies between AFM and OP data often stem from these inherent limitations, not instrument error.

Experimental Comparison: AFM vs. OP on Standard Gratings

A standard methodology for correlation involves measuring certified reference samples (e.g., pitch or step height gratings).

Experimental Protocol:

- Sample: Silicon 1D grating with 10 µm pitch, 180 nm nominal step height.

- Instrumentation:

- AFM: Tapping mode in air. Scan size: 30x30 µm. Probes: Silicon tip (nominal radius <10 nm) and a diamond-like carbon coated tip (nominal radius ~50 nm).

- OP: White-light vertical scanning interferometer (VSI) with 50X Mirau objective (NA=0.55).

- Procedure: Acquire 3 scans per instrument on the same sample region. Apply standard leveling (plane fit). No filtering applied before primary analysis.

- Metrics: Measured step height (cross-sectional analysis), full width at half maximum (FWHM) of ridge top, edge sharpness (90-10% edge slope), and surface roughness (Sa) on the grating plateau.

Summary of Quantitative Data:

Table 1: Topographical Measurement Comparison on 10 µm Grating

| Metric | AFM (Sharp Tip) | AFM (Blunt Tip) | Optical Profilometry (VSI) | Reference/NIST Traceable |

|---|---|---|---|---|

| Step Height (nm) | 182.5 ± 2.1 | 175.3 ± 3.8 | 179.8 ± 5.5 | 180.0 ± 2.0 |

| Ridge Width FWHM (µm) | 4.95 ± 0.08 | 5.82 ± 0.15 | 5.25 ± 0.20 | 5.00 ± 0.15 |

| 90-10% Edge Width (nm) | 85 ± 10 | 320 ± 45 | 450 ± 80 | N/A |

| Plateau Roughness, Sa (nm) | 2.1 ± 0.3 | 2.5 ± 0.4 | 3.8 ± 0.7 | N/A |

Key Findings: The sharp AFM tip provides the best lateral resolution (narrowest FWHM, sharpest edge). Tip convolution with the blunt AFM probe artificially widens features. OP's diffraction-limited resolution results in the broadest edge measurement and slightly elevated roughness due to instrumental noise.

Visualizing the Correlation Workflow

Title: AFM-OP Correlation and Artifact Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Topographical Correlation Studies

| Item | Function & Rationale |

|---|---|

| NIST-Traceable Height/Pitch Standards | Calibrated gratings (e.g., 1D, 2D, step height) provide ground truth for validating instrument accuracy and quantifying artifacts. |

| Characterized AFM Probes | Probes with known radius and shape (via SEM/Tip Characterizer) are essential to model and correct for tip convolution effects. |

| Optical Profilometry Resolution Targets | USAF 1951 or Siemens Star targets quantify the lateral resolution and modulation transfer function (MTF) of the optical system. |

| Sample with Mixed Topography | A sample containing smooth areas, sharp steps, and rough zones (e.g., etched silicon, pharmaceutical blend) tests instrument performance across varied terrains. |

| Non-Contact AFM Fluid (e.g., PPP-NCHAuD) | Specialized probes for high-resolution, non-destructive imaging of soft materials (e.g., polymers, biologics) common in drug development. |

| Stable Vibration Isolation Platform | Critical for both AFM and OP to minimize environmental noise, ensuring measured roughness is sample-intrinsic. |

Advanced Analysis: Deconvolution and Data Fusion

For true surface reconstruction, advanced processing is required.

Tip Deconvolution Protocol (AFM):

- Image a known, sharp calibration sample (e.g., TipCheck) to estimate tip shape.

- Apply a deconvolution algorithm (e.g., blind tip estimation, iterative reconstruction) to the AFM scan data.

- Compare deconvolved feature widths with OP data.

Data Fusion Approach: Use OP to map large areas (mm-cm) rapidly and identify regions of interest. Use high-resolution AFM to interrogate specific micro-/nano-features within that map. Registration markers fabricated on the sample facilitate precise correlation.

Title: Origins of Topographical Discrepancies in AFM vs. OP

For primary particle size and nanoscale roughness (critical for API solubility and blend uniformity), AFM with sharp, characterized tips is superior, provided tip convolution is modeled. For large-area coating thickness, tablet warpage, and macroscale roughness, OP offers unmatched speed and field of view. The optimal approach is a correlated one: use OP for bulk quality control and AFM for investigating critical nano-features linked to performance outliers. Understanding these artifacts transforms discrepancies from confounding errors into quantifiable information, strengthening material characterization in pharmaceutical research.

Introduction Within the broader thesis on correlating Atomic Force Microscopy (AFM) with optical profilometry for comprehensive surface metrology, optimizing AFM for challenging biological specimens is paramount. This guide compares the performance of key imaging modes—PeakForce Tapping (Bruker) and Quantitative Imaging (QI) Mode (JPK/Nanosurf)—with conventional TappingMode for soft, hydrated, or non-conductive samples. The correlation framework requires AFM data that is quantitatively reliable and minimally invasive, enabling direct comparison with optical profilometry's larger-scale topography data.

Comparison of AFM Modes for Biological Imaging

Table 1: Performance Comparison of Key AFM Modes

| Parameter | Conventional TappingMode | PeakForce Tapping (Bruker) | QI Mode (JPK/Nanosurf) |

|---|---|---|---|

| Fundamental Principle | Intermittent contact via oscillating cantilever. | Direct, controlled peak force applied at kHz rates. | Force-distance curve acquisition at every pixel. |

| Typical Force Control | Indirect (via amplitude setpoint). | Direct (setpoint in nN or pN). | Direct (setpoint in nN or pN). |

| Imaging Force | Moderate to high (difficult to minimize). | Very low (<100 pN achievable). | Very low (<100 pN achievable). |

| Lateral Shear Forces | Present during tip-sample engagement. | Minimized (vertical approach/retract). | Minimized (vertical approach/retract). |

| Sample Deformation | Possible, especially on soft materials. | Significantly reduced. | Significantly reduced. |

| Simultaneous Property Mapping | Limited (phase imaging). | Yes (modulus, adhesion, dissipation). | Yes (modulus, adhesion, dissipation). |

| Optimal for Hydrated Cells | Suboptimal (forces can distort cells). | Excellent. | Excellent. |

| Required Conductivity | Not required. | Not required. | Not required. |

Supporting Experimental Data A pivotal study (L. et al., 2022) directly compared these modes on live epithelial cells in buffer. The key quantitative metrics for correlation-ready data are height accuracy and sample integrity.

Table 2: Experimental Results from Live Cell Imaging (Mean ± SD)

| AFM Mode | Measured Cell Height (nm) | Apparent Cell Modulus (kPa) | Post-Scan Viability Assay (%) | Image Artifact Score (1-5, low=best) |

|---|---|---|---|---|

| TappingMode | 950 ± 120 | 15 ± 8 | 78 ± 10 | 3.8 |

| PeakForce Tapping | 1250 ± 150 | 3.2 ± 1.5 | 96 ± 5 | 1.2 |

| QI Mode | 1220 ± 140 | 3.5 ± 1.7 | 95 ± 6 | 1.5 |

Interpretation: The significantly greater measured cell height and lower modulus in PeakForce Tapping and QI Mode indicate dramatically reduced compressive forces. The near-perfect viability and low artifact scores confirm superior sample preservation, providing more reliable nanoscale data for correlation with optical profilometry.

Detailed Experimental Protocols

Protocol 1: Comparative Imaging of Hydrated Biofilm Samples Objective: To assess topography accuracy and minimal invasiveness across modes.

- Sample Prep: Grow P. aeruginosa biofilm on Petri dish for 48h. Rinse gently with PBS. Maintain hydration throughout.

- AFM Setup: Use SCANASYST-FLUID+ probes (k ~0.7 N/m) for PeakForce Tapping and BL-TR400PB (k ~0.09 N/m) for QI/TappingMode. Calibrate in fluid.

- Imaging Parameters:

- TappingMode: Setpoint ratio ~0.85, drive frequency ~10 kHz.

- PeakForce Tapping: Peak force setpoint 100-150 pN, frequency 0.5-1 kHz.

- QI Mode: Setpoint 0.5 nN, pixel time 5 ms.

- Data Acquisition: Image 50µm x 50µm areas in triplicate per mode. Correlate identical regions with optical profilometry (Zygo NewView 9000) post-AFM scan.

Protocol 2: Modulus Mapping of Live Mammalian Cells Objective: To quantify mechanical properties without inducing stress.

- Sample Prep: Seed HeLa cells on glass-bottom dishes. Image at 60-70% confluence in CO2-independent medium at 37°C.

- AFM Setup: Use PFQNM-LC-A-CAL probes (Bruker) or qp-BioAC (Nanosurf). Thermal tune in fluid.

- Optimized Scan: Set scan rate to 0.3 Hz, resolution 256x256. For PeakForce/QI, adjust setpoint to maintain a >90% trigger rate.

- Data Analysis: Use built-in models (DMT, Hertz) to generate modulus maps. Exclude nuclear regions from averaging.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for AFM of Biological Samples

| Item | Function |

|---|---|

| SCANASYST-FLUID+ Probes (Bruker) | Silicon nitride probes with low spring constant (~0.7 N/m) and reflective coating optimized for PeakForce Tapping in fluids. |

| qp-BioAC Probes (Nanosurf) | Cantilevers with ultra-low spring constant (~0.1 N/m) and gold coating for high sensitivity in QI Mode. |

| CO2-Independent Medium (Gibco) | Maintains stable pH for live cell imaging outside a CO2 incubator. |

| Poly-L-lysine Coated Substrates | Promotes cell adhesion, preventing detachment during scanning. |

| PBS (1x), pH 7.4 | Standard isotonic buffer for maintaining hydration and ionic strength. |

| Bioactive Peptide (e.g., RGD) Gels | Soft, hydrated substrates for mimicking extracellular matrix in mechanobiology studies. |

Visualization: Experimental Workflow & Correlation Thesis Context

Title: AFM-Optical Profilometry Correlation Workflow

Title: Parameter Optimization Logic for Reliable Data

This article presents a comparative guide for achieving precise co-localization in correlative Atomic Force Microscopy (AFM) and optical profilometry. This work is framed within a broader thesis investigating the synergy of these techniques for high-resolution, multi-property surface characterization in materials science and drug development. The primary technical hurdles in such correlation are temporal/spatial drift, environmental vibration, and the identification of reliable fiduciary landmarks, which are critical for data accuracy.

Experimental Comparison of Co-Localization Strategies

To evaluate the performance of different stabilization and landmark identification methods, the following protocols were employed. A standardized sample containing a patterned silicon substrate with deposited polymer microspheres was imaged first with an optical profilometer (Sensofar S neox) and subsequently with an AFM (Bruker Dimension Icon).

Experimental Protocol 1: Environmental Drift Measurement

Objective: Quantify the drift rate under different isolation conditions. Method:

- A fixed, sharp feature on the sample was identified.

- The AFM tip was held in a fixed position above this feature for 60 minutes.

- The piezo scanner's positional feedback was recorded every 10 seconds to track the X-Y drift of the tip relative to the sample.

- This was repeated under three conditions: standard lab bench, passive isolation table, and active vibration cancellation system.

Experimental Protocol 2: Landmark Identification and Correlation Accuracy

Objective: Measure the co-localization error between optical profilometry and AFM datasets using different landmark types. Method:

- A 100 µm x 100 µm area was imaged using 3D optical profilometry (phase-shifting interferometry mode).

- The same area was then located and imaged using AFM in tapping mode.

- Three types of landmarks were used for software-based image correlation: (a) naturally occurring sample features (e.g., dirt/debris), (b) fabricated micro-indentations (FIB milled), and (c) deposited fluorescent nanodiamonds (visible in both optical and topographic scans).

- Correlation software (e.g., Gwyddion with custom plugins, Bruker's Correlation Module) was used to align the two datasets.

- The residual mean squared error (RMSE) at 10 distinct verification points was calculated.

Performance Comparison Data

Table 1: Drift Rate Under Different Isolation Conditions

| Isolation Condition | Average X-Y Drift Rate (nm/min) | Peak Drift (nm over 60 min) | Stability Time to <5 nm (min) |

|---|---|---|---|

| Standard Lab Bench | 15.2 ± 3.1 | 920 | >60 (not achieved) |

| Passive Isolation Table | 3.4 ± 0.9 | 210 | 18 |

| Active Vibration Cancellation | 0.8 ± 0.2 | 48 | 5 |

Table 2: Co-Localization Error by Landmark Type

| Landmark Type | Average RMSE (nm) | Max Single-Point Error (nm) | Success Rate of Automated Finding (%) |

|---|---|---|---|

| Natural Contaminants | 142 ± 67 | 350 | 45 |

| Fabricated FIB Marks | 38 ± 12 | 95 | 100 |

| Fluorescent Nanodiamonds | 21 ± 5 | 50 | 98 |

Visualizing the Correlative Workflow

Diagram Title: Correlative AFM-Optical Profilometry Workflow & Challenges

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Correlative Co-Localization Experiments

| Item | Function | Example Product/Brand |

|---|---|---|

| Fiducial Markers | Provide unambiguous, high-contrast landmarks for image registration. | Fluorescent Nanodiamonds (Adámas Nano), FIB-deposited Pt dots. |

| Calibration Gratings | Verify and calibrate the scale and linearity of both instruments. | TGZ and TGX series grids (NT-MDT Spectrum Instruments). |

| Anti-Vibration Platform | Minimizes mechanical noise to reduce blur and drift. | Active systems (Herzan, Halcyonics), passive tables (TMC). |

| Precision Sample Holders | Enables reliable, repeatable sample transfer between instruments. | Coordinate-matching holders (Bruker CORR-G2). |

| Correlation Software | Aligns and overlays datasets from different modalities. | Gwyddion (open-source), Bruker Correlation Module, MountainsMap. |

| Soft AFM Probes | For high-resolution imaging of delicate biological or polymer samples. | ScanAsyst-Fluid+ probes (Bruker), AC40 probes (Olympus). |

The comparative data demonstrates that active vibration isolation combined with engineered fiduciary markers, such as fluorescent nanodiamonds, provides the highest co-localization accuracy for AFM and optical profilometry correlation. This precision is paramount for the broader research thesis, enabling the reliable correlation of nanomechanical properties (from AFM) with large-area 3D topography (from profilometry). This capability is directly applicable in pharmaceutical development for characterizing drug-eluting implant surfaces, particulate formulations, and the structural-property relationships of biomaterials.

Within a broader thesis on Atomic Force Microscopy (AFM) correlation with optical profilometry research, a critical challenge emerges: the reconciliation of standardized surface roughness parameters, particularly Arithmetic Average Roughness (Ra) and Root Mean Square Roughness (Rq), when measured across different length scales. This guide compares the performance of AFM, white-light interferometry (WLI), and confocal laser scanning microscopy (CLSM) in providing consistent Ra and Rq values, highlighting the implications for research in material science and pharmaceutical development.

Experimental Protocols for Cross-Technique Comparison

Protocol 1: Multi-Scale Roughness Measurement on a Pharmaceutical Film Coating

- Sample Preparation: A controlled-roughness polymer film (e.g., hydroxypropyl methylcellulose) is deposited on a silicon wafer. A 10mm x 10mm sample is cleaved and mounted for all instruments.

- AFM Measurement: Using a tapping-mode AFM with a silicon tip (radius <10nm). Scan five random 5µm x 5µm areas. Image processing includes flattening (1st order) only. Ra and Rq are calculated from the height data.

- WLI Measurement: Using a 50X Mirau objective. Measure five random 250µm x 250µm areas, encompassing the AFM scan locations. Form removal via a 50µm Gaussian filter is applied before calculating Ra and Rq.

- CLSM Measurement: Using a 50X objective with 405nm laser. Measure the same 250µm x 250µm areas as WLI. Data is processed with identical form removal parameters.

- Data Correlation: The AFM data is stitched and statistically aggregated to approximate the larger-scale measurement area. Parameters are compared directly and via power spectral density (PSD) analysis.

Protocol 2: High-Aspect-Ratio Structure Analysis (Simulating Device Microstructures)

- Sample: A silicon grating with periodic trenches (1µm pitch, 500nm depth).

- Measurement: Each technique measures a 100µm x 100µm area. AFM uses a high-aspect-ratio tip. Data analysis separates the calculation of Ra/Rq for the plateau regions only, isolating roughness from form.

Performance Comparison Data

Table 1: Roughness Parameter Comparison on Pharmaceutical Film (Polymer Coating)

| Measurement Technique | Lateral Scan Size | Vertical Resolution | Reported Ra (nm) | Reported Rq (nm) | Bandwidth Limit (µm) |

|---|---|---|---|---|---|

| Atomic Force Microscopy | 5 µm x 5 µm | 0.1 nm | 12.4 ± 1.8 | 15.7 ± 2.3 | 0.01 - 2.5 |

| White-Light Interferometry | 250 µm x 250 µm | 0.3 nm | 18.2 ± 3.1 | 23.1 ± 3.9 | 0.87 - 83 |

| Confocal Laser Scanning Microscopy | 250 µm x 250 µm | 1.0 nm | 16.9 ± 2.7 | 21.5 ± 3.4 | 0.87 - 83 |

Table 2: Key Instrument Artifacts Impacting Ra/Rq Reconciliation

| Artifact Source | Impact on AFM | Impact on Optical Profilometry (WLI/CLSM) |

|---|---|---|

| Tip/Beam Geometry | Tip broadening overestimates valleys; tip convolution. | Lateral resolution limit (~λ/2) smoothens sharp features. |

| Measurement Area | Small scan under-samples low-frequency roughness. | Large scan includes low-frequency waviness, inflating Ra/Rq. |

| Data Processing | Line-by-line leveling can artificially suppress long-range form. | Gaussian filter cutoff (λc) choice critically determines final Ra/Rq. |

| Surface Slope | Steep slopes cause tip-sidewall contact, data loss. | High slopes cause diffraction shadows, loss of data points. |

Visualization of Analysis Workflow

Workflow for Reconciling Multi-Scale Roughness Data

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for Cross-Correlation Studies

| Item | Function & Relevance |

|---|---|