Kretschmann vs Otto: A Complete Guide to SPR Configuration Selection for Biosensing and Drug Development

This comprehensive guide explores the critical distinction between Kretschmann and Otto configurations for surface plasmon resonance (SPR) sensing.

Kretschmann vs Otto: A Complete Guide to SPR Configuration Selection for Biosensing and Drug Development

Abstract

This comprehensive guide explores the critical distinction between Kretschmann and Otto configurations for surface plasmon resonance (SPR) sensing. Targeted at researchers and drug development professionals, it provides a foundational understanding of each configuration's physics, details practical methodologies and applications in biomolecular interaction analysis, offers troubleshooting and optimization strategies, and delivers a direct comparative validation of performance metrics. The article synthesizes this information to empower informed experimental design for label-free detection, binding kinetics, and novel therapeutic development.

Understanding the Core Physics: Kretschmann and Otto Configuration Fundamentals

Surface Plasmon Resonance (SPR) is a label-free, real-time optical sensing technique that exploits the evanescent wave generated under total internal reflection (TIR) to monitor molecular interactions at a metal-dielectric interface. Within the broader research context comparing Kretschmann and Otto configurations, this whitepaper serves as a technical refresher on the core principles of evanescent wave sensing underpinning both methods. This guide is intended for researchers and professionals in biophysics, biochemistry, and drug development who require a precise understanding of SPR fundamentals for experimental design and data interpretation.

Core Physical Principle: Surface Plasmons and the Evanescent Field

When p-polarized light strikes a glass prism at an angle greater than the critical angle, it undergoes TIR. Although the incident light is completely reflected, an electromagnetic field component, the evanescent wave, penetrates a short distance (typically < 200 nm) into the medium of lower refractive index. In SPR, a thin metal film (typically gold, ~50 nm) is deposited on the prism. At a specific resonance angle of incident light, the momentum of the evanescent wave couples with the free electron oscillations (plasmons) in the metal film, generating surface plasmon polaritons (SPPs). This coupling results in a sharp dip in the intensity of the reflected light.

The resonance condition is exquisitely sensitive to changes in the refractive index within the evanescent field's penetration depth. The binding of analyte molecules to ligands immobilized on the metal surface alters this local refractive index, shifting the resonance angle, which is monitored in real-time to generate a sensorgram.

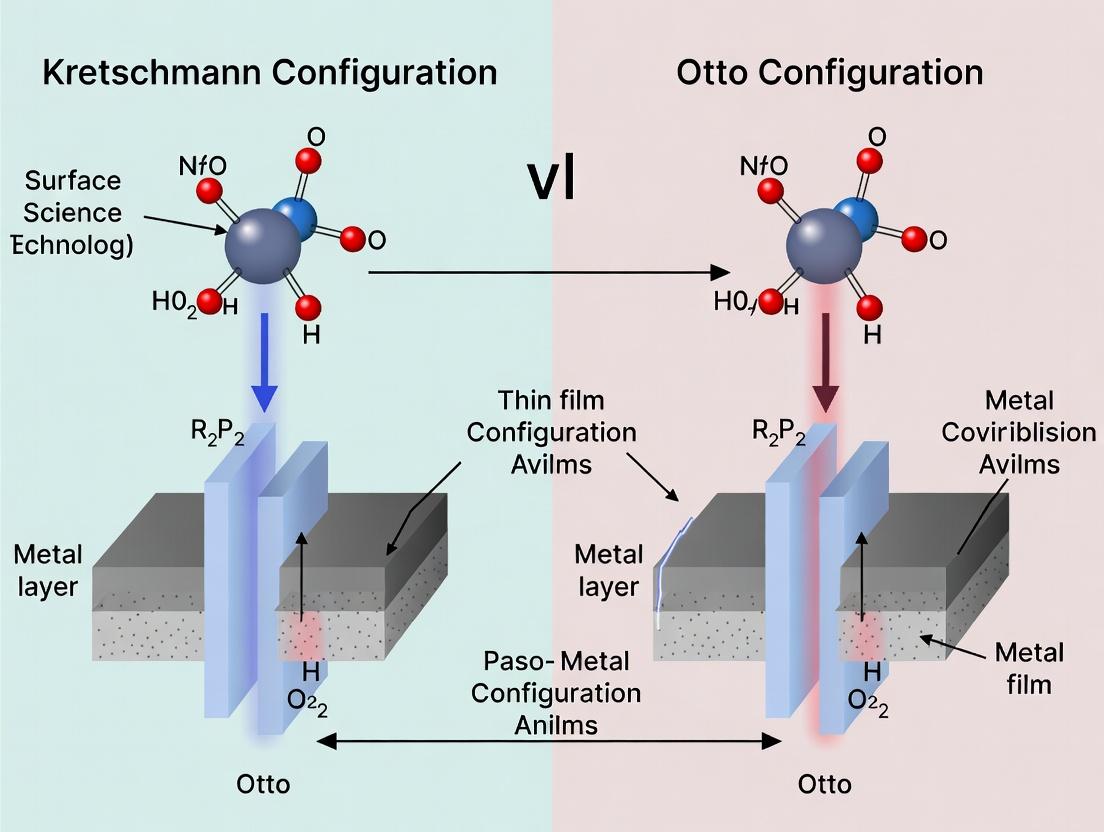

Kretschmann vs. Otto: Configurational Framework

The two primary configurations for exciting surface plasmons differ in how the evanescent field interacts with the metal layer.

Kretschmann Configuration: The metal film is deposited directly onto the prism base. The evanescent wave from the prism penetrates the thin metal film and excites surface plasmons at the outer metal-dielectric (e.g., buffer/analyte) interface. This is the most common experimental setup due to its simpler fabrication and robust fluidic handling.

Otto Configuration: A thin gap (of the order of the wavelength of light) separates the prism from the metal film. The evanescent wave traverses this gap to excite surface plasmons at the metal surface opposite the prism. This configuration is often used for studying thick films or samples where direct metal contact is undesirable but is more challenging to implement experimentally due to precise gap control requirements.

Table 1: Core Comparison of Kretschmann and Otto Configurations

| Parameter | Kretschmann Configuration | Otto Configuration |

|---|---|---|

| Metal Film Placement | Directly on prism surface | Separate from prism, with a defined gap |

| Typical Gap | N/A (direct contact) | ~λ, precisely controlled (e.g., 500-1000 nm) |

| Primary Application | Study of interactions at metal-liquid interface (bio-sensing) | Study of thick dielectric coatings or air/metal interfaces |

| Experimental Complexity | Relatively simple, robust | High, requires precise mechanical alignment |

| Sensitivity | High | Can be higher for specific dielectric studies |

| Common Use in Biosensing | Dominant | Rare |

Quantitative Data and Key Parameters

Table 2: Key Quantitative Parameters in SPR Sensing

| Parameter | Typical Range/Value | Description & Impact |

|---|---|---|

| Penetration Depth (Ev. Wave) | 100 - 200 nm | Decay length into sensing medium. Defines sensing volume. |

| Metal Film Thickness (Au) | 45 - 55 nm | Optimal for maximal coupling efficiency in Kretschmann config. |

| Resonance Angle Shift | 0.1° ≈ 10⁻³ - 10⁻⁶ RIU | Angular shift per refractive index unit (RIU) change. Core measurable output. |

| Detection Limit (Mass) | ~0.1 - 1 pg/mm² | Minimum detectable mass change on sensor surface. |

| Assay Kinetics Range | kₐ: 10³ - 10⁷ M⁻¹s⁻¹, k_d: 10⁻¹ - 10⁻⁵ s⁻¹ | Measurable association (kₐ) and dissociation (k_d) rate constants. |

| Flow Rate (Typical) | 10 - 100 µL/min | Standard for continuous flow systems to control mass transport. |

Detailed Experimental Protocol: Ligand-Amine Coupling and Analyte Binding

This protocol outlines a standard amine-coupling procedure for immobilizing a protein ligand on a CM5 (carboxymethylated dextran) sensor chip in a Kretschmann-configuration SPR instrument (e.g., Biacore series).

Materials:

- SPR instrument with continuous flow system.

- CM5 sensor chip.

- Running Buffer: HBS-EP (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% v/v Surfactant P20, pH 7.4).

- Activation Solutions: 0.4 M EDC (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide) and 0.1 M NHS (N-hydroxysuccinimide).

- Ligand Solution: Target protein in low-sodium acetate buffer (pH 4.0-5.0, optimized for isoelectric point).

- Blocking Solution: 1.0 M ethanolamine hydrochloride-NaOH, pH 8.5.

- Regeneration Solution: 10 mM glycine-HCl, pH 2.0-3.0 (or as optimized).

- Analyte Solutions: Serial dilutions in running buffer.

Procedure:

- System Startup: Prime the instrument with filtered and degassed running buffer.

- Baseline Stabilization: Dock the CM5 chip and run buffer over all flow cells at the intended operating temperature until a stable baseline is achieved.

- Surface Activation: Inject a 1:1 mixture of EDC and NHS (typical injection volume: 35 µL, flow rate: 10 µL/min) over the target flow cell(s). This converts carboxyl groups to reactive NHS esters.

- Ligand Immobilization: Immediately inject the ligand solution (typical concentration: 10-100 µg/mL in appropriate acetate buffer) over the activated surface. Monitor the response increase until the desired immobilization level (Response Units, RU) is reached.

- Deactivation/Blocking: Inject ethanolamine solution (typical injection: 35 µL) to block remaining activated esters.

- Reference Surface Creation: Use a separate flow cell activated and blocked without ligand injection, or immobilized with a non-interacting protein, for reference subtraction.

- Analyte Binding Analysis: Inject analyte solutions at varying concentrations (serial 2-fold dilutions) over ligand and reference surfaces (association phase, 60-180 s). Follow with a switch to running buffer to monitor dissociation (120-300 s). Use a flow rate of 30 µL/min to minimize mass transport limitation.

- Surface Regeneration: Inject regeneration solution (typically 10-30 s pulse) to remove bound analyte without damaging the ligand. Re-equilibrate with running buffer.

- Data Analysis: Subtract reference flow cell data. Fit the resulting sensorgrams to a 1:1 Langmuir binding model or other appropriate model to determine kinetic constants (kₐ, kd) and the equilibrium dissociation constant (KD = k_d/kₐ).

Visualizing the SPR Experimental Workflow

Diagram Title: SPR Biosensor Experimental Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for SPR Biosensing

| Item / Reagent | Function & Rationale |

|---|---|

| CM5 Sensor Chip | Gold surface with a covalently attached carboxymethylated dextran hydrogel. Provides a hydrophilic matrix for ligand immobilization, reduces non-specific binding, and increases loading capacity. |

| HBS-EP Running Buffer | Standard buffered saline with EDTA and surfactant. Maintains pH and ionic strength, chelates divalent cations, and minimizes non-specific binding via surfactant P20. |

| EDC & NHS | Cross-linking reagents for amine coupling. EDC activates carboxyl groups, NHS forms stable amine-reactive esters for efficient ligand coupling. |

| Ethanolamine-HCl | Blocking agent. Deactivates excess NHS esters after immobilization to prevent non-specific binding. |

| Low pH Acetate Buffer | Ligand dilution buffer (pH 4.0-5.5). Creates optimal electrostatic pre-concentration of positively charged proteins to the negatively charged dextran matrix for high immobilization efficiency. |

| Glycine-HCl (pH 1.5-3.0) | Regeneration solution. Low pH disrupts protein-protein interactions, stripping bound analyte to regenerate the ligand surface for subsequent cycles. Must be optimized for each interaction. |

| Series S Sensor Chips | A range of specialized surfaces (e.g., NTA for His-tag capture, streptavidin for biotinylated ligands, lipid surfaces for membrane protein studies). Provides flexibility for diverse immobilization strategies. |

| Pioneer Chips (J1, F1) | Bare gold (J1) or flat hydrophobic (F1) surfaces. Used for capturing lipid monolayers/bilayers or for custom surface chemistry, essential for studying membrane-associated interactions. |

The Kretschmann configuration is a predominant method for exciting surface plasmon polaritons (SPPs) on a thin metallic film, forming the cornerstone of modern label-free biosensing platforms like Surface Plasmon Resonance (SPR). Within the broader thesis comparing Kretschmann and Otto configurations for advanced sensing applications, this guide details the core principles, implementation, and protocols of the Kretschmann approach. The Otto configuration, which utilizes an air gap between a prism and a bulk metal surface, offers advantages in avoiding direct metal contact with analytes but suffers from precise gap control challenges. In contrast, the Kretschmann configuration's direct deposition of a thin metal film onto the prism coupling element provides robust, reproducible experimental setups ideal for high-throughput drug development research, albeit with potential for metal film degradation. This whitepaper focuses on the Kretschmann method as the industry standard for real-time, kinetic binding analysis.

Surface plasmon polaritons are electromagnetic waves coupled to electron charge density oscillations propagating along a metal-dielectric interface. Their excitation requires momentum matching between the incident photon and the SPP. For a given metal and dielectric, the SPP wavevector (k{SPP}) is greater than that of a free-space photon (k0).

The Kretschmann configuration achieves this momentum matching via total internal reflection (TIR) in a high-index prism (e.g., SF10 glass, BK7) coated with a thin (≈50 nm) noble metal film (typically gold). Under TIR, the incident light evanescently tunnels through the metal film. At a specific angle of incidence ((\theta{SPR})) greater than the critical angle, the component of the incident wavevector parallel to the interface (kx = \frac{2\pi}{\lambda} np \sin(\theta{SPR})) equals the real part of (k_{SPP}), resulting in resonant energy transfer to the surface plasmon. This manifests as a sharp minimum in the intensity of reflected light (the SPR dip).

Quantitative Data and Material Properties

The performance is governed by material optical constants and geometry. Key parameters are summarized below.

Table 1: Common Prism and Metal Film Materials

| Material | Refractive Index (n) @ 633 nm | Function | Key Property |

|---|---|---|---|

| BK7 Glass | 1.515 | Coupling Prism | High optical quality, cost-effective |

| SF10 Glass | 1.723 | Coupling Prism | Higher index, greater momentum enhancement |

| Gold (Au) | 0.172 + i·3.421 (ε) | Plasmonic Layer | Biologically inert, sharp resonance |

| Silver (Ag) | 0.055 + i·3.32 (ε) | Plasmonic Layer | Sharper resonance but oxidizes easily |

| Chromium (Cr) / Titanium (Ti) | - | Adhesion Layer | ~1-2 nm, improves Au adhesion to glass |

Table 2: Typical Kretschmann Configuration Parameters (λ=633 nm, Au/Water)

| Parameter | Typical Value | Impact on Resonance |

|---|---|---|

| Prism Index (n_p) | 1.515 - 1.723 | Higher np increases (kx), shifting (\theta_{SPR}) lower |

| Gold Film Thickness | 47 - 52 nm | Optimizes coupling efficiency (min. reflectance) |

| Adhesion Layer Thickness | ≤ 2 nm | Thicker layers broaden and dampen the resonance |

| Incident Wavelength (λ) | 633 nm (He-Ne), 760-850 nm (LED) | Longer λ shifts (\theta_{SPR}) higher, alters sensitivity |

| Sensitivity (Δθ/Δn) | ~80-120 °/RIU* | Angular shift per Refractive Index Unit change |

Detailed Experimental Protocols

Protocol 1: Substrate Preparation and Metal Deposition

Objective: Fabricate a sensor chip with a thin gold film on a prism or microscope slide. Materials: Cleaning piranha solution, Thermal evaporator or sputter coater, Quartz crystal microbalance, BK7 prism or glass slide, Gold wire (99.999%), Chromium pellets. Method:

- Substrate Cleaning: Sonicate substrate in acetone and isopropanol for 10 min each. Treat with fresh piranha solution (3:1 H₂SO₄:H₂O₂) for 1 min. CAUTION: Piranha is highly corrosive. Rinse thoroughly with deionized water and dry under N₂ stream.

- Metal Deposition: Place cleaned substrate in deposition chamber. Pump to high vacuum (<5×10⁻⁶ Torr).

- Adhesion Layer: Thermally evaporate a 1-2 nm chromium layer at 0.1-0.2 Å/s.

- Gold Layer: Immediately evaporate a 48 nm gold layer at a rate of 0.5 Å/s. Monitor thickness with a calibrated quartz crystal microbalance.

- Storage: Store fabricated chips in a clean, dry nitrogen environment. Use within 2 weeks for optimal performance.

Protocol 2: Angular Interrogation SPR Measurement

Objective: Measure the SPR angle shift upon analyte binding to a functionalized sensor surface. Materials: Kretschmann-configured SPR instrument, Microfluidic flow cell, Peristaltic pump, Running buffer (e.g., HEPES Buffered Saline), Analyte samples, Data acquisition software. Method:

- Instrument Alignment: Mount the gold-coated prism on the TIR stage of the SPR instrument using index-matching fluid. Align the optical train to achieve a collimated, p-polarized beam at the prism base.

- Fluidic Setup: Attach a clean microfluidic flow cell to the gold surface. Connect inlet/outlet tubing to a peristaltic pump and buffer reservoirs.

- Baseline Acquisition: Flow running buffer at a constant rate (e.g., 20 µL/min). Perform an angular scan (e.g., 55° to 75°) to locate the precise SPR dip minimum. Set the instrument to monitor reflectance at a fixed angle near the dip's inflection point for kinetic measurements.

- Ligand Immobilization: Functionalize the gold surface (e.g., via a self-assembled thiol monolayer). Inject ligand solution (10-100 µg/mL in running buffer) until saturation binding is observed.

- Kinetic Measurement: Inject a series of analyte concentrations (in running buffer) across the sensor surface for 3-5 minutes (association phase), followed by running buffer alone for 5-10 minutes (dissociation phase). Regenerate the surface if necessary (e.g., with mild acid or chaotropic agent).

- Data Analysis: Fit the resulting sensorgrams (reflectance vs. time) with a 1:1 Langmuir binding model using the instrument's software to extract association ((ka)) and dissociation ((kd)) rate constants, and the equilibrium dissociation constant ((KD = kd/k_a)).

Visualization: Experimental Workflow and Signal Generation

Diagram 1: Kretschmann SPR Experimental Setup

Diagram 2: Momentum Matching & Resonance Dip Generation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Kretschmann SPR Biosensing

| Item | Function & Rationale |

|---|---|

| High-Index Prism (SF10 or BK7) | Provides the necessary momentum enhancement via TIR to match the SPP wavevector. |

| Gold-Coated Sensor Chips (≈50 nm Au) | Standard plasmonic substrate; can be pre-functionalized with various chemistries (e.g., carboxyl, streptavidin). |

| Index-Matching Fluid (Cargille Labs) | Eliminates air gaps between prism and sensor chip, ensuring optimal optical coupling. |

| Piranha Solution (H₂SO₄/H₂O₂) | Extreme Hazard. Creates a clean, hydrophilic, and oxide-free glass surface prior to metal deposition. |

| Alkanethiol Self-Assembled Monolayers (SAMs) | Form a stable, ordered layer on gold (via Au-S bond) for presenting ligand capture sites (e.g., COOH for EDC/NHS coupling). |

| EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) & NHS (N-Hydroxysuccinimide) | Crosslinkers for activating carboxylated surfaces to immobilize amine-containing ligands (proteins, peptides). |

| Running Buffer (e.g., HBS-EP: 10mM HEPES, 150mM NaCl, 3mM EDTA, 0.005% v/v Surfactant P20) | Maintains pH and ionic strength; surfactant reduces non-specific binding. |

| Regeneration Solutions (e.g., 10mM Glycine-HCl pH 2.0-3.0, 10-50mM NaOH) | Gently dissociates bound analyte from ligand to regenerate the sensor surface for repeat measurements. |

| Kinetic Analysis Software (e.g., Biacore Evaluation Software, TraceDrawer) | Fits sensorgram data to binding models to extract kinetic ((ka), (kd)) and affinity ((K_D)) parameters. |

Within the field of surface plasmon resonance (SPR) spectroscopy, the prism-coupled Otto and Kretschmann configurations represent the two foundational attenuated total reflection (ATR) geometries for exciting surface plasmon polaritons (SPPs). The broader thesis of comparative research centers on their respective applications in sensing, particularly for biomolecular interactions critical to drug development. While the Kretschmann configuration, with its thin metal film deposited directly on the prism, is the industry standard for biosensing, the Otto configuration—which employs an air or dielectric gap between the prism and the metal layer—offers distinct advantages for specialized scenarios. This guide demystifies the Otto configuration, detailing its principles, implementation, and niche applications where it surpasses the Kretschmann approach, particularly in studying delicate or rigid samples where metal film integrity is paramount.

Core Principles & Quantitative Comparison

The fundamental operation of both configurations relies on the ATR method to provide the necessary momentum matching (wavevector) to excite SPPs at a metal-dielectric interface. The key distinction lies in the architecture of the coupling region.

| Parameter | Otto Configuration | Kretschmann Configuration | |||||

|---|---|---|---|---|---|---|---|

| Coupling Geometry | Prism | Air/Gap | Metal Film | Analyte | Prism | Metal Film | Analyte |

| Metal Contact | No direct contact with prism. | Direct deposition on prism base. | |||||

| Typical Gap (d) | ~λ/4 to > 1 μm (tunable). | Metal film thickness ~50 nm (fixed). | |||||

| Field Penetration | Strong evanescent field across gap. | Evanescent field in analyte. | |||||

| Key Advantage | Protects metal surface; studies solids, crystals, or sensitive films. | Robust, easier to implement; standard for liquid-phase biosensing. | |||||

| Primary Disadvantage | Precise gap control is critical and challenging. | Metal film can degrade; not suitable for all solid samples. | |||||

| Typical Refractive Index Range (Analyte) | Best for lower-index analytes (gases, thin adsorbates). | Broad range, optimized for aqueous solutions. | |||||

| Sensitivity (Angular, Δθ/ΔRIU) | ~50-150 °/RIU (highly gap-dependent). | ~50-120 °/RIU. |

Detailed Experimental Protocol for Otto Configuration Setup

Objective: To construct an Otto configuration SPR setup for characterizing a solid crystalline sample.

Materials & Reagent Solutions:

| Item | Function |

|---|---|

| High-Index Prism (e.g., SF10 glass) | Provides incident light coupling for momentum matching. |

| Precision XYZ & Goniometric Stage | Enables nanometer-scale gap control and angular scanning. |

| Laser Source (λ = 632.8 nm He-Ne typical) | Monochromatic, p-polarized light source. |

| Photodetector | Measures intensity of reflected light. |

| Index-Matching Oil | Eliminates air gaps between prism and mounting stage. |

| Gold or Silver Film Sample (on rigid substrate) | The plasmon-active metal layer. |

| Piezoelectric Actuators or Spacer Micrometer | For precise control of the air/dielectric gap distance. |

| Sample Alignment Fixture | Holds metal sample parallel to prism base. |

Methodology:

- Prism Mounting: Secure the prism to the rotating stage using index-matching fluid.

- Initial Alignment: Mount the metal film sample on a separate stage opposite the prism base. Coarsely align to achieve near-parallelism.

- Gap Initialization: Using the piezoelectric actuators, establish an initial air gap of several micrometers.

- Laser Alignment: Align the p-polarized laser beam to undergo total internal reflection at the prism base.

- Angular Scan & Gap Optimization: Perform an angular scan of incident light while monitoring reflected intensity. Initially, no SPR dip will be present. Gradually decrease the gap distance (d) in sub-100 nm steps, performing a scan after each adjustment. The SPR resonance dip (reflectivity minimum) will appear, deepen, and then broaden as d approaches the optimal value (typically λ/4 to λ/2). The process is iterative until a sharp, deep resonance is observed.

- Data Collection: With the gap fixed at the optimal distance, perform a high-resolution angular scan to record the reflectivity curve. Introduce the analyte (e.g., a gas) to the gap region and monitor the shift in the resonance angle (Δθ).

Visualizing the Comparative Workflow

Title: Decision Flow: Choosing Between Otto and Kretschmann Configurations

The Scientist's Toolkit: Key Reagent Solutions & Materials

| Category | Item | Specific Example/Function |

|---|---|---|

| Coupling Components | High-Index Prisms | SF10, BK7 with high-index coating; enables momentum matching. |

| Index-Matching Fluid | Cargille Labs oils; eliminates parasitic reflections. | |

| Metal Films | Pre-fabricated Substrates | Gold (50nm)/Chromium(2nm) on silica wafers for Otto geometry. |

| Evaporation/Sputtering Targets | 99.999% pure Au, Ag for in-house Kretschmann film creation. | |

| Probe Molecules | Functionalization Kits | Thiol-PEG-carboxyl for Au surface ligand immobilization. |

| Model Analytes | Bovine Serum Albumin (BSA), Immunoglobulin G (IgG) for binding assays. | |

| Buffer & Regeneration | Running Buffer | HEPES Buffered Saline (HBS-EP) with surfactant for microfluidics. |

| Regeneration Solution | Glycine-HCl (pH 2.0) or SDS for chip surface regeneration. | |

| Gap Control | Piezoelectric Nanopositioners | Sub-nanometer resolution for precise Otto gap adjustment. |

| Calibrated Silica Spacers | Used for fixed-gap, proof-of-concept experiments. |

Technological Advances and Application in Drug Development

Recent advances in nano-fabrication and fluidics have revived interest in the Otto configuration. Its primary drug development application lies in characterizing membrane proteins and lipid bilayers supported on solid substrates without damaging interactions with a sensor metal. By using a functionalized metal surface across a controlled gap from a cell membrane fragment, label-free binding kinetics of drug candidates can be studied in a more native environment. Furthermore, the Otto configuration is uniquely suited for gas-phase sensing and studying phase transitions in thin polymeric films, areas relevant to inhaler technology and drug delivery system design. The precise control of the gap dielectric constant allows for tuning the plasmon field profile, offering a degree of flexibility not present in the fixed Kretschmann design.

This whitepaper provides a technical guide to three interdependent parameters critical for optimizing surface plasmon resonance (SPR) sensing. The analysis is framed within a comparative research thesis on the two primary attenuated total reflection (ATR) configurations: the Kretschmann and Otto configurations. The choice between these configurations fundamentally influences the attainable resonant angle, the depth and quality of the reflectivity dip, and the electric field penetration depth into the analyte medium—parameters that directly dictate sensor sensitivity, resolution, and application suitability. This guide equips researchers with the knowledge to select and optimize the appropriate configuration for advanced applications, such as label-free biomolecular interaction analysis in drug development.

Core Parameter Definitions & Theoretical Foundation

Resonant Angle (θ_SPR)

The specific incident angle at which photon momentum couples maximally to surface plasmon polaritons (SPPs) at the metal-dielectric interface, resulting in a minimum in reflected light intensity. It is highly sensitive to the refractive index (RI) of the dielectric medium within the evanescent field.

Reflectivity Dip (ΔR)

The minimum value of reflectance at the resonant angle. Its depth (ideally reaching near zero) and width (Full Width at Half Minimum, FWHM) are indicators of coupling efficiency and plasmon resonance quality. A sharper, deeper dip correlates with higher detection accuracy.

Electric Field Penetration Depth (L_p)

The distance from the metal surface into the dielectric medium at which the evanescent electric field intensity decays to 1/e of its value at the interface. It determines the sensing volume and the size of biomolecules that can be detected effectively.

Kretschmann vs. Otto: A Comparative Framework

The core distinction lies in the interface where SPPs are excited.

- Kretschmann Configuration: A thin metal film (e.g., ~50 nm Au) is deposited directly on the prism base. The light couples through the prism and metal to excite SPPs at the metal-analyte (external) interface.

- Otto Configuration: A gap (air or dielectric) is maintained between the prism base and a thick metal film. The light couples through the prism and the gap to excite SPPs at the metal-analyte interface on the far side of the metal film.

Thesis Context: The Kretschmann configuration is the dominant choice for biosensing due to its simpler fabrication and direct contact with liquid analyte. The Otto configuration, while more challenging to align, is essential for studying plasmonics on pristine, thick metal surfaces or for analyzing highly absorbing samples where direct metal contact is undesirable. The optimal configuration is dictated by the specific experimental requirements and the trade-offs between these key parameters.

Quantitative Parameter Comparison & Data Tables

Table 1: Typical Parameter Ranges for Common Configurations (λ = 633 nm)

| Parameter | Kretschmann (50nm Au / Water) | Otto (100nm Air Gap / 50nm Au / Water) | Impact on Sensing |

|---|---|---|---|

| Resonant Angle (θ_SPR) | 70° - 75° | 41° - 45° | Determines optical setup geometry. |

| Reflectivity Min. (R_min) | < 0.01 (Near zero) | ~0.1 - 0.3 | Deeper dip = stronger coupling = better SNR. |

| Dip Width (FWHM) | 1° - 3° | 0.5° - 1.5° | Narrower width = higher angular resolution. |

| Field Penetration (L_p) | ~200 nm | ~150 - 200 nm | Deeper penetration = probes larger analytes. |

| RI Sensitivity (S_θ) | ~80 - 120 °/RIU | ~50 - 80 °/RIU | Higher is better for detecting binding events. |

| Figure of Merit (FOM=S_θ/FWHM) | ~30 - 100 RIU⁻¹ | ~60 - 120 RIU⁻¹ | Balances sensitivity and resolution. |

Table 2: Configuration Selection Guide Based on Application

| Research Objective | Recommended Configuration | Rationale Linked to Key Parameters |

|---|---|---|

| Kinetics of protein-ligand binding | Kretschmann | Robust, deep reflectivity dip for stable, real-time monitoring. |

| Detection of large cells or vesicles | Kretschmann | Larger electric field penetration depth (L_p) samples more of the analyte. |

| Study of intrinsic metal surface properties | Otto | Avoids modification of metal surface by prism adhesion layer. |

| Ultra-high spectral resolution studies | Otto | Often yields narrower resonant dips (lower intrinsic damping). |

| Sensing in conductive or corrosive liquids | Otto (with protective layer) | Metal film is isolated from the damaging analyte. |

Experimental Protocols for Parameter Characterization

Protocol 1: Measuring the Angular Reflectivity Curve

Objective: To experimentally determine θ_SPR, ΔR depth, and FWHM. Materials: SPR setup (prism, rotation stage, laser, polarizer, photodetector), sensor chip, flow cell, microfluidic pump, buffer solution. Methodology:

- Mount the sensor chip (Kretschmann: metal-coated; Otto: spaced metal film) on the prism using index-matching oil.

- Align the laser beam to the prism center and ensure p-polarization.

- Flush the flow cell with a reference buffer (e.g., PBS) to establish a baseline RI.

- Program the rotation stage to scan through a range of incident angles (e.g., 40°-80°) in small steps (e.g., 0.01°).

- Record the photodetector intensity (reflectance, R) at each angle.

- Fit the resulting R vs. θ curve with a Lorentzian or polynomial function.

- Extract Parameters: The angle at the minimum is θ_SPR. The minimum reflectance value is ΔR depth. Calculate FWHM from the fitted curve.

Protocol 2: Calibrating Refractive Index Sensitivity (S_θ)

Objective: To quantify the shift in θ_SPR per unit change in bulk refractive index. Materials: As in Protocol 1, plus a series of standard sucrose or NaCl solutions with known, incrementally different RIs. Methodology:

- Perform an angular scan (Protocol 1) with the first reference solution (lowest RI).

- Flush sequentially with solutions of increasing known RI.

- For each solution, perform an angular scan and determine the new θ_SPR.

- Plot the shift in θSPR (ΔθSPR) against the change in RI (Δn).

- Perform a linear regression. The slope of the line is the angular sensitivity (S_θ) in °/RIU.

Protocol 3: Estimating Electric Field Penetration Depth (L_p)

Objective: To derive the decay length of the evanescent field. Materials: Simulation software (e.g., COMSOL, MATLAB with transfer matrix method) or analytical calculation based on experimental data. Methodology (Computational):

- Model the multilayer structure: Prism / (Gap for Otto) / Metal / Analyte.

- Input the complex dielectric constants (ε) for each layer at the laser wavelength.

- Solve Maxwell's equations for the described geometry (often using the transfer matrix method).

- Calculate the electric field intensity profile |E(z)|² as a function of distance (z) from the metal surface into the analyte.

- Extract Lp: Determine the distance

zat which |E(z)|² falls to 1/e (~37%) of its value at the interface (z=0). *Note: Lp is primarily a theoretical parameter derived from the imaginary part of the SPP wave vector.*

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in SPR Experiment | Typical Specification / Example |

|---|---|---|

| High-Index Prism | Provides total internal reflection and momentum matching. | SF10 or BK7 glass, hemispherical or trapezoidal. |

| Sensor Chip (Kretschmann) | The functional substrate where SPPs are excited and binding occurs. | Glass slide with 2 nm Cr adhesion layer + 50 nm Au coating. |

| Index Matching Fluid | Eliminates air gaps between prism and chip, ensuring optical continuity. | Cargille Labs immersion oil, n_D = 1.515. |

| Polarizer | Filters light to ensure p-polarization, required for SPP excitation. | Glan-Thompson or wire-grid polarizer. |

| Microfluidic Flow Cell | Delays analyte solution in a controlled lamilar flow over the sensor surface. | Poly(dimethylsiloxane) (PDMS) or hard polymer with defined channel volume. |

| Running Buffer | Provides a stable ionic and pH background, minimizes non-specific binding. | 10 mM HEPES buffered saline, pH 7.4, with 0.005% surfactant P20. |

| Ligand Immobilization Kit | Enables covalent attachment of bait molecules to the gold surface. | Carboxymethylated dextran matrix, EDC/NHS chemistry for amine coupling. |

| Regeneration Solution | Gently breaks specific binding to allow chip reuse for multiple cycles. | 10 mM Glycine-HCl, pH 2.0, or 50 mM NaOH. |

Visualizations

Diagram Title: SPR Parameter Measurement Workflow

Diagram Title: Factors Governing SPR Key Parameters

Historical Context and Evolution of Both Configurations in Sensing Technology

Within the broader thesis on Kretschmann versus Otto configuration research, understanding their historical evolution is paramount. These prism-coupled configurations form the bedrock of surface plasmon resonance (SPR) sensing, a technology that has revolutionized label-free, real-time biomolecular interaction analysis. This guide details their development, technical nuances, and modern applications in drug discovery.

Historical Development and Core Principles

The Otto (1968) and Kretschmann (1971) configurations were developed to optically excite surface plasmon polaritons (SPPs) at metal-dielectric interfaces. Both overcome the photon momentum mismatch problem but employ distinct geometric arrangements.

- Otto Configuration (1968): The original attenuated total reflection (ATR) method. A thin air or dielectric gap separates a high-index prism from a thick metal film. The evanescent wave from the prism tunnels across the gap to excite SPPs on the far side of the metal. Its primary historical role was in foundational physics demonstrations.

- Kretschmann Configuration (1971): The inverted and now-predominant structure. A thin metal film (≈50 nm) is directly deposited onto the prism base. The evanescent wave penetrates the metal film to excite SPPs at its outer interface with the sample dielectric. This robust, easily fabricated configuration became the standard for sensing.

Quantitative Comparison of Configurations

Table 1: Historical & Technical Comparison of Core Configurations

| Parameter | Kretschmann Configuration | Otto Configuration |

|---|---|---|

| Year Introduced | 1971 | 1968 |

| Layer Order | Prism / Metal / Analyte | Prism / Gap / Metal / Analyte |

| Typical Metal Thickness | 45-55 nm (Au) | >100 nm (Au) |

| Gap Thickness | Not Applicable (direct contact) | 100-1000 nm (precise control critical) |

| Excitation Efficiency | High, robust | Highly gap-dependent, often lower |

| Fabrication Complexity | Low (standard metallization) | High (requires precise gap spacing) |

| Primary Historical Role | Applied sensing and commercialization | Fundamental plasmonics research |

| Dominant Modern Use | Commercial biosensors, drug binding assays | Specialized spectroscopy, 2D material studies |

Table 2: Typical Performance Metrics in Biosensing

| Metric | Kretschmann Configuration | Otto Configuration |

|---|---|---|

| Typical Refractive Index Unit (RIU) Sensitivity | 2x10^3 – 3x10^3 nm/RIU | Can be higher (theoretically) but less stable |

| Figure of Merit (FOM) | ~10-100 RIU^{-1} | Varies significantly with gap optimization |

| Detection Limit (Protein) | ~0.1 - 1 pg/mm² | Rarely reported for routine bioassays |

| Kinetic Rate Constant Range | 10^3 – 10^{-6} s^{-1} (ka / kd) | Not standard for kinetic analysis |

Experimental Protocols

Protocol 1: Standard Kretschmann SPR Binding Kinetics Assay (Ligand Immobilization)

- Sensor Chip Preparation: Use a commercially available SPR chip (e.g., CM5 dextran-coated gold). Mount it onto the prism using index-matching fluid.

- System Priming: Prime the integrated microfluidic system with running buffer (e.g., HBS-EP: 10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% v/v Surfactant P20, pH 7.4).

- Baseline Establishment: Flow buffer at a constant rate (e.g., 30 µL/min) to establish a stable baseline resonance angle (RU signal).

- Surface Activation: Inject a 1:1 mixture of 0.4 M EDC (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide) and 0.1 M NHS (N-hydroxysuccinimide) for 7 minutes.

- Ligand Immobilization: Dilute the target ligand (e.g., protein antigen) in 10 mM sodium acetate buffer (pH 4.5) and inject until the desired immobilization level (e.g., 100-200 RU) is reached.

- Surface Deactivation: Inject 1 M ethanolamine-HCl (pH 8.5) for 7 minutes to block remaining activated groups.

- Analyte Binding Analysis: Inject analyte (e.g., drug candidate) in running buffer at varying concentrations (serial dilutions) using a contact time of 120-180 seconds, followed by dissociation in buffer for 300+ seconds.

- Data Processing: Subtract reference channel data. Fit resulting sensograms globally to a 1:1 Langmuir binding model using software (e.g., Biacore Evaluation Software) to extract association (kₐ) and dissociation (kd) rate constants, and the equilibrium dissociation constant (KD = k_d/kₐ).

Protocol 2: Otto Configuration for Ultra-Sensitive Dielectric Measurement

- Gap Assembly: A high-index prism (e.g., SF10) is mounted on a precision translation stage with nano-positioning control. A thick, optically smooth metal film (100 nm Au) is deposited on a separate substrate.

- Gap Alignment: The metal substrate is brought parallel to the prism base. Using piezoelectric controllers, a precise air gap (λ/4 to several wavelengths) is established, monitored via interference fringes or capacitive sensing.

- Angular Scan: A p-polarized, monochromatic laser beam (e.g., He-Ne, 633 nm) is directed onto the prism. The stage rotates to vary the incident angle (θ) while detecting reflected intensity (R).

- SPR Dip Characterization: The angle (θ_SPR) at which the reflectance minimum (SPR dip) occurs is recorded for different dielectric samples placed atop the metal film.

- Sensitivity Calibration: Measure θSPR for known dielectrics (e.g., air, water, ethanol). Plot θSPR vs. refractive index (n) to determine system sensitivity (dθ_SPR/dn).

Visualizations

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents for SPR Biosensing (Kretschmann-based)

| Item | Function & Explanation |

|---|---|

| Biacore Series S Sensor Chip (CM5) | Gold sensor surface with a covalently attached carboxymethylated dextran hydrogel. Provides a versatile matrix for ligand immobilization via amine, thiol, or other chemistries. |

| HBS-EP+ Buffer | Standard running buffer (HEPES, NaCl, EDTA, Polysorbate 20). Maintains pH and ionic strength, minimizes non-specific binding via surfactant. |

| EDC & NHS | Crosslinking reagents. Activate carboxyl groups on the dextran surface to form amine-reactive esters for covalent ligand coupling. |

| Ethanolamine-HCl | Blocking agent. Deactivates remaining ester groups after ligand immobilization to prevent unwanted analyte attachment. |

| Format-Specific Capture Ligands | e.g., Anti-GST, Anti-His, or Streptavidin. Immobilized on the chip to uniformly capture and orient tagged (GST/His/Biotin) analytes, enabling standardized assays. |

| Regeneration Solutions | e.g., 10 mM Glycine-HCl (pH 1.5-3.0), 4M MgCl₂. Gently disrupt the specific interaction to regenerate the ligand surface for repeated use without damage. |

| Index Matching Fluid | High-viscosity, stable fluid (n ~ prism). Eliminates interfering air gaps between the sensor chip and the optical prism. |

| Precision Microfluidic Syringes/Tubing | Deliver sample and buffer in a pulse-free, precise manner essential for accurate kinetic measurements. |

Practical Implementation: Step-by-Step Guide to Configuring Kretschmann and Otto Setups

The Kretschmann configuration is the predominant method for exciting surface plasmon resonance (SPR) in biosensing applications, favored over the Otto configuration for its superior practicality and stability in liquid-phase analysis. This whitepaper details the core protocols for implementing the Kretschmann setup. The critical distinction lies in the placement of the metallic film: in Kretschmann, a thin metal layer (≈50 nm Au) is deposited directly on the prism base and interfaces with the analyte, while in Otto, a thin dielectric gap separates the metal film from the prism. Although Otto can offer sharper resonances under ideal conditions, its requirement for a precise, nanometer-scale air gap makes it unsuitable for fluidic integration and real-time biomolecular interaction analysis. Therefore, this guide focuses on the robust, industry-standard Kretschmann approach.

Substrate Preparation Protocol

A pristine, uniform gold film is paramount for high-quality SPR data.

Detailed Methodology:

- Glass Substrate Cleaning: Use 1" x 1" or 25 mm diameter BK7 or SF10 glass slides. Sonicate sequentially in 2% Hellmanex III solution (60°C, 15 min), deionized water (15 min), and absolute ethanol (15 min). Dry under a stream of dry, filtered nitrogen.

- Adhesion Layer Deposition: Load slides into an electron-beam evaporator. At a base pressure < 5 x 10⁻⁶ Torr, deposit a 2-3 nm thick chromium or titanium layer at a rate of 0.1 Å/s. This promotes Au adhesion.

- Gold Film Deposition: Without breaking vacuum, deposit 47-50 nm of high-purity (99.999%) gold at a rate of 0.5 Å/s. Lower deposition rates yield smoother films.

- Quality Control: Characterize film thickness and roughness via spectroscopic ellipsometry and Atomic Force Microscopy (AFM). Target RMS roughness < 1 nm. Store substrates in a clean, dry nitrogen atmosphere.

Prism Coupling & Optical Alignment

Detailed Methodology:

- Index Matching: Apply a small drop of refractive index matching fluid (nD = prism nD, e.g., Cargille Labs series) to the hypotenuse of a hemispherical or triangular prism (SF10, n=1.723 at 633 nm).

- Substrate Mounting: Gently place the prepared gold substrate onto the fluid-covered prism face, gold-side out. Apply slight pressure to exclude all air bubbles. Secure the substrate with a mechanical clip or holder.

- Optical Setup: Mount the prism assembly on a high-precision goniometer stage. Align a p-polarized, monochromatic laser source (e.g., 633 nm He-Ne) to strike the prism-metal interface at the center of rotation.

- Angular Scan: Connect a photodetector to measure reflected intensity. Rotate the goniometer through the expected SPR angle (typically 65-75° for Au/water interface at 633 nm) with a step resolution of ≤ 0.01°. Record reflectance (R) vs. incident angle (θ).

Quantitative SPR Response Data: Table 1: Characteristic SPR Parameters for Common Configurations (at 633 nm)

| Substrate | Prism Material | Sensing Medium (n) | SPR Angle (θ, °) | Minimum Reflectance (%) | Angular FWHM (°) | Theoretical Sensitivity (RIU/°) |

|---|---|---|---|---|---|---|

| 50 nm Au / 2 nm Cr | SF10 (n=1.723) | Water (1.333) | 68.5 | < 1 | 1.5 | 85-120 |

| 50 nm Au / 2 nm Cr | BK7 (n=1.515) | Water (1.333) | 73.2 | < 5 | 3.5 | 50-80 |

| 50 nm Ag / 2 nm Ti | SF10 (1.723) | Water (1.333) | 66.8 | < 0.5 | 0.8 | 120-180 |

Fluidics Integration Protocol

Stable, bubble-free liquid handling is critical for kinetic binding studies.

Detailed Methodology:

- Flow Cell Assembly: A polydimethylsiloxane (PDMS) or polycarbonate flow cell with a defined channel geometry (e.g., 0.1 mm height x 2 mm width x 10 mm length, volume ≈ 2 µL) is used. Align the flow cell inlet/outlet with the gold surface and clamp securely using a inert gasket (e.g., Viton) to prevent leaks.

- System Priming: Connect the flow cell via PEEK or PTFE tubing to a syringe or peristaltic pump. Prime the entire system with running buffer (e.g., 10 mM HEPES, 150 mM NaCl, pH 7.4, 0.005% surfactant P20) at a high flow rate (e.g., 100 µL/min) to wet surfaces and remove bubbles.

- Baseline Establishment: Under constant flow (typical 20-50 µL/min), establish a stable angular baseline for at least 5-10 minutes. The reflected intensity at a fixed angle near the resonance curve's inflection point is monitored for real-time sensing.

- Sample Injection: Using an automated injection valve, switch the flow from running buffer to analyte solution (e.g., antibody, drug candidate) for a defined association phase (3-5 minutes). Switch back to running buffer for the dissociation phase. Multiple concentrations are run sequentially for kinetic analysis.

Essential Research Reagent Solutions

Table 2: The Scientist's Toolkit for Kretschmann SPR Biosensing

| Item / Reagent | Function & Critical Notes |

|---|---|

| SF10 Glass Prism | High refractive index material for achieving SPR at convenient angles with visible light. |

| High-Purity Gold (99.999%) Target | Source for e-beam evaporation; purity minimizes film damping and broadens resonance. |

| Chromium (or Titanium) Target | For depositing a thin adhesion layer between glass and gold. |

| Refractive Index Matching Fluid | Optically couples prism to substrate, eliminating lossy air gaps. Must be non-reactive with prism adhesive. |

| P20 Surfactant (Tween 20) | Added to running buffer (0.005-0.01%) to reduce non-specific binding to the sensor surface. |

| Carboxymethylated Dextran Hydrogel (e.g., CM5 Chip) | Common commercial sensor chip coating. Provides a hydrophilic, carboxylic acid-rich matrix for ligand immobilization. |

| N-ethyl-N'-(3-dimethylaminopropyl)carbodiimide (EDC) / N-hydroxysuccinimide (NHS) | Crosslinking agents for activating carboxyl groups on the sensor surface for ligand coupling. |

| 1M Ethanolamine-HCl, pH 8.5 | Used to deactivate and block remaining activated ester groups after ligand immobilization. |

| HBS-EP+ Buffer (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% P20, pH 7.4) | Standard running buffer for most biomolecular interaction analyses. EDTA minimizes metal-dependent non-specific binding. |

| Regeneration Solutions (e.g., 10 mM Glycine-HCl, pH 2.0-3.0; 50 mM NaOH) | Low or high pH buffers used to dissociate tightly bound analyte from the ligand, regenerating the surface for a new cycle. |

Visualization: Experimental Workflow

Kretschmann SPR Biosensing Protocol Workflow

Kretschmann Configuration Principle & Signal Generation

The Otto configuration and the Kretschmann configuration represent the two principal experimental arrangements for exciting surface plasmon polaritons (SPPs) in the attenuated total reflection (ATR) method. This technical guide focuses on the Otto setup, a configuration where a thin dielectric gap separates a prism from a metal film. The primary research trade-off centers on experimental complexity versus signal integrity. The Kretschmann configuration (direct metal film deposition on the prism) offers simpler alignment but introduces potential sample-metal interactions and damping. The Otto configuration, while avoiding direct metal contamination and enabling studies on pristine metal surfaces, imposes critical challenges in maintaining a nanoscale, uniform air or dielectric gap. This protocol details the methodologies to overcome these challenges, specifically for applications in label-free biomolecular sensing and drug development.

Core Challenge: Gap Distance Control & Alignment

The efficacy of the Otto configuration hinges on precise control of the gap distance (d), which is typically on the order of the evanescent decay length (~λ/10, often 50-300 nm). An optimal gap allows evanescent wave coupling to the SPP on the adjacent metal surface. Too large a gap prevents coupling; too small a gap leads to scattering and damping.

Quantitative Parameters & Data

Table 1: Key Parameters for Otto Configuration Gap Control

| Parameter | Typical Range | Critical Influence | Measurement Technique |

|---|---|---|---|

| Gap Distance (d) | 50 nm - 300 nm | Coupling efficiency, resonance dip sharpness | Interferometry, piezoelectric feedback, SPR angle shift calibration. |

| Gap Uniformity | < ±5 nm variation | Quality of resonance curve (width, depth) | Imaging ellipsometry, multi-point laser reflectance. |

| Prism Refractive Index | 1.5 - 1.8 (e.g., SF11, LaSFN9) | Incident wavevector, required angle of incidence | Abbe refractometer. |

| Laser Wavelength (λ) | 633 nm (HeNe), 785 nm (diode) | Penetration depth, optimal gap distance | Spectrometer. |

| Resonance Angle (θ_SPR) | 60° - 75° (dependent on metal/λ) | Primary experimental observable | Goniometer resolution (< 0.001°). |

Detailed Protocol for Gap Alignment & Stabilization

Protocol: Piezo-Electric Gap Formation and Active Stabilization

- Materials Preparation: A high-index hemispherical or cylindrical prism is mounted on a high-precision goniometer stage. A clean, flat metal substrate (e.g., 50 nm Au on a glass slide) is mounted on a multi-axis piezo-electric transducer (PZT) stage opposite the prism base.

- Coarse Approach: Using micrometers, bring the metal substrate to within ~5 µm of the prism base. Monitor via a calibrated capacitance probe or optical interference fringes.

- Gap Formation: Engage fine control of the PZT. Move the metal substrate towards the prism in 10 nm steps. Simultaneously, direct a p-polarized laser (λ=633 nm) at a fixed angle near the expected SPR angle onto the prism and monitor reflected intensity with a photodiode.

- Initial Coupling Detection: A sharp drop in reflected intensity indicates the onset of SPP coupling. Record the PZT voltage at this point (V_contact). Retract the substrate by a predefined voltage corresponding to the target gap (e.g., 100 nm).

- Active Stabilization: Implement a feedback loop. Use a small AC modulation (e.g., 1 nm oscillation at 1 kHz) on the PZT. The reflected intensity signal will contain a component at the modulation frequency. The phase and amplitude of this component are used as an error signal to maintain a constant average gap distance via PID control of the PZT DC offset.

Sample Handling in Liquid & Gaseous Environments

Sample handling in the Otto configuration is uniquely challenged by the need to introduce analyte into the nanoscale gap without disturbing its geometry.

Protocol: Microfluidic Sample Introduction for Otto Configuration

- Flow Cell Fabrication: A microfluidic gasket (PDMS, Teflon) with a defined channel (height ~100 µm) is fabricated. The channel design must ensure uniform flow across the entire sensing area (typically 1-2 mm diameter).

- Integration: The gasket is sandwiched between the prism base and the metal substrate, with the gap distance mechanically defined by the gasket thickness minus the controlled retraction of the PZT. This creates a hybrid gap: a nano-gap for evanescent coupling and a micro-gap for fluidics.

- Priming and Flow: Use a syringe pump to prime the system with running buffer (e.g., PBS). The system must be thoroughly degassed to prevent bubble formation in the gap, which would destroy coupling.

- Kinetic Measurements: Switch the flow to analyte solution. The SPR angle shift (Δθ) is monitored in real-time. The Otto configuration's advantage is that the metal surface is pristine and can be characterized independently before assembly, allowing for more controlled surface functionalization (e.g., with drug targets) prior to the experiment.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Otto Configuration Experiments

| Item | Function | Example/Specification |

|---|---|---|

| High-Index Prism | Provides wavevector matching for SPP excitation. | Hemispherical, LaSFN9 glass (n ~1.85 @ 633 nm). |

| Piezo-Electric Transducer (PZT) | Nano-positioning for gap control and active stabilization. | 3-axis closed-loop PZT stage, sub-nm resolution. |

| Gold-coated Substrate | Provides the plasmonic surface. | 47 nm Au on 2 nm Cr adhesion layer on BK7 glass. |

| Precision Goniometer | Accurate control and measurement of incident angle. | Motorized rotation stage, < 0.001° resolution. |

| p-Polarized Laser Source | Provides polarized excitation light for SPPs. | HeNe Laser (633 nm), with Glan-Thompson polarizer. |

| Microfluidic Flow System | Introduces analyte without disturbing the nano-gap. | Syringe pump, degasser, PDMS gasket with low dead volume. |

| Index Matching Fluid | Optical coupling between prism and mount. | Cargille Labs fluid, n_D = 1.85, non-drying. |

| Surface Functionalization Kit | Modifies gold surface with biorecognition elements. | Thiol-PEG-COOH for anti-fouling; NHS/EDC coupling chemistry. |

Visualization of Protocols and Relationships

Diagram 1: Otto Setup Alignment and Measurement Workflow (64 characters)

Diagram 2: Research Trade-off: Kretschmann vs. Otto (55 characters)

Ligand Immobilization Strategies for Gold Films (Kretschmann) and Dielectric Substrates (Otto)

This technical guide details ligand immobilization strategies tailored for surface plasmon resonance (SPR) configurations. The Kretschmann configuration, employing thin gold films, and the Otto configuration, utilizing dielectric substrates, present distinct surface chemistry challenges. This whitepaper, framed within a broader thesis comparing these two SPR methodologies, provides in-depth protocols, material specifications, and data analysis frameworks for researchers in biosensing and drug development.

The choice between Kretschmann and Otto configurations dictates the substrate material, which in turn imposes specific constraints and opportunities for ligand immobilization. The Kretschmann configuration relies on a thin (typically ~50 nm) gold film deposited on a glass prism. Gold's affinity for thiols enables robust self-assembled monolayer (SAM) formation. Conversely, the Otto configuration employs a dielectric substrate (e.g., glass, silicon) separated from the metal film by an air or fluid gap. This requires covalent chemistry directly on oxide or polymer surfaces. The immobilization strategy must maximize ligand density, orientation, and activity while minimizing non-specific binding, with the method fundamentally linked to the chosen SPR geometry.

Core Immobilization Chemistries

For Gold Films (Kretschmann)

Strategies exploit gold-thiol (Au-S) chemisorption.

- Alkanethiol SAMs: The foundational layer. Molecules like 11-mercaptoundecanoic acid (11-MUA) provide a ordered monolayer with terminal carboxyl groups for further coupling.

- Thiolated Biomolecules: Direct immobilization of ligands (e.g., peptides, DNA) synthesized with a terminal cysteine or disulfide group.

- Mixed SAMs: Incorporation of spacer thiols (e.g., PEG-thiols) to reduce steric hindrance and non-specific binding.

- Commercial Gold Coatings: Often pre-functionalized with carboxymethylated dextran hydrogels (e.g., CM5 chips) for high-capacity immobilization via amine coupling.

For Dielectric Substrates (Otto)

Strategies rely on silane chemistry or polymer coatings on glass/silicon.

- Silane Coupling: (3-Aminopropyl)triethoxysilane (APTES) introduces amine groups. (3-Glycidyloxypropyl)trimethoxysilane (GPTMS) introduces epoxide groups.

- Polymer Layers: Spin-coating of functional polymers (e.g., polycarboxylates, polyacrylates) to create a 3D matrix.

- Direct Covalent Linkage: Activation of native hydroxyl groups on glass via reagents like epoxy or aldehyde silanes.

Quantitative Comparison of Substrate Properties

Table 1: Substrate & Immobilization Characteristics

| Property | Kretschmann (Gold Film) | Otto (Dielectric Substrate) |

|---|---|---|

| Typical Substrate | 47-50 nm Au on glass/chromium | Bare glass, silicon, or functionalized dielectric |

| Key Chemistry | Au-Thiol (≈ 200 kJ/mol) | Silane-Oxide (Covalent), Adsorption |

| Typical Ligand Density | 1-4 x 1012 molecules/cm² (SAM-based) | 0.5-2 x 1012 molecules/cm² (planar silane) |

| Functional Group | -COOH (from MUA), -OH, -CH3 | -NH2 (APTES), Epoxy (GPTMS) |

| Non-Specific Binding | Low with PEG-modified SAMs | Can be higher; requires careful blocking |

| Commercial Chip Availability | Extensive (Biacore, Reichert, etc.) | Limited; often custom-fabricated |

Table 2: Common Coupling Protocols & Efficiency

| Immobilization Step | Reagent/ Condition | Kretschmann Example | Otto Example | Typical Efficiency |

|---|---|---|---|---|

| Surface Activation | EDC/NHS | 0.4M EDC / 0.1M NHS in water, 7 min flow | 50mM EDC / 20mM NHS in MES buffer, 10 min | >95% COOH activation |

| Ligand Coupling | pH, Concentration | 10-100 µg/mL in acetate buffer (pH 4.5-5.5) | 10-100 µg/mL in PBS or carbonate (pH 8.5 for amine) | 50-90% depending on ligand |

| Deactivation | Ethanolamine | 1M ethanolamine-HCl, pH 8.5, 7 min | 1M ethanolamine-HCl, pH 8.5, 10 min | Blocks remaining esters |

| Stability (Operational) | Continuous Flow | High (thiol-gold bond stable) | Moderate (susceptible to hydrolysis) | Days to weeks |

Detailed Experimental Protocols

Protocol A: Kretschmann Gold Film via Mixed SAM & Amine Coupling

- Substrate Preparation: Clean gold-coated glass slide (47nm Au, 2nm Cr adhesive) in piranha solution (3:1 H2SO4:H2O2) CAUTION: Highly corrosive. Rinse with ethanol and Milli-Q water, dry under N2.

- SAM Formation: Immerse slide in 1 mM ethanolic solution of 99% 11-mercaptoundecanoic acid (11-MUA) and 1% hexa(ethylene glycol) undecanethiol (EG6-thiol) for 24 hours at room temperature.

- Rinsing: Rinse thoroughly with absolute ethanol to remove physisorbed thiols, dry under N2.

- SPR Mounting: Mount functionalized slide onto the prism using index-matching oil in the Kretschmann setup.

- In-situ Activation & Coupling (Flow System):

- Prime system with HBS-EP buffer (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.005% v/v Surfactant P20, pH 7.4).

- Inject a 1:1 mixture of 0.4 M EDC and 0.1 M NHS for 7 minutes to activate carboxyl groups.

- Inject ligand (e.g., protein) solution (10-50 µg/mL in 10 mM sodium acetate buffer, pH 5.0) for a target immobilization level (e.g., 100-200 Response Units).

- Inject 1 M ethanolamine-HCl, pH 8.5, for 7 minutes to block unreacted esters.

- Regeneration Test: Inject a series of mild regeneration solutions (e.g., 10 mM glycine-HCl, pH 2.0-3.0) to establish a stable baseline for binding studies.

Protocol B: Otto Dielectric Substrate via APTES & Glutaraldehyde

- Substrate Preparation: Clean bare glass or silicon substrate in oxygen plasma for 5 minutes.

- Silanization: Vapor-phase silanization with (3-Aminopropyl)triethoxysilane (APTES). Place substrate in a vacuum desiccator with 100 µL APTES, evacuate for 30 minutes, then leave under vacuum for 2 hours at room temperature.

- Curing: Bake silanized substrate at 120°C for 1 hour to condense silanol groups.

- Linker Attachment: Immerse substrate in 2.5% (v/v) glutaraldehyde in PBS (pH 7.4) for 1 hour at room temperature. Rinse copiously with PBS and water.

- Ligand Coupling: Incubate substrate with amine-containing ligand (e.g., antibody, protein A) at 50 µg/mL in PBS (pH 7.4) for 2 hours at 4°C.

- Quenching: Incubate with 0.1 M glycine in PBS for 30 minutes to reduce remaining aldehyde groups.

- Otto Configuration Assembly: Precisely align and space the functionalized dielectric substrate opposite the gold-coated prism (typically using a micrometer-controlled stage) to establish the critical air/fluid gap.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Ligand Immobilization

| Item | Function | Example Product/Catalog # (Illustrative) |

|---|---|---|

| Gold-coated Slides | Kretschmann substrate; 47-50nm Au with 1-2nm Cr/Ti adhesive. | G.214 from Sigma-Aldrich or equivalent from Phasis (Switzerland). |

| Functional Thiols | Form SAM on gold; provide -COOH for coupling. | 11-Mercaptoundecanoic acid (11-MUA), HS-(CH2)11-EG6-OH (PEG-thiol). |

| Coupling Agents (EDC/NHS) | Activate carboxyl groups to form amine-reactive esters. | 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) and N-Hydroxysuccinimide (NHS). |

| Silane Coupling Agents | Functionalize dielectric (Otto) surfaces with amines or epoxies. | (3-Aminopropyl)triethoxysilane (APTES), (3-Glycidyloxypropyl)trimethoxysilane (GPTMS). |

| Crosslinkers | Provide extended spacer/linker on aminated surfaces. | Glutaraldehyde (25% solution), bis(sulfosuccinimidyl) suberate (BS3). |

| SPR Running Buffer | Maintain pH and ionic strength; minimize NSB with surfactant. | HBS-EP Buffer: 10mM HEPES, 150mM NaCl, 3mM EDTA, 0.005% P20, pH 7.4. |

| Regeneration Solutions | Dissociate bound analyte without damaging immobilized ligand. | Glycine-HCl (10-100mM, pH 2.0-3.0), NaOH (10-50mM). |

| Index Matching Oil | Ensure optical contact between prism and substrate in Kretschmann. | Cargille Laser Liquid Type FF, nD = 1.515. |

Visualization: Workflow & Pathway Diagrams

Diagram 1: Kretschmann Gold Film Functionalization Workflow

Diagram 2: Otto Dielectric Substrate Functionalization Workflow

Diagram 3: Thesis Framework Linking Config to Chemistry

Surface plasmon resonance (SPR)-based biosensing is a cornerstone technology for real-time, label-free analysis of biomolecular interactions in drug discovery. The performance of SPR instruments is fundamentally governed by the optical excitation configuration. The ongoing research thesis comparing the Kretschmann configuration versus the Otto configuration is critical for advancing this field. The Kretschmann configuration, where a thin metal film (typically gold) is deposited directly on the prism, is the industrial standard due to its robust and straightforward implementation. In contrast, the Otto configuration, which employs a thin dielectric spacer between the prism and the metal film, offers advantages in protecting the metal surface and tuning the evanescent field penetration depth. Current research indicates that while Kretschmann dominates practical drug discovery applications, the Otto configuration presents unique benefits for studying membrane-associated targets and complex cellular interfaces, areas of high importance in modern biotherapeutics. This guide details the application of SPR, predominantly using the Kretschmann paradigm, within the drug discovery pipeline.

Core Principles & Quantitative Comparison of Configurations

The choice of configuration impacts sensitivity, stability, and applicability. The following table summarizes key comparative data based on recent experimental studies.

Table 1: Quantitative Comparison: Kretschmann vs. Otto Configuration for SPR Biosensing

| Parameter | Kretschmann Configuration | Otto Configuration | Implication for Drug Discovery |

|---|---|---|---|

| Typical Sensitivity (RIU⁻¹) | 80 - 120 | 60 - 100 | Kretschmann offers marginally higher bulk refractive index sensitivity, beneficial for standard binding assays. |

| Field Penetration Depth (nm) | ~200-300 | Tunable, 100-500+ | Otto allows deeper field penetration, advantageous for studying large vesicles, cell membranes, and protein aggregates. |

| Metal Film Integrity | Direct exposure to flow cell. Risk of degradation/scratching. | Protected by dielectric spacer. Enhanced long-term stability. | Otto configuration may reduce sensor chip replacement frequency in high-throughput screening. |

| Experimental Complexity | Low. Robust, reproducible chip fabrication. | High. Requires precise control of dielectric gap uniformity. | Kretschmann's simplicity favors its widespread adoption in industrial labs. |

| Optimal Application | Soluble protein-protein, protein-small molecule interactions. | Membrane proteins in native-like lipid environments, cell-surface binding. | Otto is a focus of research for difficult membrane target classes (e.g., GPCRs, ion channels). |

| Commercial Availability | Widespread (Biacore, Nicoya, etc.). | Limited to specialized or research-grade instruments. | Kretschmann is the de facto standard for integrated drug discovery platforms. |

Detailed Experimental Protocol: Kinetic Characterization of a Protein-Small Molecule Interaction

This protocol assumes an SPR instrument using the Kretschmann configuration (e.g., Cytiva Biacore T200).

A. Reagent Preparation

- Immobilization: The target protein (e.g., kinase) is purified and buffer-exchanged into HBS-EP+ running buffer (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% v/v Surfactant P20, pH 7.4).

- Ligand Solutions: Serial dilutions of the small molecule inhibitor are prepared in running buffer from a DMSO stock. Final DMSO concentration across all samples must be identical (typically ≤1%).

- Sensor Chip: A CM5 (carboxymethylated dextran) sensor chip is used.

B. Target Immobilization (via Amine Coupling)

- Conditioning: Dock the CM5 chip and prime the system with HBS-EP+.

- Activation: Inject a 1:1 mixture of 0.4 M EDC and 0.1 M NHS for 7 minutes.

- Immobilization: Dilute the target protein to 10-50 µg/mL in 10 mM sodium acetate buffer (pH 4.5). Inject over the desired flow cell until the desired immobilization level (Response Units, RU) is achieved (typically 5-10,000 RU for kinetic analysis).

- Deactivation: Inject 1 M ethanolamine-HCl (pH 8.5) for 7 minutes to block remaining active esters.

- Reference Surface: A separate flow cell is activated and deactivated without protein to serve as a reference.

C. Kinetic Binding Experiment

- Baseline Stabilization: Flow running buffer at the operational temperature (e.g., 25°C) until a stable baseline is achieved.

- Association Phase: Inject small molecule dilutions (typically 5-8 concentrations, 3-fold serial dilution) over the target and reference surfaces at a constant flow rate (e.g., 30 µL/min) for 60-180 seconds.

- Dissociation Phase: Switch back to running buffer and monitor dissociation for 300-600 seconds.

- Regeneration: Inject a regeneration solution (e.g., 10 mM glycine pH 2.0 or a mild detergent) for 30-60 seconds to completely remove bound analyte without damaging the target. The condition must be determined empirically.

- Repeat steps 2-4 for all analyte concentrations in random order to avoid injection artifacts.

D. Data Analysis

- Reference Subtraction: Subtract the sensorgram from the reference flow cell from the target flow cell sensorgram.

- Double-Referencing: Further subtract the average response from a buffer-only injection.

- Kinetic Fitting: Fit the processed, concentration-series sensorgrams to a 1:1 Langmuir binding model using the instrument’s software (e.g., Biacore Evaluation Software). The model solves the differential equations for

ka(association rate constant, M⁻¹s⁻¹) andkd(dissociation rate constant, s⁻¹). - Derived Metrics: Calculate the equilibrium dissociation constant

KD = kd/ka(M). Reportχ²and residual plots to assess goodness of fit.

Signaling Pathway & Workflow Visualizations

Diagram 1: SPR Experimental Workflow (76 chars)

Diagram 2: Binding to Phenotype Logic Flow (79 chars)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for SPR-Based Interaction Analysis

| Item | Function & Specification | Key Consideration for Drug Discovery |

|---|---|---|

| SPR Instrument | Optical system (Kretschmann/Otto), microfluidics, and detector for real-time monitoring. | Throughput, sensitivity, automation, and software for regulatory compliance (21 CFR Part 11). |

| Sensor Chips | Functionalized gold surfaces (e.g., CM5 dextran, NTA for His-tag, L1 for liposomes). | Choice dictates immobilization strategy. L1 chips are vital for membrane protein studies. |

| Running Buffer | HBS-EP+ is standard. Must minimize non-specific binding and maintain protein stability. | DMSO compatibility is essential for small molecule screening. Buffer standardization is critical for reproducibility. |

| Immobilization Kits | Amine coupling (EDC/NHS, ethanolamine), thiol coupling, or capture kits (anti-GST, anti-Fc). | Defines ligand orientation and activity. Capture methods often preserve native protein function better. |

| Regeneration Solutions | Low/high pH buffers (glycine), salts, detergents, or chaotropes. | Must fully dissociate complex without inactivating the immobilized target. Empirical screening required. |

| High-Purity Analytes/Ligands | Target proteins (>95% purity), small molecule compounds (known concentration/DMSO stock). | Protein monodispersity is crucial. Compound solubility and aggregation potential must be assessed. |

| Data Analysis Software | Proprietary (Biacore Insight) or third-party (Scrubber, TraceDrawer) for kinetic modeling. | Ability to fit complex interaction models (heterogeneity, bivalent, conformational change) is increasingly important. |

This whitepaper provides an in-depth technical guide on the application of Kretschmann and Otto configurations for studying membrane proteins and lipid bilayers. It is framed within the context of a broader thesis comparing the fundamental principles, experimental advantages, and specific use cases of these two primary surface plasmon resonance (SPR) coupling methods in biophysical research.

Core Principles: Kretschmann vs. Otto for Biological Interfaces

Surface plasmon resonance is a label-free, real-time technique for monitoring biomolecular interactions. The choice of configuration profoundly impacts the quality of data obtained from delicate membrane-mimetic systems.

- Kretschmann Configuration: The most common setup. A thin metal film (typically gold, 50 nm) is deposited directly on the prism. The biomembrane system (e.g., a supported lipid bilayer or tethered vesicle) is assembled on the metal surface. Light undergoes total internal reflection at the prism/metal interface, exciting surface plasmons.

- Otto Configuration: A dielectric spacer (e.g., a silica layer or the aqueous sample itself) separates the metal film from the prism. The biomembrane system is assembled on the metal, but the evanescent field probes it through this spacer.

The central thesis in membrane studies posits that the Kretschmann configuration offers superior signal strength and experimental simplicity for most applications, while the Otto configuration provides a critical advantage by preventing direct interaction of the biomembrane with the metal surface, reducing denaturation and more closely mimicking a native cellular environment.

Quantitative Comparison of Configurations

Table 1: Performance Comparison for Membrane Protein Studies

| Parameter | Kretschmann Configuration | Otto Configuration |

|---|---|---|

| Field Decay Length | ~200 nm (into sample) | Tunable; longer by adjusting spacer thickness. |

| Typical Sensitivity (RIU) | High (2x10⁻⁶ – 5x10⁻⁷) | Slightly Lower (requires precise spacer control) |

| Membrane Integrity | Risk of protein denaturation on metal. | Superior; spacer preserves native conformation. |

| Supported Bilayer Setup | Straightforward deposition on gold. | Complex; requires precise spacer fabrication. |

| Throughput & Robustness | High; commercially dominant. | Lower; primarily a research tool. |

| Key Application | Ligand binding kinetics to membrane targets. | Structural studies of sensitive proteins. |

Table 2: Experimental Data from a Model GPCR Study (Hypothetical Data Based on Current Literature)

| Experiment | Configuration | Measured KD (nM) | On-rate (kon) M⁻¹s⁻¹ | Off-rate (koff) s⁻¹ | Notes |

|---|---|---|---|---|---|

| Agonist Binding | Kretschmann | 5.2 ± 0.8 | 1.5 x 10⁶ | 7.8 x 10⁻³ | Strong signal, stable baseline. |

| Agonist Binding | Otto | 18.5 ± 3.2 | 4.2 x 10⁵ | 7.8 x 10⁻³ | Slower observed on-rate may reflect spacer damping. |

| Antagonist Binding | Kretschmann | 1.1 ± 0.2 | 2.1 x 10⁶ | 2.3 x 10⁻³ | Robust data. |

| Antagonist Binding | Otto | 1.3 ± 0.4 | 1.8 x 10⁶ | 2.3 x 10⁻³ | Similar kinetics, confirming native conformation. |

Detailed Experimental Protocols

Protocol 1: Forming a Hybrid Lipid Bilayer in Kretschmann Configuration for Protein Insertion

Objective: Create a stable, fluid membrane on a gold sensor chip for measuring ligand binding to an incorporated receptor.

- Surface Preparation: Clean a gold-coated SPR sensor chip (47-50 nm Au over 2 nm Cr adhesion layer) in piranha solution (3:1 H₂SO₄:H₂O₂). CAUTION: Highly corrosive. Rinse with ethanol and Millipore water, dry under N₂.

- Self-Assembled Monolayer (SAM) Formation: Immerse chip in 1 mM solution of alkanethiol (e.g., 90% mercaptounderanol : 10% mercaptohexadecanoic acid) in ethanol for 12-24 hours. This creates a hydrophilic surface.

- Lipid Monolayer Fusion: Inject small unilamellar vesicles (SUVs, 50 nm diameter) of desired lipid composition (e.g., POPC:Cholesterol 7:3) in HEPES buffer over the SAM at 25 μL/min for 30 minutes. Vesicles rupture to form a continuous lipid monolayer on the SAM.

- Membrane Protein Incorporation: Dilute detergent-solubilized, purified membrane protein (e.g., a GPCR) into a micellar solution. Inject over the hybrid bilayer. Micelles destabilize, allowing protein to insert into the lipid layer. Wash extensively.

- Ligand Binding Assay: Perform kinetic injections of ligand analytes at varying concentrations in running buffer. Analyze association/dissociation phases to determine kinetics (ka, kd) and affinity (KD).

Protocol 2: Building a Spacer-Coupled Membrane in Otto Configuration

Objective: Assemble a membrane atop a dielectric spacer to isolate proteins from the metal.

- Spacer Fabrication: Use a silica-coated SPR chip or deposit a precise layer of SiO₂ (e.g., 100-500 nm) via plasma-enhanced chemical vapor deposition (PECVD) onto the gold film.

- Surface Functionalization: Activate silica surface with oxygen plasma. Use silane chemistry (e.g., (3-aminopropyl)triethoxysilane, APTES) to create an amine-terminated layer.

- Lipid Bilayer Formation: Employ the Langmuir-Blodgett/Langmuir-Schaefer (LB/LS) transfer technique. First, a lipid monolayer is transferred vertically (LB) onto the spacer. Then, a second monolayer is transferred horizontally (LS) to form a complete bilayer. Alternatively, use vesicle fusion onto a highly hydrophilic spacer.

- Protein Reconstitution: Proteoliposomes (vesicles containing pre-reconstituted protein) are prepared. These are flowed over the spacer-supported bilayer, where they fuse, delivering the protein into the pre-formed membrane.

- SPR Measurement: Align the prism precisely to maintain the critical air/spacer gap. Perform ligand binding studies as in Protocol 1.

Signaling Pathway & Experimental Workflow Visualizations

Title: SPR Configuration Decision & Workflow

Title: GPCR Signaling Pathway & SPR Detection Point

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SPR-based Membrane Studies

| Item | Function & Description | Typical Supplier/Example |

|---|---|---|

| SPR Instrument | Core platform for excitation and detection of plasmons. | Biacore (Cytiva), SPR Navi (BioNavis), OpenSPR (Nicoya). |

| Sensor Chips (Kretschmann) | Gold-coated glass slides with precise optical properties. | Cytiva Series S Sensor Chip Au, XanTec biochips. |

| Sensor Chips (Otto) | Custom chips with dielectric spacer (SiO₂, polymers). | Fabricated in-house or by specialty vendors (e.g., Ssens). |

| Functional Lipids | Lipids for bilayer formation with reactive headgroups (e.g., DOPE-cap-biotin, DOGS-NTA-Ni). | Avanti Polar Lipids, Sigma-Aldrich. |

| Detergents | For protein solubilization and micelle formation during insertion. | n-Dodecyl-β-D-maltoside (DDM), Lauryl Maltose Neopentyl Glycol (LMNG). |

| Blocking Agents | Minimize non-specific binding to sensor surface. | Bovine Serum Albumin (BSA), casein, surfactant P20. |

| Coupling Reagents | For covalent immobilization of capture molecules (if used). | EDC/NHS chemistry kits. |

| Microfluidic System | Precise, pulsation-free buffer and sample delivery. | Integrated into commercial SPR systems. |

| Data Analysis Software | Fitting sensorgrams to kinetic and equilibrium models. | Scrubber (BioLogic), Biacore Evaluation Software, TraceDrawer. |

Overcoming Challenges: Troubleshooting and Enhancing SPR Configuration Performance

The Kretschmann configuration is the predominant method for exciting surface plasmon resonance (SPR) for label-free biosensing. Within the broader thesis comparing the Kretschmann and Otto configurations, a critical analysis reveals distinct advantages and persistent challenges. While the Kretschmann setup (thin metal film on a prism) offers superior practicality for liquid sensing compared to the Otto configuration (an air gap between prism and metal), it introduces several inherent experimental issues. This whitepaper details the core challenges of nonspecific binding, gold film degradation, and bulk refractive index effects, which are often more pronounced in Kretschmann than in Otto due to the direct sample contact with the sensor surface. Understanding and mitigating these issues is paramount for advancing SPR biosensing in drug development and basic research.

Nonspecific Binding

Nonspecific binding (NSB) refers to the adsorption of non-target molecules to the sensor surface or the molecular recognition layer, leading to false-positive signals and reduced sensitivity.