LEED for Surface Reconstruction: A Complete Guide for Biomedical Material Characterization

This comprehensive guide explores Low-Energy Electron Diffraction (LEED) as a critical technique for analyzing surface atomic structure during material reconstruction, essential for biomedical applications.

LEED for Surface Reconstruction: A Complete Guide for Biomedical Material Characterization

Abstract

This comprehensive guide explores Low-Energy Electron Diffraction (LEED) as a critical technique for analyzing surface atomic structure during material reconstruction, essential for biomedical applications. It begins with foundational principles of LEED and surface science, then details step-by-step experimental methodology for characterizing biomaterial coatings and implant surfaces. The guide provides expert troubleshooting for common challenges in analyzing complex biological interfaces and compares LEED with complementary techniques like STM and XPS. Designed for researchers in biomaterials, drug delivery, and implant development, this article synthesizes current best practices to optimize surface analysis for improved biocompatibility and therapeutic function.

Understanding LEED and Surface Reconstruction: Core Principles for Biomaterial Science

What is LEED? Defining Low-Energy Electron Diffraction and Its Physical Basis

Low-Energy Electron Diffraction (LEED) is a surface-sensitive analytical technique used to determine the structure of crystalline surfaces. Its physical basis lies in the wave-particle duality of electrons. Electrons with kinetic energies in the range of 20-500 eV exhibit de Broglie wavelengths on the order of 0.05-0.3 nm, comparable to atomic spacings. At these low energies, electrons have a very short inelastic mean free path (typically 0.5-2 nm), making the technique highly surface-sensitive, probing only the top few atomic layers.

The diffraction pattern observed on a fluorescent screen results from the constructive interference of elastically scattered electrons from the ordered lattice of the surface atoms, providing a direct real-space projection of the surface reciprocal lattice.

Key Quantitative Parameters in LEED

Table 1: Core Quantitative Parameters of a Typical LEED Experiment

| Parameter | Typical Range | Physical Significance |

|---|---|---|

| Electron Beam Energy | 20 – 500 eV | Determines electron wavelength and surface penetration depth. |

| Beam Current | 0.1 – 10 nA | Balances signal intensity against surface charging and damage. |

| Base Pressure | < 5 x 10⁻¹⁰ mbar | Maintains surface cleanliness for the duration of the experiment. |

| Coherence Length | 10 – 100 nm | Determines sharpness of diffraction spots; limited by surface defects. |

| Inelastic Mean Free Path | 0.5 – 2 nm | Defines the surface sensitivity (~3-5 atomic layers). |

| Angular Resolution | < 1° | Critical for spot-profile analysis (SPA-LEED). |

Research Reagent Solutions & Essential Materials

Table 2: Key Research Reagent Solutions for Surface Preparation in LEED Studies

| Item | Function / Explanation |

|---|---|

| Sputter Ion Source (Ar⁺) | Provides inert gas ions (typically 0.5-5 keV) for physical removal of contaminated surface layers via sputtering. |

| Direct Sample Heater | Resistive or electron-beam heating for annealing the crystal post-sputtering to restore atomic order and remove defects. |

| Liquid Nitrogen Cryostat | Allows cooling of the sample (to ~100 K or lower) to reduce thermal vibrations, sharpening diffraction spots, and stabilizing adsorbate layers. |

| High-Purity Single Crystal | The substrate under study (e.g., Pt(111), Si(100), Cu(110)). Must be oriented, polished, and mounted on a precision manipulator. |

| Calibrated Gas Dosing System | Precise leak valves and manifolds for exposing the clean surface to controlled amounts of gases (e.g., O₂, CO) for adsorption studies. |

| Standard Reference Sample | A material with a known, stable surface structure (e.g., cleaved MoS₂) used for instrument alignment and calibration. |

Detailed Experimental Protocol: LEED for Surface Reconstruction Analysis

Protocol: Determining a Clean Surface Reconstruction

Objective: To prepare a clean, well-ordered single-crystal surface and characterize its intrinsic reconstruction using LEED.

Materials & Equipment:

- UHV Chamber (< 5x10⁻¹⁰ mbar base pressure)

- Four-Grid Reverse-View LEED Optics

- Sample holder with heating (to 1500 K) and cooling (to 100 K) capabilities

- Sample manipulator with x, y, z, polar, and azimuthal control

- Sputter ion gun

- High-purity argon gas supply

- Direct current power supply for resistive heating

Procedure:

- Sample Introduction & Mounting:

- Mount the single crystal onto the sample holder using high-purity Ta or W wires.

- Insert the sample into the UHV chamber via the load lock.

- Bake the entire chamber to achieve ultra-high vacuum.

In-situ Surface Cleaning (Cyclic Sputter-Anneal):

- Sputtering: Backfill the chamber with high-purity Ar to a pressure of 5x10⁻⁵ mbar. Activate the ion gun, focusing a 1-2 keV Ar⁺ beam onto the sample surface for 15-30 minutes. Rotate the sample during sputtering for uniform erosion.

- Annealing: Turn off the ion gun and evacuate the Ar gas. Resistively heat the sample to a temperature specific to the material (e.g., 1000 K for Pt, 1200 K for Si) for 1-5 minutes. This step repairs the damage caused by sputtering and promotes surface ordering.

- Repeat the sputter-anneal cycle 3-5 times until no contaminants (C, O, S) are detectable by Auger Electron Spectroscopy (AES).

LEED Pattern Acquisition:

- Cool the cleaned sample to near-room temperature (~350 K) to minimize thermal diffuse background.

- Align the sample normal with the center of the LEED screen and optics.

- Gradually increase the electron gun acceleration voltage from 20 eV to 300 eV.

- Observe the diffraction pattern on the phosphor screen. Adjust the sample position (z, tilt) to center the pattern.

- Record the pattern using a CCD camera at characteristic energies (e.g., every 10 eV) for analysis.

Pattern Analysis for Reconstruction Identification:

- Identify Fundamental Spots: Locate the (1x1) spots corresponding to the bulk-terminated lattice.

- Measure Spot Positions: Note the appearance of additional "fractional-order" spots between the fundamental spots.

- Determine Surface Unit Mesh: Calculate the reciprocal lattice vectors from the spot pattern. Their real-space equivalents define the surface unit cell.

- Index Pattern: Compare the observed pattern to known models. A pattern with fractional-order spots along one direction indicates a missing-row or added-row reconstruction.

Protocol: LEED-I(V) for Quantitative Structure Determination

Objective: To extract quantitative information on atomic positions (bond lengths, layer relaxations) via analysis of spot intensity versus electron energy (I-V) curves.

Procedure:

- Data Collection:

- Following Protocol 4, obtain a clean, ordered surface.

- Using a computer-controlled system, select a specific diffraction spot (e.g., (1,0) or a fractional-order spot).

- Ramp the electron beam energy smoothly from 50 eV to 400 eV in 1-5 eV increments.

- At each step, measure and record the integrated spot intensity using a photodiode or CCD pixel count, subtracting the background intensity.

- Data Processing & Theoretical Fitting:

- Normalize the acquired I(V) curves to the incident beam current.

- Compare the experimental I(V) curves to dynamical scattering theory calculations performed for multiple trial structural models.

- Use a reliability factor (R-factor, e.g., Rp or RDE) to quantify the agreement between experiment and theory.

- Iteratively refine the structural parameters (layer spacings, atomic coordinates, vibrational amplitudes) in the theoretical model until the R-factor is minimized, yielding the most probable surface structure.

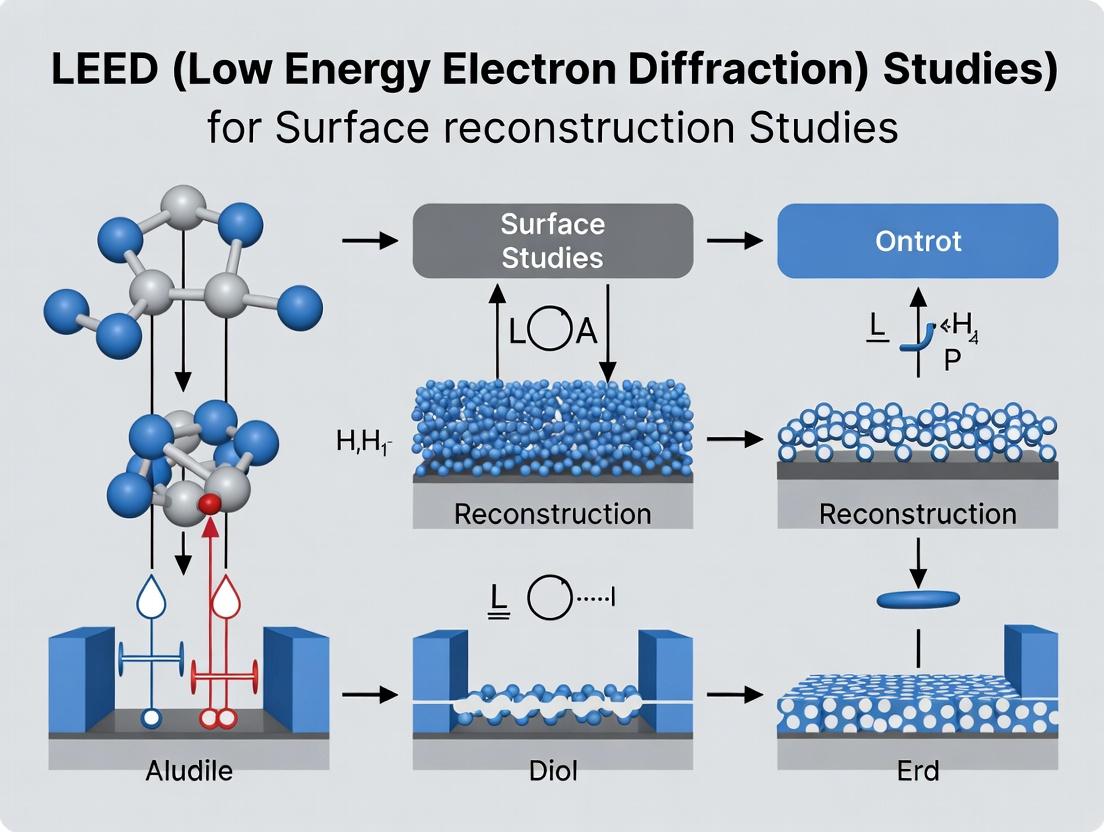

Visualization of Core Concepts and Workflows

Diagram 1: Core LEED Principle & Signal Path

Diagram 2: Surface Prep & Analysis Workflow

Diagram 3: LEED I(V) Quantitative Analysis Method

The Critical Role of Surface Reconstruction in Biomaterial Performance and Biocompatibility

Within the framework of Low-Energy Electron Diffraction (LEED) for surface reconstruction studies, surface reconstruction is defined as the thermodynamic rearrangement of atoms at a biomaterial interface upon exposure to a biological milieu. This dynamic process, which can be initially characterized in vacuo using LEED, dictates the subsequent adsorption of water, ions, proteins, and lipids, forming the "biological interface" that cells encounter. This document provides Application Notes and Protocols for investigating this critical phenomenon, linking ultra-high vacuum (UHV) surface science techniques like LEED to downstream biological outcomes.

Application Notes: Key Findings & Data

Table 1: Impact of Surface Reconstruction on Key Biocompatibility Metrics

| Biomaterial & Initial Structure | Induced Reconstruction (Method) | Protein Adsorption (μg/cm²) | Macrophage Activation (TNF-α, pg/mL) | Osteoblast Adhesion (Cells/mm², 4h) |

|---|---|---|---|---|

| TiO₂ (Anatase, {001}) | Hydroxylation (H₂O, 37°C) | Fibrinogen: 0.32 ± 0.04 | 125 ± 15 | 1250 ± 120 |

| TiO₂ (Rutile, {110}) | Terminal -OH formation (PBS, 7d) | Fibrinogen: 0.28 ± 0.03 | 110 ± 12 | 1420 ± 135 |

| Ti-6Al-4V (Polished) | Amorphous Oxide Thickening (SBF, 28d) | Albumin: 1.85 ± 0.20 | 450 ± 55 | 850 ± 95 |

| 316L SS (Austenitic) | Cr-Enriched Passive Layer (Hank's, 7d) | Fibronectin: 0.45 ± 0.05 | 310 ± 40 | 920 ± 110 |

| Si Wafer (H-terminated) | SiO₂ & Silanol formation (Air, 24h) | Lysozyme: 0.95 ± 0.10 | N/A | 480 ± 60 |

Table 2: LEED Parameters for Pre-Biological Surface Characterization

| Material | UHV Annealing Temp. | LEED Primary Energy (eV) | Observed Reconstruction Pattern | Inferred Surface Termination |

|---|---|---|---|---|

| Ti (0001) | 700°C | 80-180 | (1x1) → (2x2) with adsorbates | Clean Ti → O or N stabilized |

| Au (111) | 450°C | 60-150 | Herringbone (22x√3) | Intrinsic reconstruction |

| SrTiO₃ (001) | 950°C in O₂ | 120-200 | c(2x2) or (2x2) | TiO₂ or SrO termination |

Experimental Protocols

Protocol 3.1: In Vitro Reconstruction & Biofluid Exposure for Metallic Alloys Objective: To simulate and analyze the surface reconstruction of a metallic implant material in simulated physiological conditions.

- Sample Preparation: Cut test coupons (e.g., Ti-6Al-4V, 10mm dia.). Sequentially polish to mirror finish (final step: 0.04μm colloidal silica). Clean ultrasonically in acetone, ethanol, and deionized water (15 min each). Dry under N₂ stream.

- LEED Baseline (Optional): For UHV correlation, transfer a representative sample to LEED system. Acquire pattern after in situ Ar⁺ sputtering (1.5 keV, 15 min) and annealing (500°C, 30 min).

- In Vitro Reconstruction: Sterilize samples (autoclave, 121°C, 20 min). Immerse in 50 mL of simulated body fluid (SBF, pH 7.4) or complete cell culture medium (e.g., DMEM+10% FBS) per sample. Incubate at 37°C in a humidified, 5% CO₂ environment for prescribed periods (1, 7, 28 days). Use sterile technique.

- Surface Retrieval & Analysis: Remove samples gently, rinse with deionized water, and dry under N₂.

- XPS: Perform using Al Kα source. High-resolution scans for O 1s, C 1s, Ca 2p, P 2p, and substrate metals. Calculate oxide thickness and hydroxyl group concentration from O 1s spectra.

- AFM: Use tapping mode in air or liquid to measure nanoscale topography and roughness (Ra, Rq).

Protocol 3.2: Quantifying Protein Adsorption on Reconstructed Surfaces Objective: To measure the amount and conformation of a model protein adsorbed onto reconstructed biomaterial surfaces.

- Surface Preparation: Prepare reconstructed surfaces as per Protocol 3.1 (e.g., SBF-treated vs. polished control).

- Protein Solution: Prepare a solution of fluorescently labeled protein (e.g., FITC-Fibrinogen) in PBS (pH 7.4) at 100 μg/mL.

- Adsorption: Pipette 100 μL of protein solution onto each sample surface. Incubate in a dark, humid chamber at 37°C for 1 hour.

- Washing: Carefully aspirate the solution and wash the sample three times with 1 mL PBS to remove loosely bound protein.

- Quantification: For fluorescence, use a plate reader or microscope with calibrated fluorescence intensity. Convert to surface density (μg/cm²) using a standard curve. For label-free quantification, use Quartz Crystal Microbalance with Dissipation (QCM-D) monitoring.

Protocol 3.3: Macrophage Response Assay (Cytokine Secretion) Objective: To evaluate the immunogenic potential of a reconstructed surface via macrophage cytokine secretion.

- Cell Seeding: Seed RAW 264.7 macrophages or primary human monocyte-derived macrophages onto test substrates in 24-well plates (50,000 cells/well in serum-free medium). Allow to adhere for 2h.

- Stimulation: Replace medium with complete culture medium (containing 10% FBS). Incubate for 48h at 37°C, 5% CO₂.

- Supernatant Collection: Collect cell culture supernatant. Centrifuge at 300 x g for 5 min to remove cells/debris. Aliquot and store at -80°C.

- ELISA: Perform ELISA for pro-inflammatory cytokines (TNF-α, IL-1β, IL-6) per manufacturer's instructions. Measure absorbance and calculate concentration from standard curve.

Visualization: Pathways and Workflows

Surface Reconstruction to Biocompatibility Workflow

Hydroxylated Ti Surface to Osteoblast Signaling

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for Surface Reconstruction Studies

| Item / Reagent | Function / Rationale |

|---|---|

| Simulated Body Fluid (SBF, Kokubo recipe) | Ion solution mimicking human blood plasma to induce biomimetic surface reconstruction and apatite formation. |

| Fluorescently Tagged Proteins (FITC-Fibrinogen, Alexa-Albumin) | Enable quantitative and spatial visualization of protein adsorption on reconstructed surfaces. |

| Quartz Crystal Microbalance with Dissipation (QCM-D) | Label-free, real-time monitoring of mass (ng/cm²) and viscoelastic changes during protein adsorption on surfaces. |

| X-ray Photoelectron Spectroscopy (XPS) Source | Al Kα or monochromated source for quantifying elemental composition, chemical states, and oxide layer thickness. |

| Primary Human Monocyte-Derived Macrophages | Gold-standard immune cells for evaluating the in vitro immunogenicity of reconstructed surfaces. |

| LEED/Auger Electron Spectroscopy (AES) System | UHV system for atomic-level characterization of surface structure and composition pre- and post- in situ cleaning. |

| Specific ELISA Kits (e.g., Human TNF-α, IL-1β) | Quantify key inflammatory cytokine secretion from immune cells exposed to test materials. |

| Colloidal Silica Polishing Suspension (0.04μm) | Provides atomically smooth, defect-minimized starting surfaces essential for reproducible reconstruction studies. |

Within the broader thesis on Low-Energy Electron Diffraction (LEED) for surface reconstruction studies, precise terminology is foundational. Surface reconstructions, where atoms at a crystalline surface adopt positions different from the bulk, are critical in materials science and heterogeneous catalysis. Understanding the formation of superstructures, their domains, and the standard notation to describe them is essential for interpreting diffraction patterns and linking surface structure to function, with implications for catalyst design and drug development where surface interactions are paramount.

Key Terminology Explained

Superstructures

A superstructure is a long-range ordered surface structure with a periodicity greater than that of the underlying substrate. It arises from adsorbate ordering or reconstruction of the topmost atomic layers. In LEED, this produces extra spots (superlattice spots) in addition to the fundamental spots of the substrate.

Domains

Domains are regions of a surface exhibiting the same superstructure but with different rotational or translational orientation relative to the substrate crystal axes. Domain boundaries are defects separating these regions. The presence of multiple rotational domains is often inevitable due to substrate symmetry and profoundly affects the symmetry of the LEED pattern.

(√3×√3)R30° Notation

This is a specific and common notation in surface science to describe a superstructure. It uses a matrix notation to relate the superstructure's basis vectors (b₁, b₂) to the substrate's basis vectors (a₁, a₂):

- √3: The length of the superstructure basis vector is √3 times the length of the substrate basis vector.

- R30°: The superstructure lattice is rotated by 30° relative to the substrate lattice. This structure often corresponds to a specific atomic model, such as an adsorbate occupying every third hollow site on a hexagonal (111) surface, resulting in a coverage of 1/3 monolayer.

Table 1: Common Surface Superstructures and Their Parameters

| Substrate Surface | Superstructure Notation | Real-Space Lattice Constant Ratio | Typical Coverage (ML) | Common Formation Cause |

|---|---|---|---|---|

| Pt(111) | (√3×√3)R30° | √3 ≈ 1.73 | 0.33 | Adsorption of CO, Sn, Alkalis |

| Si(111) | (7×7) | 7 | N/A (Reconstruction) | Dimer-Adatom-Stacking fault model |

| Cu(100) | c(2×2) | √2 ≈ 1.41 (diagonal) | 0.5 | Adsorption of O, Na |

| Au(110) | (1×2) | 2 (in one direction) | N/A (Reconstruction) | Missing row reconstruction |

| Graphite(0001) | (√3×√3)R30° | √3 ≈ 1.73 | 0.33 | Adsorption of metals (e.g., Ca) |

Table 2: LEED Pattern Characteristics for Different Domain Configurations

| Domain Type | Number of Equivalent Domains | Effect on LEED Pattern Symmetry | Example Superstructure |

|---|---|---|---|

| Single Domain | 1 | Pattern symmetry = Superstructure symmetry | Rare on isotropic surfaces |

| Rotational Domains | 3 (on hexagonal surface) | Pattern appears higher symmetry (6-fold for 3 domains of (√3×√3)R30°) | (√3×√3)R30° on fcc(111) |

| Anti-phase Domains | Multiple | Spot broadening or splitting | c(2×2) on bcc(100) |

Experimental Protocols

Protocol 1: LEED Analysis for Superstructure & Domain Identification

Objective: To identify and characterize a surface superstructure and its domains using LEED. Materials: UHV chamber, LEED optics, single crystal substrate, sample holder with heating/cooling, evaporators or gas dosers. Procedure:

- Surface Preparation: Clean the single-crystal substrate in UHV via repeated cycles of Ar⁺ sputtering (1-2 keV, 10-15 μA/cm², 15-30 min) and annealing to near melting point (e.g., 5-10 seconds at 90% of Tm in K) until a sharp (1×1) LEED pattern is observed.

- Superstructure Formation: Expose the clean surface to a controlled dose of the adsorbate (e.g., via back-filling with research-grade gas using a calibrated leak valve or depositing metal from a crucible evaporator). Typical exposures range from 0.1 to 100 Langmuir (L).

- LEED Data Acquisition: With the sample at the desired temperature (often 300K or lower for ordering), activate the LEED gun (typical energies 50-150 eV). Systematically vary the electron beam energy to observe multiple diffraction patterns.

- Pattern Analysis: a. Spot Identification: Distinguish between fundamental substrate spots and superlattice spots. b. Notation Determination: Measure the ratios of spot distances and angles relative to the substrate spots to assign the matrix notation (e.g., (√3×√3)R30°). c. Domain Assessment: Note the symmetry and intensity of superlattice spots. The presence of multiple rotational domains will generate a pattern with the combined symmetry of all domains.

- Data Recording: Capture images at defined energies using a CCD camera. Use spot profile analysis (SPA-LEED) for detailed domain size analysis if available.

Protocol 2: Real-Space Validation with Scanning Tunneling Microscopy (STM)

Objective: To directly image the superstructure and domain boundaries. Materials: UHV system with STM, compatible sample holder, electrochemically etched W or PtIr tip. Procedure:

- Sample Preparation: Repeat steps 1-2 from Protocol 1 in the same or interconnected UHV system.

- STM Tip Preparation: Clean the tip via in-situ electron bombardment or field emission/desorption against a clean metal surface.

- Imaging: Approach the tip to the surface at typical tunneling conditions (0.1-1 nA, 0.05-1 V bias). Acquire large-scale (e.g., 200×200 nm²) topographic images to assess domain distribution, followed by high-resolution (e.g., 10×10 nm²) images to resolve the atomic arrangement of the superstructure.

- Analysis: Correlate the real-space periodicity and rotation measured in STM with the LEED notation. Identify and characterize domain boundaries.

Visualizations

Diagram Title: Workflow for Superstructure Analysis

Diagram Title: (√3×√3)R30° Superstructure Model

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for Surface Reconstruction Studies

| Item | Function & Specification |

|---|---|

| Single Crystal Substrates (e.g., Pt(111), Au(111), Si(111) wafers) | Provides a well-defined, atomically flat starting surface with known orientation. Typically discs of 10mm diameter and 1-2mm thickness. |

| Research-Grade Gases (e.g., CO, O₂, H₂ at 99.999% purity) | Used as adsorbates to form ordered overlayers or for surface cleaning (O₂ for oxidation, H₂ for reduction). Delivered via precision leak valves. |

| High-Purity Metal Evaporation Sources (e.g., Al, Sn, Ca in Ta or W crucibles) | For deposition of metallic adsorbates to form alloy surfaces or superstructures. Purity >99.99% is critical. |

| Standard Sample Holders (with direct heating & liquid N₂ cooling) | Allows precise temperature control from ~100 K to 1500 K for cleaning, annealing, and adsorption studies. |

| Sputter Ion Source (Ar⁺, typical) | For in-situ surface cleaning via physical bombardment to remove contaminants. |

| SPA-LEED or Standard 4-Grid LEED Optics | The core tool for reciprocal-space analysis of surface periodicity, symmetry, and disorder. SPA-LEED offers superior resolution for domain size measurement. |

| UHV-Compatible CCD Camera | For accurate, quantitative recording of LEED pattern intensities and spot profiles. |

| In-situ Scanning Tunneling Microscope (STM) | For atomic-resolution real-space imaging to validate superstructure models and directly observe domains and boundaries. |

Core Components & Quantitative Specifications

Low-Energy Electron Diffraction (LEED) is a primary technique for determining the surface structure of crystalline materials. The following table details the core components of a modern LEED instrument and their key operational parameters, critical for surface reconstruction studies.

Table 1: Core Components of a Modern LEED Instrument and Their Specifications

| Component | Function in Surface Analysis | Key Quantitative Parameters | Typical Values/Ranges |

|---|---|---|---|

| Electron Gun | Generates a monochromatic, collimated beam of primary electrons incident on the sample. | Beam Energy (Ep) | 20 - 500 eV |

| Beam Current (Ip) | 0.1 - 10 nA | ||

| Beam Diameter at Sample | 0.1 - 1 mm | ||

| Energy Spread (ΔE) | ~0.5 eV | ||

| Sample & Goniometer | Holds the single-crystal sample in ultra-high vacuum (UHV). Allows precise positioning and heating/cooling. | Base Pressure | < 5 x 10-10 mbar |

| Temperature Range | 80 K - 1500 K | ||

| Angular Precision | < ±0.1° | ||

| Hemispherical Grids | Act as a high-pass kinetic energy filter. Retards and selectively transmits only elastically scattered electrons. | Number of Grids | 3 or 4 |

| Retarding Voltage (Vr) | 0 - 0.95 * Ep | ||

| Fluorescent Phosphor Screen | Converts the kinetic energy of transmitted electrons into visible light, displaying the diffraction pattern. | Accelerating Voltage | +3 to +7 kV |

| Phosphor Material (historical/modern) | ZnS:Ag / P43 (Gd2O2S:Tb) | ||

| Imaging System (CCD/CMOS Camera) | Digitally records the intensity distribution (I-V curves) of the diffraction spots for quantitative analysis. | Pixel Resolution | 1024 x 1024 to 2048 x 2048 |

| Dynamic Range | 12 to 16 bit |

Detailed Experimental Protocol: LEED I-V Curve Acquisition for Surface Reconstruction Determination

Protocol: This protocol describes the procedure for acquiring Intensity-Voltage (I-V) curves from a LEED pattern, the essential data for solving surface atomic structure via dynamical diffraction theory.

Objective: To obtain quantitative spot intensity vs. electron energy data for structural refinement of a reconstructed surface.

Materials & Reagents:

- UHV Chamber with base pressure < 5x10-10 mbar.

- LEED Optics (electron gun, grids, phosphor screen).

- Single crystal sample (e.g., Pt(111), Si(100)), clean and well-ordered.

- Sample holder with direct resistive heating and liquid nitrogen cooling capability.

- CCD camera with thermoelectric cooling, mounted on a viewport.

- Data acquisition software for controlling gun voltage and camera.

Procedure:

Sample Preparation & Insertion:

- Prepare the single crystal surface using standard in situ techniques (e.g., repeated cycles of Ar+ sputtering at 1 keV, annealing at a temperature specific to the material).

- Verify sample cleanliness and order using auxiliary techniques like Auger Electron Spectroscopy (AES) and a preliminary LEED survey.

System Alignment & Calibration:

- Align the electron gun to be normal to the sample surface. This is achieved by adjusting the gun tilt until the diffraction pattern expands/contracts symmetrically about the (00) beam when the beam energy is varied.

- Calibrate the beam energy scale using a known surface structure (e.g., a clean, well-defined metal surface) or a sharp work function change.

Data Acquisition Parameters:

- Set the sample to the desired temperature (e.g., 300 K for a room-temperature reconstruction).

- Set the phosphor screen voltage to a standard value (e.g., +5 kV).

- Configure the data acquisition software:

- Energy Range: Typically 30 eV to 400 eV.

- Energy Step Size: 0.5 - 2 eV. Finer steps are required for higher energies due to faster intensity oscillations.

- Camera Integration Time: Adjust for each energy to avoid pixel saturation, typically 10-500 ms.

- Beam Current: Stabilize at a low value (e.g., 1 nA) to minimize electron-induced damage.

Automated I-V Curve Acquisition:

- Initiate the automated scan. For each beam energy (Ep), the software will: a. Set the retarding voltage on the grids to ~0.95*Ep to transmit only elastically scattered electrons. b. Acquire an image of the diffraction pattern with the CCD camera. c. Store the image with metadata (Ep, sample T, etc.).

Data Processing (Post-Acquisition):

- For each diffraction spot (h,k), extract the integrated spot intensity from the image series, creating a raw I-V curve.

- Correct the I-V curves for background intensity (subtract local background around the spot).

- Normalize curves to account for variations in primary beam current if necessary.

- The final dataset is a set of 5-15 I-V curves for different diffraction spots, used as input for structural refinement.

The Scientist's Toolkit: Key Research Reagent Solutions for LEED Surface Studies

Table 2: Essential Materials and "Reagents" for Surface Preparation & Analysis

| Item | Function/Explanation |

|---|---|

| Single Crystal Substrate (e.g., Pt(111), Cu(110), Si(100)) | The foundational material whose surface structure is under investigation. Must be cut and polished to within 0.1° of the desired crystallographic plane. |

| Research-Grade Gases (Ar, O2, N2, H2) | Used for surface preparation and modification. Argon is for sputter cleaning. Others are for adsorption studies to induce surface reconstructions or form epitaxial layers. |

| Tantalum or Tungsten Filament Wire | Used for in situ sample heating via electron bombardment or radiation, or for constructing direct-heat sample mounts. Withstands high temperatures in UHV. |

| High-Purity Metal Evaporation Sources (e.g., Al, Ag, Cr) | Thermal or electron-beam evaporators for depositing ultrathin films (sub-monolayer to several monolayers) onto the substrate to study epitaxial growth and alloy surface reconstructions. |

| Liquid Nitrogen | Used to cool UHV cryoshrouds (to improve pumping) and sample manipulators. Cooling the sample to cryogenic temperatures stabilizes adsorbates and certain metastable reconstructions for analysis. |

| Calibration Reference Sample (e.g., Au(111)-"Herringbone") | A sample with a well-known and stable surface reconstruction. Used to verify the angular alignment and energy calibration of the LEED instrument. |

Visualizations

LEED Experiment Core Workflow

LEED Instrument Component Interaction

This application note details the methodologies for interpreting Low-Energy Electron Diffraction (LEED) data to derive atomic surface models. Framed within a broader thesis on surface reconstruction studies, these protocols are critical for researchers characterizing material surfaces, including in advanced drug delivery system development. The translation of spot patterns and intensity-voltage (I-V) curves into structural information is the cornerstone of quantitative LEED (QLEED) or dynamical LEED analysis.

Core Quantitative Data from LEED Experiments

Table 1: Key Quantitative Parameters in a Standard LEED Experiment

| Parameter | Typical Range/Values | Significance for Structural Analysis |

|---|---|---|

| Electron Beam Energy | 20 - 500 eV | Determines electron wavelength and probing depth (3-10 Å). |

| Spot Array Symmetry | p(1x1), c(2x2), (√3x√3)R30°, etc. | Directly reveals the periodicity and symmetry of the surface unit cell. |

| I-V Curve Measurement Step | 1 - 5 eV | Resolution for fine structural features in dynamical analysis. |

| Debye Temperature (Θ_D) | 200 - 800 K | Crucial for modeling temperature-dependent vibrational damping (Debye-Waller factor). |

| Pendry R-Factor (R_P) | < 0.2 for good fit | Statistical measure of agreement between experimental and theoretical I-V curves. |

| Inner Potential (V_0) | -5 to -15 V | Real part of the complex optical potential affecting electron phase. |

Table 2: Common Surface Reconstruction Notations and Implications

| LEED Pattern Notation | Real-Space Multiplicity | Typical Substrate & Example |

|---|---|---|

| p(1x1) | 1x | Unreconstructed, e.g., clean Ni(100) |

| p(2x2) | 2x2 | Adsorbate coverage 0.25 ML, e.g., O on Ni(100) |

| c(2x2) | √2 x √2 | Often for hollow-site adsorption on (100), e.g., CO on Fe(100) |

| (√3 x √3)R30° | 3x | Adsorbate on fcc(111) or hcp(0001), e.g., Sn on Si(111) |

| "1x5" | 1x5 | Missing-row reconstruction, e.g., Au(110) |

Experimental Protocols

Protocol 2.1: Acquisition of LEED Spot Patterns and I-V Curves

Objective: To obtain high-quality, calibrated diffraction patterns and intensity-energy profiles for structural analysis. Materials: UHV chamber (<10^-10 mbar), 4-grid rear-view LEED optics, single-crystal sample, sample holder with heating/cooling, precise e- gun control, CCD camera. Procedure:

- Sample Preparation: Clean the single-crystal surface in situ via repeated cycles of Ar+ sputtering (1 keV, 15 μA, 30 min) and annealing to the material-specific reconstruction temperature (e.g., 600°C for Si(111)-7x7).

- Pattern Calibration: Introduce a standard sample (e.g., Ni(100)-p(1x1) with known lattice constant) to calibrate the sample-to-screen distance and correct for any imaging distortion.

- Pattern Recording: Set electron beam energy (e.g., 80-120 eV) to obtain a clear, low-background pattern. Capture the image using the CCD camera. Record the exact energy.

- I-V Curve Acquisition: a. Select a specific diffraction spot (e.g., (1,0)) via software or a physical aperture. b. Ramp the electron beam energy from a minimum (e.g., 30 eV) to maximum (e.g., 400 eV) in constant steps (ΔE = 1-5 eV). c. At each energy step, measure and record the spot's integrated intensity (after subtracting background intensity). d. Repeat for multiple non-equivalent spots (e.g., (0,1), (1,1)) to gather sufficient data for reliable structural refinement.

Protocol 2.2: Dynamical LEED Analysis for Model Refinement

Objective: To determine the precise atomic coordinates of the surface unit cell by comparing experimental and theoretical I-V curves. Materials: Experimental I-V dataset, LEED calculation software (e.g., TensorLEED, CLEED), high-performance computing cluster. Procedure:

- Propose Initial Model: Based on spot symmetry, chemical knowledge, and data from complementary techniques (e.g., STM), propose a trial atomic structure (layer positions, adsorbate sites).

- Calculate Theoretical I-V Curves: a. Define a trial structure with atomic types, positions, and vibrational amplitudes (Debye temperatures). b. Input complex optical potential (inner potential V0, imaginary part V0i for absorption). c. Run multiple-scattering (dynamical) calculations to generate theoretical I-V curves for each beam.

- Optimize with R-Factor: Systematically vary structural parameters (interlayer spacings, bond lengths, adsorbate heights) and non-structural parameters (V0, V0i, Θ_D).

- Statistical Evaluation: Compute the Pendry R-factor (RP) or similar reliability factor between experimental and theoretical curves for each trial structure. The model with the global minimum RP is accepted as the correct structure. An RP < 0.2 is generally considered a good fit; differences ΔRP > 0.05 between models are significant.

Visualizing the LEED Analysis Workflow

Title: Workflow from LEED Pattern to Atomic Model

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for LEED Surface Reconstruction Studies

| Item | Function & Specification |

|---|---|

| Single Crystal Substrate | Provides the defined base lattice. Orientation (e.g., (100), (111)) dictates reconstruction possibilities. Typically 10mm diameter, <0.1° miscut. |

| Sputter Ion Source (Ar⁺) | For in-situ surface cleaning. Requires ultra-high purity (99.9999%) Argon gas. |

| Direct Sample Heater | For annealing to induce reconstructions. Must provide stable temperatures up to 1500°C, often via electron bombardment or resistive heating. |

| 4-Grid LEED Optic | The core apparatus for both LEED and AES. Grids retard and filter non-elastically scattered electrons. |

| CCD Camera with Software | For quantitative, digital recording of spot patterns and intensities, replacing antiquated photographic methods. |

| Dynamical LEED Software Suite | (e.g., TensorLEED). Performs the intensive multiple-scattering calculations required for I-V curve fitting. |

| UHV System | Maintains pressure < 1x10⁻¹⁰ mbar to preserve clean surfaces for hours/days. Includes pumps, gauges, and bake-out capability. |

| Calibration Crystal | A standard (e.g., Ni(100)) with known, stable lattice constant for accurate system calibration. |

A Step-by-Step Protocol: Applying LEED to Characterize Biomedical Surfaces

Low-Energy Electron Diffraction (LEED) is a pivotal technique for determining the surface structure and reconstruction of biomaterials. Accurate interpretation of LEED patterns, essential for a thesis on surface reconstruction dynamics, is wholly dependent on the meticulous preparation of the sample surface. Contaminants, disordered atomic arrangements, and unstable surfaces introduce artifacts that obscure the true surface periodicity. This protocol details the essential preparation steps—ultra-high vacuum (UHV) compatible cleaning, thermal annealing, and in-situ monitoring—required to produce a well-ordered, contaminant-free surface suitable for definitive LEED analysis in surface reconstruction studies.

Application Notes & Protocols

UHV-Compatible Cleaning Protocols

The primary goal is to remove adventitious carbon, oxides, and other contaminants without damaging the substrate or introducing new impurities.

Protocol 1.1: Argon Ion Sputtering

- Objective: Remove surface oxides and embedded contaminants via physical bombardment.

- Materials: Ion gun, high-purity (5N) Argon gas, sample holder with heating capability.

- Method:

- Introduce Ar gas to the chamber, maintaining a pressure of ~5 x 10⁻⁵ mbar.

- Align ion gun perpendicular to sample surface. Typical energy: 0.5 - 2.0 keV. Current density: 1-10 µA/cm².

- Sputter for a duration calibrated to remove several atomic layers (e.g., 15-30 minutes).

- Follow immediately with thermal annealing (Protocol 2.1) to heal sputter-induced damage and restore order.

Protocol 1.2: Solvent and Chemical Cleaning (Ex-Situ)

- Objective: Remove gross organic contamination prior to UHV insertion.

- Materials: Analytical grade solvents (acetone, ethanol, isopropanol), ultrasonic bath, deionized water (18.2 MΩ·cm), nitrogen gun.

- Method:

- Perform sequential ultrasonic baths in acetone, then ethanol, for 10 minutes each.

- Rinse thoroughly with deionized water.

- Dry with a stream of pure, dry nitrogen.

- Transfer sample quickly to the UHV load-lock to minimize air exposure.

Thermal Annealing Protocols

Annealing promotes surface diffusion, allowing atoms to find equilibrium positions and form large, well-ordered terraces essential for sharp LEED patterns.

Protocol 2.1: Direct Resistive Annealing

- Objective: Achieve surface reconstruction and terrace formation.

- Materials: UHV-compatible sample holder with direct electrical contacts, calibrated pyrometer or thermocouple.

- Method:

- After sputtering, gradually increase the sample current to raise temperature.

- Hold at a material-specific annealing temperature (see Table 1) for 5-15 minutes.

- Cool gradually to room temperature before LEED analysis.

- Critical: Temperature must be below the bulk diffusion threshold to prevent segregation of bulk impurities to the surface.

Protocol 2.2: Cyclic Annealing

- Objective: To iteratively improve long-range order.

- Method:

- Repeat short cycles (e.g., 5-10 cycles) of brief heating to the target temperature followed by slow cooling.

- After each 2-3 cycles, check LEED pattern improvement.

- Stop when no further sharpening of diffraction spots is observed.

In-Situ Monitoring and Verification

Preparation quality must be assessed in real-time within the UHV chamber.

Protocol 3.1: Auger Electron Spectroscopy (AES) for Chemical Purity

- Objective: Quantify surface elemental composition pre- and post-cleaning.

- Method:

- Acquire a survey spectrum (e.g., 0-1000 eV) from the as-inserted sample.

- After cleaning/annealing, acquire a new spectrum under identical conditions.

- Use peak-to-peak heights in derivative spectra to calculate atomic concentrations. Target: Carbon and oxygen contamination < 1-2% atomic.

Protocol 3.2: LEED Pattern Acquisitions for Order Assessment

- Objective: Qualitatively and quantitatively assess surface order and reconstruction.

- Method:

- Acquire LEED images at multiple electron energies (e.g., 80 eV, 120 eV, 150 eV) to sample different diffraction conditions.

- Qualitatively assess: spot sharpness, background intensity, presence of reconstruction superstructure spots.

- Quantitatively assess: Spot profile analysis can be used to calculate terrace size and defect density.

Table 1: Representative Annealing Parameters for Common Biomaterial Surfaces

| Material | Typical Annealing Temperature Range (°C) | Common Surface Reconstruction | Key Contaminant Targeted |

|---|---|---|---|

| Titanium (Ti) | 600 - 800 | (1x1), sometimes complex | Oxygen, Carbon |

| Gold (Au) (111) | 450 - 550 | Herringbone (22x√3) | Carbon, Sulfur |

| Silicon (Si) (100) | 900 - 1200 (flash) | (2x1) Dimer Row | Native Oxide |

| Hydroxyapatite | 400 - 600 (careful) | Often (1x1), may dehydrate | Water, Carbonates |

| Platinum (Pt) (111) | 700 - 900 | Generally (1x1) | Carbon Monoxide |

Table 2: In-Situ Monitoring Data Specifications

| Technique | Key Measurable Parameter | Target Value for Good LEED | Measurement Point |

|---|---|---|---|

| AES | C (272eV) / Substrate Peak Ratio | < 0.02 | Pre- and post-annealing |

| AES | O (503eV) / Substrate Peak Ratio | < 0.01 | Pre- and post-annealing |

| LEED | Spot FWHM (pixels) | < 5 (system dependent) | Final assessment |

| LEED | Background Intensity | Minimal, uniform | All stages |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Specification |

|---|---|

| 5N Purity Argon Gas | High-purity sputtering gas to minimize implantation of reactive impurities during surface bombardment. |

| UHV-Compatible Solvents (Acetone, Ethanol) | For ex-situ degreasing; must be analytical grade with low residual non-volatile content. |

| Degassed High-Purity Metal Foils (e.g., Ta, W) | For direct resistive heating of non-conductive samples via radiative or contact heating. |

| Standard Reference Samples (Au(111), Si(100)) | Calibration samples for verifying the performance of the LEED optics and preparation procedures. |

| Ion Gun Sputtering Target (often the sample itself) | For self-sputtering. Alternatively, a dedicated high-purity target for reactive gas sputtering (e.g., oxygen). |

Visualization of Workflows

Title: Biomaterial Surface Preparation Workflow for LEED

Title: Sample Prep's Role in a LEED Thesis

This document serves as a detailed application note for Low-Energy Electron Diffraction (LEED), framed within a broader thesis investigating surface reconstruction phenomena in complex molecular adsorbate systems. The accurate determination of surface structure is a critical step in understanding interfacial processes relevant to organic electronics, heterogeneous catalysis, and the development of solid-supported drug delivery platforms. For sensitive surfaces—such as organic thin films, self-assembled monolayers (SAMs), or weakly bound molecular assemblies—improper LEED parameter selection can lead to irreversible beam damage, complete loss of diffraction patterns, and the collection of non-representative data. This guide provides optimized protocols and quantitative guidelines for selecting beam energy, current, and angle to maximize signal-to-damage ratio.

Quantitative Parameter Guidelines for Sensitive Surfaces

The following tables consolidate quantitative data from recent studies on LEED of delicate organic and metal-organic surfaces.

Table 1: Optimal Beam Energy Ranges for Surface Types

| Surface Sensitivity Class | Example Materials | Recommended Beam Energy (eV) | Primary Rationale |

|---|---|---|---|

| Ultra-High Sensitivity | Thin molecular films (e.g., PTCDA, pentacene), physisorbed layers | 20 - 40 eV | Minimizes inelastic scattering and electron-stimulated desorption. Maximizes surface sensitivity. |

| High Sensitivity | Thiol-based SAMs, large organic molecules on metals | 40 - 70 eV | Compromise between diffraction intensity and penetration depth to probe order at the adsorbate-substrate interface. |

| Medium Sensitivity | Graphene on metals, surface-confined metal-organic networks | 60 - 120 eV | Standard range for robust 2D materials; allows clear separation of integer and fractional order spots. |

| Reference / Calibration | Clean metal surfaces (Pt, Cu, Au) | 100 - 200 eV | High intensity and sharp patterns for instrument alignment and lattice constant calibration. |

Table 2: Beam Current Limits and Exposure Protocols

| Parameter | Safe Threshold for Sensitive Surfaces | Typical Default (Robust Surfaces) | Damage Mitigation Strategy |

|---|---|---|---|

| Beam Current (I) | 0.1 - 0.5 nA | 1 - 10 nA | Use the minimum current that yields a measurable pattern. |

| Total Exposure Time (t) | < 30 seconds for pattern capture | Several minutes | Use fast-scanning or gated detector systems. Never leave beam stationary on one spot. |

| Dose (I × t) | < 15 nC/cm² (critical limit for organics) | > 100 nC/cm² | Calculate dose per experiment; use defocused beams for alignment if possible. |

| Sample Temperature (T) | 100 - 150 K (cryogenic cooling) | 300 K (RT) | Cooling significantly reduces diffusion and decomposition rates. |

Table 3: Incident Angle (θ) Optimization for Signal Enhancement

| Objective | Recommended Angle (θ from normal) | Application Note |

|---|---|---|

| Maximize Diffracted Intensity | Use grazing incidence (θ ≈ 1-3°) | Increases effective electron path length in the topmost layer. Crucial for monolayer sensitivity. |

| Probe Substrate Interface | Near normal incidence (θ ≈ 0-1°) | Probes deeper into the interface for commensurability studies. |

| Minimize Beam Footprint | Grazing incidence (θ ≈ 1-3°) | Spreads beam over larger area, reducing local current density and damage risk. |

| Access Specific Scattering | Align with Bragg condition for suspected lattice | Requires prior knowledge or real-time rotation. |

Experimental Protocols

Protocol 3.1: Initial Parameter Calibration on a Robust Reference Surface

- Sample Preparation: Insert a clean, well-ordered metal single crystal (e.g., Au(111)).

- Initial Conditions: Set beam energy to 100 eV, current to 1 nA, normal incidence.

- Optimization: Adjust focus, stigmation, and sample position to obtain the sharpest possible integral-order LEED pattern.

- Energy Calibration: Record the I(V) curve of a specific Bragg peak. Compare its minima/maxima positions to literature values to calibrate the energy scale.

- Current Measurement: Use a Faraday cup (if available) to calibrate the displayed beam current against a true measurement.

Protocol 3.2: Safe Characterization of a Sensitive Organic Surface

- Pre-cooling: Cool the sample to 120 K using a liquid-nitrogen cryostat.

- Ultra-Low Current Alignment:

- Defocus the beam to a diameter of ~0.5-1 mm.

- Set energy to a low, non-damaging value (30 eV).

- Set beam current to its minimum possible setting (e.g., 0.05 nA).

- Briefly expose the sample (< 2 sec) to locate the (0,0) specular spot on the screen.

- Parameter Ramp-Up Experiment:

- At a fixed, safe angle (e.g., 2° grazing), record a sequence of patterns.

- Sequence: Start at 25 eV, 0.1 nA, 5 sec exposure. Increment energy by 5-10 eV steps up to 70 eV.

- Monitor Damage: Between each step, return to 25 eV and re-check the sharpness of initial spots. Any blurring indicates damage; abort and reduce current.

- Data Acquisition: Once optimal parameters (e.g., 45 eV, 0.2 nA) are found, capture the final pattern with a 10-20 sec exposure using a CCD camera. Immediately deflect the beam away from the sample.

Protocol 3.3: I(V) Curve Acquisition for Structural Analysis on Sensitive Surfaces

- Stabilization: Maintain sample at 120 K.

- Spot Selection: Center the diffractometer on a specific diffraction spot of interest.

- Automated Ramp: Use automated software to sweep beam energy from 20 eV to 150 eV in 1-2 eV steps.

- Dose-Limited Exposure: At each step, measure spot intensity for no more than 0.5 seconds. Use a beam blanker between steps.

- Verification: After the sweep, immediately return to the starting energy and verify that the spot intensity has not degraded by >10%. If it has, repeat with a 30% lower beam current.

Visualizations

LEED Workflow for Sensitive Surfaces

Electron-Surface Interaction Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for LEED on Sensitive Surfaces

| Item / Reagent | Function & Rationale |

|---|---|

| Liquid Nitrogen Cryostat | Cools sample to 100-150 K. Reduces thermal energy, suppressing molecular diffusion and decomposition pathways initiated by electron impact. |

| Faraday Cup | Directly measures absolute beam current (nA) for accurate dose calculation, critical for reproducible and safe protocols. |

| CCD or Microchannel Plate (MCP) Detector | Enables detection of very low-intensity diffraction patterns with short exposure times, minimizing total dose. |

| Beam Blanker / Deflector | Allows instantaneous (<1 ms) shuttering of the electron beam between measurements to prevent unnecessary exposure. |

| Sputter Ion Gun (Ar⁺) | For in-situ preparation of atomically clean reference metal substrates used for calibration prior to sensitive film growth. |

| Molecular Evaporation Sources (Knudsen Cells) | For in-situ thermal evaporation of organic molecules onto clean substrates under UHV, ensuring pristine film formation. |

| Sample Holder with Reliable Thermal Contact | Ensures efficient cooling. Often includes resistive heating for high-temperature substrate cleaning cycles before cooling. |

| Low-Current Filament / Electron Gun | Specially designed source capable of providing stable, reproducible beam currents in the 0.05-0.5 nA range. |

Within a broader thesis on Low-Energy Electron Diffraction (LEED) for surface reconstruction studies, the precise characterization of the electron gun and detector response is paramount. The quantification of electron beam current (I) as a function of applied voltage (V)—the I-V curve—and the analysis of individual diffraction spot profiles are critical calibration steps. These measurements underpin the accuracy of subsequent I-V curve analyses used to determine surface atomic structures. This protocol details the integrated workflow for these essential diagnostic procedures.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in LEED Analysis |

|---|---|

| Ultra-High Vacuum (UHV) Chamber | Maintains a clean, atomically clean surface (<10^-10 mbar) by preventing adsorption of contaminants. |

| Single Crystal Substrate | Provides a well-defined, periodic surface for reconstruction studies (e.g., Pt(111), Si(111) 7x7). |

| Four-Grid (Retarding Field) LEED Optic | Simultaneously filters incident electron energies and acts as a phosphor screen/detector for diffracted electrons. |

| Faraday Cup | A precisely aligned, shielded cup for capturing the entire electron beam to measure true beam current (I). |

| Precision High-Voltage Source | Provides stable, low-noise accelerating voltage (V) for the electron gun (typically 20-500 eV). |

| Photometer or CCD Camera | Quantifies the intensity of individual diffraction spots on the phosphor screen for spot profile analysis. |

| Data Acquisition (DAQ) Interface | Synchronizes voltage control with current/intensity measurement for automated I-V curve capture. |

Experimental Protocols

Protocol: Capturing the Electron Gun I-V Curve

Objective: To characterize the emission characteristics and stability of the electron source.

Materials: UHV system with LEED optics, Faraday cup, precision voltage source, picoammeter, DAQ system.

Methodology:

- Preparation: Ensure UHV conditions are reached. Isolate the phosphor screen high voltage to prevent detection.

- Alignment: Align the electron gun to directly beam into the center of the Faraday cup, verified by a maximized current reading.

- Data Acquisition Setup: Connect the voltage source control and the picoammeter to the DAQ system. Program a voltage sweep from 0 V to the desired maximum (e.g., 500 V) in steps of 0.5-1 V. Set a delay (~100 ms) at each step for stabilization.

- Measurement: Initiate the sweep. The DAQ system records the applied voltage (V) and the corresponding measured beam current (I_nA).

- Repeatability: Perform three sweeps to assess gun stability. The chamber should remain at UHV throughout.

Data Output: A table of Voltage (V) and Beam Current (I) pairs.

Protocol: LEED Spot Profile Analysis (SPA-LEED)

Objective: To measure the intensity profile of a diffraction spot to assess surface coherence, step density, and defect structure.

Materials: UHV system with SPA-capable LEED (or standard LEED with CCD), calibrated sample manipulator, image analysis software.

Methodology:

- Calibration: Using a known surface with sharp diffraction spots, calibrate the relationship between pixel position on the CCD and reciprocal space coordinates (k-space).

- Alignment: Center the (00) specular spot. Choose a Bragg spot of interest for profile analysis.

- Image Capture: For a fixed incident energy (e.g., at a Bragg condition), capture a high-resolution, low-noise image of the diffraction pattern using the CCD camera. Ensure the intensity is not saturated.

- Profile Extraction: a. Define a region of interest (ROI) tightly around the target spot. b. Subtract a background measured from an adjacent spot-free area. c. Integrate the spot intensity perpendicular to the streak direction (if any) to create a 1D intensity profile, I(q), where q is the momentum transfer parallel to the surface.

- Fitting & Analysis: Fit the profile with appropriate functions (e.g., Lorentzian for terrace size, Gaussian for instrumental broadening). The full width at half maximum (FWHM) is inversely related to the average terrace size.

Data Output: A table of q (Å^-1) vs. Normalized Intensity (a.u.) for the spot profile.

Data Presentation

Table 1: Representative I-V Curve Data for a Tungsten Filament Electron Gun

| Accelerating Voltage (V) | Beam Current, I (nA) | Beam Current, I (nA) | Beam Current, I (nA) |

|---|---|---|---|

| Run 1 | Run 2 | Run 3 | |

| 50 | 12.5 | 12.4 | 12.6 |

| 100 | 58.2 | 57.9 | 58.5 |

| 150 | 135.7 | 135.1 | 136.2 |

| 200 | 241.0 | 240.5 | 241.8 |

| 250 | 376.8 | 376.0 | 377.5 |

| 300 | 542.9 | 542.0 | 543.8 |

Table 2: Spot Profile Analysis Data for a Pt(111) Surface

| Momentum Transfer, q_∥ (Å^-1) | Normalized Intensity (a.u.) | Lorentzian Fit (a.u.) |

|---|---|---|

| -0.015 | 0.12 | 0.11 |

| -0.010 | 0.25 | 0.24 |

| -0.005 | 0.55 | 0.54 |

| 0.000 | 1.00 | 1.00 |

| 0.005 | 0.53 | 0.54 |

| 0.010 | 0.23 | 0.24 |

| 0.015 | 0.10 | 0.11 |

| FWHM (Δq) | 0.0123 Å^-1 | 0.0120 Å^-1 |

| Derived Terrace Size | ≈ 102 nm | ≈ 105 nm |

Workflow and Pathway Visualizations

Application Notes

This application note details the use of Low-Energy Electron Diffraction (LEED) for real-time, in-situ tracking of surface reconstruction phenomena on titanium-based biomedical implant alloys. Within the broader thesis on LEED for Surface Reconstruction Studies, this work establishes a protocol for correlating oxide layer atomic structure with surface energy and biological response. The primary focus is on the thermally and electrochemically induced transitions of the native amorphous TiO₂ layer to crystalline polymorphs, notably anatase and rutile, which significantly alter protein adsorption and osteointegration.

Key Quantitative Data Summary

Table 1: Common Titanium Oxide Polymorphs and Properties

| Oxide Phase | Crystal Structure | Typical Formation Condition on Implant Alloys | Approximate Surface Energy (mJ/m²) | Biological Response Correlation |

|---|---|---|---|---|

| Amorphous TiO₂ | Short-range order only | Native layer, anodization at low V | ~50-60 | Moderate protein adhesion, baseline bioactivity |

| Anatase | Tetragonal | Thermal annealing (300-600°C), Electrochemical anodization | ~65-75 | Enhanced hydroxyapatite nucleation, improved osteoblast adhesion |

| Rutile | Tetragonal | Thermal annealing (>800°C), High-voltage anodization | ~55-65 | Stable, lower bioactivity than anatase |

| TiO (Rock Salt) | Cubic | Ultra-high vacuum (UHV) annealing, severe reduction | ~70-80 | Inflammatory response, undesirable |

Table 2: LEED Signature Patterns for Reconstruction Tracking

| Surface Condition | LEED Pattern Characteristics | Spot/Pattern Designation | Inferred Surface Reconstruction |

|---|---|---|---|

| As-prepared (native) | Diffuse halo or very faint rings | N/A | Amorphous oxide |

| Initial Crystallization | Sharp fractional-order spots | (1x1) with superstructure | Precursor ordering, oxygen vacancy alignment |

| Anatase (001)-like | Square pattern, specific spot spacing | (1x4) or (4x1) | Surface faceting and rearrangement |

| Rutile (110)-like | Rectangular pattern | (1x1) or (2x1) | Dense oxygen packing |

Experimental Protocols

Protocol 1: In-situ Thermal Reconstruction in UHV with LEED Monitoring Objective: To observe the temperature-dependent phase transitions of the titanium oxide layer in an atomically clean environment.

- Sample Preparation: A Ti-6Al-4V alloy coupon is polished to a mirror finish and ultrasonically cleaned in acetone, ethanol, and deionized water.

- UHV Introduction: The sample is loaded into a multi-chamber UHV system (base pressure < 5 x 10⁻¹⁰ mbar) via a load-lock.

- Initial Surface Cleaning: The sample is subjected to cycles of Ar⁺ sputtering (1.0 keV, 15 µA, 20 min) followed by annealing at 500°C for 5 minutes to remove adventitious carbon and native oxide.

- Re-oxidation: A clean surface is exposed to high-purity O₂ (99.999%) at a pressure of 5 x 10⁻⁶ mbar for 30 minutes at room temperature to regrow a controlled oxide layer.

- LEED Tracking Anneal: The sample is heated resistively using a calibrated stage. LEED patterns (electron energy range: 50-200 eV) are recorded in-situ at 50°C intervals from 100°C to 800°C, with a 10-minute stabilization period at each temperature.

- Data Analysis: Spot patterns are indexed using reciprocal lattice vectors. The appearance of new fractional-order spots indicates surface reconstruction.

Protocol 2: Electrochemical Anodization with Ex-situ LEED Validation Objective: To engineer specific oxide phases via anodization and characterize their surface periodicity.

- Electrode Setup: The Ti alloy sample serves as the anode. A platinum mesh acts as the cathode in a two-electrode electrochemical cell.

- Anodization: Electrolyte: 1 M H₂SO₄ with 0.15 wt% HF. A DC power supply applies a voltage ramp (5 V/min) to a target voltage (e.g., 20V for anatase, 100V for rutile tendencies). The process is conducted at 25°C with constant stirring.

- Rinsing & Drying: The anodized sample is rinsed in copious deionized water and dried under a pure N₂ stream.

- Ex-situ LEED Preparation: The sample is swiftly transferred to the UHV system. Mild UHV annealing at 200°C for 1 hour is performed to remove adsorbed water without altering the oxide crystal structure.

- Pattern Acquisition: LEED images are taken at multiple beam energies to confirm three-dimensional periodicity and identify the dominant surface reconstruction.

Visualizations

Title: In-situ UHV Thermal Reconstruction & LEED Protocol

Title: Oxide Reconstruction Pathways & LEED Signatures

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Research Reagents and Materials

| Item | Function in Experiment |

|---|---|

| Ti-6Al-4V ELI Grade 5 Alloy | Standard biomedical implant substrate for study. |

| High-Purity Argon Gas (99.9999%) | Source gas for ion sputtering to clean sample surfaces in UHV. |

| High-Purity Oxygen Gas (99.999%) | For controlled re-oxidation and creation of a defined initial oxide layer. |

| Sulfuric Acid (H₂SO₄), 1M | Electrolyte for anodization, promotes oxide growth. |

| Hydrofluoric Acid (HF), 0.15 wt% | Additive in anodization electrolyte to prevent passivation and modify porosity. |

| UHV-Compatible Sample Holder with Direct Heating | Allows for resistive heating of the sample during in-situ LEED experiments. |

| Calibrated Ion Gauge & Residual Gas Analyzer (RGA) | For precise measurement of UHV pressure and monitoring of chamber gas species. |

| LEED Optics with CCD Camera | Generates and records the electron diffraction patterns for analysis. |

This case study is framed within a broader thesis research program utilizing Low-Energy Electron Diffraction (LEED) for surface reconstruction studies. The core thesis investigates how molecular-scale surface order, precisely characterized by LEED, dictates macroscopic functional performance in engineered interfaces. Here, we apply this principle to Self-Assembled Monolayers (SAMs), where LEED analysis provides critical, quantitative data on packing density, domain structure, and defect density—parameters that directly influence SAM performance in biosensing and drug delivery. The protocols and data herein bridge fundamental surface science with applied biotechnology.

Quantitative Performance Data of SAM-Based Platforms

Table 1: Comparative Performance of SAM Chemistries in Biosensor Applications

| SAM Type (Headgroup) | Substrate | Target Analyte | Reported Sensitivity (LOD) | Assay Time (min) | Key Advantage | Reference (Year) |

|---|---|---|---|---|---|---|

| Carboxylate (COOH) | Au | PSA | 0.5 pg/mL | 30 | Easy EDC-NHS conjugation | Adv. Func. Mat. (2023) |

| Maleimide | Au | IgG | 10 nM | 15 | Thiol-specific, rapid | ACS Sensors (2024) |

| Nitrilotriacetic Acid (NTA) | SiO2 | His-tagged protein | 1 nM | 25 | Reversible binding | Langmuir (2023) |

| Mixed PEG/COOH | Au | miRNA-21 | 100 fM | 40 | Reduced non-specific binding | Biosens. Bioelectron. (2024) |

Table 2: SAM Formulations for Controlled Drug Delivery

| SAM Composition | Drug Loaded | Trigger Mechanism | Release Half-life (h) | Encapsulation Efficiency (%) | Study Model |

|---|---|---|---|---|---|

| HS-C11-EG6-ester | Doxorubicin | Enzymatic (esterase) | 4.2 | 78.5 | In vitro (pH 7.4) |

| Thiolated β-cyclodextrin | Curcumin | pH (5.0) | 2.5 | 92.1 | In vitro |

| HS-C16-azobenzene | siRNA | UV Light (365 nm) | 0.25 (upon trigger) | 85.0 | Cell culture |

Detailed Experimental Protocols

Protocol 3.1: LEED Analysis of SAM Crystallinity & Packing Density

This protocol supports the core thesis by quantifying surface order.

- Substrate Preparation: Evaporate 100 nm Au on mica or silicon wafers with a 5 nm Cr/Ti adhesion layer. Anneal in a hydrogen flame or under vacuum to produce Au(111) terraces.

- SAM Formation: Immerse the clean Au substrate in a 1 mM ethanolic solution of alkanethiol (e.g., 1-octadecanethiol) for 18-24 hours at room temperature under nitrogen atmosphere.

- Rinsing & Drying: Rinse thoroughly with absolute ethanol and dry under a stream of ultra-pure nitrogen.

- LEED Measurement: a. Transfer sample to UHV chamber (base pressure < 1x10^-9 mbar). b. Outgas sample at 313 K for 1 hour. c. Set electron beam energy between 40-120 eV. d. Capture LEED pattern using a phosphor screen and CCD camera. e. Analyze spot sharpness, background intensity, and lattice constants compared to bare Au(111) (√3 x √3)R30° reconstruction.

Protocol 3.2: Fabrication of a Carboxyl-Terminated SAM for Antibody Immobilization (Biosensor)

- Materials: Gold sensor chip, 11-mercaptoundecanoic acid (11-MUA), absolute ethanol, 100 mM MES buffer (pH 5.5).

- Cleaning: Sonicate gold chip in ethanol for 10 min, treat with UV-ozone for 20 min.

- SAM Assembly: Immerse chip in 1 mM 11-MUA in ethanol for 24 hours.

- Activation: Rinse with ethanol/MES. Incubate in a fresh solution of 400 mM EDC and 100 mM NHS in MES buffer for 30 min to activate carboxyl groups.

- Ligand Coupling: Rinse with PBS (pH 7.4). Incubate with 50 µg/mL antibody solution in PBS for 2 hours.

- Quenching: Block unreacted sites with 1 M ethanolamine-HCl (pH 8.5) for 15 min.

- Validation: Characterize using surface plasmon resonance (SPR) or quartz crystal microbalance (QCM-D).

Protocol 3.3: Preparation of Enzyme-Responsive SAM-Coated Drug Carriers

- Synthesis of Ester-linked Thiol: Synthesize HS-C11-EG6-O-CO-CH2-CH3 via esterification.

- Nanoparticle (NP) Functionalization: Prepare 100 nm PLGA NPs loaded with drug. Incubate 1 mL of NP suspension (5 mg/mL) with 1 mL of 0.5 mM thiol solution in Tris-EDTA buffer (pH 8.0) for 12 h on a shaker.

- Purification: Purify SAM-coated NPs via centrifugal filtration (100 kDa MWCO) 3 times with DI water.

- Release Testing: Incubate NPs in PBS with/without 10 U/mL esterase at 37°C. Sample at intervals and analyze drug concentration via HPLC.

Visualization Diagrams

Diagram Title: Workflow for SAM-Based Biosensor Fabrication

Diagram Title: LEED Analysis of SAM Structure for Thesis

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for SAM Research

| Reagent/Material | Function & Role in Experiment | Key Consideration |

|---|---|---|

| Alkanethiols (e.g., 11-Mercaptoundecanoic acid) | Forms the SAM backbone; terminal group (COOH, OH, CH3) dictates surface chemistry. | Use high purity (>95%), store under inert gas; concentration (0.1-5 mM) affects packing. |

| EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) | Crosslinker for activating carboxyl groups to form amine-reactive O-acylisourea intermediates. | Unstable in water; must be prepared fresh in pH 4.5-7.5 buffer. |

| NHS (N-Hydroxysuccinimide) | Stabilizes EDC-activated carboxyl groups, forming NHS ester for efficient amine coupling. | Increases coupling efficiency and stability of the activated surface. |

| QCM-D Sensor Chips (Gold-coated) | For real-time, label-free measurement of mass & viscoelastic changes during SAM formation & binding. | Crystal base frequency determines mass sensitivity; requires precise temperature control. |

| SPR Chips (e.g., Carboxylated Dextran on Au) | For real-time, label-free measurement of biomolecular binding kinetics on SAM surfaces. | Must match refractive index of running buffer; sensitive to bulk solution effects. |

| UV-Ozone Cleaner | Generates atomic oxygen to remove organic contaminants from gold substrates pre-SAM formation. | Critical for reproducible SAMs; over-exposure can oxidize gold surface. |

| LEED/Auger System | Characterizes long-range order, crystallinity, and elemental composition of SAMs in UHV. | Requires high vacuum; samples must be UHV-compatible (low outgassing). |

Solving Common LEED Challenges in Biomedical Surface Analysis

Addressing Sample Charging and Degradation of Non-Conductive or Organic Layers

Within the broader thesis on the use of Low-Energy Electron Diffraction (LEED) for surface reconstruction studies, a significant technical challenge is the inherent instability and charging of non-conductive or organic samples under electron beam interrogation. This application note details protocols to mitigate these effects, which are critical for obtaining reliable, high-fidelity structural data essential for materials science and molecular film research pertinent to drug development interfaces.

The interaction of electron beams with sensitive layers leads to two primary artifacts: electrostatic charging and radiation-induced degradation. The following table summarizes key quantitative observations from recent studies on model organic layers under electron beam exposure.

Table 1: Electron Beam Effects on Model Organic/Non-Conductive Layers

| Sample Type | Beam Energy (eV) | Critical Dose for Observable Damage (e⁻/cm²) | Primary Degradation Mechanism | Typical Surface Potential Shift (V) | Mitigation Strategy Effectiveness* |

|---|---|---|---|---|---|

| Self-Assembled Monolayers (Alkanethiols on Au) | 50-150 | ~10¹⁵ | C-C bond scission, desorption | +2 to +10 | Metal coating: High; Low Temp: Medium |

| Polymer Film (PMMA) | 100-500 | ~10¹⁶ | Chain scission, mass loss | +5 to +20 | Low-dose protocols: High; Conductive grid: High |

| Thin Organic Semiconductor (e.g., Pentacene) | 20-100 | ~10¹⁴ | Molecular rearrangement, trap formation | +1 to +15 | Low Temp (100K): Very High; Charge Flood Gun: High |

| Protein Layer (Lysozyme) on SiO₂ | 10-50 | <10¹³ | Denaturation, cleavage, mass loss | +10 to +50 | Rapid freezing/Vitrification: Very High; Negative Stain: High |

| Insulating Oxide (e.g., SiO₂) | 50-1000 | N/A (Structural) | Charging dominates | +1 to +100⁺ | Conductive surface coating: Very High; Low kV: Medium |

Effectiveness Key: High (>70% signal preservation), Medium (40-70%), Low (<40%). Data compiled from recent surface science literature.

Experimental Protocols

Protocol 3.1: Ultra-Thin Metal Coating via Sputter Deposition for Charge Dissipation

Objective: Apply a minimally invasive, conductive layer to enable LEED analysis without complete obscuration of underlying structure. Materials: Sputter coater (e.g., Pt/Pd target), argon gas, sample holder, quartz crystal microbalance (QCM) thickness monitor. Procedure:

- Place the organic/non-conductive sample in the sputter chamber. Ensure the sample is dry and stable.

- Evacuate chamber to base pressure ≤ 5 x 10⁻² mbar.

- Introduce high-purity Ar gas to a process pressure of 0.05-0.1 mbar.

- Set sputter current to 10-20 mA for a Pt/Pd target.

- Activate deposition for 10-30 seconds, as calibrated by QCM to achieve a nominal coating thickness of 0.5-2.0 nm.

- Rotate the sample during deposition to ensure uniform coverage.

- Immediately transfer the coated sample to the LEED analysis chamber under vacuum, if possible.

Protocol 3.2: Low-Temperature & Low-Dose LEED Acquisition

Objective: Minimize radiation damage and kinetic energy for decomposition by cooling and dose reduction. Materials: LEED system with liquid N₂ or He cryostat, phosphor screen/CCD camera, beam blanker. Procedure:

- Mount the sample on a cryogenic holder.

- Cool the sample to the desired temperature (typically 100-150 K for organics). Allow temperature to stabilize for 20 minutes.

- Use the lowest incident electron beam energy that still yields a discernible diffraction pattern (often 20-50 eV for sensitive layers).

- Reduce the beam current to the lowest usable setting (e.g., 0.1-0.5 nA, spot size ~1 mm).

- Employ a fast-shuttering beam blanker. Open the beam only during the camera acquisition window.

- Use a sensitive CCD camera to capture the pattern in a single, short integration (e.g., 0.5-2 seconds). Do not use prolonged visual inspection on the phosphor screen.

- Immediately blank the beam after acquisition.

Protocol 3.3:In-SituCharge Neutralization with a Flood Gun

Objective: Actively neutralize positive surface charge built up during electron beam exposure. Materials: LEED system equipped with a low-energy electron flood gun (typically 0-10 eV), or a combined LEED/Auger system with a built-in neutralizer. Procedure:

- Align the flood gun to provide a broad, low-energy electron flux over the sample analysis area.

- Set the flood gun energy to 1-5 eV. This is below the secondary electron emission threshold, ensuring net charge deposition is negative.

- Tune the flood gun current (typically 1-10 μA) while observing the LEED pattern stability.

- Optimize by finding the flood gun parameters that result in the sharpest, most stable diffraction spots with minimal background. This often requires a balance between the primary beam and flood gun currents.

- For sequential analysis, operate the flood gun continuously during primary beam exposure.

Visualized Workflows and Pathways

Diagram Title: Workflow for Charge & Degradation Mitigation in LEED

Diagram Title: Electron Beam Damage Pathways on Organics

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Mitigating Charging & Degradation

| Item | Primary Function | Key Considerations for LEED on Sensitive Layers |

|---|---|---|

| Platinum/Palladium Target (for sputter) | Provides source for ultra-thin, granular conductive coating. | Pt/Pd provides finer grain size vs. Au for less pattern obscuration. Use ultra-high purity (99.99%). |

| Conductive Carbon Adhesive Tabs | Provides electrical contact from sample holder to insulating sample edge. | Low outgassing, vacuum-compatible. Apply minimally to avoid shadowing or contamination. |

| Cryogenically-Compatible Sample Holders | Enables sample cooling to 100 K or lower to reduce diffusion and reaction rates. | Ensure good thermal contact. Use OFHC copper or similar. Check for magnetic properties if using. |

| Low-Energy Electron Flood Gun | Actively neutralizes positive surface charge with very low energy electrons (0-10 eV). | Must be differentially pumped if used in UHV. Alignment is critical for uniform neutralization. |

| Low-Dose, Sensitive CCD Camera | Enables pattern capture with extremely short, controlled beam exposure. | High quantum efficiency at relevant wavelengths. Must be synchronized with beam blanker. |

| Iridium-Coated TEM Grids (Lacey Carbon) | Provides a conductive, ultra-thin support for depositing organic films for ex-situ preparation. | Iridium coating improves conductivity. Grid structure can be subtracted from analysis. |

| Glow Discharge Unit (Ar/O₂) | For hydrophilic treatment of substrates to improve film uniformity before organic deposition. | Creates a reproducible, clean surface. O₂ plasma can help decompose contaminants. |

| Calibrated Quartz Crystal Microbalance (QCM) | Precisely monitors deposition thickness during metal coating. | Essential for ensuring sub-nanometer coating control. Must be placed at sample position for calibration. |

Optimizing Signal-to-Noise for Weak Diffraction from Disordered or Complex Biological Interfaces

Thesis Context: This work is situated within a broader thesis investigating the application of Low-Energy Electron Diffraction (LEED) for surface reconstruction studies, extending the paradigm from well-ordered crystalline surfaces to the challenging domain of biologically relevant, disordered, or complex interfacial structures.

The study of biological interfaces—such as lipid bilayers, protein adlayers, or complex polymeric coatings—using surface-sensitive diffraction techniques like LEED is critically limited by inherently weak diffraction signals. These signals are buried in noise arising from substrate incoherence, thermal vibrations, and the diffuse scattering characteristic of disordered systems. Optimizing the signal-to-noise ratio (SNR) is paramount for extracting meaningful structural data.

Quantitative Factors Affecting SNR in Biological LEED

Table 1: Key Parameters and Their Impact on Diffraction SNR

| Parameter | Typical Range (Biological Interfaces) | Effect on Signal | Effect on Noise | Recommended Optimization Strategy |

|---|---|---|---|---|

| Electron Energy (E) | 20 - 150 eV | Maxima at specific E due to cross-section; generally weak. | Inelastic background increases with E. | Use very low currents; sweep E to find resonance enhancements. |

| Beam Current (I) | 0.1 - 10 pA | Scales linearly with I. | Scales linearly with I; sample damage increases drastically. | Use ultra-low currents (≈0.1 pA) combined with long exposure. |

| Sample Temperature (T) | 100 - 300 K | Decreases with T due to Debye-Waller factor. | Thermal diffuse scattering decreases with T. | Cryogenic cooling (100-120 K) is critical for noise reduction. |

| Surface Order | Short-range only | Produces broad, weak diffraction features. | Increases diffuse background. | Employ background subtraction protocols (see Protocol 1). |

| Detector Type | Microchannel Plate/CCD | Quantum efficiency (QE) varies. | Dark current, read noise. | Use post-detection electron amplification and cool CCD. |

| Integration Time (t) | 30 - 600 s | Scales linearly with t. | Scales with sqrt(t) for shot noise. | Long integrations (100s+); frame averaging. |

Application Notes & Protocols

Application Note 1: Cryogenic Cooling for Diffuse Scatter Reduction

- Principle: Thermal vibrations (phonons) cause a large fraction of the incident electron beam to scatter incoherently, creating a high, structured background. Cooling the sample to cryogenic temperatures (≤120 K) significantly suppresses this thermal diffuse scattering (TDS), revealing weak superlattice or broad diffraction features from biological assemblies.

- Protocol Integration: This is a prerequisite for all subsequent measurements on hydrated or soft interfaces.

Application Note 2: Energy-Dependent Resonance Scanning

- Principle: Weakly ordered organic layers can exhibit resonance enhancements in diffraction intensity at specific incident electron energies due to transient negative ion formation or multiple scattering effects.

- Protocol: After initial cool-down, perform a rapid I(V) curve on a suspected diffraction spot or a region of interest in reciprocal space. Energy steps of 0.5-2 eV from 20 to 250 eV. Plot intensity vs. E to identify optimal energies for data acquisition.

Protocol 1: Background Subtraction for Disordered Interfaces

Objective: Isolate the weak, diffuse diffraction signal from the high, uneven background. Materials: LEED system with CCD camera; cryogenically cooled sample stage; automated beam blanker. Procedure:

- Cool: Stabilize sample at 110 K.

- Align: Set electron gun to optimal energy (E_opt) identified via resonance scan.

- Acquire Data Image (D): At E_opt, with ultra-low beam current (0.2 pA), integrate for 120s.

- Acquire Background Image (B): Deflect the electron beam slightly (or move sample stage) to a nearby non-diffracting zone at the same scattering vector magnitude. Use identical E_opt, I, and t.

- Subtract: Create processed image P = D - B.