Mastering Thin Film Surface Roughness: A Comprehensive Guide to AFM Analysis for Pharmaceutical Research

This article provides a detailed, practical guide to Atomic Force Microscopy (AFM) for quantifying thin film surface roughness, tailored for researchers and professionals in drug development.

Mastering Thin Film Surface Roughness: A Comprehensive Guide to AFM Analysis for Pharmaceutical Research

Abstract

This article provides a detailed, practical guide to Atomic Force Microscopy (AFM) for quantifying thin film surface roughness, tailored for researchers and professionals in drug development. It covers foundational principles of AFM operation and surface metrics, methodological best practices for analyzing pharmaceutical films and coatings, troubleshooting common artifacts and optimization techniques for reliable data, and validation strategies comparing AFM to profilometry and SEM. The synthesis empowers scientists to implement robust, nanoscale surface characterization critical for controlling drug product performance, stability, and manufacturing.

Understanding the Nanoscale Landscape: AFM Fundamentals and Surface Roughness Metrics

Within the broader thesis on Atomic Force Microscopy (AFM) for thin film surface roughness analysis, understanding the core operational principle is paramount. AFM provides three-dimensional, nanoscale resolution of surface topography without requiring conductive or vacuum conditions, making it indispensable for materials science and drug development (e.g., characterizing drug-eluting coatings or nanoparticle morphology). The fundamental principle involves the mechanical interaction between a sharp tip and the sample surface.

Core Operating Principle: Contact vs. Dynamic Mode

The AFM measures topography by scanning a sharp probe (tip) across the surface. The tip, mounted on a flexible cantilever, interacts with surface forces. Deflection of the cantilever is monitored, typically via a laser beam reflected onto a photodetector. Two primary modes are employed:

1. Contact Mode: The tip is in constant physical contact with the surface. The cantilever deflection (corresponding to force) is held constant by a feedback loop that adjusts the sample height (Z). This vertical adjustment maps the topography.

2. Dynamic Mode (Including Tapping Mode): The cantilever is oscillated at or near its resonance frequency. Tip-sample interactions (van der Waals, capillary forces) alter the oscillation’s amplitude, frequency, or phase. A feedback loop maintains a constant oscillation amplitude, and the Z-adjustment creates the topographic image. This mode is preferred for soft samples (e.g., biological films) as it minimizes shear forces.

The following parameters are critical for thin film roughness analysis.

Table 1: Core AFM Performance Metrics and Typical Ranges

| Parameter | Description | Typical Range (for high-resolution imaging) |

|---|---|---|

| Lateral Resolution | Minimum distinguishable feature separation in XY plane. | 0.2 nm (contact) to 1 nm (tapping) |

| Vertical Resolution | Minimum distinguishable height difference. | < 0.1 nm |

| Scan Range (XY) | Maximum area for a single scan. | ~1 µm² to > 100 µm² |

| Z-Range | Maximum measurable height difference. | ~1 µm to ~10 µm |

| Noise Floor (Z) | Background electronic/mechanical noise. | 20 - 50 pm RMS (in air) |

| Cantilever Spring Constant (k) | Stiffness; dictates applied force. | 0.1 - 100 N/m |

| Resonant Frequency (f₀) | For dynamic modes. | 10 kHz - 1 MHz (in air) |

| Typical Tip Radius (R) | Defines ultimate lateral resolution. | < 10 nm (sharp probes) |

Table 2: Common Surface Roughness Parameters Extracted from AFM Topography

| Parameter (ISO 4287) | Formula (Discrete) | Relevance to Thin Film Analysis |

|---|---|---|

| Ra (Average Roughness) | $$Ra = \frac{1}{n} \sum{i=1}^{n} | y_i |$$ | General average texture; baseline film quality. |

| Rq / RMS (Root Mean Square) | $$Rq = \sqrt{\frac{1}{n} \sum{i=1}^{n} y_i^2}$$ | More sensitive to peaks and valleys than Ra. |

| Rz (Average Max Height) | Average height between 5 highest peaks & 5 lowest valleys. | Assesses local defect severity. |

| Sa (3D Areal Average) | 3D analogue of Ra over a measured area. | Comprehensive for isotropic thin films. |

Experimental Protocols for Thin Film Roughness Analysis

Protocol 1: Sample Preparation and Mounting

Objective: Securely mount thin film sample to minimize acoustic and vibrational noise.

- Materials: Double-sided adhesive tape, conductive carbon tape, or magnetic disks; clean glass slides or AFM specimen discs.

- Procedure: Cut sample to appropriate size (<1 cm²). Using tweezers, attach sample to disc using adhesive. Ensure no adhesive contaminates the top surface. For powdery films, use a gentle stream of clean, dry air to remove loose particles.

- Critical Note: For soft polymeric or biological films, consider immersion in appropriate fluid if using a liquid cell.

Protocol 2: Probe Selection and Installation

Objective: Choose an appropriate cantilever for the measurement mode and sample.

- Materials: AFM probe (e.g., Si tip for contact mode, Si-coated tip for conductive AFM, diamond-coated for wear resistance).

- Procedure: a. Using clean tweezers, remove probe from its storage box. b. Mount the probe chip securely into the probe holder following the manufacturer's torque specifications. c. For dynamic modes, note the nominal resonant frequency and spring constant (from manufacturer's sheet) for initial parameter input into the AFM controller software.

Protocol 3: System Alignment and Engagement

Objective: Align the optical lever system and safely bring the tip into interaction with the surface.

- Procedure: a. Laser Alignment: Adjust the position of the laser diode so the beam is focused on the end of the cantilever. b. Photodetector Alignment: Center the reflected laser spot on the quadrant photodetector. Set the vertical (A-B) and horizontal (C-D) difference signals to zero. c. Approach: Initiate the automated coarse and fine approach sequence. The system moves the tip toward the surface until a preset deflection or amplitude setpoint is detected (e.g., -1 V for contact, 80% of free amplitude for tapping).

Protocol 4: Imaging and Parameter Optimization

Objective: Acquire a stable, high-resolution topographic image.

- Setpoint Adjustment: Adjust the deflection/amplitude setpoint to apply minimal force. Reduce setpoint until tip just tracks the surface without losing contact.

- Gain Tuning (PID Controller): Increase proportional and integral gains until the system is responsive but not oscillatory. Watch the error signal during scanning.

- Scan Parameters: Set a slow scan rate (e.g., 0.5-1 Hz) for high resolution. Choose an appropriate number of data points (512 x 512 or 1024 x 1024). Select a scan size representative of the film's features.

- Capture Image: Initiate scanning. Capture both trace and retrace images to check for scan artifacts.

Protocol 5: Image Processing and Roughness Analysis

Objective: Extract quantitative roughness parameters from raw topographic data.

- Flattening: Apply a 1st or 2nd order flattening algorithm to remove sample tilt and bow. Do not over-flatten.

- Filtering (if necessary): Apply a low-pass filter to remove high-frequency noise or a median filter to remove outliers (single pixel spikes). Document all processing steps.

- Region Selection: Select a representative, defect-free area for analysis.

- Parameter Calculation: Use the instrument's software or external software (e.g., Gwyddion, SPIP) to calculate Sa, Sq, Sz, etc., over the selected area. Report scan size and calculation algorithm.

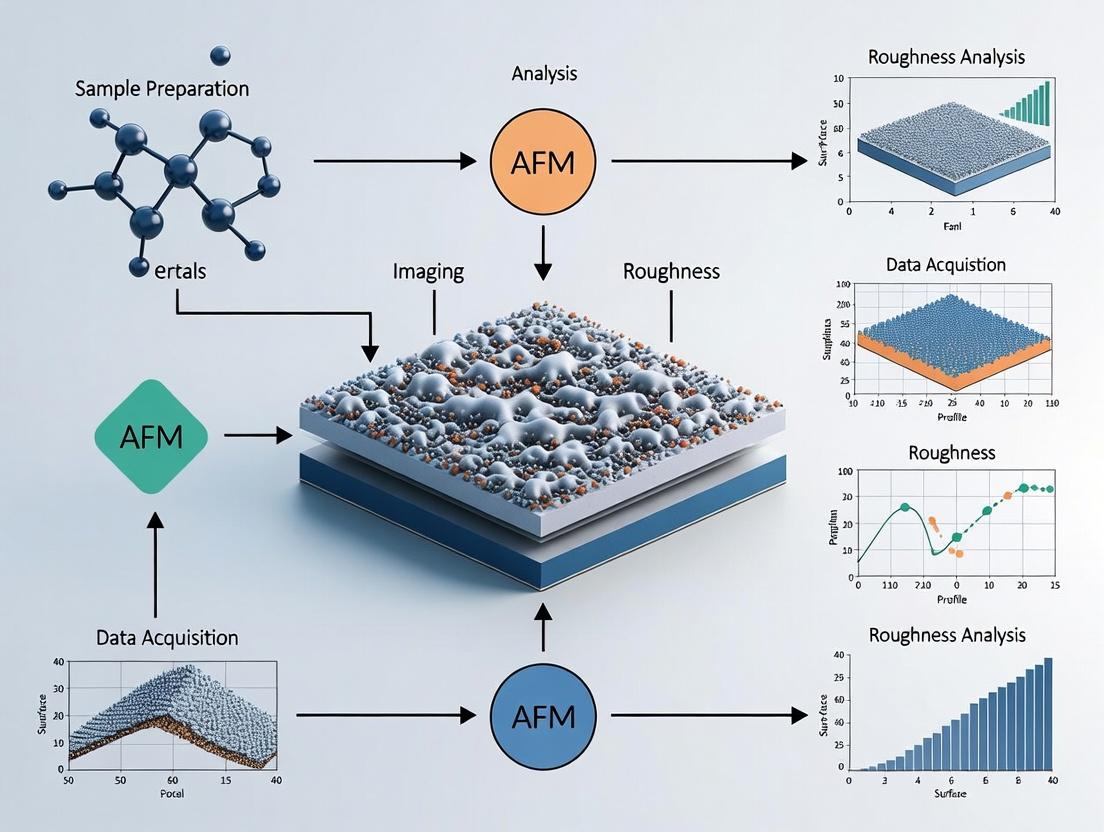

Visualization of AFM Operational Principles

Diagram Title: AFM Operational Workflow and Mode Comparison

Diagram Title: Core AFM Feedback Loop for Topography

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for AFM Thin Film Characterization

| Item | Function & Relevance |

|---|---|

| Silicon Probes (Tapping Mode) | Standard probes with a sharp Si tip (tip radius <10 nm). Oscillated at resonance (70-400 kHz) to minimize sample damage. Essential for polymer and soft film imaging. |

| Silicon Nitride Probes (Contact Mode) | Softer cantilevers (lower spring constant, ~0.1 N/m) for low-force contact imaging in air or liquid. Suitable for biological thin films. |

| Diamond-Coated Probes | Extremely wear-resistant. Used for scanning abrasive or very hard thin films (e.g., certain ceramics, diamond-like carbon coatings). |

| Conductive Diamond or Pt/Ir Coated Probes | Enable electrical characterization (e.g., conductive AFM, Kelvin Probe) alongside topography. Critical for analyzing semiconductor or conductive polymer films. |

| PeakForce Tapping Probes | Specialized probes for modes that directly control the maximum applied force on each tap cycle. Crucial for quantifying nanomechanical properties (modulus, adhesion) simultaneously with topography. |

| Vibration Isolation Table | Active or passive isolation system to dampen ambient building vibrations (floor noise). Fundamental for achieving sub-nanometer vertical resolution. |

| Acoustic Enclosure | Box or chamber to minimize air currents and acoustic noise that can disturb the cantilever, especially in dynamic modes. |

| Cleanroom Wipes & Solvents | Isopropyl alcohol, acetone, and lint-free wipes for cleaning sample stages, tweezers, and (cautiously) samples to prevent particulate contamination. |

| Calibration Gratings | Samples with known pitch and step height (e.g., TGZ01, TGXY02). Used to verify the AFM's X, Y, and Z scaling accuracy and scanner linearity. |

| Liquid Cell | Allows imaging under fluid. Essential for studying thin films in their native hydrated state (e.g., lipid bilayers, hydrogel coatings) or for electrochemistry. |

Why Surface Roughness Matters in Pharmaceutical Thin Films

Surface roughness is a critical quality attribute of pharmaceutical thin films, directly influencing drug release kinetics, adhesion, stability, and bioavailability. This Application Note, framed within broader atomic force microscopy (AFM) research, details the quantitative impact of roughness and provides standardized protocols for its analysis in drug development.

Surface roughness, typically measured as Ra (arithmetic average) or Rq (root mean square), is a non-invasive predictor of thin film performance. The following table summarizes key quantitative relationships established in recent literature.

Table 1: Impact of Surface Roughness on Pharmaceutical Thin Film Performance

| Performance Metric | Roughness Parameter | Quantitative Relationship / Optimal Range | Key Consequence |

|---|---|---|---|

| Drug Release Rate | Ra, Rq | Increased Ra (10-50 nm to 200+ nm) correlates with 1.5-3x faster initial release. | Modulation of dissolution profile; risk of dose dumping. |

| Bioadhesion Strength | Ra | Optimal adhesion at Ra ~100-200 nm; outside this range, adhesion drops by up to 40-60%. | Ensures proper residence time at application site (oral, transdermal). |

| Chemical & Physical Stability | Rq | Rq > 250 nm linked to ~25% higher recrystallization rate in amorphous solid dispersions. | Reduces shelf-life; promotes drug degradation. |

| Uniformity of Dose | Ra, Rz | Ra variability >15% across batch correlates with dose content uniformity failures (RSD >6%). | Impacts safety and efficacy. |

| Wettability | Contact Angle (θ) | Linear correlation between increased Ra (0-150 nm) and decreased θ (improved wettability). | Enhances dissolution for poorly soluble drugs. |

Experimental Protocols for AFM-Based Roughness Analysis

Protocol 2.1: Sample Preparation & Mounting

Objective: To prepare thin film samples for AFM analysis without inducing artifacts.

- Substrate Cleaving: For free-standing films, use a clean, sharp blade to cleave a section (approx. 5mm x 5mm). Avoid bending or touching the surface.

- Adhesive Mounting: Affix the film to a standard AFM metal puck using a double-sided adhesive tape (e.g., Scotch). Apply gentle, uniform pressure to avoid deformation.

- Spin-Coated Films: Analyze directly on their substrate (e.g., silicon wafer). Secure the wafer to the puck with adhesive.

- Dust Removal: Use a steady stream of clean, dry nitrogen or air (Dust-Off) to remove loose particulates.

Protocol 2.2: AFM Imaging & Parameter Selection

Objective: To acquire high-fidelity topographical data.

- Instrument Setup: Use a quantitative AFM mode (e.g., Tapping/AC Mode in air, PeakForce Tapping).

- Probe Selection: Use a sharp silicon tip (e.g., RTESPA-150 from Bruker, k ~5 N/m, f0 ~150 kHz). Confirm radius <10 nm via tip characterization sample.

- Scan Parameters:

- Scan Size: 10 µm x 10 µm for overview; 1 µm x 1 µm for detailed morphology.

- Resolution: 512 x 512 pixels.

- Scan Rate: 0.5-1.0 Hz.

- Setpoint: Optimize to achieve ~85-90% of free air amplitude to minimize force.

- Environmental Control: Perform analysis in a controlled environment (22 ± 2°C, 40 ± 5% RH). Allow sample thermal equilibration for 15 minutes.

Protocol 2.3: Data Processing & Roughness Calculation (ISO 4287)

Objective: To extract statistically relevant roughness parameters from raw AFM data.

- Flattening: Apply a 1st or 2nd order flattening algorithm to remove sample tilt.

- Plane Fit: Apply a mean plane subtraction.

- Masking: Exclude obvious artifacts or voids from the analysis area.

- Parameter Calculation: On the processed, flattened image, calculate:

- Sa / Ra: Arithmetic mean height deviation from the mean plane.

- Sq / Rq: Root mean square of height deviations.

- Sz / Rz: Maximum height of the profile.

- Reporting: Report the mean ± standard deviation from at least three independent sample locations (n≥3).

Visualizing the Role of Surface Roughness

The following diagrams, created using DOT language, illustrate the causal pathways and experimental workflow.

Title: Key Factors and Impacts of Thin Film Surface Roughness

Title: AFM Surface Roughness Analysis Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for AFM Thin Film Roughness Studies

| Item Name | Supplier Examples | Function / Rationale |

|---|---|---|

| Silicon AFM Probes (Tapping Mode) | Bruker (RTESPA-150), Olympus (OMCL-AC160TS) | High-resolution imaging with minimal surface damage. Standardized spring constant for comparability. |

| Silicon Wafer Substrates | University Wafer, SI-MAT | Ultra-smooth, chemically inert substrate for casting spin-coated films as a reference or for testing. |

| Double-Sided Conductive Tape | Ted Pella, Plano GmbH | Secure mounting of samples to AFM pucks without inducing charge artifacts. |

| Standard Roughness Sample (TGZ1) | Bruker, NT-MDT | Calibration grating for verifying AFM lateral (X,Y) and vertical (Z) scale accuracy and tip condition. |

| High-Purity Solvents (HPLC Grade) | Sigma-Aldrich, Fisher Scientific | For cleaning substrates and, if applicable, film preparation. Ensures no particulate contamination. |

| Dust-Free Nitrogen Gas Regulator & Gun | Microdynamis, Falcon | For critical sample cleaning prior to AFM scanning to remove environmental contaminants. |

| Vibration Isolation Table | TMC, Herzan | Essential platform to isolate the AFM from ambient building vibrations for stable imaging. |

Atomic Force Microscopy (AFM) is a cornerstone technique for quantifying the nanoscale surface topography of thin films, critical in fields ranging from semiconductor fabrication to pharmaceutical coatings. The three-dimensional height data acquired via AFM must be distilled into standardized, quantitative roughness parameters to enable material characterization, process control, and correlation with functional properties (e.g., adhesion, optical scatter, biological response). Among these, the amplitude parameters Ra (arithmetic mean roughness), Rq (root mean square roughness), and Rz (mean roughness depth) are foundational. This application note details their physical meaning, calculation, and protocols for reliable measurement within AFM-based research on thin films.

Definition and Physical Meaning of Core Parameters

These parameters are calculated from a defined evaluation length (L) of a surface profile, z(x), after tilting and curvature have been removed (form removal).

| Parameter | Name & Formula | Physical Meaning | Key Insight for Thin Films |

|---|---|---|---|

| Ra | Arithmetic Average RoughnessRa = (1/L) ∫₀ᴸ |z(x)| dx | The average absolute deviation of the profile from its mean line. | Provides a stable, general measure of surface texture. Less sensitive to extreme peaks/valleys than Rq. Widely used for quality control. |

| Rq (RMS) | Root Mean Square RoughnessRq = √[ (1/L) ∫₀ᴸ z(x)² dx ] | The standard deviation of the height distribution. | Statistically more meaningful; emphasizes larger deviations (outliers). Critical for optical and electrical properties where peaks/valleys have disproportionate effects. |

| Rz | Mean Roughness DepthRz = (1/5) ∑_{i=1}⁵ (Rpi - Rvi) | The average height difference between the five highest peaks and five deepest valleys within five sampling lengths. | Gives a measure of the total height of the surface texture over a localized area. Useful for predicting sealing, lubrication, and initial wear characteristics. |

Detailed Experimental Protocol for AFM-Based Roughness Measurement

Protocol Title: Acquisition and Analysis of Surface Roughness Parameters (Ra, Rq, Rz) from AFM Topography Data of Thin Films.

Objective: To obtain statistically robust roughness parameters from AFM scans, minimizing instrumental and analytical artifacts.

Materials & Reagents (The Scientist's Toolkit):

| Item / Reagent | Function & Specification |

|---|---|

| Atomic Force Microscope | Core instrument for non-contact or tapping mode topography acquisition. Must be calibrated in X, Y, and Z axes. |

| Calibrated Grating (e.g., TGZ1, TGX1) | Reference sample for lateral (XY) and vertical (Z) scale verification and scanner calibration. |

| Anti-Vibration Table | Essential to isolate the AFM from ambient building vibrations for stable imaging. |

| Standard Probe (e.g., Si cantilever, f~300 kHz, k~40 N/m) | Tip geometry (radius < 10 nm preferred) directly impacts resolution and measured roughness of fine features. |

| Sample Mounting Kit (Double-sided tape, magnetic disks) | Ensures sample is rigidly fixed to the AFM stage to prevent drift during scanning. |

| AFM Software | For image acquisition, flattening (form removal), and roughness analysis (e.g., Gwyddion, SPIP, NanoScope Analysis). |

| Statistical Analysis Software (e.g., Origin, Python/R) | For batch processing, histogram generation, and statistical comparison of parameters from multiple scans. |

Procedure:

Step 1: Pre-Measurement Calibration and Setup 1.1 Power on the AFM and laser system, allowing thermal equilibration (≥ 30 mins). 1.2 Mount a calibration grating with known pitch and step height. 1.3 Acquire an image (e.g., 10 µm x 10 µm, 512 x 512 pixels). Verify that measured pitch and step height are within 2% of the certified values. Recalibrate scanner if necessary. 1.4 Mount the thin film sample securely using double-sided tape.

Step 2: Image Acquisition 2.1 Select an appropriate AFM probe and engage on the sample surface using non-contact or tapping mode. 2.2 Acquire topography images at multiple, non-overlapping locations (minimum n=3, preferably n≥5) to assess homogeneity. Critical: Scan size must be sufficiently large to be representative of the surface texture (typically ≥ 5x the dominant feature size). 2.3 Set resolution to at least 256 x 256 pixels, with 512 x 512 preferred for accurate parameter extraction. 2.4 Optimize scan rate and feedback parameters to minimize noise and tip-sample convolution artifacts.

Step 3: Data Processing (Form Removal) 3.1 Apply a Flattening or Plane Fit (1st or 2nd order) to each raw image to remove sample tilt and bow. Do not apply high-pass filtering, as it can artificially alter roughness values. 3.2 Optionally, apply a Scan Line Leveling correction if line-by-line offsets are present.

Step 4: Parameter Calculation and Reporting 4.1 Define the Evaluation Area. For thin films, use the entire image after removing edge artifacts (e.g., exclude 5% from borders). 4.2 Using the software's roughness analysis tool, calculate Ra, Rq (RMS), and Rz for each image. 4.3 Export the numerical data for statistical summary. 4.4 Report with Context: Present data as Mean ± Standard Deviation across all measured areas. Always report the scan size and resolution used, as these parameters are scale-dependent.

Critical Considerations for AFM Roughness Analysis

- Scale Dependence: Ra, Rq, and Rz values are intrinsically linked to the measurement scale (scan size and resolution). Always report the scan size.

- Tip Convolution: A blunt or contaminated tip will smooth out fine features, underestimating true roughness. Regularly inspect tips via SEM or test on a sharp calibration sample.

- Statistical Significance: A single AFM scan is a microscopic sample of the surface. Measurements from multiple, random locations are mandatory for a representative value.

- Parameter Choice: Use Rq for properties influenced by outliers (e.g., electrical breakdown). Use Ra for general process monitoring. Use Rz for interfacial contact phenomena.

Data Interpretation and Visualization

AFM Roughness Analysis Workflow

Physical Meaning of Ra, Rq, and Rz

Within the broader scope of a thesis on Atomic Force Microscopy (AFM) for thin film surface roughness analysis, selecting the appropriate initial characterization technique is paramount. For preliminary explorations, researchers often weigh AFM against Optical Profilometry (OP). This application note provides a critical comparison of these two techniques, detailing their operational principles, capabilities, and optimal use cases to guide researchers in drug development and materials science in selecting the right tool for initial surface assessment.

Core Principle Comparison

Atomic Force Microscopy (AFM): A scanning probe technique that measures surface topography by physically scanning a sharp tip (probe) across the sample. It records tip-sample interactions (e.g., van der Waals forces) to generate a 3D map with sub-nanometer vertical resolution.

Optical Profilometry (OP): A non-contact optical technique, typically using white-light interferometry or focus variation. It measures surface height by analyzing the interference pattern or focus quality of reflected light, generating a 3D topography map over large areas quickly.

Quantitative Comparison Table

Table 1: Technical Specifications and Performance Comparison

| Parameter | Atomic Force Microscopy (AFM) | Optical Profilometry (OP) |

|---|---|---|

| Vertical Resolution | < 0.1 nm | ~0.1 - 1 nm |

| Lateral Resolution | ~1 - 10 nm | ~0.3 - 1 µm (diffraction-limited) |

| Maximum Scan Area | Typically ~100 x 100 µm; up to ~150 x 150 µm for large scanners | Several mm x mm to cm x cm |

| Measurement Speed | Slow (minutes to hours per scan) | Very Fast (seconds to minutes per scan) |

| Measurement Mode | Contact, Tapping, Non-contact (near-field) | Truly non-contact (far-field) |

| Sample Damage Risk | Medium to Low (dependent on mode & force) | None |

| Sample Requirements | Must be clean; very rough or sticky surfaces problematic. | Can measure rough surfaces; transparent films may require coating. |

| Data Type | True 3D topography, can measure nanoscale phase, adhesion, modulus. | 3D topography, reflectivity. |

| Key Roughness Parameter (Sa) | Excellent for nanoscale Sa (< 100 nm range). | Excellent for microscale Sa (> 0.1 µm range). |

| Primary Best Use Case | Nanoscale features, ultra-thin films, soft materials, local property mapping. | Large-area surveys, microscale roughness, step heights, layer thickness. |

Table 2: Operational and Practical Considerations

| Consideration | Atomic Force Microscopy (AFM) | Optical Profilometry (OP) |

|---|---|---|

| Ease of Use | Requires significant expertise for operation and data interpretation. | Generally user-friendly, faster learning curve. |

| Sample Preparation | Often critical; samples must be firmly fixed; minimal particulate contamination. | Less stringent; can often measure as-received samples. |

| Cost (Acquisition) | Very High | Medium to High |

| Cost (Operation) | High (specialized probes, maintenance) | Low (minimal consumables) |

| Throughput | Low (single point, detailed analysis) | High (large-area, rapid screening) |

| Ideal Role in Workflow | Nano-verification & detailed analysis after initial screening. | Initial exploration, large-area mapping, and quality control. |

Experimental Protocols

Protocol 1: Initial Surface Exploration Using Optical Profilometry Objective: To rapidly assess the microscale topography and roughness (Sa) of a thin film sample over a large area.

- Sample Preparation: Mount the sample securely on the OP stage. For reflective metal or semiconductor films, measure as-is. For transparent or low-reflectivity organic films, apply a thin (~10 nm) gold/palladium sputter coat to enhance signal.

- Instrument Setup: Select a suitable objective lens (e.g., 10X-50X) to balance field of view and lateral resolution. Set the vertical scan range to exceed the expected film thickness and roughness.

- Measurement: Use the instrument's software to define the measurement area (e.g., 1 x 1 mm). Perform an automated scan. The system acquires a series of interferograms or focus stacks.

- Data Processing: Apply standard leveling (tilt removal) and a noise-reduction filter. Use masking to exclude obvious artifacts (e.g., dust).

- Analysis: Calculate the areal roughness parameters (e.g., Sa, Sq) over the entire scan or selected regions. Visually identify areas of interest (e.g., defects, representative zones) for higher-resolution AFM analysis.

Protocol 2: Nanoscale Verification Using Atomic Force Microscopy Objective: To obtain high-resolution nanoscale topography and roughness data from a region of interest identified by OP.

- Sample Transfer: Carefully transfer the sample from the OP to the AFM stage, ensuring the area of interest is accessible. Clean the sample with dry air or nitrogen to remove dust.

- Probe Selection: For thin films, a silicon tip with a nominal radius < 10 nm is suitable. For soft materials (e.g., polymer films), use a silicon tip with a lower spring constant (< 5 N/m) for tapping mode.

- AFM Setup: Engage the tip using the instrument's standard engagement procedure. For most thin films, Tapping Mode is recommended to minimize lateral forces and sample damage.

- Scan Parameter Optimization: Set the scan size to a representative area (e.g., 10 x 10 µm or 50 x 50 µm). Adjust the scan rate (typically 0.5-1 Hz), setpoint, and feedback gains to achieve a stable, noise-free image.

- Data Acquisition: Acquire both height and phase images (in tapping mode). Perform multiple scans on different spots to ensure reproducibility.

- Data Analysis: Flatten the height image (1st or 2nd order). Use software to calculate nanoscale Sa, Sq, and analyze grain size or feature dimensions. Correlate these findings with the larger-scale OP data.

Visualization: Technique Selection Workflow

Workflow for Choosing AFM or Profilometry

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for Thin Film Roughness Analysis

| Item | Function/Brief Explanation |

|---|---|

| AFM Silicon Probes (Tapping Mode) | Sharp tips (radius < 10 nm) on cantilevers for high-resolution, low-force imaging of thin film surfaces. |

| Sputter Coater (Au/Pd target) | Applies a thin, conductive metal layer to non-conductive or transparent samples for enhanced OP signal and SEM imaging. |

| PMMA or PDMS | Polymer materials used to create reference samples with known roughness for instrument calibration and validation. |

| Cleanroom Wipes & Solvents (IPA, Acetone) | For meticulous cleaning of sample substrates and AFM stages to eliminate particulate contamination. |

| Calibration Gratings | Grids with precisely known pitch and step height (e.g., 1 µm pitch, 180 nm step) for daily verification of AFM and OP lateral/vertical scales. |

| Vibration Isolation Platform | Critical for AFM to dampen environmental noise, ensuring stable imaging at the nanoscale. |

| Adhesive Tabs or Carbon Tape | For secure, non-damaging mounting of thin film samples to AFM and OP specimen holders. |

For initial explorations in thin film roughness analysis, Optical Profilometry is the superior tool for rapid, large-area assessment to identify regions of interest and quantify microscale topography. Atomic Force Microscopy serves as the essential follow-up technique for nanoscale verification, providing unparalleled resolution and detail on specific features. An integrated workflow, starting with OP screening and proceeding to targeted AFM analysis, is the most efficient and comprehensive strategy for a thesis focused on the nanoscale capabilities of AFM, ensuring observations are placed in the correct macroscopic context.

Within the context of a thesis on Atomic Force Microscopy (AFM) for thin film surface roughness analysis, selecting the appropriate imaging mode is a foundational decision that dictates data fidelity, sample preservation, and measurement throughput. This Application Note provides a detailed comparison and experimental protocols for the three primary amplitude-modulation modes: Contact Mode, Tapping Mode, and PeakForce Tapping Mode, with a focus on applications relevant to materials science and pharmaceutical development.

Comparative Analysis of AFM Modes

The selection of an AFM mode involves balancing lateral resolution, vertical resolution, applied force, and imaging speed. The following table summarizes the key quantitative and qualitative parameters for each mode, based on current instrumentation and literature.

Table 1: Comparative Analysis of Contact, Tapping, and PeakForce Tapping AFM Modes

| Parameter | Contact Mode | Tapping Mode | PeakForce Tapping Mode |

|---|---|---|---|

| Tip-Sample Interaction | Constant, repulsive physical contact | Intermittent contact (oscillating) | Intermittent contact (quasi-static, controlled peak force) |

| Lateral (Shear) Forces | High | Very Low | Very Low |

| Typical Applied Force | 0.1 - 100 nN (difficult to control) | 0.01 - 1 nN (indirectly controlled) | < 10 pN - 10 nN (directly controlled and quantified) |

| Best Vertical Resolution | ~0.1 nm | ~0.1 nm | < 0.1 nm |

| Best Lateral Resolution | ~1 nm (can degrade soft samples) | ~1 nm | ~1 nm |

| Sample Damage Risk | Very High for soft, adhesive, or loosely bound samples | Moderate to Low | Very Low |

| Ideal Sample Type | Very hard, rigid, flat surfaces (e.g., HOPG, mica, silicon wafer) | Moderate stiffness, heterogeneous surfaces (e.g., polymers, composites, biological fixed cells) | Soft, adhesive, fragile, or loosely bound materials (e.g., live cells, lipid bilayers, organic thin films, pharmaceutical formulations) |

| Simultaneous Nanomechanical Mapping | No (Friction/Lateral Force only) | Possible with advanced modes (e.g., HarmoniX) | Yes (native) - Elasticity, Adhesion, Deformation, Dissipation |

| Imaging in Liquid | Challenging (high adhesion, drag) | Standard, but can be unstable | Excellent - superior force control |

Detailed Experimental Protocols

Protocol 1: Contact Mode Imaging for Reference Substrates

Objective: To obtain high-resolution topographical data on an atomically flat, hard reference sample (e.g., muscovite mica) for scanner calibration and tip characterization. Materials: Freshly cleaved mica substrate, Si or Si₃N₄ contact-mode cantilever (spring constant: 0.01 - 0.5 N/m). Procedure:

- Sample Preparation: Cleave the top layers of a mica sheet using adhesive tape to reveal a fresh, atomically flat surface. Mount securely on the AFM metal puck.

- Cantilever Selection & Installation: Choose a soft, sharp contact-mode cantilever. Install the probe holder into the AFM head, ensuring secure electrical connections.

- Engagement: Align the laser spot on the cantilever's end and maximize the sum signal. Approach the tip to the surface using the automated engagement routine.

- Feedback Parameter Optimization: Set a low scan rate (0.5-1.0 Hz). Adjust the setpoint to achieve a low, stable deflection error signal. Set proportional (P) and integral (I) gains as high as possible without introducing feedback oscillation.

- Image Acquisition: Acquire a 1 µm x 1 µm scan. Process the image with a first-order flattening to remove sample tilt.

Protocol 2: Tapping Mode for Polymer Blend Thin Film Analysis

Objective: To characterize the surface morphology and phase separation of a polystyrene-poly(methyl methacrylate) (PS-PMMA) blend thin film without inducing sample deformation. Materials: Spin-coated PS-PMMA film on silicon, etched silicon tapping-mode cantilever (resonant frequency: ~300 kHz in air, spring constant: ~40 N/m). Procedure:

- Cantilever Tuning: Before engagement, perform an automatic thermal tune or frequency sweep to identify the fundamental resonance frequency (f₀) of the cantilever in air.

- Engagement Parameters: Set the drive amplitude to a moderate level (e.g., 500 mV). Engage using an amplitude setpoint typically 10-20% lower than the free-air amplitude.

- Optimization: Adjust the drive frequency to be slightly below f₀ for stable imaging. Fine-tune the amplitude setpoint and feedback gains to track topography accurately while maintaining tip oscillation. Reduce the scan rate for high-resolution images.

- Phase Imaging: Simultaneously acquire the phase lag signal, which provides contrast based on viscoelastic and adhesive properties, highlighting different polymer phases.

Protocol 3: PeakForce Tapping for Pharmaceutical Particulate Roughness

Objective: To quantitatively measure the surface roughness of an active pharmaceutical ingredient (API) crystal and simultaneously map its nanomechanical properties (elastic modulus, adhesion). Materials: API crystals dispersed on a glass slide, ScanAsyst-Air or equivalent cantilever (spring constant: ~0.4 N/m, resonant frequency: ~70 kHz). Procedure:

- Cantilever Calibration: Precisely calibrate the cantilever's deflection sensitivity (nm/V) on a hard, clean surface (e.g., sapphire) and its spring constant using the thermal tune method.

- PeakForce Setpoint Selection: This is the critical parameter. Start with a very low setpoint (e.g., 50 pN) to ensure no damage. Gradually increase until stable topography tracking is achieved. For most soft materials, a setpoint of 100-500 pN is sufficient.

- Frequency & Rate Optimization: Set the PeakForce Frequency (typically 0.5-2 kHz) and scan rate such that multiple taps occur per pixel. A ratio of 256 samples per line is recommended.

- Multi-Channel Data Acquisition: Acquire topography, peak force error, DMT modulus, adhesion, and deformation maps simultaneously.

- Roughness Analysis: On the flattened topography image, use the instrument's analysis software to calculate RMS Roughness (Rq) and Average Roughness (Ra) over defined areas.

Logical Workflow for AFM Mode Selection

AFM Mode Selection Workflow for Thin Films

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials and Reagents for AFM Thin Film Roughness Analysis

| Item | Function & Explanation |

|---|---|

| Freshly Cleaved Muscovite Mica | An atomically flat, negatively charged substrate. Essential for tip characterization, scanner calibration, and as a substrate for depositing thin films or biomolecules. |

| Silicon Wafers (P-type/Boron-doped) | Extremely flat, rigid, and conductive (if doped) substrates. Ideal for depositing model thin films and for electrical AFM modes. |

| UV-Ozone Cleaner | Provides a reproducible, chemically clean, and hydrophilic surface on substrates (Si, SiO₂) by removing organic contaminants and increasing surface energy for uniform film deposition. |

| Polystyrene (PS) & Poly(methyl methacrylate) (PMMA) | Standard polymer blend components used as model systems for phase separation studies, validating AFM phase imaging capabilities. |

| Scanning Probe Calibration Grating (e.g., TGZ1, TGQ1) | Grating with periodic structures and known step heights (e.g., 20 nm, 500 nm). Critical for verifying the AFM's lateral (X,Y) and vertical (Z) dimensional accuracy and scanner linearity. |

| Cantilever Calibration Kit | Includes a clean, rigid sample (e.g., sapphire) for deflection sensitivity, and may include pre-calibrated cantilevers. Fundamental for converting photodetector voltage to force (nN). |

| PeakForce Tapping Cantilevers (ScanAsyst family) | Silicon nitride cantilevers with optimized geometry, reflective coating, and consistent spring constants. Designed for superior force control and durability in PeakForce Tapping mode. |

| High-Resolution Tapping Mode Cantilevers (e.g., RTESPA, AC40) | Etched silicon probes with high resonant frequency and sharp tips (<10 nm radius). Provide optimal resolution for Tapping Mode in air and liquid. |

| Soft Contact Mode Cantilevers (e.g., MLCT-Bio) | Silicon nitride cantilevers with very low spring constants (0.01 N/m). Minimize contact force for imaging soft samples in contact mode, though risks remain. |

From Theory to Lab Bench: A Step-by-Step AFM Protocol for Thin Film Analysis

Sample Preparation Best Practices for Drug-Loaded Films and Coatings

Within the broader context of Atomic Force Microscopy (AFM) research for thin film surface roughness analysis, reproducible and artifact-free sample preparation is paramount. For drug-loaded polymeric films and coatings, surface topography directly influences drug release kinetics, biocompatibility, and performance. This protocol details best practices for preparing such samples to ensure their surfaces are representative and suitable for high-resolution AFM characterization, enabling accurate correlation between roughness parameters (Ra, Rq) and functional performance.

Key Challenges in Preparation

Improper preparation can introduce artifacts (scratches, debris, uneven drying) that obscure true surface morphology, leading to erroneous AFM data. Primary challenges include controlling solvent evaporation, achieving uniform thickness, preventing particle aggregation, and ensuring adhesion without contamination.

Essential Research Reagent Solutions

| Reagent/Material | Function in Preparation |

|---|---|

| Poly(lactic-co-glycolic acid) (PLGA) | Biodegradable polymer matrix for controlled drug release. |

| Polyvinyl alcohol (PVA) | Common hydrophilic polymer used as a film-forming agent or stabilizer. |

| Dichloromethane (DCM) | Volatile organic solvent for dissolving hydrophobic polymers (e.g., PLGA). |

| Phosphate Buffered Saline (PBS) | Aqueous medium for simulating physiological conditions during hydration studies. |

| Polydimethylsiloxane (PDMS) molds | Non-adhesive molds for casting films with defined geometry and easy release. |

| Spin Coater | Instrument for creating uniform thin films on substrates via centrifugal force. |

| Oxygen Plasma Cleaner | Treats substrates (e.g., glass, silicon) to increase hydrophilicity and improve film adhesion. |

| Vacuum Desiccator | Removes residual solvents and moisture slowly to prevent film cracking and bubbling. |

Standardized Protocols for AFM-Ready Samples

Protocol 1: Solvent Casting Method for Free-Standing Films

Objective: Produce homogeneous, flat, free-standing films for bulk property analysis.

- Polymer/Drug Solution Preparation: Dissolve the polymer (e.g., 100 mg PLGA) and active pharmaceutical ingredient (API, e.g., 5-20% w/w) in an appropriate volatile solvent (e.g., 5 mL DCM). Stir magnetically for 6 hours until fully dissolved.

- Casting: Pour the solution into a leveled, flat-bottomed PTFE or PDMS mold (e.g., 60 mm diameter).

- Controlled Evaporation: Cover the mold loosely with an aluminum foil lid (punched with 3-4 pinholes) and place it in a fume hood at ambient temperature for 12 hours.

- Final Drying: Transfer the partially dried film into a vacuum desiccator (<50 mTorr) for 24 hours to remove all residual solvent.

- Detachment: Gently peel the free-standing film from the mold. Store in a desiccator until AFM analysis.

Protocol 2: Spin-Coating Method for Thin Coatings on Substrates

Objective: Create ultra-thin, uniform coatings on rigid substrates for nano-scale roughness measurement.

- Substrate Preparation: Clean a silicon wafer or glass slide with successive sonication in acetone, isopropanol, and deionized water (5 minutes each). Dry under nitrogen stream. Treat with oxygen plasma for 2 minutes to enhance wettability.

- Solution Preparation: Prepare a lower-viscosity polymer/drug solution (e.g., 20 mg PLGA + API in 5 mL DCM). Filter through a 0.45 μm PTFE syringe filter.

- Spin-Coating: Pipette 1 mL of solution onto the center of the static substrate. Initiate spin program: 500 rpm for 5 s (spread), then 2000-4000 rpm for 30 s (thin).

- Post-Processing: Immediately transfer the coated substrate to a vacuum desiccator for 4 hours to remove solvent.

- Hydration (if needed): For in situ AFM, immerse the coated substrate in PBS for a predetermined time, then gently blot the edges before mounting on the AFM stage.

Protocol 3: Critical Point Drying for Hydrated/Gel-Based Films

Objective: Prepare hydrated or hydrogel-based films for AFM without introducing drying artifacts like collapse.

- Initial Dehydration: After any aqueous processing or hydration study, gradually dehydrate the sample using a graded ethanol series (30%, 50%, 70%, 90%, 100% v/v, 10 minutes per step).

- Critical Point Drying: Transfer the sample to a critical point dryer. Purge the chamber with liquid CO₂, then perform multiple exchange cycles to replace ethanol with CO₂. Bring the chamber above the critical point of CO₂ (31°C, 1072 psi).

- Vent: Slowly vent the chamber to gas phase CO₂, leaving a dry, uncollapsed film structure.

- Storage: Place the dried sample in a desiccator until AFM imaging.

Table 1: Average Surface Roughness (Ra) of PLGA Films Prepared by Different Methods (AFM Scan Size: 10 µm x 10 µm)

| Preparation Method | Drying Condition | Drug Loading (% w/w) | Average Ra (nm) | Rq (nm) | Key Observation |

|---|---|---|---|---|---|

| Solvent Casting | Ambient, 48 hrs | 0% (Placebo) | 45.2 ± 12.1 | 58.7 ± 15.3 | Moderate roughness, some dust inclusions. |

| Solvent Casting | Vacuum, 24 hrs | 0% (Placebo) | 18.7 ± 4.3 | 24.1 ± 6.2 | Significantly smoother, fewer artifacts. |

| Solvent Casting | Vacuum, 24 hrs | 10% (Model Drug) | 32.5 ± 8.9 | 41.3 ± 10.5 | Increased roughness due to drug particles. |

| Spin Coating | Vacuum, 4 hrs | 0% (Placebo) | 2.1 ± 0.5 | 2.8 ± 0.7 | Very smooth, uniform surface. |

| Spin Coating | Vacuum, 4 hrs | 10% (Model Drug) | 15.8 ± 3.2 | 20.4 ± 4.8 | Nanoscale drug domains visible. |

Table 2: Effect of Hydration and Drying Method on Alginate Film Roughness

| Film State | Drying Method | Average Ra (nm) | Note for AFM Analysis |

|---|---|---|---|

| Hydrated (Wet) | In situ Liquid Cell | 5.8 ± 1.2 | True in operando morphology. |

| Air-Dried | Ambient | 210.5 ± 45.6 | Severe collapse, high Ra. |

| Critical Point Dried | CO₂ CPR | 22.4 ± 6.7 | Preserved porous structure. |

Integrated Workflow for AFM-Centric Sample Preparation

Title: Workflow for Preparing AFM-Ready Drug-Loaded Films

Key Recommendations for AFM Research

- Substrate Control: Always include a placebo (non-drug-loaded) film and a bare substrate control to deconvolute preparation artifacts from drug-induced topography.

- Documentation: Record all parameters: solvent evaporation time/temperature, humidity, spin speed, vacuum duration, and storage conditions.

- Replication: Prepare a minimum of n=3 samples per formulation to assess preparation reproducibility via AFM roughness metrics.

- AFM Tip Selection: For soft, drug-loaded films, use silicon probes with low spring constants (e.g., 0.1-5 N/m) in tapping mode to prevent surface deformation during scanning.

Consistent application of these preparation protocols ensures that AFM-derived surface roughness data is reliable and can be meaningfully correlated with drug release profiles and biological interactions in subsequent thesis research.

Within the context of a broader thesis on Atomic Force Microscopy (AFM) for thin film surface roughness analysis, the precise definition of scan parameters is fundamental to obtaining accurate, reproducible, and meaningful data. This application note details the principles, trade-offs, and experimental protocols for setting the three interdependent core parameters: Scan Size, Resolution, and Scan Rate. Optimizing these parameters is critical for researchers, scientists, and drug development professionals analyzing surface topography of thin films for applications ranging from semiconductor coatings to pharmaceutical formulations.

Core Parameter Definitions & Interdependencies

Scan Size: The physical dimension (X and Y) of the area imaged by the AFM tip, typically measured in micrometers (µm) or nanometers (nm). It defines the field of view.

Resolution: The number of data points sampled within the scan area, defined by the number of pixels (e.g., 256 x 256, 512 x 512, 1024 x 1024). Higher resolution yields more detail but increases acquisition time.

Scan Rate: The frequency at which the probe scans a single line (in Hz), inversely related to the time per line scan. Faster scan rates reduce imaging time but can compromise image quality due to system lag and tip inertia.

These parameters are intrinsically linked by the relationship: Scanning Speed (µm/s) = Scan Size (µm) × Scan Rate (Hz). Adjusting one parameter necessitates adjustments to the others to maintain image fidelity.

Table 1: Parameter Trade-offs and Typical Ranges for Thin Film Roughness Analysis

| Parameter | Typical Range | Impact on Image Quality | Impact on Acquisition Time | Recommended for Roughness Analysis |

|---|---|---|---|---|

| Scan Size | 1 µm² to 100 µm² | Larger size reduces effective lateral resolution. | Increases linearly with area. | 5x5 µm to 20x20 µm for representative sampling. |

| Resolution (pixels) | 256² to 1024² | Higher resolution reveals finer features; lowers noise in roughness calc. | Increases with square of pixel count (e.g., 512² is 4x longer than 256²). | 512 x 512 minimum; 1024 x 1024 for critical features. |

| Scan Rate | 0.5 Hz to 2 Hz (Contact Mode) 0.8 Hz to 5 Hz (Tapping Mode) | Too high causes distortion, lag, and tip damage. Too low increases drift. | Directly inverse: doubling rate halves time. | 0.8-1.2 Hz for high-res (512²+); 1.5-2 Hz for survey scans. |

| Pixel Size (Calc.) | Scan Size / Resolution | Defines smallest detectable lateral feature. | N/A | Should be < 1/3 of feature size of interest. |

Table 2: Example Parameter Sets for Different Thin Film Analysis Goals

| Analysis Goal | Scan Size (µm) | Resolution (pixels) | Pixel Size (nm) | Scan Rate (Hz) | Approx. Time (min) | Mode |

|---|---|---|---|---|---|---|

| Large-scale uniformity | 50 x 50 | 256 x 256 | 195 | 2.0 | ~4.3 | Tapping |

| Standard roughness (Sa) | 10 x 10 | 512 x 512 | 19.5 | 1.0 | ~8.5 | Tapping |

| High-res feature imaging | 2 x 2 | 1024 x 1024 | 2.0 | 0.8 | ~21.3 | Tapping |

| Fast survey scan | 5 x 5 | 256 x 256 | 19.5 | 3.0 | ~1.4 | Contact |

Experimental Protocols

Protocol 1: Systematic Optimization for Reproducible Roughness Measurement

Objective: To establish a standardized AFM imaging protocol for quantifying root-mean-square (Rq) and arithmetic average (Ra) roughness of a polymer thin film.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Sample Preparation: Mount the thin film sample securely on a magnetic or adhesive stub. Use a clean, particulate-free environment.

- Probe Selection & Engagement: Install a silicon cantilever appropriate for the mode (e.g., RTESPA-300 for Tapping Mode). Engage the probe onto the surface using the automated routine at a scan size of 0 µm.

- Initial Survey Scan: Set initial parameters to a moderate scan size (e.g., 20 µm), low resolution (256 x 256), and a scan rate of 1 Hz. Perform a scan to identify a representative, defect-free region of interest.

- Parameter Optimization Loop:

- Set Scan Size: Zoom to a 10 x 10 µm area deemed representative of the film's surface.

- Set Resolution: Increase resolution to 512 x 512. This defines a pixel size of ~19.5 nm.

- Optimize Feedback Gains: Adjust proportional and integral gains to achieve a crisp error signal without oscillation.

- Adjust Scan Rate: Start at 0.5 Hz. Gradually increase the rate until the trace and retrace profiles are nearly identical (indicating minimal distortion). For a 512-line image, this is typically 0.8-1.2 Hz.

- Validate: Capture the image. Check the trace/retrace line profiles for congruence. Calculate the roughness (Rq) in the AFM software. Repeat the scan on the same spot; Rq values should vary by < 5%.

- Data Acquisition: Once optimized, scan at least three different, non-overlapping locations on the sample using the identical parameter set.

- Roughness Analysis: Use the AFM software's plane fitting (usually 1st or 2nd order flattening) and roughness analysis tool. Report both Ra and Rq, along with the scan parameters used.

Protocol 2: Calibrating Scan Rate to Minimize Distortion

Objective: To empirically determine the maximum permissible scan rate for a given tip-sample system to prevent image artifacts.

Methodology:

- Using a sample with known, sharp features (e.g., a grating with vertical steps), engage the probe as in Protocol 1.

- Set a fixed, small scan size (e.g., 2 µm) and high resolution (1024 x 1024).

- Starting at a very low scan rate (0.1 Hz), acquire an image. This is the "reference" image.

- Incrementally increase the scan rate (0.2, 0.5, 1.0, 2.0, 3.0 Hz), acquiring an image at each setting.

- Analyze the sharpness and symmetry of the step edges in each image. The maximum usable scan rate is the highest rate before the step edge broadening (distortion) exceeds 10% of its width in the reference image.

Visualization of Parameter Relationships & Protocols

Title: AFM Parameter Optimization Workflow

Title: Core Parameter Interdependencies

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for AFM Thin Film Analysis

| Item | Function & Relevance to Scan Parameters |

|---|---|

| Standard Reference Sample (e.g., Grating) | A sample with known, periodic features (pitch, step height) for calibrating scan size (X,Y) and Z-scanner, and for validating scan rate limits. |

| Silicon Probes (Tapping Mode, e.g., RTESPA-300) | Sharp, consistent cantilevers with known resonant frequency and spring constant. Essential for achieving high resolution and stable feedback at optimal scan rates. |

| Vibration Isolation Table/Platform | Mitigates environmental noise, enabling stable imaging at slow scan rates and high resolutions without artifacts. |

| Adhesive Mounting Discs (e.g., Carbon Tape) | Secures thin film samples firmly to stubs, preventing movement during scanning which is crucial for large scan sizes and slow rates. |

| Compressed Air/Dust-Free Gas Duster | Removes particulate contamination from sample and stage, preventing tip contamination and image streaks, especially at high magnifications. |

| AFM Software with Advanced Scan Controls | Software allowing independent control of scan size, pixel density, and scan rate, plus real-time display of trace/retrace for optimization. |

1. Introduction within Thesis Context This application note is a component of a broader thesis investigating Atomic Force Microscopy (AFM) methodologies for the quantitative surface roughness analysis of functional thin films (e.g., pharmaceutical coatings, polymer layers, nanostructured materials). A fundamental, yet often underestimated, challenge is the statistically sound acquisition of surface topography data. The core thesis posits that inaccurate roughness parameters (Ra, Rq, Rz) stem less from instrument error and more from non-representative sampling. This protocol details systematic strategies to capture surface areas that truly represent the film's macroscopic properties, ensuring downstream roughness analysis yields reliable, reproducible, and physically meaningful data for research and drug product development.

2. Core Principles of Representative Sampling

Representative sampling for AFM-based roughness analysis requires addressing lateral heterogeneity across multiple scales. The following table summarizes key quantitative considerations for planning data acquisition.

Table 1: Quantitative Parameters for Representative Area Selection

| Parameter | Typical Range/Consideration | Rationale & Impact on Representativeness |

|---|---|---|

| Total Sampled Area | 10 µm² to 1 mm² (aggregate) | Must exceed the correlation length of surface features by at least a factor of 100 to ensure statistical stationarity. |

| Number of Discrete Scans (N) | N ≥ 5-9 per sample condition | Required to estimate the standard error of mean roughness parameters. |

| Scan Size per Location | 1 µm x 1 µm to 100 µm x 100 µm | Must capture the largest relevant lateral feature (e.g., particle, domain). A 10x10 µm scan is often a practical starting point. |

| Spatial Sampling (Pixels) | 256 x 256 to 1024 x 1024 | Must satisfy the Nyquist criterion for the smallest feature of interest. Pixel size should be < (lateral resolution)/2. |

| Inter-Scan Spacing | ≥ 2x the scan size | Minimizes spatial autocorrelation between measurement sites, assuming random or grid-based sampling. |

3. Detailed Experimental Protocols

Protocol 3.1: Systematic Grid-Based Sampling for Macroscopic Homogeneity Assessment Objective: To obtain an unbiased overview of surface variation across a large sample area (e.g., a coated substrate). Materials: AFM with closed-loop XY scanner, pristine AFM probes (e.g., RTESPA-300), optical microscope integrated with AFM. Procedure:

- Sample Mapping: Using the optical microscope, identify and mark a region of interest (ROI) devoid of gross defects. Define a square or rectangular grid within this ROI.

- Grid Definition: Using the AFM software's mapping or automated sequencing function, define a grid of N (e.g., 3x3=9) measurement points. Set the center-to-center spacing between points to be at least twice the chosen scan size (e.g., for 10 µm scans, use ≥20 µm spacing).

- Automated Acquisition: Program the sequence to acquire a topography image at each grid point using identical parameters: scan size, resolution (pixels), scan rate, and feedback gains.

- Data Logging: For each image, record the precise XY stage coordinates alongside the raw data file.

- Analysis: Calculate primary roughness parameters (Ra, Rq) for each individual image. Perform descriptive statistics (mean, standard deviation) across the set of N images.

Protocol 3.2: Targeted Multi-Scale Sampling for Heterogeneous or Structured Films Objective: To intentionally capture data from distinct morphological regions (e.g., domains, particles, valleys) identified a priori. Materials: As in Protocol 3.1, plus SEM or high-resolution optical profilometry data for guidance. Procedure:

- Pre-Screening: Characterize the sample using a low-magnification technique (e.g., optical profilometry, SEM) to identify distinct topographic regions (e.g., "granular domains," "smooth matrix," "boundary regions").

- Region Classification: Classify and label at least three distinct morphological region types.

- Targeted AFM Setup: Transfer the sample to the AFM. Using the optical microscope and correlation with the pre-screen map, navigate to a representative location of Region Type 1.

- Scale-Dependent Imaging: At this location, perform a nested scan series: a. Acquire a large-area scan (e.g., 50x50 µm) to capture the local context and feature distribution. b. Within that image, select a representative sub-region for a high-resolution scan (e.g., 5x5 µm, 1024x1024 pixels) to resolve fine details.

- Replicate Sampling: Repeat Step 3 and 4 for at least three different, spatially separated locations per Region Type.

- Analysis: Report roughness parameters segregated by Region Type. The overall surface representation is the area-weighted average of these regional analyses.

4. Visualization of Strategic Workflows

Workflow for Representative AFM Area Selection

5. The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Representative AFM Surface Acquisition

| Item | Function & Rationale |

|---|---|

| AFM with Automated XY Stage | Enables precise, repeatable navigation to predefined grid coordinates for systematic sampling (Protocol 3.1). Closed-loop control is critical for accuracy. |

| Sharp Silicon Probes (e.g., Tap300-G series) | Standard probes for high-resolution topography of thin films. Consistent tip geometry (radius < 10 nm) is vital for comparable measurements across scans. |

| Vibration Isolation System | Active or passive isolation table to minimize acoustic/floor noise, preventing artifacts that corrupt data, especially during long automated sequences. |

| Sample Mounting Kit | Includes double-sided conductive tape, magnetic disks, or vacuum chucks to secure the sample firmly, preventing drift during measurement. |

| Optical Microscope (Integrated) | Used for initial sample navigation, identification of gross regions of interest, and correlation with pre-screen maps for targeted sampling. |

| Reference Sample (e.g., Gratings) | Used to calibrate the AFM scanner's XY and Z dimensions, ensuring scan size accuracy, which is fundamental for comparing areas. |

| Automated Scripting Software | AFM vendor-specific or third-party software (e.g., Pycroscopy) to program automated multi-location measurements, ensuring consistency and saving time. |

| Clean Room Supplies | Lint-free wipes, compressed air or nitrogen duster, UV-ozone cleaner. To remove particulate contamination from the sample surface before measurement. |

Within the context of a broader thesis on Atomic Force Microscopy (AFM) for thin film surface roughness analysis, this application note details the critical post-processing steps required to extract quantitative, reliable data. For researchers, scientists, and drug development professionals, proper data treatment is essential for correlating surface topography with material properties, coating uniformity, or biological interactions. Raw AFM height data contains artifacts, such as scanner bow, tilt, and noise, which must be removed before meaningful roughness parameters can be calculated. This protocol outlines standardized methodologies for flattening, filtering, and parameter calculation.

Core Post-Processing Workflow

The following workflow diagram illustrates the logical sequence of steps for AFM data post-processing.

AFM Data Post-Processing Sequential Workflow

Experimental Protocols

Protocol 1: Polynomial Flattening (Order 0, 1, or 2)

Objective: Remove instrument-induced vertical offset (0th order), tilt (1st order), and scanner bow (2nd order) from the image data.

- Load Data: Import the raw AFM scan file (e.g., .ibw, .spm, .txt) into analysis software (e.g., Gwyddion, NanoScope Analysis, MountainsSPIP).

- Select Flattening Function: Choose the "Flatten" or "Plane Correct" algorithm.

- Choose Polynomial Order:

- 0th Order (Mean): Subtracts the average height of the entire scan or selected rows. Use for data already horizontally level.

- 1st Order (Linear): Fits and subtracts a flat plane (Ax + By + C). Standard for removing scan tilt.

- 2nd Order (Parabolic): Fits and subtracts a second-order polynomial surface. Essential for removing non-linear scanner bow artifacts.

- Apply per Row/Line: For most contact-mode images, apply 1st order flattening to each scan line individually to remove line-wise bow.

- Apply to Whole Image: Finally, apply a global 1st or 2nd order flatten to the entire dataset.

- Validation: Visually inspect the flattened image; the background should appear level without artificial curvature.

Protocol 2: Spatial Frequency Filtering

Objective: Isolate surface roughness features of interest by removing high-frequency noise and low-frequency waviness.

- Define Cut-offs: Determine the spatial wavelength cut-offs based on feature size.

- High-Pass Filter (Removes Low Frequencies): Set a cut-off wavelength (λlow) to remove waviness larger than the relevant lateral scale. Features smaller than λlow are retained.

- Low-Pass Filter (Removes High Frequencies): Set a cut-off wavelength (λhigh) to remove noise smaller than the smallest relevant feature. Features larger than λhigh are retained.

- Select Filter Type: Use a Gaussian or Median filter for gentle smoothing. A Fourier Transform (FFT) bandpass filter offers precise frequency control.

- Apply Filter:

- For Gaussian Low-Pass, select a kernel size (σ) approximately equal to λ_high.

- For FFT Bandpass, transform the image to frequency space, manually suppress frequencies outside the λlow to λhigh band, then perform an inverse FFT.

- Caution: Document all filter parameters. Over-filtering can artificially alter roughness values.

Protocol 3: Parameter Calculation According to ISO 25178

Objective: Calculate standardized height and spatial roughness parameters from the processed topography data.

- Define Evaluation Area: Use a masking tool to exclude obvious dust particles, scan artifacts, or deep scratches from the analysis area.

- Create the Primary Surface (S): This is the flattened and filtered height map.

- Calculate Height Parameters (based on S):

- Sa (Arithmetic Mean Height): The average absolute deviation from the mean plane.

- Sq (Root Mean Square Height): The standard deviation of height values. More sensitive to peaks and valleys than Sa.

- Sz (Maximum Height): The sum of the largest peak height and pit depth within the defined area.

- Calculate Hybrid & Spatial Parameters (may require additional processing):

- Sdr (Developed Interfacial Area Ratio): The percentage of additional surface area contributed by roughness compared to a flat plane.

- Calculate the Autocorrelation Function (ACF): Derive the Sal (Autocorrelation Length) – the horizontal distance at which the ACF decays to a specified fraction (e.g., 0.2). This characterizes lateral feature size.

Data Presentation: Roughness Parameter Comparison

The table below summarizes key ISO 25178 parameters and their relevance for thin-film analysis.

Table 1: Core AFM Roughness Parameters for Thin Film Characterization

| Parameter | Symbol | Description & Formula (Discrete) | Relevance to Thin Films | ||

|---|---|---|---|---|---|

| Arithmetic Mean Height | Sa | ( Sa = \frac{1}{A} \iint_A | z(x,y) | \,dx\,dy ) | General surface quality, coating uniformity. |

| Root Mean Square Height | Sq | ( Sq = \sqrt{\frac{1}{A} \iint_A z^2(x,y) \,dx\,dy} ) | Power of surface roughness, more sensitive to extremes. | ||

| Maximum Height | Sz | ( Sz = \max(z(x,y)) + | \min(z(x,y)) | ) | Detects large outliers, agglomerates, or deep pores. |

| Developed Interfacial Area Ratio | Sdr | ( Sdr = \frac{A{textured} - A{projected}}{A_{projected}} \times 100\% ) | Wettability, adhesion, and biological cell attachment potential. | ||

| Autocorrelation Length | Sal | Horizontal distance for ACF to drop to 0.2. | Dominant lateral feature size, grain, or domain size estimation. |

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials for AFM Roughness Analysis

| Item | Function/Description |

|---|---|

| AFM with Closed-Loop Scanner | Provides accurate XYZ positioning without non-linear piezo drift, essential for quantitative height measurement. |

| Low-Noise Vibration Isolation Table | Minimizes environmental mechanical noise, which directly impacts Sq and high-frequency filtering needs. |

| Standard Calibration Grating (e.g., TGZ1, TGX1) | Grid of periodic pits or steps with known depth/height (e.g., 180 nm ± 5%). Used for vertical (Z) calibration and scanner linearity verification. |

| Software with ISO-Compliant Analysis (e.g., Gwyddion, SPIP, NanoScope Analysis) | Provides standardized flattening routines, FFT filters, and automatic calculation of ISO 25178 parameters. |

| Sharp AFM Probes (e.g., RTESPA-300) | High-resolution silicon probes with a nominal tip radius of ~8 nm. Crucial for accurately imaging fine nanoscale roughness without tip convolution artifacts. |

| Cleanroom Wipes & Solvents (IPA, Acetone) | For meticulous cleaning of substrates and sample stages to prevent particulate contamination that falsely increases Sz and Sa. |

| Sample Mounting Tape/Adhesive | Double-sided conductive or non-conductive tape to firmly immobilize thin film samples, preventing drift during scanning. |

This application note details the use of Atomic Force Microscopy (AFM) for the quantitative surface roughness analysis of three critical thin-film systems: cast polymer films, spray coatings, and electrospun nanofiber mats. Surface roughness is a critical performance determinant for applications in drug delivery, biomedical implants, and functional coatings. AFM provides non-destructive, three-dimensional topographical data at nanoscale resolution, enabling rigorous correlation between fabrication parameters and surface morphology.

Case Study 1: Solvent-Cast Polymer Films for Drug Elution

Objective: To correlate polymer solution concentration with surface roughness and drug release kinetics.

Protocol: Film Preparation and AFM Analysis

- Solution Preparation: Prepare poly(lactic-co-glycolic acid) (PLGA) solutions in dimethyl sulfoxide (DMSO) at concentrations of 5%, 10%, and 15% (w/v). Add a model drug (e.g., Rhodamine B) at 2% (w/w of polymer).

- Casting: Pipette 1 mL of each solution onto a clean, leveled glass slide (75 mm x 25 mm).

- Drying: Allow films to dry under ambient conditions for 24 hours, followed by 24 hours in a vacuum desiccator.

- AFM Imaging: Use tapping mode AFM with a silicon probe (spring constant ~40 N/m, resonant frequency ~300 kHz). Scan five random 10 µm x 10 µm areas per sample at a resolution of 512 samples/line.

- Data Analysis: Calculate the root-mean-square roughness (Rq) and arithmetic average roughness (Ra) for each scan.

Results Summary Table 1: AFM Roughness Analysis of Cast PLGA Films

| PLGA Concentration (% w/v) | Avg. Ra (nm) ± SD | Avg. Rq (nm) ± SD | Observed Drug Release Half-life (hr) |

|---|---|---|---|

| 5 | 12.3 ± 2.1 | 15.8 ± 2.7 | 28.5 |

| 10 | 8.7 ± 1.4 | 11.2 ± 1.9 | 52.1 |

| 15 | 5.1 ± 0.9 | 6.6 ± 1.2 | 89.7 |

Case Study 2: Antifouling Spray Coatings

Objective: To assess the uniformity and nanoscale roughness of a polyurethane-siloxane spray coating designed to prevent biofilm adhesion.

Protocol: Coating Application and Multi-Scale Analysis

- Substrate Preparation: Clean stainless-steel coupons (20 mm x 20 mm) with ethanol and oxygen plasma treat for 5 minutes.

- Spray Coating: Load the polymer solution into an airbrush spray gun. Apply coatings using a robotic arm for consistency: 6 passes at a distance of 15 cm, 30 psi nozzle pressure, with 30-second drying intervals between passes.

- AFM Protocol: Employ ScanAsyst-Air mode for optimal imaging of soft coatings. Use a SCANASYST-AIR probe. Perform scans from large (50 µm x 50 µm) to small (2 µm x 2 µm) areas to assess uniformity.

- Roughness Correlation: Calculate roughness parameters at each scale. Perform image analysis to identify and count nanoscale defect features (pits, protrusions > 50 nm in height).

Results Summary Table 2: Multi-Scale Roughness of Sprayed Antifouling Coating

| Scan Size (µm) | Avg. Ra (nm) ± SD | Avg. Rq (nm) ± SD | Defect Density (features/100 µm²) |

|---|---|---|---|

| 50 x 50 | 45.2 ± 8.3 | 57.9 ± 9.1 | 0.8 |

| 10 x 10 | 18.6 ± 4.1 | 23.7 ± 5.2 | 2.3 |

| 2 x 2 | 6.5 ± 1.7 | 8.3 ± 2.1 | 5.5 |

Case Study 3: Drug-Loaded Electrospun Nanofiber Mats

Objective: To quantify the relationship between fiber diameter distribution, mat porosity, and surface roughness for cell adhesion studies.

Protocol: Electrospinning and 3D Topography

- Fiber Production: Electrospin a 20% (w/v) polycaprolactone (PCL) solution in chloroform/DMF (7:3) with 5% (w/w) tetracycline hydrochloride. Parameters: 18 kV applied voltage, 15 cm collector distance, 1 mL/hr flow rate.

- Sample Preparation: Mount a small section (10 mm x 10 mm) of the mat on a metal stub using conductive tape.

- AFM Challenges & Setup: Use a high-aspect-ratio probe (e.g., Tap300HD-G) to accurately profile deep pores. Use non-contact mode to avoid displacing fibers. Adjust drive amplitude and setpoint carefully.

- Analysis: Use watershed analysis in AFM software to segment individual fibers. Determine fiber diameter distribution from height profiles. Calculate the true surface area ratio (r) = (Actual 3D Surface Area / Projected 2D Area).

Results Summary Table 3: Topographical Properties of Electrospun PCL Fiber Mat

| Parameter | Measured Value ± SD / Distribution |

|---|---|

| Average Fiber Diameter | 245 ± 67 nm |

| Mat Roughness, Ra (10 µm scan) | 320 ± 45 nm |

| True Surface Area Ratio (r) | 3.1 ± 0.4 |

| Estimated Porosity (from AFM) | 78% ± 6% |

Experimental Protocols in Detail

Protocol A: Standard Tapping Mode AFM for Polymer Films

- Probe Calibration: Calibrate the probe's deflection sensitivity on a clean sapphire surface. Determine the spring constant via the thermal tune method.

- Mounting: Secure the sample to the magnetic AFM stage using double-sided tape.

- Engagement: Use the automated engage routine, setting a target amplitude reduction of 10-15% for stable imaging.

- Scan Optimization: Adjust scan rate to 0.5-1 Hz. Manually tune the drive amplitude and feedback gains (proportional and integral) to minimize imaging artifacts.

- Data Acquisition: Acquire both height and phase images simultaneously. Save raw data files for offline analysis.

Protocol B: Non-Contact Mode for Delicate Electrospun Mats

- Probe Selection: Install a non-contact high-frequency probe (e.g., 190-325 kHz).

- Frequency Tune: Perform a frequency sweep to identify the resonant peak. Lock the drive frequency to the peak.

- Setpoint Selection: Set the oscillation amplitude (~10-20 nm). Engage at a setpoint very close to (typically >95% of) the free-air amplitude to ensure minimal tip-sample interaction.

- Low-Stress Imaging: Use a low scan rate (0.3-0.5 Hz) and low feedback gains to track the surface without dislodging fibers.

The Scientist's Toolkit

Table 4: Key Research Reagent Solutions for Thin Film AFM Studies

| Item & Example | Primary Function in Analysis |

|---|---|

| AFM Probe (Tap300Al-G) | Silicon tip for high-resolution tapping mode imaging of polymers; Al coating enhances laser reflection. |

| Calibration Grating (TGQ1) | Grid of 1 µm pitch pits; verifies scanner accuracy in X, Y, and Z dimensions before measurement. |

| Oxygen Plasma Cleaner | Generates a reactive plasma to remove organic contaminants from substrates and samples, ensuring clean analysis. |

| Conductive Adhesive Tape | Secures non-magnetic samples (e.g., glass slides, fibers) to the AFM specimen disk without damaging them. |

| Vibration Isolation Table | Provides mechanical damping to isolate the AFM from ambient building vibrations for stable imaging. |

| Image Analysis Software (Gwyddion) | Open-source software for processing AFM data: leveling, grain analysis, roughness calculation, and 3D rendering. |

Visualizations

Title: Thin Film AFM Study Workflow

Title: How Roughness Affects Performance

Solving Common Problems: Optimizing AFM Measurements for Reliable Roughness Data

Atomic Force Microscopy (AFM) is a cornerstone technique for quantifying thin-film surface roughness, a critical parameter in fields from semiconductor fabrication to pharmaceutical coating uniformity. Accurate measurement is paramount, as roughness influences adhesion, optical properties, and biological interactions. However, the fidelity of AFM data is inherently compromised by three principal artifacts: Tip Convolution, Instrumental Drift, and Environmental Vibrations. This document, framed within a broader thesis on robust AFM methodologies for thin-film analysis, details the origin, impact, and systematic mitigation of these artifacts through validated application notes and protocols.

Artifact Analysis and Quantitative Impact

Tip Convolution

Tip convolution occurs when the finite dimensions and geometry of the AFM probe tip interact with surface features, resulting in a scanned image that represents a blend of the tip and sample topography. This effect artificially widens narrow features and reduces apparent depth.

Table 1: Impact of Tip Geometry on Measured Roughness Parameters

| Tip Radius (nm) | Actual Feature Width (nm) | Measured Width (nm) | Error in Ra (RMS)* |

|---|---|---|---|

| 2 (Sharp) | 20 | ~22 | < 5% |

| 10 | 20 | ~30 | 15-25% |

| 50 (Blunt) | 20 | ~70 | 50-100% |

| 2 (Sharp) | 50 | ~52 | < 5% |

| 10 | 50 | ~60 | 10-15% |

*Ra: Average Roughness; RMS: Root Mean Square Roughness. Error is indicative for features with aspect ratio >1.

Thermal and Instrumental Drift

Drift refers to the undesired, time-dependent movement of the probe relative to the sample, caused primarily by thermal expansion/contraction of components and piezoelectric creep. It distorts image geometry and hinders long-term stability for force spectroscopy or sequential imaging.

Table 2: Typical Drift Rates and Impact on Imaging

| AFM Mode | Ambient Temp. Stability | Typical Drift Rate (nm/min) | Impact on 10-min Scan |

|---|---|---|---|

| Open-Bench AFM | ±1°C | 20-50 | Severe distortion (>200 nm offset) |

| Enclosed AFM | ±0.1°C | 5-15 | Moderate distortion (50-150 nm) |

| Temperature-Stabilized AFM | ±0.01°C | 0.5-2 | Minimal distortion (<20 nm) |

Mechanical and Acoustic Vibrations

Environmental vibrations from building infrastructure, equipment, and acoustic noise couple into the AFM, inducing periodic noise or streaking in images, obscuring true nanoscale topography.

Table 3: Vibration Sources and Their Spectral Impact

| Vibration Source | Frequency Range | Effect on AFM Image | Recommended Isolation |

|---|---|---|---|

| Building Floor | 5-50 Hz | Low-frequency waves, streaks | Active or passive air table |

| Acoustic Noise (Talk, Equipment) | 100-500 Hz | High-frequency noise, fuzziness | Acoustic enclosure |

| Pump/Mechanical Equipment | Discrete peaks (e.g., 60 Hz) | Regular repeating artifacts | Anti-vibration mounts, relocation |

Experimental Protocols for Artifact Minimization

Protocol 3.1: Characterizing and Correcting for Tip Convolution

Objective: To determine the effective tip geometry and apply deconvolution algorithms to recover more accurate surface topography. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Tip Characterization Imaging:

- Use a Tip Characterization Sample (e.g., sharp spike array or known sharp edge) with features sharper than the probe.

- Acquire a high-resolution image (512x512 pixels) of the characterization sample in tapping mode.

- Use the instrument's tip reconstruction software (e.g., Blind Tip Reconstruction algorithm) to generate a 3D model of the tip's effective shape.

- Sample Imaging:

- Image the thin-film sample of interest using the same probe and identical parameters.

- Software Deconvolution:

- Import both the tip model and the sample image into image processing software (e.g., Gwyddion, SPIP).

- Apply a deconvolution algorithm (e.g., Morphological Reconstruction or Reverse Convolution).

- Validate by comparing the width and depth of isolated features before and after processing.

Protocol 3.2: Drift Measurement and Compensation Protocol

Objective: To quantify and minimize the impact of lateral and vertical drift during imaging. Procedure:

- Pre-Imaging Thermal Equilibration:

- Load the sample and probe, then allow the AFM head and stage to equilibrate for a minimum of 60 minutes in its operational environment.

- Drift Measurement via Sequential Imaging:

- Select a small scan area (e.g., 1x1 µm) with distinct, high-contrast features.

- Acquire two sequential images of the same region with a short pause (30 s) between them. Do not move the scan area.

- Use image cross-correlation analysis to calculate the X and Y offset between the two images. This offset divided by the time interval is the drift rate.

- Drift-Compensated Imaging:

- If the measured drift rate is >5 nm/min for high-resolution work, implement compensation.