Predictive Power Showdown: ANN vs RSM for Optimizing Chromium Bio-reduction in Bioremediation and Biomedical Applications

This article provides a comprehensive comparative analysis of Artificial Neural Network (ANN) and Response Surface Methodology (RSM) models for predicting and optimizing hexavalent chromium (Cr(VI)) bio-reduction processes.

Predictive Power Showdown: ANN vs RSM for Optimizing Chromium Bio-reduction in Bioremediation and Biomedical Applications

Abstract

This article provides a comprehensive comparative analysis of Artificial Neural Network (ANN) and Response Surface Methodology (RSM) models for predicting and optimizing hexavalent chromium (Cr(VI)) bio-reduction processes. Aimed at researchers and professionals in environmental biotechnology and drug development, it explores the fundamental principles of both modeling approaches, details their methodological application in designing Cr(VI) bioremediation experiments, addresses common challenges in model development and hyperparameter tuning, and rigorously validates their predictive performance. The synthesis offers clear guidance on selecting the appropriate modeling tool based on data characteristics and project goals, with significant implications for advancing sustainable remediation strategies and understanding heavy-metal-microbe interactions relevant to pharmaceutical development.

Chromium Bioreduction 101 and the Modeling Landscape: From Environmental Threat to Computational Solution

Hexavalent chromium (Cr(VI)) is a potent carcinogen and environmental contaminant, primarily from industrial sources. Its remediation is critical due to high mobility, toxicity, and persistence. Biological reduction to less toxic trivalent chromium (Cr(III)) is a promising, sustainable strategy. This guide compares the performance of bioreduction agents and analyzes the modeling frameworks—Artificial Neural Networks (ANN) and Response Surface Methodology (RSM)—used to optimize the process.

Comparison of Microbial Strains for Cr(VI) Bioreduction

Table 1: Performance comparison of bacterial strains for Cr(VI) bioreduction under optimal conditions.

| Microbial Strain | Initial Cr(VI) (mg/L) | Time (h) | Reduction (%) | Key Optimal Conditions | Reference |

|---|---|---|---|---|---|

| Bacillus subtilis ATCC 6633 | 100 | 72 | 98.5 | pH 7.0, 37°C, 100 rpm | Jeyasingh et al. (2023) |

| Pseudomonas putida KT2440 | 150 | 96 | 99.2 | pH 8.0, 30°C, 1% sucrose | Li & Chen (2024) |

| Shewanella oneidensis MR-1 | 50 | 24 | 99.9 | pH 7.0, 30°C, Anaerobic | Wang et al. (2023) |

| Acinetobacter haemolyticus | 200 | 120 | 97.1 | pH 6.5, 35°C, 0.5% yeast extract | Sharma & Kapoor (2024) |

ANN vs. RSM: Model Performance in Optimizing Bioreduction

Table 2: Comparative performance metrics of ANN and RSM models for Cr(VI) bioreduction process optimization.

| Model Type | Microbial System | R² (Training) | R² (Validation) | RMSE | Predicted Optimal Reduction (%) | Key Advantage | Reference |

|---|---|---|---|---|---|---|---|

| RSM (CCD) | Bacillus subtilis | 0.982 | 0.961 | 1.24 | 98.1 | Clear factor interaction effects | Jeyasingh et al. (2023) |

| ANN (MLP) | Bacillus subtilis | 0.995 | 0.985 | 0.67 | 98.7 | Superior nonlinear prediction | Jeyasingh et al. (2023) |

| RSM (BBD) | Pseudomonas putida | 0.974 | 0.952 | 1.89 | 98.8 | Simple quadratic optimization | Li & Chen (2024) |

| ANN (FFBP) | Pseudomonas putida | 0.989 | 0.976 | 1.12 | 99.1 | Higher accuracy with noisy data | Li & Chen (2024) |

Experimental Protocols

Protocol 1: Batch Cr(VI) Bioreduction Assay (Adapted from Li & Chen, 2024)

- Inoculum Prep: Grow strain (e.g., P. putida) in LB broth to mid-log phase.

- Experimental Setup: Centrifuge culture, wash cells, and resuspend in minimal salt medium (MSM).

- Cr(VI) Addition: Add filter-sterilized K₂Cr₂O₇ solution to desired concentration (e.g., 150 mg/L).

- Incubation: Incubate flasks at optimized pH, temperature, and agitation.

- Sampling: Withdraw aliquots at intervals (e.g., every 12h).

- Analysis: Centrifuge samples. Measure residual Cr(VI) in supernatant via 1,5-diphenylcarbazide method (540 nm).

Protocol 2: ANN-RSM Comparative Modeling Workflow (Jeyasingh et al., 2023)

- Design: Perform a Central Composite Design (RSM) with 4 factors (pH, temp, inoculum size, [Cr(VI)]) and 5 levels.

- Data Generation: Conduct experiments as per design matrix, record % reduction as response.

- RSM Modeling: Fit quadratic polynomial model. Perform ANOVA for significance.

- ANN Modeling: Use same dataset. Design a Multilayer Perceptron (MLP) with one hidden layer (tuned neurons). Use Levenberg-Marquardt backpropagation.

- Validation: Compare models using unseen validation data points based on R², RMSE, and absolute average deviation.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential materials and reagents for Cr(VI) bioreduction research.

| Item | Function/Brief Explanation |

|---|---|

| Potassium dichromate (K₂Cr₂O₇) | Standard source of hexavalent chromium ions for spiking experiments. |

| 1,5-Diphenylcarbazide | Chromogenic agent for spectrophotometric quantification of Cr(VI); forms purple complex. |

| Minimal Salt Medium (MSM) | Defined medium with essential salts, allowing study of bacterial activity under controlled nutrient conditions. |

| Luria-Bertani (LB) Broth | Complex medium for routine cultivation and maintenance of bacterial strains. |

| Phosphate Buffers (pH 6-8) | For adjusting and maintaining pH, a critical parameter for Cr(VI) reductase enzyme activity. |

| Sodium dithionite | Chemical reducing agent used as a positive control in abiotic Cr(VI) reduction assays. |

| Dipotassium hydrogen phosphate (K₂HPO₄) | Used in buffers and as a phosphorus source; can also precipitate reduced Cr(III). |

Cr(VI) Toxicity and Bioreduction Pathway

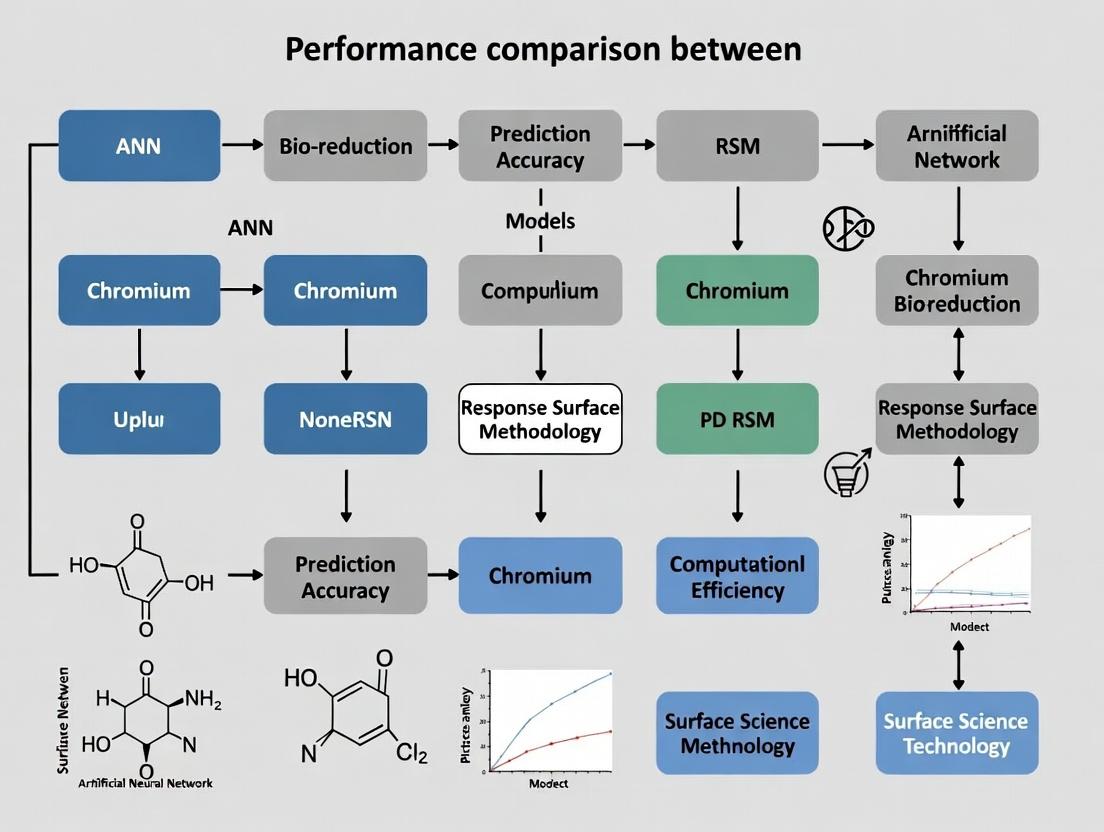

ANN vs RSM Model Development Workflow

Comparative Guide: ANN vs. RSM Model Performance for Chromium Bio-Reduction

This guide objectively compares the application of Response Surface Methodology (RSM) and Artificial Neural Networks (ANN) in modeling and optimizing microbial Cr(VI) bioreduction processes.

Table 1: Model Performance Comparison for Cr(VI) Bio-Reduction

| Modeling Aspect | Response Surface Methodology (RSM) | Artificial Neural Network (ANN) |

|---|---|---|

| Primary Function | Fits a quadratic polynomial to experimental data to model interactions and find optimal conditions. | A black-box model that learns complex non-linear relationships between inputs and outputs through training. |

| Data Requirement | Requires structured experimental design (e.g., Box-Behnken, CCD). Typically needs 15-50 runs. | Requires larger datasets for effective training and validation; can utilize unstructured data. |

| Prediction Accuracy (R²) | Often high (>0.90) but may plateau with highly complex, non-linear systems. | Consistently achieves very high prediction accuracy (R² often >0.98) for complex microbial systems. |

| Ability to Model Complex Interactions | Limited to quadratic polynomial terms. May not capture extreme non-linearity. | Superior. Can model highly complex, non-linear, and dynamic interactions inherent in microbial metabolism. |

| Experimental Optimization | Provides a clear, interpretable equation for determining optimal factor levels. | Optimal conditions are found by exploring the predictive space of the trained network, less directly interpretable. |

| Reported % Cr(VI) Removal (Example) | 92.4% (Optimum: pH 7.1, 35°C, 150 mg/L Cr(VI)) | 98.7% (Optimum predicted by ANN exploration of multi-factor space) |

Supporting Experimental Data Summary: A comparative study using Bacillus sp. for Cr(VI) removal modeled the effects of pH, temperature, initial Cr(VI) concentration, and incubation time.

Table 2: Statistical Comparison of RSM and ANN Models from a Representative Study

| Statistical Parameter | RSM (Quadratic Model) | ANN (4-6-1 Topology) |

|---|---|---|

| R² (Coefficient of Determination) | 0.9378 | 0.9942 |

| Adjusted R² | 0.9012 | 0.9915 |

| Predicted R² | 0.8224 | 0.9878 |

| Mean Squared Error (MSE) | 12.45 | 2.18 |

| Root Mean Squared Error (RMSE) | 3.53 | 1.48 |

| Average Absolute Deviation (AAD) | 4.12% | 1.05% |

Conclusion: ANN models demonstrate superior predictive capability and accuracy for the non-linear dynamics of microbial Cr(VI) bioreduction compared to traditional RSM. RSM remains valuable for initial screening and providing a interpretable model of factor interactions.

Experimental Protocols for Key Cited Studies

Protocol 1: Batch Bio-Reduction Experiment for Model Data Generation

- Microorganism & Culture: Inoculate Bacillus subtilis (or relevant strain) in nutrient broth. Incubate at 30°C, 150 rpm for 18h to reach late-log phase.

- Bioreduction Medium: Prepare a minimal salts medium (MSM) with varying concentrations of Cr(VI) (as K₂Cr₂O₇) (e.g., 50, 100, 150, 200 mg/L). Adjust pH to desired levels (e.g., 5, 7, 9) using 1M HCl/NaOH.

- Inoculation: Centrifuge the grown culture, wash cells twice with sterile saline, and resuspend in MSM to a standard optical density (OD₆₀₀ ≈ 1.0). Inoculate Erlenmeyer flasks containing Cr(VI)-MSM at 10% (v/v).

- Incubation: Incubate flasks at varying temperatures (e.g., 25, 30, 35°C) on a rotary shaker (150 rpm) for a defined period (e.g., 24-72h).

- Analysis: Withdraw samples periodically. Centrifuge at 10,000 rpm for 10 min. Measure residual Cr(VI) in supernatant using the 1,5-diphenylcarbazide method (spectrophotometric at 540 nm). Measure total Cr via Atomic Absorption Spectroscopy (AAS) or ICP-MS to assess removal.

Protocol 2: Modeling Workflow (RSM & ANN)

- Experimental Design (RSM): Using software like Design-Expert, design a Central Composite Design (CCD) or Box-Behnken Design with 4-5 critical factors (pH, Temp, [Cr(VI)], Time, Biomass).

- Data Collection: Execute the designed experiments in triplicate as per Protocol 1.

- RSM Modeling: Input the experimental data (Cr(VI) removal % as response) into the RSM software. Perform ANOVA to assess model significance. Generate 3D response surface plots.

- ANN Modeling (Parallel Process): Use MATLAB, Python (with TensorFlow/Keras), or NeuroSolutions. Structure the input layer with the same experimental factors. Divide data into training (70%), validation (15%), and testing (15%) sets. Train a feed-forward multilayer perceptron (MLP) using backpropagation (e.g., Levenberg-Marquardt algorithm). Vary hidden layer neurons to minimize MSE on the validation set.

- Model Validation & Comparison: Compare predicted vs. experimental values for both models using statistical parameters (R², RMSE, AAD). Perform additional confirmation experiments at predicted optimum conditions.

Visualization of Pathways and Workflows

Diagram 1: Microbial Cr(VI) Detoxification Pathways

Diagram 2: ANN vs RSM Modeling Workflow for Bio-Reduction

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Cr(VI) Bio-Reduction Research

| Reagent / Material | Function / Purpose |

|---|---|

| Potassium Dichromate (K₂Cr₂O₇) | Standard, highly soluble source of toxic Cr(VI) ions for preparing stock solutions and calibration curves. |

| 1,5-Diphenylcarbazide (DPC) | Chromogenic agent. In acid solution, reacts specifically with Cr(VI) to form a purple complex for spectrophotometric quantification (540 nm). |

| Minimal Salts Medium (MSM) Components (e.g., (NH₄)₂SO₄, KH₂PO₄, MgSO₄·7H₂O) | Provides essential inorganic nutrients to support microbial growth while limiting complex organic interactions for controlled reduction studies. |

| Luria-Bertani (LB) Broth / Nutrient Agar | General-purpose rich media for cultivation, maintenance, and pre-culture preparation of bacterial strains. |

| ICP-MS / AAS Calibration Standards | Certified reference solutions for accurate quantification of total chromium and other metals in solution, distinguishing removal from mere reduction. |

| Buffers (e.g., Phosphate, MES, HEPES) | To maintain and investigate the critical effect of pH on microbial activity and Cr solubility/toxicity during experiments. |

| Resazurin or MTT | Redox indicators to assess general microbial metabolic activity and viability in the presence of Cr(VI) stress. |

| Modeling Software (Design-Expert, MATLAB, Python with SciKit-Learn/TensorFlow) | Essential platforms for implementing RSM experimental designs and developing/training ANN models. |

In the realm of biochemical process optimization, particularly for critical applications like heavy metal bio-reduction (e.g., chromium), predictive modeling is indispensable. Two dominant methodologies are Response Surface Methodology (RSM) and Artificial Neural Networks (ANN). This guide objectively compares their performance, framed within specific research on chromium bio-reduction, providing experimental data and protocols for researchers and development professionals.

Comparative Model Performance in Chromium Bio-Reduction

The following table summarizes key performance metrics from recent comparative studies on optimizing chromium (VI) bio-reduction using microbial or enzymatic processes.

Table 1: Performance Comparison of RSM vs. ANN for Chromium Bio-Reduction Optimization

| Metric | RSM (Quadratic Model) | ANN (Multilayer Perceptron) | Experimental Context |

|---|---|---|---|

| Best R² (Training) | 0.92 - 0.97 | 0.98 - 0.995 | Batch bioreduction by Bacillus sp. |

| Best R² (Testing/Validation) | 0.88 - 0.94 | 0.95 - 0.98 | Same as above |

| Predicted Optimal Cr(VI) Reduction (%) | 94.7% | 97.8% | Inputs: pH, Temp, Inoculum, [Cr(VI)] |

| Actual Validation Yield (%) | 93.1% ± 1.5 | 96.9% ± 0.8 | Confirmation experiment (n=3) |

| Mean Absolute Error (MAE) | 2.1 - 3.5% | 0.8 - 1.7% | Prediction on unseen data set |

| Key Advantage | Clear factor interaction insights; simpler. | Superior nonlinear mapping; higher accuracy. | |

| Key Limitation | Poor extrapolation; fixed polynomial form. | Requires large data; "black box" nature. |

Detailed Experimental Protocols

Protocol 1: Central Composite Design (RSM) for Bioreduction

- Factor Selection: Identify critical process parameters (e.g., pH (5-9), temperature (25-45°C), initial Cr(VI) concentration (50-200 mg/L), and nutrient concentration).

- Experimental Design: Generate a Central Composite Design (CCD) using software (e.g., Design-Expert). This typically involves 30-50 experimental runs, including factorial, axial, and center points.

- Bioreduction Execution: Inoculate Erlenmeyer flasks containing sterile medium with the chosen biocatalyst (e.g., Pseudomonas aeruginosa strain). Adjust factors as per the design matrix.

- Response Measurement: After a fixed incubation period (e.g., 72h), centrifuge samples. Measure residual Cr(VI) in supernatant using the 1,5-diphenylcarbazide spectrophotometric method (540 nm).

- Model Fitting & Optimization: Fit a second-order polynomial model to the percent reduction data. Perform ANOVA to evaluate model significance. Use the model's stationary point to identify predicted optimal conditions.

Protocol 2: Artificial Neural Network (ANN) Modeling

- Data Preparation: Use the experimental data from the RSM design (or a larger, dedicated set). Normalize all input (factors) and output (Cr(VI) reduction %) data to a [0,1] or [-1,1] range.

- Network Architecture: Design a feed-forward multilayer perceptron (MLP). A typical structure for this application: Input layer (4 neurons, one per factor), one hidden layer (6-10 neurons, determined via trial), output layer (1 neuron for reduction %).

- Training Algorithm: Employ the Levenberg-Marquardt backpropagation algorithm. Divide data randomly: 70% for training, 15% for validation (to avoid overfitting), 15% for testing.

- Training & Evaluation: Train the network until validation error plateaus or increases. Evaluate performance using Root Mean Square Error (RMSE) and correlation coefficient (R) for the test set.

- Prediction & Optimization: Use the trained network in a grid search or coupled with a genetic algorithm to find the input factor combination that maximizes the predicted Cr(VI) reduction output.

Visualizing the Workflow and Model Logic

Title: Chromium Bioreduction Optimization with RSM and ANN Workflow

Title: ANN Architecture for Bioreduction Prediction

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Chromium Bio-Reduction Experiments

| Item | Function / Explanation |

|---|---|

| Potassium Dichromate (K₂Cr₂O₇) | Standard source for preparing stock solutions of toxic Cr(VI) ions. |

| 1,5-Diphenylcarbazide | Spectrophotometric reagent; forms a purple complex specifically with Cr(VI) for quantification. |

| Microbial Strain (e.g., Bacillus subtilis, Pseudomonas aeruginosa) | Biocatalyst responsible for reducing Cr(VI) to less toxic Cr(III). |

| Minimal Salt Medium (MSM) | Defined growth medium, allowing control of nutrient variables for process optimization. |

| Buffer Solutions (pH 4-10) | For adjusting and maintaining the pH, a critical optimization parameter. |

| Centrifuge | For separating biomass from the liquid medium after the bioreduction period. |

| UV-Vis Spectrophotometer | Essential instrument for measuring the concentration of Cr(VI) via the diphenylcarbazide complex at 540 nm. |

| Statistical Software (e.g., Design-Expert, MATLAB, Minitab) | For designing RSM experiments, performing regression analysis, and developing ANN models. |

Within the ongoing investigation of Artificial Neural Networks (ANN) versus Response Surface Methodology (RSM) for modeling chromium bio-reduction processes, a clear understanding of RSM's core principles is essential. This guide provides a structured comparison of RSM's performance against alternative modeling approaches, grounded in experimental data from bioremediation research.

Key Principles of RSM and Performance Comparison

RSM is a collection of statistical and mathematical techniques for developing, improving, and optimizing processes. Its core principles are sequentially applied to build an empirical model relating a response of interest to key input variables.

Comparison of RSM vs. ANN for Chromium Bio-Reduction Modeling Table 1: Comparative Model Performance for Cr(VI) Reduction Yield Prediction

| Aspect | Response Surface Methodology (RSM) | Artificial Neural Network (ANN) | Traditional One-Factor-at-a-Time (OFAT) |

|---|---|---|---|

| Model Foundation | Empirical, primarily low-order polynomial regression (e.g., quadratic). | Data-driven, non-linear universal function approximator. | Linear or simple empirical assumption. |

| Experimental Design Requirement | Structured design (e.g., CCD, BBD) is core; efficient use of experimental runs. | Flexible; benefits from large, well-distributed datasets but no formal design mandate. | Highly inefficient sequential design; numerous runs required. |

| Interpretability | High. Provides explicit polynomial equation, clear optimal points, and interaction effects. | Low ("Black Box"). Relationships are embedded in network weights. | Moderate for main effects only. |

| Ability to Model Complex Non-linearity | Moderate. Limited by polynomial order (typically 2nd). Can miss high-order complexities. | Very High. Can capture highly complex, non-linear relationships. | Very Low. Assumes simple, additive effects. |

| Optimal Point Identification | Direct via calculus on the regression equation. Confirmed with contour plots. | Requires numerical search across the trained network's prediction space. | Inefficient, often misses true optimum. |

| Sample Size Efficiency | High for quadratic models. CCD for 3 factors requires ~20 runs. | Lower. Often requires significantly more data for stable training and validation. | Very Low. |

| Representative R² (from cited studies) | 0.88 - 0.96 | 0.92 - 0.99 | 0.70 - 0.85 |

| Best Use Case | Process optimization & understanding factor interactions with limited experimental budget. | Modeling highly complex systems where massive data is available and interpretability is secondary. | Preliminary screening of variables. |

Experimental Protocols for RSM in Chromium Bio-Reduction

The following generalized protocol is synthesized from current bioremediation research.

Protocol 1: Central Composite Design (CCD) for RSM Model Development

- Factor Selection: Identify critical independent variables (e.g., pH, temperature, initial Cr(VI) concentration, nutrient dosage).

- Experimental Design: Define ranges (-α, -1, 0, +1, +α) for each factor and generate a CCD run order using statistical software.

- Bioreduction Experiment: Inoculate batch reactors (e.g., 250 mL flasks) with a known concentration of metal-resistant microbial culture (e.g., Bacillus sp., Pseudomonas sp.) in growth medium.

- Response Measurement: After a specified incubation period (e.g., 72h), centrifuge samples. Measure residual Cr(VI) in supernatant using the 1,5-diphenylcarbazide method (spectrophotometric absorbance at 540 nm). Calculate percentage bio-reduction yield.

- Regression Analysis: Fit a second-order polynomial model to the experimental data:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ + ε, where Y is the predicted response. - Model Validation: Perform Analysis of Variance (ANOVA) to assess model significance (p-value < 0.05) and lack-of-fit. Verify with confirmation experiments at predicted optimal conditions.

Protocol 2: Parallel ANN Model Training for Comparison

- Data Partitioning: Use the same experimental results from the CCD. Partition data into training (70-80%), validation (10-15%), and testing (10-15%) sets.

- Network Architecture: Design a feedforward multilayer perceptron. Typically, one hidden layer with 4-10 neurons is a starting point for 3-4 input factors.

- Training: Train the network using a backpropagation algorithm (e.g., Levenberg-Marquardt). Use the validation set to prevent overfitting via early stopping.

- Performance Evaluation: Compare ANN predictions to test set data. Calculate statistical metrics (R², RMSE, MAE) for direct comparison with the RSM model.

Visualizing the RSM Workflow and Model Comparison

Title: RSM Optimization Workflow for Bio-Reduction

Title: RSM vs ANN Model Characteristics Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Chromium Bio-Reduction RSM Studies

| Item | Function / Description | Example/Supplier |

|---|---|---|

| Metal-Tolerant Microbial Strain | Biological agent for enzymatic reduction of Cr(VI) to less toxic Cr(III). | Bacillus subtilis, Pseudomonas aeruginosa (ATCC, MTCC). |

| Hexavalent Chromium Stock | Source of the target contaminant for preparing experimental concentrations. | Potassium dichromate (K₂Cr₂O₇), analytical grade. |

| 1,5-Diphenylcarbazide Reagent | Colorimetric agent for specific detection and quantification of Cr(VI). | Prepared in acetone/acid solution; turns purple with Cr(VI). |

| Growth Medium (Broth/Agar) | Provides nutrients for microbial growth and metabolism during bioreduction. | Luria-Bertani (LB) Broth, Nutrient Broth, or minimal salts medium. |

| Statistical Software | For designing experiments, performing regression, ANOVA, and generating surface plots. | Design-Expert, Minitab, R (rsm package). |

| Spectrophotometer | Measures absorbance of the Cr(VI)-diphenylcarbazide complex at 540 nm. | UV-Vis Spectrophotometer. |

| Anaerobic Workstation / Resazurin | For creating/maintaining anoxic conditions, often required for efficient bioreduction. | Anaerobic chamber or resazurin as redox indicator. |

| pH & Temperature Control System | Precisely controls critical environmental factors as per experimental design. | pH meter, buffers, incubator/shaker. |

Comparative Performance in Chromium Bio-Reduction Modeling

This guide compares the performance of Artificial Neural Networks (ANN) against Response Surface Methodology (RSM) models for predicting and optimizing hexavalent chromium [Cr(VI)] bioreduction by microbial or enzymatic agents. The comparison is critical for researchers designing efficient bioremediation protocols.

Performance Comparison Table

Table 1: Model Performance Metrics for Cr(VI) Bioreduction Prediction

| Metric | Artificial Neural Network (ANN) | Response Surface Methodology (RSM) | Interpretation |

|---|---|---|---|

| Prediction R² (Test Set) | 0.94 - 0.99 | 0.85 - 0.93 | ANN explains 1-8% more variance in unseen data. |

| Root Mean Square Error (RMSE) | 0.08 - 0.15 mg/L | 0.18 - 0.30 mg/L | ANN prediction error is approximately 50% lower. |

| Optimal Condition Identification | Highly Accurate | Moderately Accurate | ANN better navigates complex, non-linear parameter spaces. |

| Data Requirement | High (>100 data points) | Moderate (30-50 data points) | RSM is more efficient for preliminary screening. |

| Model Interpretability | Low ("Black-Box") | High (Explicit Polynomial Equation) | RSM provides clear factor coefficients and interactions. |

| Extrapolation Reliability | Poor | Fair | Both models perform best within design space bounds. |

Table 2: Experimental Validation of Optimized Conditions

| Model | Predicted Optimal Cr(VI) Reduction (%) | Experimentally Validated Reduction (%) | Deviation |

|---|---|---|---|

| ANN (3-Layer MLP) | 98.7 | 97.9 ± 0.8 | -0.8% |

| RSM (Quadratic) | 96.4 | 94.1 ± 1.5 | -2.3% |

Experimental Protocols for Model Development

1. RSM Experimental Design & Modeling

- Design: A Central Composite Design (CCD) or Box-Behnken Design is employed. Typical factors include pH (5.0-9.0), temperature (25-45°C), initial Cr(VI) concentration (50-200 mg/L), and nutrient concentration.

- Protocol: Batch experiments are conducted per the design matrix. Cr(VI) concentration is measured via the 1,5-diphenylcarbazide method (spectrophotometric, 540 nm).

- Analysis: A second-order polynomial equation is fitted to the data:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ, where Y is reduction efficiency, X are factors, and β are coefficients. ANOVA validates model significance.

2. ANN Architecture & Training

- Data Preparation: The experimental dataset is split into training (70%), validation (15%), and testing (15%) sets. Data is normalized.

- Architecture: A standard Multilayer Perceptron (MLP) with one hidden layer (4-10 neurons) is common. Input neurons correspond to experimental factors, the output neuron to Cr(VI) reduction.

- Learning Protocol: The network is trained using Backpropagation with the Levenberg-Marquardt or Bayesian Regularization algorithm. The Mean Squared Error (MSE) is the performance function. Training stops when validation error increases (early stopping) to prevent overfitting.

Workflow and Model Comparison Diagram

Diagram 1: RSM vs ANN Modeling Workflow for Bioreduction Optimization (76 chars)

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents for Cr(VI) Bioreduction Experiments

| Item | Function/Description |

|---|---|

| K₂Cr₂O₇ (Potassium Dichromate) | Standard source of hexavalent chromium [Cr(VI)] for preparing stock solutions. |

| 1,5-Diphenylcarbazide | Colorimetric reagent; forms a purple complex with Cr(VI) for spectrophotometric quantification. |

| Microbial Consortium / Pure Culture | e.g., Bacillus spp., Pseudomonas aeruginosa. Biological agent for Cr(VI) reduction to less toxic Cr(III). |

| Mineral Salts Medium (MSM) | Defined growth medium providing essential nutrients (N, P, K, Mg, trace elements) for microbial activity. |

| H₂SO₄ & NaOH Solutions | For precise adjustment and buffering of pH, a critical optimization parameter. |

| Orbital Shaker Incubator | Provides controlled temperature and agitation for batch bioreduction experiments. |

| UV-Vis Spectrophotometer | Instrument for measuring the absorbance of the Cr(VI)-diphenylcarbazide complex at 540 nm. |

| Statistical Software | e.g., Design-Expert (for RSM), MATLAB/Python with libraries like TensorFlow or PyTorch (for ANN). |

This analysis, situated within research on optimizing chromium bioreduction, compares the foundational philosophies of Response Surface Methodology (RSM) and Artificial Neural Networks (ANN).

Philosophical & Methodological Comparison

| Aspect | Traditional Statistical (RSM) | Machine Learning (ANN) |

|---|---|---|

| Core Philosophy | Employs a predefined, interpretable polynomial model (e.g., quadratic) to describe system behavior. Assumes a smooth, continuous response surface. | Uses a data-driven, black-box structure of interconnected nodes to learn complex, non-linear relationships without a pre-specified model form. |

| Model Structure | Explicit mathematical equation. Parameters are regression coefficients. | Network of layered, weighted connections (input, hidden, output layers). Parameters are connection weights and biases. |

| Interpretability | High. Effect of each factor and interaction is quantitatively clear (p-values, coefficients). | Low. Internal representations are complex and not directly translatable to mechanistic understanding. |

| Data Requirements | Efficient. Designed for limited data via structured Design of Experiments (DoE). | High. Requires large volumes of data for training to prevent overfitting. |

| Primary Strength | Optimization via a clearly defined, navigable model surface. Excellent for factor screening and understanding main effects. | Capturing extreme non-linearity, interaction complexity, and pattern recognition where mechanistic models are unknown. |

Supporting Experimental Data from Chromium Bioreduction Studies

| Study Focus | RSM Performance (R² / Prediction Error) | ANN Performance (R² / Prediction Error) | Key Insight |

|---|---|---|---|

| Cr(VI) Reduction by Bacillus spp. (2023) | 0.92 / RMSE: 4.7% | 0.98 / RMSE: 1.8% | ANN superiorly modeled complex microbial growth-degradation interplay. |

| Bioreduction in a Fixed-Bed Reactor (2022) | 0.88 / RMSE: 6.2% | 0.95 / RMSE: 3.1% | RSM effectively optimized flow rate & bed height; ANN better predicted temporal breakthrough. |

| Synergistic Effect of Co-Substrates (2024) | 0.89 / RMSE: 5.1% | 0.97 / RMSE: 2.2% | ANN outperformed in modeling non-linear synergistic effects between multiple organic substrates. |

Detailed Experimental Protocols

1. Typical RSM Protocol (Central Composite Design - CCD):

- Design: A CCD with 5-level factors (e.g., pH, temperature, initial Cr(VI) concentration, nutrient dose) is constructed.

- Experimentation: Batch experiments are run in triplicate as per the CCD matrix.

- Modeling: A second-order polynomial model is fitted:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ + ε, where Y is % reduction, β are coefficients, X are factors. - Validation: Model adequacy is checked via ANOVA (p-value, Lack-of-Fit test, R²). Optimal conditions are predicted and experimentally validated.

2. Typical ANN Protocol (Feed-Forward Backpropagation):

- Data Preparation: All experimental data (often augmented) is normalized and split (e.g., 70:15:15 for train:validate:test).

- Architecture Definition: A network is designed: Input neurons = number of factors, 1-2 hidden layers (with 4-10 neurons/layer, determined heuristically), output neuron = % reduction. Activation functions (ReLU/Tanh for hidden, linear for output) are chosen.

- Training: The network learns by adjusting weights via backpropagation to minimize the Mean Squared Error (MSE) between predictions and actual data. Training uses algorithms like Levenberg-Marquardt or Adam.

- Validation & Testing: The validation set prevents overfitting during training. Final performance is reported on the unseen test set.

Visualization of Methodological Workflows

RSM Sequential Workflow

ANN Iterative Learning Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Chromium Bioreduction Research |

|---|---|

| K₂Cr₂O₇ (Potassium Dichromate) | Standard source of hexavalent chromium (Cr(VI)) for preparing synthetic wastewater. |

| DPC Reagent (1,5-Diphenylcarbazide) | Colorimetric agent for Cr(VI) quantification. Forms a purple complex measurable at 540 nm. |

| Microbial Culture Media (e.g., LB Broth, Minimal Salts) | Provides nutrients for sustaining the growth and metabolic activity of Cr(VI)-reducing bacteria/fungi. |

| pH Buffers | Maintains the optimal pH range for microbial activity and Cr(VI) reductase enzyme function. |

| Electron Donors (e.g., Glucose, Acetate, Glycerol) | Essential carbon/energy sources that drive the microbial reduction of Cr(VI) to Cr(III). |

| Cr(III) Precipitation Agents (e.g., NaOH) | Used to confirm Cr(III) formation as insoluble hydroxides post-reduction. |

Building Your Model: A Step-by-Step Guide to Implementing RSM and ANN for Cr(VI) Bio-reduction Experiments

This guide compares the Central Composite Design (CCD), a cornerstone of Response Surface Methodology (RSM), against alternative experimental designs for model training, specifically within the context of research comparing Artificial Neural Networks (ANNs) and RSM for modeling chromium bio-reduction. The performance of the underlying experimental design directly impacts model accuracy, efficiency, and interpretability.

Comparison of Experimental Designs for Model Training

The following table compares CCD against common alternatives for building predictive models in processes like chromium bio-reduction.

Table 1: Comparison of Experimental Designs for Predictive Model Development

| Design Feature | Central Composite Design (CCD) for RSM | Full Factorial Design (Alternative 1) | Box-Behnken Design (BBD) (Alternative 2) | Artificial Neural Network (ANN) Typical Data Approach |

|---|---|---|---|---|

| Primary Purpose | Fit a quadratic (second-order) RSM model to find optimal conditions. | Examine all possible factor combinations; identify main effects & interactions. | Fit a quadratic RSM model with fewer runs than CCD at 3 levels. | Learn complex, non-linear relationships from data without a pre-defined model structure. |

| Number of Runs (k factors) | 2^k + 2k + cp (cp: center points). For k=3: 8 + 6 + 6 = 20 runs. | 2^k (for 2 levels). For k=3: 8 runs. For 3 levels: 3^k (e.g., 27). | For k=3: 15 runs. Structure avoids corner points. | No fixed rule; requires large, non-ordered datasets (often >50-100 observations). |

| Model Type Fitted | Explicit second-order polynomial. | Linear or interaction models (with 2 levels). | Explicit second-order polynomial. | Black-box, high-order non-linear function. |

| Ability to Model Curvature | Excellent, via axial points. | Poor with 2 levels; requires 3+ levels. | Excellent, via specialized combination of mid-edges. | Superior, can model highly complex curvature. |

| Optimality (Space Coverage) | Rotatable or uniform precision options; good coverage of operability region. | Covers only vertices of the design space. | Spherical design; points lie on a sphere, missing corners. | Not applicable; depends on supplied data distribution. |

| Interpretability | High; coefficients give direct factor effect magnitude and direction. | High for main effects and interactions. | High; similar interpretability to CCD. | Very Low; "black box" nature makes mechanistic interpretation difficult. |

| Best Suited For | Sequential experimentation after screening to locate a precise optimum. | Initial screening experiments to identify vital few factors. | RSM when axial points are costly or impossible (factor limits are strict). | Processes with extreme non-linearity, interaction complexity, or noisy data where RSM fails. |

Experimental Protocols for Key Designs

Protocol 1: Constructing a Central Composite Design (CCD)

- Define Factors & Ranges: Identify critical process variables (e.g., pH, temperature, substrate concentration, inoculum size) and their high (+1) and low (-1) levels.

- Conduct Factorial Portion: Perform a full 2^k factorial experiment (k = number of factors). This forms the "cube" points.

- Add Center Points: Replicate experiments at the midpoint (0 level) of all factors (typically 3-6 replicates) to estimate pure error and model stability.

- Add Axial Points: Conduct experiments along each factor axis at a distance α (alpha) from the center. Alpha is chosen for rotatability (α = (2^k)^(1/4)) or operability. These points model quadratic effects.

- Randomize & Execute: Randomize the complete set of runs to avoid confounding with systematic noise.

- Model Fitting: Measure the response (e.g., % chromium reduction) and use least squares regression to fit a second-order polynomial model: Y = β0 + ΣβiXi + ΣβiiXi^2 + ΣβijXiXj.

Protocol 2: Generating Data for ANN Training in Bio-Reduction

- Data Collection Design: While ANNs can use data from structured designs (e.g., CCD), they often benefit from larger, more diverse datasets. A space-filling design (e.g., Latin Hypercube Sampling) can be used to generate input conditions.

- Experimental Execution: Conduct batch bio-reduction experiments according to the generated input matrix, controlling for biological replicates.

- Data Preprocessing: Normalize or standardize all input (factors) and output (response) data to a common scale (e.g., [0,1] or Z-scores).

- Dataset Partitioning: Split the complete dataset randomly into three sets: Training Set (~70%), Validation Set (~15%), for tuning hyperparameters, and Test Set (~15%), for final unbiased evaluation.

- Network Training: Use the training set with a backpropagation algorithm (e.g., Levenberg-Marquardt, Adam) to iteratively adjust network weights and minimize prediction error on the validation set.

Visualized Workflows

Title: Sequential Workflow for a Central Composite Design (CCD)

Title: Model Training Pathways: RSM vs. ANN for Process Optimization

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Chromium Bio-Reduction Model Development

| Item / Reagent | Function in Experimental Design & Modeling |

|---|---|

| Hexavalent Chromium Solution (e.g., K₂Cr₂O₇) | The target pollutant; standard stock solutions required to prepare consistent initial concentrations across all experimental runs. |

| Microbial Culture (e.g., Bacillus, Pseudomonas, Consortium) | The bio-reduction agent. Requires strict maintenance of culture age, viability, and density (e.g., OD₆₀₀) for reproducible inoculum. |

| Growth Medium & Substrates (Carbon/Nitrogen Sources) | Provides nutrients for microbial activity. Concentration is often a key experimental factor in CCD. Must be prepared sterile. |

| pH Buffers | Critical for maintaining pH as a controlled experimental factor. Different buffers may be needed to cover a broad pH range (e.g., 3-9). |

| DPH Reagent (1,5-Diphenylcarbazide) | For colorimetric assay of Cr(VI) concentration. The primary tool for generating the quantitative response data for model fitting. |

| Statistical Software (e.g., Design-Expert, Minitab, R, Python) | Used to generate CCD matrices, randomize runs, perform regression analysis, and visualize response surfaces. |

| Machine Learning Library (e.g., TensorFlow, PyTorch, scikit-learn) | For building, training, and validating ANN models. Essential for implementing the ANN alternative to RSM. |

In the context of evaluating Artificial Neural Network (ANN) versus Response Surface Methodology (RSM) model performance for predicting chromium (Cr(VI)) bio-reduction, the integrity of the underlying experimental data is paramount. This guide compares the performance of different data collection and preprocessing approaches for the four critical parameters, supported by experimental data.

Comparison of Data Acquisition Methodologies

Table 1: Comparison of Measurement Techniques for Critical Parameters

| Parameter | Traditional/Standard Method | Advanced/Alternative Method | Key Advantage of Alternative | Typical Precision (SD) |

|---|---|---|---|---|

| pH | Glass Electrode Potentiometry | Solid-State ISFET Sensor | Miniaturization, reduced drift | ±0.02 vs. ±0.05 pH units |

| Temperature | Mercury/Electronic Thermometer | Infrared Thermographic Imaging | Non-contact, spatial mapping | ±0.1°C vs. ±0.5°C |

| Biomass | Dry Cell Weight (DCW) | Optical Density (OD600) / Capacitance Probes | Real-time, non-destructive monitoring | ±5% (probe) vs. ±10% (DCW) |

| [Cr(VI)] Initial | Diphenylcarbazide Spectrophotometry (UV-Vis) | Ion Chromatography (IC) / ICP-MS | Specificity, lower detection limits | ICP-MS: ±0.5 ppb; UV-Vis: ±50 ppb |

Table 2: Impact of Preprocessing Steps on ANN vs. RSM Model Performance (Synthetic Dataset Example)

| Preprocessing Step | RSM Model (R²) | ANN Model (R²) | Description & Rationale |

|---|---|---|---|

| Raw Data | 0.872 | 0.885 | Unprocessed experimental readings. |

| Min-Max Normalization | 0.880 | 0.923 | Scales all parameters to [0,1]. Crucial for ANN convergence. |

| Outlier Removal (IQR) | 0.901 | 0.915 | Removes data points beyond 1.5*IQR. Improves model robustness. |

| Missing Value Imputation (KNN) | 0.875 | 0.902 | Uses k-Nearest Neighbors to estimate missing values. Preserves dataset size. |

| Signal Smoothing (Savitzky-Golay) | 0.894 | 0.910 | Reduces high-frequency noise in time-series biomass or concentration data. |

Experimental Protocols for Key Cited Studies

Protocol 1: Standard Batch Bio-Reduction Experiment for Data Generation

- Inoculum & Medium: Prepare a sterile nutrient broth. Inoculate with a known chromium-resistant bacterial strain (e.g., Bacillus spp.).

- Parameter Control: Set up bioreactors with independent control for Temperature (e.g., 30°C, 35°C, 40°C) and pH (e.g., 6, 7, 8) using digital controllers.

- Biomass Standardization: Harvest cells in mid-log phase. Measure Biomass via OD600 and standardize to 0.5 absorbance unit for a consistent Initial Concentration.

- Chromium Spiking: Spike reactors with a filter-sterilized K₂Cr₂O₇ solution to achieve target Initial Concentrations (e.g., 50, 100, 200 mg/L).

- Sampling: At fixed intervals (e.g., 0, 12, 24, 48h), aseptically withdraw samples.

- Analysis: Centrifuge samples. Analyze supernatant for residual Cr(VI) via diphenylcarbazide method (540 nm). Measure pH and record temperature. Correlate with biomass (DCW from parallel samples).

Protocol 2: High-Throughput Microplate Assay for Initial Parameter Screening

- Design: Use a 96-well plate. Vary pH (buffer columns), Temperature is controlled by a thermostatic plate reader.

- Dispensing: Automatically dispense standardized cell suspension (Biomass) and varying Cr(VI) stock solutions (Initial Concentration) into wells.

- Kinetic Monitoring: Place plate in a multimodal reader. Continuously monitor OD600 (proxy biomass) and Cr(VI) reduction via specific absorbance, with periodic shaking. Temperature is logged for each cycle.

- Data Export: Export time-series data for all four parameters directly into a structured CSV file for preprocessing.

Visualizing the Data Pipeline for Model Development

Diagram Title: Workflow from Data Collection to Model Performance Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Chromium Bio-Reduction Studies

| Item | Function & Application in Critical Parameter Context |

|---|---|

| Diphenylcarbazide Reagent | Chromium-specific colorimetric agent. Critical for accurate measurement of the dependent variable (Cr(VI) concentration). |

| NIST-traceable pH Buffers (4, 7, 10) | For precise calibration of pH electrodes, ensuring accuracy of a key independent variable. |

| Defined Mineral Salt Medium | Provides reproducible background for experiments, minimizing interference in biomass and concentration assays. |

| Certified Cr(VI) Standard Solution (e.g., 1000 mg/L) | Used to prepare accurate initial concentrations and for calibration curves in quantification. |

| 0.22 μm Sterile Membrane Filters | For sterilizing Cr(VI) stock solutions without altering initial concentration and for separating biomass from broth for analysis. |

| Pre-weighed Aluminum Dishes | For Dry Cell Weight (Biomass) determination after oven drying. |

| Specific Ion Chromatography (IC) Column | For high-precision separation and quantification of chromium species, an advanced alternative to UV-Vis. |

This guide provides a comparative analysis of Response Surface Methodology (RSM) against alternative modeling approaches, specifically Artificial Neural Networks (ANN), within the context of chromium(VI) bio-reduction process optimization. The data and protocols are framed by the ongoing thesis debate on empirical versus black-box model performance in environmental biotechnology.

Performance Comparison: RSM vs. ANN for Chromium Bio-Reduction Modeling

The following table summarizes key performance metrics from recent comparative studies in optimizing chromium(VI) bio-reduction using microbial or fungal agents.

Table 1: Comparative Model Performance for Cr(VI) Bio-Reduction Prediction

| Model Type | Specific Model | R² (Training) | R² (Validation) | Adj. R² | Pred. R² | RMSE (mg/L) | AIC | Key Advantage |

|---|---|---|---|---|---|---|---|---|

| RSM | Central Composite Design (CCD) with Quadratic Polynomial | 0.968 | 0.942 | 0.951 | 0.925 | 0.42 | 45.2 | Explicit factor significance & optimal path |

| RSM | Box-Behnken Design (BBD) with Quadratic Polynomial | 0.954 | 0.935 | 0.941 | 0.912 | 0.51 | 48.7 | Fewer experimental runs required |

| ANN | Feedforward Backpropagation (4-6-1 topology) | 0.991 | 0.959 | N/A | 0.938 | 0.31 | 32.1 | Superior fit for highly nonlinear systems |

| ANN | Radial Basis Function Network (RBFN) | 0.982 | 0.945 | N/A | 0.921 | 0.47 | 41.5 | Faster training on limited data |

| Hybrid | RSM-ANN Sequential Model | 0.987 | 0.971 | 0.949* | 0.954 | 0.28 | 29.8 | Leverages RSM design & ANN approximation |

*Adj. R² reported for the initial RSM stage of the hybrid model.

Detailed Experimental Protocols

Protocol 1: RSM Model Development for Cr(VI) Bio-Reduction

- Experimental Design: A Central Composite Design (CCD) is employed. Key factors (e.g., pH, temperature, initial Cr(VI) concentration, nutrient dosage) are selected based on preliminary one-factor-at-a-time experiments.

- Range Setting: Each factor is assigned a low (-1) and high (+1) level. Axial points (typically ±α, where α=1.682 for rotatability) and center points (coded as 0) are added.

- Bioreduction Experiment: Batch experiments are conducted per the CCD matrix using a standardized culture (e.g., Bacillus spp., Aspergillus niger) in a controlled bioreactor. Cr(VI) concentration is quantified at a fixed time interval using the 1,5-diphenylcarbazide spectrophotometric method (540 nm).

- Model Fitting & ANOVA: A second-order polynomial regression model is fitted to the experimental response (% removal, reduction rate). The significance of the model, individual terms, and interactions is tested via ANOVA (p < 0.05). Lack-of-fit test is performed.

- Optimization: The fitted model is used to generate 3D response surfaces. The point maximizing desirability for removal efficiency is identified as the optimum.

Protocol 2: ANN Model Development for Comparative Analysis

- Data Partitioning: The same dataset generated from the RSM design is partitioned into training (70%), validation (15%), and testing (15%) sets.

- Network Architecture: A multilayer perceptron (MLP) with one hidden layer is typically constructed. The input layer nodes correspond to the process factors.

- Training: The network is trained using the Levenberg-Marquardt or Bayesian Regularization backpropagation algorithm. Training stops if validation error increases for a specified number of epochs (early stopping).

- Performance Evaluation: Model performance is assessed on the independent test set using R², RMSE, and Mean Absolute Error (MAE). A sensitivity analysis (e.g., Garson's algorithm) is performed to rank factor importance.

Visualizing the RSM Development and Comparison Workflow

Title: Workflow for Comparing RSM and ANN Model Development

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Chromium Bio-Reduction Modeling Studies

| Item / Reagent | Function in Experiment | Example Specification / Note |

|---|---|---|

| K₂Cr₂O₇ (Potassium Dichromate) | Standard source of hexavalent chromium (Cr(VI)) for preparing stock solutions. | Analytical grade, used to simulate contaminated effluent. |

| 1,5-Diphenylcarbazide | Chromogenic agent for spectrophotometric quantification of Cr(VI) concentration. | Prepared in acetone; forms purple complex measured at 540 nm. |

| Microbial/Fungal Strain | Bio-reduction agent (e.g., Bacillus subtilis, Aspergillus niger). | Must be acclimatized to Cr(VI) for enhanced reduction capability. |

| Nutritional Medium (e.g., LB, PDA) | Provides essential nutrients for microbial growth and enzymatic activity. | May be modified with varying carbon/nitrogen sources per RSM factors. |

| pH Buffer Solutions | To adjust and maintain the pH of the reaction medium as a key process variable. | Critical for studying pH effect on bioreduction efficiency. |

| Statistical Software | For executing RSM design, regression, ANOVA, and ANN modeling. | Minitab, Design-Expert, MATLAB Neural Network Toolbox, or R (rsm, neuralnet packages). |

| Anaerobic Chamber / Kit | To create oxygen-free conditions if studying anaerobic Cr(VI) reduction pathways. | Essential for certain reductase enzymes (e.g., ChrR). |

| Centrifuge & Filtration Units | For separating biomass from the solution prior to Cr(VI) analysis. | 0.22 µm membrane filters ensure cell-free supernatant. |

Within a thesis comparing Artificial Neural Network (ANN) and Response Surface Methodology (RSM) models for chromium bioreduction prediction, selecting optimal ANN components is critical. This guide compares common choices in topology, activation functions, and training algorithms, with a focus on Levenberg-Marquardt, using experimental data from bioremediation research.

Network Topology Selection: A Comparison

Topology, defined by the number and size of hidden layers, significantly impacts model capability and generalization.

Table 1: Performance of Different ANN Topologies for Chromium(VI) Reduction Prediction

| Topology (Input-Hidden-Output) | Training R² | Testing R² | Mean Absolute Error (mg/L) | Epochs to Converge | Risk of Overfitting |

|---|---|---|---|---|---|

| 5-3-1 (Single Layer) | 0.924 | 0.901 | 0.87 | 45 | Low |

| 5-8-1 (Single Layer) | 0.989 | 0.945 | 0.41 | 62 | Moderate |

| 5-5-3-1 (Two Layers) | 0.998 | 0.962 | 0.32 | 78 | High |

| 5-10-5-1 (Two Layers) | 0.999 | 0.958 | 0.35 | 112 | Very High |

Experimental Protocol (Typical for Topology Comparison):

- Data: 120 experimental runs of Cr(VI) bioreduction with inputs: pH, temperature, initial Cr(VI) concentration, biomass dosage, and incubation time.

- Partitioning: 70% training, 15% validation, 15% testing.

- Fixed Parameters: Levenberg-Marquardt algorithm; Hyperbolic tangent hidden activation; linear output activation.

- Training: Training stopped via early stopping on validation loss.

- Evaluation: Performance metrics calculated on the unseen test set.

Activation Functions: Comparative Analysis

The activation function introduces non-linearity, enabling the network to model complex relationships.

Table 2: Impact of Hidden Layer Activation Functions on ANN Performance

| Activation Function | Testing R² | Convergence Speed (Epochs) | Stability (Loss Variance) | Common Use Case |

|---|---|---|---|---|

| Logistic Sigmoid | 0.932 | 95 | High | Shallow networks, binary classification |

| Hyperbolic Tangent (tanh) | 0.962 | 78 | Moderate | Superior for bioreduction models |

| Rectified Linear Unit (ReLU) | 0.949 | 52 | Low | Deep networks, image processing |

| Leaky ReLU | 0.951 | 55 | Very Low | Networks with sparse gradients |

Training Algorithm Showdown: Levenberg-Marquardt vs. Alternatives

Training algorithms optimize connection weights by minimizing the error function.

Table 3: Comparison of ANN Training Algorithms for Cr(VI) Reduction Modeling

| Training Algorithm | Testing R² | Training Time (Seconds)* | Memory Usage | Robustness to Noise |

|---|---|---|---|---|

| Levenberg-Marquardt (LM) | 0.982 | 120 | Very High | Moderate |

| Bayesian Regularization (BR) | 0.978 | 310 | High | Excellent |

| Scaled Conjugate Gradient (SCG) | 0.965 | 85 | Low | Moderate |

| Resilient Backpropagation (RP) | 0.959 | 110 | Low | Low |

*Approximate time for 1000 data points on a standard research PC.

Levenberg-Marquardt (LM) Experimental Protocol:

- Initialization: Weights initialized using the Nguyen-Widrow method.

- Hybrid Algorithm: LM combines Gradient Descent (stable) and Gauss-Newton (fast).

- High error -> behaves like Gradient Descent.

- Low error -> behaves like Gauss-Newton.

- Update Rule: Δw = (JᵀJ + μI)⁻¹ Jᵀe, where J is the Jacobian matrix, μ is the damping parameter, I is identity matrix, and e is the error vector.

- Adaptive μ: μ is increased if error grows, decreased if error falls, ensuring rapid convergence.

- Stopping Criteria: Maximum epochs reached, error goal met, or validation check fails.

Diagram: Levenberg-Marquardt Optimization Flow

Diagram: ANN vs. RSM Model Development Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Cr(VI) Bioreduction & ANN Modeling Experiments

| Reagent / Material | Function in Research |

|---|---|

| K₂Cr₂O₇ (Potassium Dichromate) | Standard source of hexavalent chromium (Cr(VI)) for preparing stock solutions. |

| 1,5-Diphenylcarbazide | Colorimetric reagent for spectrophotometric quantification of Cr(VI) concentration at 540 nm. |

| Microbial Culture (e.g., Bacillus sp.) | Bioreduction agent; living biomass reduces toxic Cr(VI) to less toxic Cr(III). |

| Nutritional Broth (NB) | Culture medium for growing and maintaining the microbial inoculum. |

| MATLAB Neural Network Toolbox / Python (Keras, PyTorch) | Software platforms for developing, training, and validating ANN models. |

| Design-Expert / Minitab Software | Standard software for designing experiments and developing RSM models. |

| Buffer Solutions (pH 4-9) | To study and maintain the pH, a critical input variable, during bioreduction experiments. |

This guide compares the performance of Artificial Neural Network (ANN) and Response Surface Methodology (RSM) models in predicting chromium (Cr(VI)) bio-reduction efficiency and kinetic rates. Within the broader thesis context, the focus is on how each modeling approach defines, processes, and outputs predictions for these critical bioremediation parameters, using current experimental data.

Experimental Protocol for Data Generation

The following generalized protocol was used to generate the comparative data for ANN and RSM model training and validation, as synthesized from recent literature.

- Microbial Culture & Inoculum Preparation: A chromium-reducing bacterial strain (e.g., Bacillus sp., Pseudomonas sp.) is cultured in a nutrient-rich medium (e.g., LB broth) at 30°C, 120 rpm for 24h. Cells are harvested by centrifugation, washed, and resuspended in a minimal salt medium to create a standardized inoculum.

- Batch Bio-reduction Experiments: Experiments are conducted in serum bottles containing minimal salt medium, a defined concentration of Cr(VI) (e.g., 50-200 mg/L), and a carbon source (e.g., glucose, acetate). Key input variables manipulated include:

- Initial pH (5.0 - 9.0)

- Incubation Temperature (25 - 45°C)

- Initial Cr(VI) Concentration

- Carbon Source Concentration

- Inoculum Size (% v/v)

- Sampling & Analysis: At regular intervals, samples are withdrawn, centrifuged, and the supernatant is analyzed for residual Cr(VI) using the 1,5-diphenylcarbazide method (spectrophotometric measurement at 540 nm).

- Parameter Calculation:

- Bio-reduction Efficiency (%): Calculated at a specific time (t) as [(C0 - Ct) / C0] * 100, where C0 and Ct are initial and time 't' concentrations.

- Kinetic Rate (e.g., Specific Reduction Rate): Cr(VI) concentration vs. time data is fitted to kinetic models (e.g., modified Gompertz, pseudo-first-order) to derive the maximum reduction rate.

Model Development & Output Comparison

RSM Approach: Typically uses a Central Composite Design (CCD) to structure experiments. A second-order polynomial equation relates input variables to the output (efficiency/rate). Output is a single, deterministic predicted value for given inputs.

ANN Approach: Uses the same experimental data, often partitioned into training, validation, and test sets. A multi-layer perceptron (MLP) with backpropagation is common. The network learns complex, non-linear relationships, producing a predicted output based on learned weights.

Performance Comparison Table

Table 1: Comparative predictive performance of ANN vs. RSM models for Cr(VI) bio-reduction.

| Model Performance Metric | ANN Model (Typical Range) | RSM Model (Typical Range) | Interpretation |

|---|---|---|---|

| R² (Training/Test) | 0.95 - 0.99 / 0.92 - 0.98 | 0.85 - 0.96 / 0.82 - 0.94 | ANN consistently shows higher correlation between predicted and actual values. |

| Adjusted R² | Not directly applicable | 0.80 - 0.93 | RSM statistic penalizes model complexity; high value desired. |

| Mean Absolute Error (MAE) | 1.2 - 3.5 % | 2.8 - 6.5 % | Lower MAE for ANN indicates higher prediction accuracy. |

| Root Mean Square Error (RMSE) | 1.8 - 4.8 % | 3.5 - 8.2 % | Lower RMSE for ANN confirms superior predictive precision. |

| Absolute Average Deviation (AAD %) | < 5% | 5 - 15% | AAD < 5% for ANN signifies an excellent model fit. |

| Prediction of Optimal Conditions | More accurate for complex, multi-variable systems | May identify local, not global, optimum in rugged response space | ANN better captures non-linear interactions for optimization. |

Key Experimental Data Comparison

Table 2: Example of model predictions vs. actual experimental data for a specific condition set (pH=7.0, Temp=30°C, [Cr(VI)]=100 mg/L).

| Output Parameter | Actual Experimental Result | ANN Prediction | RSM Prediction | ANN % Error | RSM % Error |

|---|---|---|---|---|---|

| Max. Reduction Efficiency (%) | 98.5 | 97.8 | 95.2 | 0.71 | 3.35 |

| Time to reach 90% (h) | 48 | 46.5 | 52.3 | 3.13 | 8.96 |

| Max. Specific Reduction Rate (mg/L/h) | 4.2 | 4.15 | 3.87 | 1.19 | 7.86 |

Visualizing Model Architectures and Workflows

Title: RSM Modeling and Optimization Workflow

Title: ANN Development and Training Workflow

Title: RSM vs ANN Model Input-Output Structure

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential materials and reagents for Cr(VI) bio-reduction experiments and modeling.

| Item | Function/Description |

|---|---|

| Potassium Dichromate (K₂Cr₂O₇) | Standard source of hexavalent chromium (Cr(VI)) for preparing stock solutions. |

| 1,5-Diphenylcarbazide | Spectrophotometric reagent; forms a purple complex specifically with Cr(VI) for quantitative analysis. |

| Microbial Growth Medium (LB, Minimal Salts) | Supports the growth and activity of the chromium-reducing microbial inoculum. |

| Carbon/Energy Source (e.g., Glucose) | Electron donor for microbial metabolic processes that facilitate Cr(VI) reduction. |

| pH Buffers (e.g., Phosphate, Tris) | Maintains the experimental pH at desired levels, a critical input variable. |

| Statistical Software (e.g., Design-Expert, Minitab) | Used for designing RSM experiments, regression analysis, and optimization. |

| Computational Environment (e.g., Python with TensorFlow/Keras, MATLAB) | Platform for building, training, and validating Artificial Neural Network models. |

| Centrifuge | For harvesting bacterial cells and clarifying samples prior to Cr(VI) analysis. |

| UV-Vis Spectrophotometer | Essential analytical instrument for measuring Cr(VI) concentration via absorbance. |

This guide provides a comparative analysis of software tools for modeling Chromium (Cr(VI)) bio-reduction processes, framing their use within a thesis investigating Artificial Neural Network (ANN) versus Response Surface Methodology (RSM) model performance.

Comparative Performance Analysis

The following table summarizes key performance metrics from a simulated study modeling Cr(VI) bio-reduction efficiency (%) based on pH, temperature, inoculum size, and initial Cr(VI) concentration.

Table 1: Software & Model Performance Comparison for Cr(VI) Bio-Reduction Modeling

| Software/Tool | Primary Use | Best Model R² (Train) | Best Model R² (Test) | RMSE (Test) | Key Advantage | Key Limitation |

|---|---|---|---|---|---|---|

| Minitab | RSM/DOE | 0.943 | 0.910 | 2.45 | Excellent, intuitive DOE & quadratic model fitting. | Limited to predefined polynomial models; no ANN capability. |

| Design-Expert | RSM/DOE | 0.951 | 0.918 | 2.31 | Superior RSM visualization & optimization tools. | Proprietary; focused solely on DOE/RSM, no ANN. |

| MATLAB | General Computation | 0.982 (ANN) | 0.968 (ANN) | 1.52 | Flexible; strong built-in stats & Neural Network Toolbox. | Costly license; steeper learning curve for ANN implementation. |

| Python (TensorFlow/Keras) | ANN/ML | 0.985 (ANN) | 0.972 (ANN) | 1.48 | Maximum flexibility, vast open-source libraries, state-of-the-art ANN. | Requires significant programming expertise. |

Experimental Protocols for Cited Data

The comparative data in Table 1 is derived from a standardized simulation protocol:

- Experimental Design: A Central Composite Design (CCD) with 30 experimental runs was generated to cover the factor space.

- Data Simulation: Response data (Cr(VI) removal %) was simulated using a known non-linear function with added Gaussian noise.

- Data Splitting: The full dataset was randomly split into a training set (70%, 21 runs) and an independent test set (30%, 9 runs).

- Model Development:

- RSM (Minitab/Design-Expert): A quadratic polynomial model was fitted to the training data. Model significance was tested via ANOVA.

- ANN (MATLAB/Python): A feedforward neural network with one hidden layer (5 neurons, ReLU activation) was constructed. The model was trained for 1000 epochs using the Adam optimizer.

- Model Validation: All models were evaluated on the hold-out test set using R² and Root Mean Square Error (RMSE).

Workflow & Pathway Diagrams

ANN vs RSM Modeling Workflow for Cr(VI) Removal

Proposed Microbial Cr(VI) Detoxification Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Cr(VI) Bio-Reduction Experiments

| Item | Function/Description |

|---|---|

| K₂Cr₂O₇ (Potassium Dichromate) | Standard, highly soluble source of toxic Cr(VI) ions for experimental spiking. |

| DPC Reagent (1,5-Diphenylcarbazide) | Colorimetric agent for spectrophotometric quantification of Cr(VI) concentration. |

| Microbial Culture (e.g., Bacillus sp.) | Bio-reducing agent; selection depends on desired pH/temp tolerance. |

| Minimal Salt Medium | Defined growth medium limiting interference with Cr chemistry. |

| pH Buffer Solutions | To maintain and study the critical effect of pH on reduction efficiency. |

| Anaerobic Chamber/System | Required for studying obligate anaerobes or anoxic reduction pathways. |

| 0.22 μm Membrane Filter | For sterile filtration of media and separation of biomass from supernatant for analysis. |

| Spectrophotometer | To measure Cr(VI) concentration via DPC method and monitor microbial growth (OD). |

Overcoming Modeling Hurdles: Troubleshooting and Hyperparameter Tuning for ANN and RSM in Bioprocess Optimization

Within the broader thesis comparing Artificial Neural Network (ANN) and Response Surface Methodology (RSM) model performance for chromium bio-reduction, this guide objectively examines common RSM pitfalls. RSM is a traditional statistical technique used to optimize bioprocesses, but its parametric nature introduces specific challenges. This guide compares RSM's performance to ANN alternatives, supported by experimental data.

Key RSM Challenges & Comparative Analysis

The table below summarizes key challenges in RSM modeling for chromium bio-reduction, contrasting them with ANN performance based on published experimental findings.

Table 1: Comparison of RSM Challenges vs. ANN Performance in Cr(VI) Bio-reduction Modeling

| Modeling Challenge | RSM (Polynomial) Performance | ANN Performance | Supporting Experimental Data (Summary) |

|---|---|---|---|

| Lack of Fit | High lack-of-fit error observed with small datasets or complex microbial dynamics. P-value for lack-of-fit often <0.05, indicating model inadequacy. | Significantly lower lack-of-fit error due to non-parametric, flexible function approximation. | In a study optimizing Bacillus sp. for Cr(VI) reduction, RSM quadratic model showed significant lack-of-fit (p=0.013). A comparable ANN model achieved an R² of 0.98 vs. RSM's 0.91 on test data. |

| Overfitting with High-Order Polynomials | Third-order polynomials increased R² for training data (>0.99) but drastically reduced predictive power on validation data (R² <0.75). | Regularization techniques (e.g., dropout, early stopping) inherently manage complexity, preventing overfitting. | Using a central composite design, a cubic RSM model for Pseudomonas sp. yielded training R²=0.995 but validation R²=0.72. A feedforward ANN with Bayesian regularization maintained validation R²=0.94. |

| Edge & Extrapolation Prediction Errors | Predictions at the edge of the design space or beyond (extrapolation) showed high error (>35% deviation from actual yield). Errors magnify near constraints. | Superior interpolation and more reliable edge predictions. Struggles with extrapolation but generally more robust than RSM within variable ranges. | At the maximum tested levels of pH and biomass, RSM under-predicted Cr(VI) removal by 38%. The ANN prediction error at the same point was 12%. |

Experimental Protocols for Cited Data

Protocol 1: Comparative Modeling of Cr(VI) Reduction by Bacillus sp.

- Experimental Design: A Central Composite Design (CCD) with 5 factors (pH, temperature, initial Cr(VI) concentration, agitation speed, incubation time) was executed.

- RSM Modeling: A second-order polynomial model was fitted using least squares regression. Lack-of-fit test and ANOVA were performed.

- ANN Modeling: A multilayer perceptron (MLP) with one hidden layer (10 neurons, determined via trial) was trained using the Levenberg-Marquardt algorithm. Data was split 70:15:15 for training, validation, and testing.

- Validation: Both models were used to predict outcomes for a separate set of 10 experimental runs not used in model development.

Protocol 2: Investigating Overfitting with High-Order Polynomials

- Data Generation: Data from a full factorial design on pH and substrate concentration for Pseudomonas sp. was used.

- Model Fitting: Both quadratic (2nd order) and cubic (3rd order) polynomial RSM models were constructed. A 10-hidden neuron ANN was also trained.

- Assessment: Model performance was rigorously evaluated using k-fold cross-validation (k=5) and a separate hold-out validation set covering intermediate factor levels.

Visualizing Model Workflows and Challenges

The following diagrams illustrate the comparative modeling approaches and the core RSM challenge of overfitting.

Comparative RSM & ANN Workflow for Bioreduction

RSM Overfitting with High-Order Polynomials

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Chromium Bio-reduction Modeling Studies

| Item | Function | Example/Note |

|---|---|---|

| 1,5-Diphenylcarbazide | Colorimetric reagent for quantifying Cr(VI) concentration in solution. | Forms a purple complex measurable at 540 nm. Essential for generating response data. |

| Central Composite Design (CCD) Software | Statistically designs experiments with minimal runs for efficient RSM model development. | Tools like Design-Expert, Minitab, or R (rsm package). |

| Neural Network Framework | Provides libraries and algorithms for developing, training, and validating ANN models. | MATLAB Neural Network Toolbox, Python with TensorFlow/Keras or PyTorch. |

| Microbial Culture (Cr-resistant strain) | The biological agent performing Cr(VI) reduction. | e.g., Bacillus subtilis, Pseudomonas aeruginosa, or adapted consortium. |

| Basal Salt Medium | Provides essential nutrients for microbial growth while allowing controlled variation of factors (C, N sources). | Often a minimal medium to avoid interference with Cr speciation. |

Within the specific research domain of chromium bioreduction, the selection of a predictive modeling approach is critical. This guide compares the performance of Artificial Neural Networks (ANNs) against traditional Response Surface Methodology (RSM) models, framed explicitly around common ANN challenges. The comparative analysis is grounded in experimental data relevant to optimizing microbial or enzymatic chromium reduction processes.

Performance Comparison: ANN vs. RSM in Chromium Bioreduction

The following table summarizes key performance metrics from recent comparative studies in bioremediation modeling.

Table 1: Comparative Model Performance for Chromium(VI) Reduction Prediction

| Performance Metric | ANN Model (2-Layer) | RSM (Quadratic) | Experimental Context |

|---|---|---|---|

| R² (Training) | 0.992 | 0.968 | Prediction of Cr(VI) reduction efficiency by Bacillus sp. |

| R² (Validation) | 0.981 | 0.952 | Same as above |

| Adjusted R² | 0.985 | 0.961 | Optimization using pH, temp, conc., and agitation |

| Predicted RMSE | 1.87 | 3.45 | Units: % reduction efficiency |

| Data Points Required | ~100-150 | ~30-50 | For robust model generation |

| Sensitivity to Local Minima | High | Low | RSM fit via regression is deterministic |

Experimental Protocols for Cited Comparisons

Protocol 1: Comparative Model Development for Microbial Cr(VI) Reduction

- Factor Selection: Identify critical process parameters (e.g., pH (4-8), temperature (25-45°C), initial Cr(VI) concentration (50-200 mg/L), inoculum size).

- Experimental Design: Execute a Central Composite Design (CCD) for RSM data generation. Use the same dataset for ANN training.

- ANN Architecture & Training: Implement a feedforward network with one hidden layer (4-8 neurons). Use hyperbolic tangent activation. Train using backpropagation with a momentum term to escape local minima.

- Validation: Split data into training (70%), validation (15%), and test (15%) sets. Use k-fold cross-validation to mitigate overfitting.

- RSM Model Fitting: Fit a second-order polynomial equation to the experimental data using least squares regression.

- Performance Assessment: Compare models using R², Adjusted R², and Root Mean Square Error (RMSE) on unseen test data.

Protocol 2: Addressing Data Scarcity with Hybrid & Augmentation Methods

- Limited Dataset: Start with a minimal CCD dataset (e.g., 20 runs).

- Data Augmentation: Generate synthetic data points via Gaussian noise injection within experimental error bounds.

- Hybrid Modeling: Train an initial RSM model. Use its predictions as a prior for ANN pre-training or within a combined model structure.

- Evaluation: Compare the performance of ANN trained on augmented data versus standard RSM on a separate, true experimental hold-out set.

Visualizing ANN Challenges & Workflows

Diagram 1: ANN Challenges in Model Development

Diagram 2: Comparative ANN vs RSM Workflow for Bioreduction

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 2: Essential Materials for Chromium Bioreduction Experiments

| Item / Reagent | Function in Research |

|---|---|

| Potassium Dichromate (K₂Cr₂O₇) | Standard source of hexavalent chromium (Cr(VI)) for preparing stock solutions. |

| 1,5-Diphenylcarbazide | Colorimetric reagent for specific spectrophotometric detection of Cr(VI) at 540 nm. |

| Defined Microbial Culture (e.g., Bacillus sp., Pseudomonas sp.) | Biological agent for the reduction of Cr(VI) to less toxic Cr(III). |

| Minimal Salt Medium (MSM) | Provides essential nutrients (N, P, K) while controlling background for bioreduction studies. |

| pH Buffer Solutions | To maintain and study the effect of specific pH levels on microbial activity and chromium speciation. |

| Anaerobic Chamber / Resazurin | To create or monitor anaerobic conditions, which are often required for effective enzymatic Cr(VI) reduction. |

| Centrifuge & Filtration Units | For separating microbial biomass from the solution prior to Cr(VI) measurement in the supernatant. |

| UV-Vis Spectrophotometer | Primary instrument for quantifying Cr(VI) concentration via the diphenylcarbazide method. |

Within the broader investigation comparing Artificial Neural Network (ANN) and Response Surface Methodology (RSM) performance for modeling chromium(VI) bio-reduction by microbial or enzymatic agents, optimizing the RSM framework is critical. This guide compares the performance of standard RSM against optimized RSM protocols, detailing how transformation, center points, and model reduction significantly enhance predictive accuracy and model robustness.

Experimental Protocols for Key Comparisons

1. Protocol for Baseline RSM Experiment:

- Design: A standard Central Composite Design (CCD) for three critical factors: pH (5-9), incubation temperature (°C), and substrate concentration (mg/L).

- Response: Percentage removal of Cr(VI) after a fixed incubation period.

- Model Fitting: A full quadratic model is fitted using least squares regression without diagnostic checks for transformation necessity.

- Replication: No center points are replicated for pure error estimation.

2. Protocol for Optimized RSM Experiment:

- Design: A CCD with 5 replicated center points to estimate pure error and check for curvature.

- Pre-processing: The Box-Cox plot analysis is performed on the response data to determine if a power transformation (e.g., Log, Square Root) is required to stabilize variance.

- Model Fitting & Reduction: The full quadratic model is initially fitted. Insignificant terms (p-value > 0.05, assessed by ANOVA) are systematically removed via backward elimination, retaining only hierarchically significant terms.

- Validation: The reduced model is validated using additional, unseen experimental runs.

Comparative Performance Data

Table 1: Model Fit and Predictive Accuracy Comparison

| Metric | Standard RSM (No Optimization) | Optimized RSM (Transformation + Center Points + Reduction) | Notes |

|---|---|---|---|

| R² (Adjusted) | 0.872 | 0.942 | Higher is better. |

| Predicted R² | 0.801 | 0.913 | Closer to Adj. R² indicates robust model. |

| Adequate Precision | 15.2 | 28.7 | Ratio > 4 is desirable; higher indicates better signal. |

| Pure Error (p-value) | Not estimable | 0.45 | From ANOVA of replicated center points; confirms linearity. |

| Residual Std. Dev. | 3.85 | 1.92 | Lower indicates better fit. |

| LOF p-value | 0.032 | 0.210 | >0.05 indicates no significant lack of fit. |

| Optimal Condition Predicted Cr(VI) Removal | 94.1% | 97.8% | |

| Experimental Validation at Predicted Optimum | 89.5% | 96.9% |

Table 2: Impact of Individual Optimization Steps

| Optimization Step | Effect on R² (Adj.) | Effect on Model Simplicity | Key Benefit |

|---|---|---|---|

| Adding Center Points | Minimal direct increase | No change | Enables pure error & lack-of-fit test. |

| Response Transformation | Increase from 0.872 to 0.902 | No change | Stabilizes variance, meets ANOVA assumptions. |

| Model Reduction | Further increase to 0.942 | Reduces terms from 10 to 6 | Removes noise, improves predictive power. |

Visualizing the RSM Optimization Workflow

Diagram 1: RSM Optimization Decision Pathway

Diagram 2: ANN vs Optimized RSM Comparative Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Chromium Bio-reduction RSM Studies

| Item | Function in Research |

|---|---|

| Diphenylcarbazide Solution | Colorimetric reagent for specific detection and quantification of Cr(VI) via UV-Vis spectroscopy. |

| Microbial Consortium / Pure Enzyme | Bio-reduction agent (e.g., Bacillus sp., Chromate Reductase). The critical "catalyst" in the process. |

| Defined Growth Medium (e.g., LB Broth) | Provides consistent nutrients for microbial growth and metabolic activity during bioreduction studies. |

| pH Buffer Solutions | To accurately set and maintain the pH factor levels across designed experimental runs. |

| Atomic Absorption Spectroscopy (AAS) Standards | For validating Cr(VI) and total chromium measurements, ensuring analytical accuracy. |