Revolutionizing Electrocatalysis: 3D-Printed Porous Carbon Electrodes for Enhanced CO2-to-Fuel Conversion

This article explores the cutting-edge synthesis, functional mechanisms, and biomedical potential of 3D-printed porous carbon electrodes for electrochemical CO2 reduction (CO2R).

Revolutionizing Electrocatalysis: 3D-Printed Porous Carbon Electrodes for Enhanced CO2-to-Fuel Conversion

Abstract

This article explores the cutting-edge synthesis, functional mechanisms, and biomedical potential of 3D-printed porous carbon electrodes for electrochemical CO2 reduction (CO2R). Tailored for researchers and drug development professionals, it provides a comprehensive analysis from foundational material science to advanced application. We detail the fabrication methodologies, including direct ink writing and stereolithography, and characterize the critical role of hierarchical porosity in facilitating mass transport and providing abundant active sites. The content addresses common synthesis challenges and optimization strategies for stability and selectivity. A comparative evaluation against traditional electrodes highlights the superior performance metrics of 3D-printed architectures. Finally, we discuss the transformative implications of this platform technology for producing pharmaceutical precursors and enabling sustainable biomedical manufacturing, charting a course for future interdisciplinary research.

The Science Behind the Structure: Why Porous Carbon and 3D Printing are Ideal for CO2 Electroreduction

Electrochemical CO2 reduction (CO2R) is a promising pathway for converting a greenhouse gas into value-added chemicals and fuels using renewable electricity. Within the context of a broader thesis on 3D printing porous carbon electrodes for CO2 conversion research, this technology gains enhanced significance. 3D printing enables the fabrication of electrodes with tailored porosity, surface area, and tortuosity, which are critical for overcoming mass transport limitations and improving selectivity in CO2R. The biomedical relevance of CO2R emerges from its potential to produce critical feedstocks for pharmaceutical synthesis (e.g., formate, acetate, ethylene glycol) and its intersection with bio-electrocatalysis for therapeutic gas signaling or metabolic modulation.

Core Challenges in Electrochemical CO2R

The efficient and selective electrochemical reduction of CO2 is hindered by several interconnected challenges, which 3D-printed porous carbon electrodes aim to address.

| Challenge Category | Specific Issue | Quantitative Impact / Typical Value |

|---|---|---|

| Mass Transport | Low solubility & diffusion of CO2 in aqueous electrolytes | Solubility: ~34 mM at 25°C, 1 atm; Diffusivity: ~1.9×10⁻⁵ cm²/s |

| Competing Reaction | Hydrogen Evolution Reaction (HER) | In aqueous media, HER thermodynamics often favored over CO2R |

| Product Selectivity | Multi-electron transfer pathways leading to >16 products | e.g., Faradaic Efficiency (FE) for desired C₂+ products often <50% |

| Catalyst Stability | Deactivation via poisoning, aggregation, or oxidation | Catalyst durability often <100 hours at industrially relevant currents |

| Energy Efficiency | High overpotentials required for desired products | Cell energy efficiency for CO or formate typically 40-60% |

Biomedical Relevance and Applications

CO2R intersects with biomedical science through the synthesis of medically relevant compounds and novel therapeutic strategies.

| Biomedical Application | CO2R-Derived Product | Relevance / Function |

|---|---|---|

| Pharmaceutical Feedstocks | Formate, Acetate, Glyoxal | Precursors for drug synthesis and isotope-labeled compounds |

| Metabolic Modulators | Carbon Monoxide (CO) | Therapeutic gas for anti-inflammatory and cytoprotective effects |

| Diagnostic Agents | ¹³C/¹⁴C-labeled compounds | Tracers for metabolic flux analysis and imaging (PET/MRI) |

| Tissue Engineering | Polyhydroxyalkanoates (PHA) precursors | Biocompatible polymers for scaffolds from CO2-derived acetate |

| Antimicrobial Agents | Ethylene, Ethanol | Intermediate for sterilant and disinfectant production |

Application Notes: 3D-Printed Porous Carbon Electrodes for CO2R

Rationale for 3D-Printed Architectures

3D printing (additive manufacturing) allows for the precise design of electrode geometries that enhance CO2R performance by:

- Creating hierarchical porosity: Macro-pores (>>50 µm) for bulk CO2 transport, meso-pores (2-50 µm) for electrolyte wetting, and micro-pores (<2 nm) for high surface area.

- Minimizing transport barriers: Tailored channel designs reduce diffusion distances for CO2 to active sites.

- Enabling gradient structures: Functional gradients can be integrated (e.g., catalyst loading, hydrophobicity) to optimize local reaction environments.

Key Performance Data from Recent Studies

| Electrode Material / Design | Primary Product | Faradaic Efficiency (FE) | Current Density (j) | Stability | Reference Year |

|---|---|---|---|---|---|

| 3D-printed Graphene/PLA (pyrolyzed) | CO | 85% | -10 mA/cm² @ -0.6 V vs RHE | >20 h | 2023 |

| DIW-printed Carbon Nanotube Foam w/ Cu | C₂H₄ | 52% | -150 mA/cm² @ -0.9 V vs RHE | >50 h | 2024 |

| SLS-printed Porous Carbon w/ SnO₂ | HCOOH | 78% | -50 mA/cm² @ -1.2 V vs RHE | >35 h | 2023 |

| Copper-infused 3D Carbon Lattice | C₂₊ Products | 65% (C₂₊) | -300 mA/cm² @ -0.8 V vs RHE | >75 h | 2024 |

DIW: Direct Ink Writing; SLS: Selective Laser Sintering; RHE: Reversible Hydrogen Electrode

Experimental Protocols

Protocol: Fabrication of a 3D-Printed Porous Carbon Electrode via DIW and Pyrolysis

Aim: To create a hierarchically porous carbon electrode with integrated catalytic sites for CO2-to-CO reduction.

Materials: See "The Scientist's Toolkit" (Section 7).

Methodology:

- Ink Formulation:

- Mix 5 wt% graphene oxide (GO) flakes, 2 wt% cellulose nanocrystals (CNC, as rheology modifier), and 93 wt% deionized water.

- Homogenize using a planetary centrifugal mixer (2000 rpm, 10 minutes).

- Add 0.5 wt% (relative to GO) of cobalt phthalocyanine (CoPc) catalyst precursor and sonicate for 1 hour.

3D Printing (DIW):

- Load ink into a syringe barrel fitted with a conical nozzle (200 µm diameter).

- Print onto a glass substrate at room temperature using the following parameters: Print speed: 10 mm/s, Layer height: 150 µm, Pressure: 25 psi.

- Design a gyroid lattice structure (CAD file) with 500 µm pore size to maximize geometric surface area.

- Air-dry the printed structure for 12 hours.

Post-processing & Pyrolysis:

- Place the dried structure in a tube furnace under argon flow.

- Heat at 2°C/min to 900°C, hold for 2 hours, then cool naturally under Ar.

- This step reduces GO to rGO, carbonizes the CNC, and pyrolyzes CoPc to form Co-N-C active sites.

Characterization:

- Perform SEM to confirm porous morphology.

- Conduct Raman spectroscopy (ID/IG ratio ~1.1) to assess graphitization.

- Use XPS to confirm Co-Nₓ coordination.

Protocol: Electrochemical CO2R Testing in an H-Cell

Aim: To evaluate the performance of the 3D-printed electrode for CO2 reduction to CO.

Methodology:

- Cell Assembly:

- Use a standard two-compartment H-cell separated by an anion exchange membrane (e.g., Sustainion).

- The 3D-printed electrode is mounted as the working electrode in the cathodic chamber.

- Fill the catholyte (20 mL of 0.1 M KHCO₃) and anolyte (20 mL of 0.1 M KOH) after purging with CO₂ for 30 minutes.

Electrochemical Measurement:

- Employ a potentiostat with a standard three-electrode setup (3D electrode as WE, Pt mesh as CE, Ag/AgCl (3M KCl) as RE).

- Perform Linear Sweep Voltammetry (LSV) from +0.2 to -1.2 V vs. RHE at 10 mV/s under CO₂ saturation.

- Conduct potentiostatic electrolysis at -0.7 V vs. RHE for 2 hours.

Product Analysis:

- Analyze the gas phase from the cathode headspace using online Gas Chromatography (GC) with TCD and FID detectors at 30-minute intervals.

- Analyze the liquid phase using Nuclear Magnetic Resonance (NMR) spectroscopy (¹H) with water suppression.

- Calculate Faradaic Efficiency (FE) for each product using charge and quantified product amounts.

Visualizations

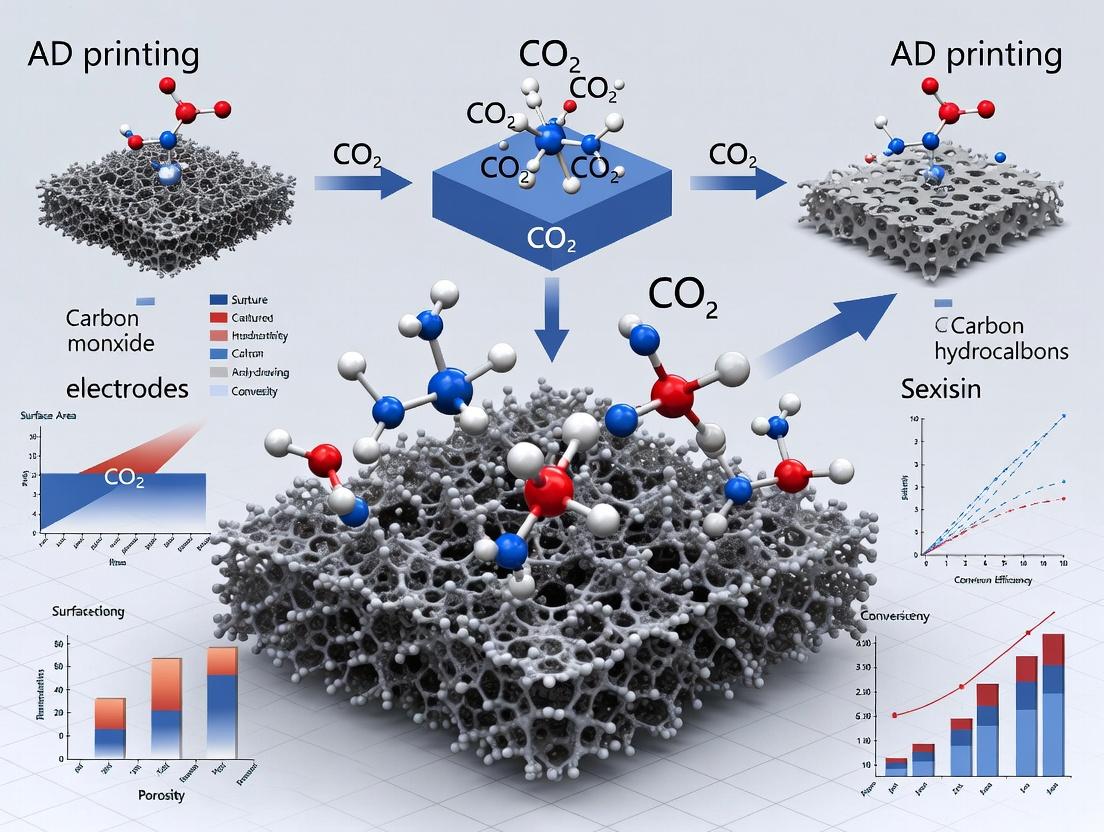

Title: Workflow for 3D-Printed Electrode CO2R Research

Title: CO2R Pathways to Biomedically Relevant Products

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function / Role in CO2R Research with 3D Electrodes |

|---|---|

| Graphene Oxide (GO) Flakes | Primary carbon source for ink; provides conductive backbone and functional groups for catalyst anchoring. |

| Cellulose Nanocrystals (CNC) | Rheological modifier for DIW ink; imparts shear-thinning behavior and shape retention. Pyrolyzes to amorphous carbon. |

| Cobalt Phthalocyanine (CoPc) | Molecular catalyst precursor; forms atomically dispersed Co-Nₓ sites upon pyrolysis for selective CO production. |

| 0.1 M Potassium Bicarbonate (KHCO₃) | Standard aqueous catholyte; provides buffering capacity and source of protons for CO2R. |

| Anion Exchange Membrane (Sustainion) | Separates cathodic and anodic chambers while allowing bicarbonate/OH⁻ transport, minimizing product crossover. |

| Ionic Liquids (e.g., [BMIM][BF₄]) | Co-solvent or electrolyte component; enhances CO2 solubility and lowers overpotential. |

| ¹³C-labeled CO₂ | Isotopic tracer for mechanistic studies and quantification of carbon flow to specific products via NMR or GC-MS. |

| Polytetrafluoroethylene (PTFE) Nanoparticles | Additive to increase electrode hydrophobicity, creating triple-phase boundaries for enhanced gas diffusion. |

Application Notes: Porous Carbon in 3D-Printed Electrodes for CO₂ Conversion

Rationale and Advantages

The integration of porous carbon into 3D-printed architectures for electrochemical CO₂ reduction (CO₂R) presents a transformative approach. This synergy leverages:

- High Surface Area: Provides abundant active sites for catalyst loading and reactant adsorption, directly enhancing reaction rates.

- High Conductivity: Ensures efficient electron transfer to the catalytic sites, minimizing energy losses as heat.

- Tunability: Allows precise control over pore size distribution (micro-, meso-, macro-pores), surface chemistry, and composite formation to optimize mass transport, catalyst dispersion, and product selectivity.

Key Performance Data from Recent Studies

Recent advancements (2023-2024) highlight the efficacy of 3D-printed porous carbon electrodes.

Table 1: Performance Metrics of 3D-Printed Porous Carbon Electrodes in CO₂ Reduction

| Electrode Composition & Architecture | Key Advantage Leveraged | Primary CO₂R Product | Faradaic Efficiency (%) | Current Density (mA/cm²) | Stability (hours) | Reference/Key Finding |

|---|---|---|---|---|---|---|

| 3D-Printed Graphene Aerogel (3D-GA) with Bi Catalyst | Ultra-high surface area (>1500 m²/g), conductivity | Formate | 92% | ~200 | >50 | Nat. Commun. 2023: Hierarchical pores enhance mass transport and catalyst exposure. |

| DIW-printed Carbon Nanotube/Resorcinol-Formaldehyde | Tunable mesoporosity, conductive network | CO | 85% | 150 | 100 | Adv. Energy Mater. 2023: Macro-meso pore network reduces diffusion limitations. |

| SLS-printed Micro-porous Carbon with Cu₂O | Tunable surface chemistry (N-doping), conductivity | C₂+ (Ethylene) | 55% | 300 | 35 | Science Advances 2024: N-functionalization stabilizes Cu⁺ species for C-C coupling. |

| DIW-printed Reduced Graphene Oxide-PEDOT:PSS | Conductive, mechanically robust 3D scaffold | CO | 78% | 120 | >80 | ACS Nano 2023: Flexible, binder-free design enables flow-cell integration. |

DIW: Direct Ink Writing; SLS: Selective Laser Sintering

Experimental Protocols

Protocol: Fabrication of 3D-Printed Porous Carbon Electrode via DIW

Objective: To fabricate a hierarchically porous carbon electrode functionalized with a metal catalyst for CO₂R. Materials: See "The Scientist's Toolkit" below.

Procedure:

- Ink Formulation:

- Disperse 5 wt% activated carbon powder and 2 wt% carbon nanotubes in 93 wt% deionized water.

- Add 4 wt% sodium alginate as a viscosifier. Stir for 2 hours.

- Sonicate the mixture (probe sonicator, 30% amplitude, 10 min ON/30 sec OFF cycle) to ensure homogeneity.

- 3D Printing (DIW):

- Load ink into a syringe barrel equipped with a conical nozzle (inner diameter 410 µm).

- Set print parameters: Pressure = 25-30 psi, print speed = 8 mm/s, layer height = 300 µm.

- Print the desired 3D lattice structure (e.g., log-pile, grid) onto a polished graphite current collector.

- Freeze-Drying & Pyrolysis:

- Immediately freeze the printed structure at -80°C for 4 hours.

- Lyophilize for 24 hours to remove ice crystals, creating macro-pores.

- Pyrolyze in a tube furnace under N₂ atmosphere: Ramp to 800°C at 5°C/min, hold for 2 hours. This carbonizes the binder, enhancing conductivity and creating micro-pores.

- Catalyst Functionalization (e.g., Sn):

- Use electrochemical deposition: Immerse the pyrolyzed electrode in a 5 mM SnSO₄, 0.5 M H₂SO₄ solution.

- Apply a constant potential of -0.8 V vs. Ag/AgCl for 300 seconds to deposit Sn nanoparticles.

- Post-treatment: Rinse thoroughly with deionized water and dry under N₂ flow.

Protocol: Electrochemical CO₂ Reduction Testing

Objective: To evaluate the performance of the fabricated electrode in converting CO₂ to valuable products. Setup: H-cell or flow cell, potentiostat, Ag/AgCl reference electrode, Pt counter electrode.

Procedure:

- Cell Assembly: Assemble an H-cell separated by a Nafion 117 membrane. Fill the cathode chamber with 20 mL of 0.5 M KHCO₃ electrolyte. Saturate the cathode compartment with CO₂ by bubbling for at least 30 minutes prior to and throughout the experiment.

- Electrochemical Activation: Perform 10 cyclic voltammetry cycles from -0.5 to -1.2 V vs. RHE at 50 mV/s in CO₂-saturated electrolyte to condition the electrode surface.

- Controlled Potential Electrolysis:

- Apply the target constant potential (e.g., -0.9 V vs. RHE) for 1-2 hours.

- Record the current throughout.

- Product Analysis:

- Gas-Phase Products: Sample the headspace gas periodically using a gas-tight syringe. Analyze via Gas Chromatography (GC) equipped with TCD and FID detectors. Quantify using calibrated standard curves.

- Liquid-Phase Products: Collect 0.5 mL aliquots of the electrolyte post-experiment. Analyze via Nuclear Magnetic Resonance (NMR) spectroscopy (e.g., ¹H NMR with water suppression) or Ion Chromatography (IC) for formate, acetate, etc.

- Data Calculation:

- Faradaic Efficiency (FE): FE (%) = (z * F * n) / Q * 100%, where z is electrons transferred per product molecule, F is Faraday's constant, n is moles of product, and Q is total charge passed.

- Normalize current to the geometric or electrochemically active surface area (ECSA) of the electrode.

Visualizations

Diagram: 3D-Printed Porous Carbon Electrode Fabrication Workflow

Diagram: Structure-Function Relationships in Porous Carbon Electrodes

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for Fabricating & Testing 3D-Printed Porous Carbon Electrodes

| Item | Function/Benefit | Example Product/Specification |

|---|---|---|

| Activated Carbon Powder | Primary source of high microporous surface area. | >1000 m²/g BET surface area, high purity. |

| Carbon Nanotubes (CNTs) | Enhances electrical conductivity and mechanical strength of the ink. | Multi-walled, carboxyl-functionalized, >95% purity. |

| Sodium Alginate | Natural polysaccharide binder; provides shear-thinning behavior for DIW. | High viscosity grade, suitable for bio-printing. |

| Graphite Current Collector | Conductive, inert substrate for printing electrodes. | Polished foil, 99.8% purity, 0.5 mm thickness. |

| SnSO₄ or Other Metal Salts | Precursor for electrocatalyst deposition onto the carbon scaffold. | Anhydrous, 99.9% trace metals basis. |

| KHCO₃ Electrolyte | Common CO₂R electrolyte; provides bicarbonate buffer and K⁺ ions known to promote CO₂ reduction. | 0.5 M solution in ultra-pure water (18.2 MΩ·cm). |

| Nafion 117 Membrane | Cation-exchange membrane; separates cathode and anode compartments while allowing ion transport. | Pre-treated by boiling in H₂O₂ and H₂SO₄. |

| CO₂ Gas (Research Grade) | High-purity reactant gas for saturation of the electrolyte. | 99.999% purity. |

| Calibration Gas Mixture | Essential for quantifying gaseous products via GC. | Custom mix of CO, CH₄, C₂H₄, H₂ in balance CO₂ or N₂. |

| D₂O with NMR Reference | Solvent for ¹H NMR analysis of liquid products (e.g., formate). | Contains 0.05% w/w TSP-d₄ as chemical shift reference. |

Principles of 3D Printing (Additive Manufacturing) for Electrode Fabrication

This document provides application notes and experimental protocols for fabricating porous carbon electrodes via additive manufacturing (AM) for electrochemical CO₂ conversion. Within the broader thesis on optimizing 3D-printed porous architectures for enhanced mass transport and catalytic activity in CO₂ reduction reactions (CO2RR), these guidelines are essential for reproducible electrode development.

Key AM Technologies for Porous Carbon Electrodes

The selection of AM technology dictates the electrode's porosity, conductivity, and geometric complexity.

| Technology | Typical Materials | Feature Resolution | Porosity Origin | Key Advantage for CO2RR | Major Limitation |

|---|---|---|---|---|---|

| Material Extrusion (MEX) | Carbon-loaded thermoplastics (PLA, ABS), ionogels | 100 - 500 µm | Designed macro-pores, post-printing treatments (pyrolysis) | Low-cost, multi-material capability, complex geometries | Lower conductivity, requires pyrolysis (>500°C). |

| Vat Photopolymerization (VPP) | Photopolymer resins with carbon/graphene nanoplatelets | 25 - 100 µm | Microlattice design, post-curing pyrolysis | High resolution, excellent surface finish | Brittleness pre-pyrolysis, limited carbon loading. |

| Direct Ink Writing (DIW) | Graphene aerogel inks, CNT pastes, MOF composites | 200 - 1000 µm | Inherent ink rheology, solvent evaporation | High electrical conductivity, no pyrolysis needed | Ink formulation critical, slower build rates. |

Table 1: Quantitative comparison of 3D printing technologies for porous carbon electrode fabrication.

Experimental Protocol: Fabrication via MEX & Pyrolysis

This detailed protocol outlines the fabrication of a pyrolytic carbon (PC) electrode from a carbon-loaded filament.

Protocol 2.1: MEX Printing and Pyrolysis for Porous PC Electrodes

- Objective: To fabricate a 3D-printed, porous pyrolytic carbon electrode with an ordered lattice structure for CO2RR.

- Materials & Equipment:

- 3D Printer (MEX/FDM type), heated build plate.

- Carbon black/polylactic acid (CB/PLA) conductive filament (e.g., Proto-pasta).

- Curing oven (for annealing).

- Tube furnace with inert gas (Ar/N₂) supply.

- Electrochemical cell, potentiostat.

- Procedure:

- Design: Use CAD software to design a 3D lattice (e.g., gyroid, cubic) with strut diameter of 400 µm and pore size of 800 µm. Export as

.STL. - Slicing: Import

.STLinto slicer software. Key parameters:- Nozzle Diameter: 0.4 mm

- Layer Height: 0.2 mm

- Printing Temperature: 210 °C

- Bed Temperature: 60 °C

- Infill: 100% (geometry defined by model)

- Print Speed: 30 mm/s

- Printing: Execute print. Ensure good first-layer adhesion.

- Pre-Pyrolysis Annealing: Place printed green part in oven. Ramp from 25°C to 200°C at 1°C/min, hold for 2 hours. This reduces thermal stress during pyrolysis.

- Pyrolysis:

- Place annealed part in tube furnace.

- Purge with Argon (≥30 mins, 200 sccm flow).

- Ramp temperature: 5°C/min to 900°C.

- Hold at 900°C for 2 hours under Argon.

- Cool naturally to <100°C under Argon before removal.

- Post-Processing: The part is now a fragile, conductive porous carbon monolith. Optional: Electrochemical activation via cyclic voltammetry (e.g., 100 cycles, -1.0 to +1.0 V vs. Ag/AgCl in 0.5 M H₂SO₄).

- Design: Use CAD software to design a 3D lattice (e.g., gyroid, cubic) with strut diameter of 400 µm and pore size of 800 µm. Export as

The Scientist's Toolkit: Key Reagents & Materials

| Item | Function in Protocol |

|---|---|

| CB/PLA Conductive Filament | Base printing material; carbon black provides conductivity, PLA is a carbon precursor. |

| Argon Gas (High Purity) | Inert atmosphere during pyrolysis to prevent combustion, enabling conversion to carbon. |

| Electrolyte (0.5 M KHCO₃) | Common CO2RR aqueous electrolyte; bicarbonate buffers pH and supplies CO₂. |

| Nafion Binder | Used in catalyst inks to adhere noble metal/heteroatom catalysts to the printed carbon surface. |

| Polydimethylsiloxane (PDMS) | Used to create gaskets/seals for custom electrochemical flow cells housing 3D electrodes. |

Protocol: Functionalization of 3D-Printed Electrodes

Printed carbon electrodes require functionalization for selective CO₂ conversion.

Protocol 3.1: Electrodeposition of Cu Catalyst onto 3D-PC Electrode

- Objective: To deposit a copper catalyst layer onto the 3D-printed porous carbon electrode for the electrochemical reduction of CO₂ to multi-carbon products (C₂₊).

- Procedure:

- Electrode Preparation: Clean pyrolyzed PC electrode via sonication in isopropanol for 5 minutes. Dry at 80°C.

- Electrodeposition Setup: Use a standard 3-electrode cell with the PC electrode as the working electrode, Pt mesh as counter, and Ag/AgCl (sat. KCl) as reference. Use 0.1 M CuSO₄ in 0.5 M H₂SO₄ as plating bath.

- Deposition: Perform chronoamperometry at a constant potential of -0.3 V vs. Ag/AgCl for 600 seconds under gentle stirring.

- Post-Treatment: Rinse electrode thoroughly with deionized water. Dry under N₂ stream. Optional annealing at 200°C in Ar for 1 hour to stabilize Cu nanoparticles.

Performance Characterization Data

Critical metrics for evaluating 3D-printed electrodes in CO2RR.

| Electrode Type | Total Electroactive Surface Area (ECSA, cm²) | Jₜₒₜₐₗ @ -1.0 V vs. RHE (mA/cm²) | C₂₊ Faradaic Efficiency (%) | Stability (hours) |

|---|---|---|---|---|

| 3D-PC (MEX, Gyroid) | 12.5 ± 1.8 | -25.3 ± 3.1 | 45.2 ± 5.1 | >12 |

| 3D-PC (DIW, Graphene) | 28.4 ± 3.5 | -41.7 ± 4.8 | 38.7 ± 4.3 | >20 |

| Flat Carbon Paper (Control) | 1.0 (geometric) | -8.5 ± 1.2 | 15.3 ± 3.7 | >8 |

Table 2: Exemplary electrochemical performance data for 3D-printed porous carbon electrodes in CO2RR (0.5 M KHCO₃, CO₂-saturated).

3D-Printed Electrode Fabrication Workflow

CO2RR Pathways on a Catalytic 3D Electrode

Within the broader thesis on advancing CO2 conversion technologies, this application note details how 3D printing (additive manufacturing) provides unprecedented synergistic control over the macro- and micro-architecture of porous carbon electrodes. This precision directly translates to enhanced electrochemical performance for CO2 reduction reactions (CO2RR) by optimizing mass transport, active site accessibility, and electron transfer pathways.

Table 1: Comparison of 3D-Printed Porous Carbon Architectures for CO2RR

| Printing Method | Precursor Material | Pore Size Range (µm) | Specific Surface Area (m²/g) | Faradaic Efficiency for Target Product (e.g., CO) | Reference/Notes |

|---|---|---|---|---|---|

| Direct Ink Writing (DIW) | Graphene Oxide / CNT Composite | 50 - 500 (macro) | 450 - 650 | ~85% | Tunable filament spacing enables convective flow. |

| Stereolithography (SLA) | Photoresin with Carbonaceous Fillers | 10 - 150 (micro) | 200 - 400 | ~78% | High-resolution lattice structures. |

| Powder Bed Fusion | Polyimide Powder | 1 - 50 (micro/meso) | 550 - 1200 | ~90% | Laser pyrolysis creates inherent microporosity. |

| DIW with Sacrificial Template | Resorcinol-Formaldehyde Gel + Polymer Fibers | 5 (micro) - 300 (macro) | 800 - 1200 | >92% | Dual-templating for hierarchical porosity. |

Table 2: Electrochemical Performance Metrics

| Architecture Type | Electrode Porosity (%) | Limiting Current Density (mA/cm²) for CO2RR | Tafel Slope (mV/dec) | Stability (hours) |

|---|---|---|---|---|

| 3D Printed Hierarchical Lattice | 75 | 45 | 120 | 100+ |

| Conventional Carbon Felt | 90 | 15 | 140 | 80 |

| 3D Printed Ordered Microtruss | 65 | 60 | 115 | 120 |

Application Notes & Experimental Protocols

Protocol 1: DIW of Hierarchical Porous Carbon Electrodes

Objective: Fabricate a carbon electrode with tri-modal porosity (macro/meso/micro) for CO2RR.

Materials & Reagents: See "Scientist's Toolkit" below.

Methodology:

- Ink Formulation:

- Mix 5 g of graphene oxide (GO) dispersion (10 mg/mL) with 1 g of multi-walled carbon nanotubes (MWCNTs).

- Add 2 g of resorcinol-formaldehyde (RF) sol-gel precursor as a carbonizable binder.

- Incorporate 0.5 g of Pluronic F-127 as a rheology modifier.

- Homogenize using a centrifugal mixer at 2000 RPM for 5 minutes.

- Printing Process:

- Load ink into a syringe barrel fitted with a conical nozzle (diameter 200 µm).

- Utilize a 3-axis robotic deposition stage. Set printing pressure to 25-30 psi.

- Print a 3D orthogonal lattice structure (e.g., 5x5x5 mm) with a center-to-center filament spacing of 300 µm.

- Freeze-dry the printed structure at -50°C for 24 hours.

- Pyrolysis & Activation:

- Carbonize in a tubular furnace under N2 atmosphere. Ramp at 3°C/min to 800°C, hold for 2 hours.

- For activation, subsequently heat to 900°C under a CO2 flow for 45 minutes to develop microporosity.

- Post-Processing:

- Functionalize by electrochemical deposition of Cu or Sn nanoparticles for CO2RR catalysis.

Key Control Parameters: Ink viscosity, printing speed, nozzle diameter, pyrolysis ramp rate, activation time.

Protocol 2: SLA Printing of Micro-Architected Carbon Lattices

Objective: Create high-surface-area, ordered micro-lattices for catalyst support.

Methodology:

- Resin Preparation:

- Prepare a photocurable resin by mixing 70 wt% acrylate monomer, 25 wt% surface-modified carbon black/graphene nanoplatelets, and 5 wt% photoinitiator (phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide).

- Sonicate for 1 hour to ensure homogeneous dispersion.

- Printing & Washing:

- Print using a commercial SLA printer (e.g., 385 nm wavelength) with a layer thickness of 25 µm. Design a gyroid or octet-truss lattice unit cell (strut diameter ~100 µm).

- Wash printed "green" part in isopropanol to remove uncured resin.

- Thermal Processing:

- Post-cure under UV light for 30 minutes.

- Pyrolyze in an argon atmosphere using a slow ramp (1-2°C/min) to 1000°C, hold for 1 hour.

Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 3D Printing Porous Carbon Electrodes

| Item | Function in Experiment | Example/Supplier Notes |

|---|---|---|

| Graphene Oxide (GO) Dispersion | Primary ink component for DIW; provides conductive carbon backbone and enables rheological control. | Cheap Tubes, Graphenea. Typically 4-10 mg/mL aqueous dispersion. |

| Photocurable Acrylate Resin | Matrix for SLA printing; binds carbon fillers and forms solid polymer upon UV exposure. | Anycubic, Formlabs. Must be compatible with carbon filler dispersion. |

| Resorcinol-Formaldehyde (RF) Sol-Gel | Carbonizable binder in DIW inks; creates glassy carbon and mesoporous structure upon pyrolysis. | Sigma-Aldrich. Prepared via base-catalyzed polymerization. |

| Pluronic F-127 or PEG | Rheology modifier; imparts shear-thinning behavior essential for DIW. | Sigma-Aldrich. |

| Multi-Walled Carbon Nanotubes (MWCNTs) | Conductive additive; enhances electrical conductivity and mechanical strength of printed structure. | NanoLab, Timesnano. |

| Polyimide Powder (e.g., Kapton) | Precursor for powder-based 3D printing; yields high carbon content and intrinsic porosity upon laser pyrolysis. | Dupont. |

| Sacrificial Template (e.g., PMMA microspheres) | Creates additional, ordered pore networks; removed during pyrolysis. | Microbeads AS. |

| Inert Atmosphere Furnace | For controlled pyrolysis and activation processes. | Tube furnace with N2/Ar and CO2 gas lines. |

This document provides application notes and experimental protocols for evaluating the three primary KPIs for electrocatalytic CO2 reduction (CO2R) electrodes, specifically within the context of a doctoral thesis investigating 3D-printed porous carbon architectures for enhanced CO2-to-fuel conversion. Optimizing these interdependent KPIs is critical for advancing the technology toward industrial viability.

Core KPI Definitions and Quantitative Benchmarks

Table 1: Core KPIs for CO2R Electrodes: Targets and Implications

| KPI | Definition | Typical Target Range (State-of-the-Art) | Primary Influence in 3D-Printed Electrodes |

|---|---|---|---|

| Current Density (j) | The total electrical current per geometric electrode area (e.g., mA/cm²). Indicates reaction rate. | >200 mA/cm² for C2+ products (e.g., ethylene, ethanol) | Dictated by porosity, surface area, and mass transport properties of the 3D printed structure. |

| Faradaic Efficiency (FE) | The fraction of charge used to produce a specific CO2R product versus all electrochemical processes. | >70% for a single desired C2+ product; >90% for CO or formate. | Determined by the intrinsic catalyst activity and the local micro-environment (pH, CO₂ concentration) shaped by pore geometry. |

| Overpotential (η) | The extra voltage beyond the thermodynamic requirement needed to drive the reaction at a given rate. | Low onset potential; <0.5 V overpotential for j=10 mA/cm² for C2+ products. | Affected by catalyst loading, electrical conductivity, and active site accessibility within the 3D printed scaffold. |

Table 2: Recent Performance Data for Representative CO2R Electrodes (2023-2024)

| Electrode Type / Catalyst | Main Product | Current Density (mA/cm²) | Faradaic Efficiency (%) | Overpotential (mV vs. RHE) | Reference Key |

|---|---|---|---|---|---|

| 3D-Printed Cu-Ag Bimetallic Porous Carbon | C₂H₄ | 325 @ -0.87V | 67% | ~570 | Adv. Energy Mater. 2023 |

| Nano-porous Copper on Carbon Felt | C₂H₅OH | 421 @ -0.8V | 52% | ~550 | Nat. Commun. 2024 |

| Oxide-derived Cu in Gas Diffusion Electrode (GDE) | C₂₊ | >500 | 75% (C₂₊) | N/A | Joule 2023 |

| Bi-based Catalyst on 3D Printed Carbon | HCOOH | 200 @ -0.9V | >92% | ~450 | ACS Catal. 2024 |

Detailed Experimental Protocols

Protocol 1: Electrochemical Cell Setup for KPI Measurement (H-type cell)

Objective: To measure KPIs under controlled, aqueous conditions. Materials:

- Working Electrode: 3D-printed porous carbon electrode (e.g., 1x1 cm²), functionalized with catalyst (e.g., Cu, Sn, Bi).

- Counter Electrode: Pt wire or foil.

- Reference Electrode: Reversible Hydrogen Electrode (RHE) (e.g., Hg/HgO or Ag/AgCl with conversion to RHE scale).

- Electrolyte: 0.1 M KHCO₃ or 0.1 M KOH, saturated with CO₂.

- Equipment: Potentiostat/Galvanostat, CO₂ bubbler, gas-tight cell.

Procedure:

- Electrode Preparation: Immerse the 3D-printed electrode in catalyst precursor solution (e.g., Cu(NO₃)₂), dry, and electrochemically reduce to metal.

- Cell Assembly: Assemble H-cell with Nafion membrane separator. Fill both compartments with CO₂-saturated electrolyte.

- Electrochemical Reduction: Apply constant potential (chronoamperometry) for 30-60 minutes. Record current continuously.

- Product Analysis:

- Liquid Products: Analyze electrolyte post-experiment via NMR or HPLC.

- Gaseous Products: Sample headspace gas periodically via gas-tight syringe and analyze via GC (FID & TCD detectors).

- Data Calculation:

- j = I / Ageo, where I is average current, Ageo is geometric area.

- FE = (z * F * n) / Q, where z is electrons per mole product, F is Faraday constant, n is moles of product, Q is total charge passed.

- η = Eapplied - Ethermodynamic (for target product at experimental pH).

Protocol 2: Flow Cell Testing with Gas Diffusion Electrode (GDE) Configuration

Objective: To measure KPIs at industrially relevant high current densities. Materials: Membrane electrode assembly (MEA), gas diffusion layer (GDL), CO₂ gas flow controller, liquid electrolyte (e.g., 1 M KOH) pump, high-current potentiostat. Procedure:

- GDE Fabrication: Coat catalyst ink onto GDL or directly integrate catalyst into 3D-printed porous carbon current collector.

- Flow Cell Assembly: Assemble cell with cathode GDE, anode, and ion-exchange membrane.

- Operation: Flow CO₂ gas to cathode side and liquid electrolyte to anode side. Apply constant potential/current.

- Analysis: Quantify effluent gas (GC) and liquid (HPLC) streams. Calculate KPIs as in Protocol 1, correcting for geometric or electrochemical surface area.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for CO2R Electrode Testing

| Item | Function / Relevance | Example Product/Specification |

|---|---|---|

| CO2-Saturated Electrolyte | Provides reactant (CO₂) and conductive medium. pH controls product selectivity. | 0.1 M - 1 M KHCO₃ or KOH, saturated with >99.999% CO₂ for 30 min. |

| Catalyst Precursor Salts | Source of active metal catalyst for electrode modification. | Copper(II) nitrate trihydrate (Cu(NO₃)₂·3H₂O), Bismuth(III) nitrate (Bi(NO₃)₃). |

| Nafion Binder/Proton Exchange Membrane | Binds catalyst particles; serves as ion-conducting separator in cells. | Nafion 117 membrane, 5 wt% Nafion solution. |

| Internal Standard for NMR | Quantifies liquid products accurately. | Dimethyl sulfoxide (DMSO) or 3-(trimethylsilyl)-1-propanesulfonic acid sodium salt (DSS). |

| Calibration Gas Mixture | Essential for quantifying gaseous product yields via GC. | Certified standard mix: H₂, CO, CH₄, C₂H₄, C₂H₆ in balance CO₂ or N₂. |

| 3D Printing Ink | Forms the porous conductive scaffold. | Carbon composite ink: Carbon black/graphite, polymer binder (e.g., PLA, PVDF), solvent. |

Visualization of Concepts and Workflows

Diagram Title: Interdependence of CO2R KPIs in 3D Electrodes

Diagram Title: KPI Measurement Workflow for CO2R Electrodes

From Digital Design to Functional Electrode: A Step-by-Step Guide to Fabrication and Activation

1. Introduction: Context within CO2 Conversion Research This document provides application notes and protocols for formulating 3D printable carbon inks, a critical enabling technology for fabricating porous carbon electrodes. Within a broader thesis on 3D printing for electrochemical CO2 conversion, these electrodes are designed to possess tailored porosity (micro/meso/macro), high electrical conductivity, and catalytic activity. The rational selection of precursors, binders, and additives directly governs the printability, structural integrity, and final electrochemical performance of the printed electrode.

2. Research Reagent Solutions: The Formulator's Toolkit Table 1: Essential Materials for Carbon Ink Formulation

| Material Category | Example Reagents | Primary Function | Key Consideration |

|---|---|---|---|

| Carbon Precursor | Polyacrylonitrile (PAN), Phenolic resin, Cellulose, Polyimide, Lignin | Forms the conductive carbon matrix upon pyrolysis. | Carbon yield, purity, graphitizability, and inherent heteroatom doping (N, O, S). |

| Conductive Filler | Carbon black (Vulcan XC-72), Graphene nanoplatelets, Carbon nanotubes (CNTs) | Enhances electrical conductivity and mechanical robustness pre- and post-pyrolysis. | Aspect ratio, dispersion stability, percolation threshold, and potential catalytic sites. |

| Binder/Polymer | Polyvinylpyrrolidone (PVP), Ethyl cellulose, Polyvinyl alcohol (PVA), Pluronic F-127 | Provides rheological control (shear-thinning, yield stress) for printability and green strength. | Decomposition temperature, compatibility with solvent, and interaction with filler. |

| Solvent | N,N-Dimethylformamide (DMF), Deionized Water, Terpineol, Dimethyl sulfoxide (DMSO) | Dissolves/disperses components to achieve target viscosity and evaporation rate. | Boiling point, safety, environmental impact, and ability to disperse fillers. |

| Rheology Modifier | Fumed silica (Aerosil), Clay (Laponite), Polyethylene glycol (PEG) | Adjusts viscoelasticity (yield stress, storage modulus) to prevent sagging and enable self-supporting prints. | Thixotropic behavior and thermal stability. |

| Catalytic Precursor | Metal-Organic Frameworks (ZIF-8), Cobalt acetate, Copper nitrate, Nickel phthalocyanine | Introduces active sites (e.g., single atoms, nanoparticles) for CO2 reduction. | Decomposition profile, metal loading, and dispersion within carbon matrix. |

3. Quantitative Comparison of Common Formulations Table 2: Representative Formulations and Key Properties

| Ink ID | Precursor | Binder | Additives | Solvent | Viscosity @ 10 s⁻¹ (Pa·s) | Pyrolysis Yield (%) | Conductivity (S/m) |

|---|---|---|---|---|---|---|---|

| I-1 | 10 wt% PAN | 5 wt% PVP (1300 kDa) | 2 wt% CNTs | DMF | 120 ± 15 | 52 | 1.5 x 10³ |

| I-2 | 15 wt% Phenolic Resin | 3 wt% Ethyl Cellulose | 5 wt% Carbon Black, 1 wt% Fumed Silica | Terpineol/EtOH | 250 ± 30 | 48 | 8.0 x 10² |

| I-3 | 8 wt% Cellulose Nanofibrils | (Self-binding) | 10 wt% Graphene, 0.5M CoAc | Water | 85 ± 10 | 30 | 2.0 x 10³ |

| I-4 | 20 wt% Polyimide | 2 wt% Pluronic F-127 | 3 wt% ZIF-8 powder | DMF | 180 ± 20 | 58 | 9.0 x 10² |

4. Detailed Experimental Protocols

Protocol 4.1: Synthesis of a Standard Catalytic Carbon Ink (Ink I-1 Variant) Objective: To prepare a shear-thinning, 3D printable carbon ink doped with catalytic metal sites. Materials: Polyacrylonitrile (PAN, Mw 150,000), Polyvinylpyrrolidone (PVP, Mw 1,300,000), Multi-walled Carbon Nanotubes (MWCNTs), Cobalt(II) acetate tetrahydrate, N,N-Dimethylformamide (DMF), Magnetic stirrer, Sonicator (tip), Planetary centrifugal mixer. Procedure:

- Solution Preparation: Dissolve 1.0 g of PVP in 8.5 g of DMF using magnetic stirring at 60°C for 4 hours until fully dissolved. Cool to room temperature.

- Catalyst Integration: Add 0.25 g of Cobalt(II) acetate to the PVP solution. Stir for 1 hour.

- Precursor Addition: Slowly add 1.5 g of PAN powder to the stirring solution. Maintain stirring at 50°C for 12 hours to ensure complete dissolution, resulting in a viscous solution.

- Filler Dispersion: In a separate vial, disperse 0.3 g of MWCNTs in 2.0 g of DMF using tip sonication (50% amplitude, 5 min, pulse 5s on/2s off, in an ice bath).

- Mixing: Combine the PAN/PVP/Co solution with the MWCNT dispersion. Mix thoroughly using a planetary centrifugal mixer (2000 rpm, 5 minutes) to achieve a homogeneous, agglomerate-free ink.

- Degassing: Place the mixed ink in a vacuum desiccator for 30 minutes to remove entrapped air bubbles.

- Rheology Check: Characterize viscosity using a rotational rheometer (see Protocol 4.2). The ink is ready for printing if it exhibits shear-thinning behavior with an apparent viscosity between 50-200 Pa·s at a shear rate of 10 s⁻¹.

Protocol 4.2: Rheological Characterization for Printability Assessment Objective: To measure the viscosity and yield stress of an ink to evaluate its suitability for extrusion-based 3D printing. Materials: Rheometer (parallel plate geometry, 500 μm gap), Carbon ink sample. Procedure:

- Loading: Load approximately 0.5 mL of ink onto the lower plate of the rheometer. Lower the upper plate to the target gap.

- Flow Ramp Test: Perform a steady-state flow sweep, measuring shear stress (τ) as a function of shear rate (˙γ), typically from 0.01 to 100 s⁻¹. Plot τ vs. ˙γ and fit to the Herschel-Bulkley model (τ = τy + K˙γⁿ) to extract yield stress (τy) and power-law index (n). A printable ink typically has τ_y > 50 Pa and n < 1 (shear-thinning).

- Oscillation Stress Sweep: Perform an amplitude sweep at a constant frequency (e.g., 1 Hz) to determine the linear viscoelastic region (LVR) and the storage (G') and loss (G'') moduli. The point where G' = G'' defines the flow point. A high G' at low stress indicates good shape fidelity post-extrusion.

Protocol 4.3: Direct Ink Writing (DIW) and Pyrolysis of a Porous Electrode Objective: To 3D print and pyrolyze a freestanding, porous carbon electrode lattice. Materials: Prepared carbon ink, 3D bioprinter or dispensing system (e.g., BIO X, Nordson EFD), Syringe (3-10 mL), Tapered nozzle (100-410 μm), Substrate (Glass, Alumina), Tube furnace, N₂ gas. Procedure:

- Print Setup: Load the degassed ink into a syringe. Attach the chosen nozzle. Mount the syringe in the printer. Set the print bed temperature to 40-60°C to aid solvent evaporation.

- Print Parameters: Define a rectilinear or grid pattern (e.g., 2 mm spacing). Typical parameters: Nozzle speed: 5-15 mm/s, Extrusion pressure: 150-400 kPa, Layer height: 70-90% of nozzle diameter.

- Printing: Execute the print file. Ensure layers fuse properly without spreading excessively.

- Drying: Dry the printed "green" structure in air at 80°C for 12 hours.

- Stabilization (for PAN-based inks): Place the dried structure in a furnace. Heat in air from RT to 280°C at 1°C/min, hold for 1 hour. This step crosslinks the polymer to prevent melting.

- Pyrolysis: Transfer the stabilized structure to a tube furnace under continuous N₂ flow (200 sccm). Use the following ramp: RT to 900°C at 5°C/min, hold for 2 hours. Cool naturally to <100°C under N₂ flow.

- Post-Processing: The resulting black, mechanically stable carbon monolith is ready for electrochemical testing or further activation/modification.

5. Visualization of Workflows and Relationships

Title: Carbon Ink Formulation to Electrode Performance Workflow

This application note compares Direct Ink Writing (DIW) and Stereolithography (SLA) for fabricating 3D-printed porous carbon electrodes, a critical component in advancing electrochemical CO₂ conversion systems. Within a thesis focused on optimizing 3D-printed architectures for enhanced mass transport and catalytic activity in CO₂RR (CO₂ Reduction Reaction), selecting the appropriate fabrication technique is paramount. DIW offers versatility in pore engineering, while SLA provides high-resolution, complex geometries.

Comparative Analysis: DIW vs. SLA for Porous Carbon

Table 1: Technique Comparison for Porous Carbon Electrodes

| Parameter | Direct Ink Writing (DIW) | Stereolithography (SLA) |

|---|---|---|

| Basic Principle | Extrusion of a shear-thinning ink through a nozzle, followed by post-processing. | Photopolymerization of a photosensitive resin layer-by-layer using UV laser, followed by pyrolysis. |

| Typical Resolution | 50 - 500 µm | 10 - 100 µm |

| Porosity Control | High. Directly tunable via ink composition (e.g., porogen content, particle size) and printing parameters (e.g., filament spacing). | Moderate. Primarily determined by resin formulation and pyrolysis conditions; requires sacrificial templates for ordered macropores. |

| Architectural Freedom | Good for lattice and filamentary structures. Limited by gravity and need for self-support. | Excellent for highly complex, intricate, and self-supporting 3D geometries. |

| Key Material Precursor | Carbonizable polymers (e.g., PVA, PAN) or nanoparticles (graphene, CNTs) in solvent. | Photopolymer resin with high carbon yield (e.g., acrylate/epoxy with aromatic moieties). |

| Critical Post-Process | 1. Drying/Curing. 2. Pyrolysis/Carbonization (600-1200°C, inert atmosphere). | 1. Washing (solvent bath). 2. Post-curing (UV). 3. Pyrolysis/Carbonization (800-1400°C, inert atmosphere). |

| Typical Carbon Yield | 20-50% (dependent on ink polymer) | 15-40% (dependent on resin formulation) |

| Advantages for CO₂ Electrodes | Easier integration of catalysts (pre- or post-print); hierarchical porosity feasible. | Superior feature resolution for structured microfluidic flow channels; smooth surfaces. |

| Key Limitations | Lower resolution; potential nozzle clogging; longer drying times for thick parts. | Limited resin formulations for high-performance carbon; shrinkage/ cracking during pyrolysis. |

Table 2: Performance Data in CO₂ Electrochemical Systems (Representative)

| Property | DIW-Printed Porous Carbon | SLA-Printed Porous Carbon | Measurement Method |

|---|---|---|---|

| BET Surface Area | 150 - 800 m²/g | 50 - 400 m²/g | N₂ Physisorption |

| Electrical Conductivity | 10 - 100 S/m | 5 - 50 S/m | 4-Point Probe |

| Electrochem. Active Surface Area (ECSA) | High (porosity-dependent) | Moderate to High | Capacitive Current Measurement |

| CO₂ Conversion FE (to CO)* | 65-85% (with catalyst) | 70-90% (with catalyst) | Online Gas Chromatography |

*FE: Faradaic Efficiency. Performance heavily dependent on integrated catalyst (e.g., Zn, Ag) and electrode design.

Experimental Protocols

Protocol 1: DIW of a Hierarchically Porous Carbon Lattice Electrode Objective: Fabricate a 3D carbon electrode with macro-pores from printing and micro/mesopores from pyrolysis. Materials: See "The Scientist's Toolkit" (Section 4). Procedure:

- Ink Preparation: In a planetary mixer, combine 10 wt% Polyvinyl alcohol (PVA), 5 wt% graphene oxide (GO) dispersion, and 30 wt% polystyrene (PS) microsphere porogen (10µm diameter) in deionized water. Mix at 2000 rpm for 30 mins until a homogeneous, viscous paste is formed.

- Printing: Load ink into a syringe barrel equipped with a conical nozzle (150-250 µm diameter). Set pneumatic pressure to 250-400 kPa and printing speed to 5-10 mm/s. Print a 3D orthogonal lattice structure (e.g., 5x5x5 mm, 500 µm filament spacing) onto a build plate at 60°C to aid drying.

- Post-Processing:

- Drying: Dry the printed structure at 80°C for 12 hours.

- Thermal Treatment: Place the dried structure in a tube furnace. Pyrolyze under N₂ atmosphere with the following ramp: RT → 250°C (1°C/min, hold 1h), 250°C → 800°C (5°C/min, hold 2h). Cool naturally to RT under N₂ flow.

- Catalyst Integration (Optional Post-Printing): Immerse the pyrolyzed carbon lattice in 0.1M AgNO₃ solution for 1 hour, then reduce under H₂/Ar (5%/95%) at 300°C for 2h to deposit Ag nanoparticles.

Protocol 2: SLA and Pyrolysis of a Microfluidic Carbon Electrode Objective: Create a high-resolution 3D carbon electrode with integrated flow channels. Materials: See "The Scientist's Toolkit" (Section 4). Procedure:

- Resin Preparation: In an amber vial, mix 70 wt% bisphenol A ethoxylate diacrylate, 25 wt% trimethylolpropane triacrylate, and 5 wt% Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide (photoinitiator). Stir in the dark until fully dissolved.

- Printing: Use a commercial or research SLA printer (405 nm wavelength). Slice the 3D model (e.g., a gyroid flow field with 300 µm channel width). Print with layer thickness of 25-50 µm.

- Post-Processing:

- Washing: Submerge the printed "green" part in isopropyl alcohol for 5 mins to remove uncured resin. Repeat with fresh IPA.

- Post-Curing: Cure the washed part under broad-spectrum UV light for 20 mins.

- Pyrolysis: Transfer the part to an alumina boat in a tube furnace. Use a slow pyrolysis profile under Ar: RT → 600°C (1°C/min, hold 1h), 600°C → 1100°C (2°C/min, hold 2h). Cool to RT at <5°C/min.

Visualized Workflows

Title: DIW Process Flow for Porous Carbon Electrodes

Title: SLA Process Flow for Porous Carbon Electrodes

Title: Research Pathway for 3D-Printed CO2 Electrodes

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Materials for DIW and SLA of Porous Carbon

| Material Category | Example Reagents | Function & Rationale |

|---|---|---|

| DIW Ink Polymers | Polyvinyl alcohol (PVA), Polyacrylonitrile (PAN) | Carbon precursor providing structural integrity and carbon yield after pyrolysis. |

| DIW Conductivity Additives | Graphene Oxide (GO), Carbon Nanotubes (CNTs) | Enhances electrical conductivity and mechanical strength of the ink and final carbon. |

| DIW Porogens | Polystyrene (PS) microspheres, Ammonium Bicarbonate | Sacrificial templates that volatilize during pyrolysis to create controlled micropores. |

| SLA Photopolymer Resins | Acrylate-based resins (e.g., Bisphenol A ethoxylate diacrylate) | Forms the 3D polymer matrix via photopolymerization; high carbon yield formulations are critical. |

| SLA Photoinitiators | Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide | Absorbs UV light to initiate the polymerization reaction of the resin. |

| Post-Processing Agents | Isopropyl Alcohol (IPA), N₂/Ar gas | IPA washes uncured resin (SLA). Inert gas (N₂/Ar) creates oxygen-free atmosphere for pyrolysis. |

| Catalyst Precursors | AgNO₃, Zn(NO₃)₂, Metal-Organic Frameworks | Source for electro-catalytically active sites (e.g., Ag, Zn) for CO₂ reduction on the carbon electrode. |

Within the context of 3D printing porous carbon electrodes for CO₂ conversion research, post-printing treatments are critical for transforming polymeric precursors into functional, porous, and catalytically active carbon architectures. This document provides detailed application notes and protocols for pyrolysis, activation, and functionalization, essential for tuning electrode properties such as surface area, pore structure, and surface chemistry to enhance electrochemical CO₂ reduction reaction (CO₂RR) performance.

Pyrolysis Protocol for 3D-Printed Carbon Precursors

Objective: To convert a 3D-printed thermosetting resin (e.g., SU-8, PI, or custom formulations) into a glassy carbon structure via controlled thermal decomposition in an inert atmosphere.

Detailed Protocol:

- Sample Preparation: Place the 3D-printed part in a ceramic or quartz boat. Ensure the part is stable and does not contact the boat walls excessively to allow uniform gas flow.

- Furnace Loading: Insert the boat into a tube furnace. Seal the furnace and begin purging with an inert gas (Ar or N₂) at a high flow rate (e.g., 500 sccm) for at least 30 minutes to eliminate oxygen.

- Pyrolysis Program:

- Ramp from room temperature to 350°C at 2°C/min. Hold for 60 minutes to allow for gradual devolatilization and prevent structural blistering.

- Ramp from 350°C to the target carbonization temperature (700°C – 1100°C) at 5°C/min.

- Hold at the target temperature for 120 minutes to ensure complete carbonization and graphitization.

- Allow the furnace to cool naturally to below 100°C under continuous inert gas flow before removing the sample.

- Post-Processing: The resulting carbon monolith may be fragile. Handle with care. Characterize yield, shrinkage (typically 20-40% linearly), and initial conductivity.

Table 1: Effect of Pyrolysis Temperature on Carbon Electrode Properties

| Pyrolysis Temp. (°C) | Linear Shrinkage (%) | BET Surface Area (m²/g) | Electrical Conductivity (S/cm) | Recommended Application |

|---|---|---|---|---|

| 700 | 20-25 | 10-50 | 1-10 | Structural support |

| 900 | 30-35 | 50-200 | 50-200 | General CO₂RR electrode |

| 1100 | 35-40 | 5-20 | 500-1000 | Conductive backbone for composites |

Chemical Activation Protocol for Porosity Enhancement

Objective: To significantly increase the specific surface area and pore volume of pyrolyzed 3D carbon electrodes using KOH chemical activation.

Detailed Protocol:

- Impregnation: Prepare a KOH solution in deionized water (mass ratio KOH: Carbon = 2:1 to 4:1). Submerge the pyrolyzed carbon electrode in the solution. Sonicate for 30 minutes, then let it impregnate for 6 hours under vacuum.

- Drying: Transfer the sample to an oven and dry at 120°C overnight.

- Thermal Activation: Place the dried sample in a tube furnace. Under a continuous N₂ flow (200 sccm), heat to 700-800°C at a ramp rate of 5°C/min. Hold for 60-90 minutes.

- Washing: Cool the sample under N₂. Carefully wash the activated carbon monolith sequentially with: 1M HCl to neutralize residual KOH, then copious amounts of deionized water until the effluent reaches neutral pH.

- Final Drying: Dry the washed sample at 120°C for 12 hours.

Table 2: Porosity Metrics Before and After KOH Activation

| Sample Condition | BET Surface Area (m²/g) | Total Pore Volume (cm³/g) | Micropore Volume (cm³/g) | Average Pore Width (nm) |

|---|---|---|---|---|

| Pyrolyzed at 900°C | 85 | 0.08 | 0.03 | ~3.5 |

| After KOH Activation | 2150 | 1.15 | 0.85 | ~2.1 |

Functionalization Protocol via Nitrogen-Doping

Objective: To incorporate nitrogen heteroatoms into the carbon lattice to modify electronic structure and create active sites for CO₂ adsorption and activation.

Detailed Protocol – Post-Pyrolysis Ammonia Treatment:

- Sample Preparation: Use a pyrolyzed or activated carbon electrode. Ensure it is thoroughly dried.

- Furnace Setup: Place the sample in a tube furnace. Connect gas lines for NH₃ and an inert gas (Ar).

- Functionalization Program:

- Purge the tube with Ar (200 sccm) for 20 minutes.

- Switch the gas flow to a mixture of NH₃/Ar (e.g., 20%/80%) at a total flow of 200 sccm.

- Ramp temperature to 500-700°C at 10°C/min.

- Hold for 2-4 hours to allow for nitrogen incorporation.

- Switch gas back to pure Ar and cool to room temperature.

- Characterization: Analyze surface atomic composition via XPS. Expect N-content of 2-10 at.%, with configurations of pyridinic-N, pyrrolic-N, and graphitic-N.

Experimental Workflow Visualization

Title: Workflow for 3D Printed Carbon Electrode Fabrication

Signaling Pathways in CO₂ Reduction on Functionalized Carbon

Title: Key CO₂ Reduction Reaction Pathways on Doped Carbon

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Post-Printing Carbon Electrode Processing

| Item | Function/Application | Key Consideration |

|---|---|---|

| High-Temperature Tube Furnace | Provides controlled atmosphere pyrolysis/activation. | Must have programmable temperature ramps and inert gas fittings. |

| Alumina or Quartz Boats | Holds samples during high-temperature treatment. | Chemically inert at temperatures >1000°C. |

| Anhydrous Inert Gas (Ar, N₂) | Creates oxygen-free environment during pyrolysis. | High purity (>99.99%) to prevent oxidation. |

| Potassium Hydroxide (KOH) Pellets | Chemical activating agent for porosity development. | Highly corrosive. Requires careful handling and acid neutralization. |

| Ammonia Gas (NH₃) / Urea | Source of nitrogen for heteroatom doping. | Toxic gas. Requires proper ventilation/scrubbing. Urea is a solid alternative. |

| Polymeric 3D-Printing Resin (e.g., SU-8, PI-based) | Carbon precursor. Determines initial geometry and carbon yield. | Must be a thermoset to retain structure during pyrolysis. |

| Electrochemical Cell (H-cell or Flow Cell) | Testing functionalized electrodes for CO₂RR. | Should have separate gas/liquid compartments for product analysis. |

Within the broader thesis on 3D-printed porous carbon electrodes for electrocatalytic CO₂ conversion, the incorporation of active sites via heteroatom doping and metal integration is paramount. This application note details contemporary strategies and protocols for engineering these sites to enhance selectivity and efficiency towards valuable products like CO, formate, and hydrocarbons.

Table 1: Performance Metrics of Heteroatom-Doped Porous Carbon Electrodes for CO₂RR

| Dopant | Precursor Material | Electrolyte | Main Product | Faradaic Efficiency (%) | Partial Current Density (mA/cm²) | Stability (hours) | Ref. Year |

|---|---|---|---|---|---|---|---|

| N | Chitosan-based 3D-PC | 0.1 M KHCO₃ | CO | 85 | 12.5 | 12 | 2023 |

| B, N | PANI-derived carbon | 0.5 M KHCO₃ | CO | 91 | 18.2 | 20 | 2024 |

| S | Lignin-derived 3D-PC | 0.1 M KCl | CO | 78 | 8.7 | 10 | 2023 |

| N, S | Carbon Black Ink | 0.1 M KHCO₃ | Formate | 65 | 5.5 | 15 | 2024 |

Table 2: Performance Metrics of Metal-Integrated Porous Carbon Electrodes for CO₂RR

| Metal | Integration Method | Support/Dopant | Main Product | Faradaic Efficiency (%) | Partial Current Density (mA/cm²) | Stability (hours) | Ref. Year |

|---|---|---|---|---|---|---|---|

| Cu | Electro-deposition | N-doped 3D-PC | C₂H₄ | 45 | 25.1 | 8 | 2024 |

| Sn | Wet Impregnation | S-doped Carbon | Formate | 89 | 15.3 | 30 | 2023 |

| Ag | In-situ pyrolysis | N-doped Gel | CO | 95 | 22.0 | 40 | 2024 |

| Cu-Sn | Co-deposition | B,N-doped Carbon | CO/Formate | 75 (CO), 20 (Formate) | 30.5 (total) | 25 | 2024 |

Experimental Protocols

Protocol 3.1: Synthesis of N, S Co-Doped 3D-Printable Carbon Ink

Objective: To create a viscoelastic ink for direct ink writing (DIW) containing N and S active sites. Materials: See Scientist's Toolkit. Procedure:

- Dissolve 1.0 g of chitosan and 0.5 g of thiourea in 20 mL of 2% (v/v) acetic acid solution. Stir for 6h at 60°C.

- Add 2.0 g of carbon black (Vulcan XC-72) and 0.1 g of nanofibrillated cellulose (binder) to the mixture. Homogenize using a shear mixer at 2000 rpm for 30 min.

- Concentrate the slurry at 70°C under stirring until a paste-like consistency suitable for 3D printing is achieved.

- Load ink into a syringe barrel and extrude through a conical nozzle (410 µm) using a 3D bioprinter. Print in a layer-by-layer fashion (0°/90° infill) to construct a 10x10x1 mm³ porous grid electrode.

- Freeze-dry the printed structure for 12h.

- Carbonize in a tubular furnace under N₂ atmosphere (100 sccm) with a thermal program: ramp 3°C/min to 800°C, hold for 2h, then cool naturally.

Protocol 3.2: Electrochemical Deposition of Cu Nanoparticles on Doped Carbon Electrodes

Objective: To decorate pre-doped 3D-printed carbon electrodes with Cu active sites for hydrocarbon production. Materials: See Scientist's Toolkit. Procedure:

- Prepare an electrolyte containing 0.05 M CuSO₄ and 0.1 M H₂SO₄.

- Use the 3D-printed, carbonized, and doped electrode as the working electrode. Assemble a standard three-electrode H-cell with a Pt mesh counter electrode and Ag/AgCl (sat. KCl) reference electrode.

- Perform electrochemical deposition via chronoamperometry at a constant potential of -0.6 V vs. Ag/AgCl for 300 seconds under gentle stirring.

- Rinse the electrode thoroughly with deionized water and dry under N₂ stream before CO₂RR testing.

Protocol 3.3: In-situ Pyrolysis for Ag-N-C Composite Synthesis

Objective: To synthesize a 3D-printed electrode with atomically dispersed Ag-Nₓ sites. Procedure:

- Prepare an ink by mixing 1.5 g of polyacrylonitrile (PAN, N source), 0.1 g of AgNO₃, and 0.05 g of phenanthroline (ligand) in 15 mL of DMF. Stir overnight.

- Add 1.0 g of silica templating agent (Ludox HS-40). Mix and concentrate.

- 3D print the desired structure as in Protocol 3.1.

- Stabilize the printed object in air at 250°C for 1h.

- Pyrolyze in Ar at 900°C for 2h.

- Etch the silica template using 10% HF solution for 24h, followed by extensive washing and drying.

Diagrams & Workflows

Title: Workflow for 3D Printed Doped Carbon Electrode

Title: Metal Integration and CO2RR Testing Pathway

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions

| Item | Function/Brief Explanation | Example Supplier/Catalog |

|---|---|---|

| Chitosan | Biopolymer precursor for N-doped carbon; provides viscoelasticity for 3D printing inks. | Sigma-Aldrich, 448877 |

| Thiourea | Common precursor for simultaneous N and S doping during pyrolysis. | Sigma-Aldrich, T7876 |

| Polyacrylonitrile (PAN) | Polymer precursor for creating high N-content carbon structures. | Sigma-Aldrich, 181315 |

| Boric Acid | Precursor for B-doping, modifies electron density of carbon matrix. | Fisher Scientific, A73-500 |

| Carbon Black (Vulcan XC-72) | Conductive carbon filler for ink formulation. | FuelCellStore, XC-72R |

| Nanofibrillated Cellulose (NFC) | Sustainable rheology modifier and binder for 3D printable inks. | CelluForce, NCC-1 |

| Copper(II) Sulfate Pentahydrate | Source of Cu²⁺ ions for electrochemical deposition of Cu active sites. | Sigma-Aldrich, 209198 |

| Silver Nitrate | Precursor for Ag nanoparticle or single-atom site integration. | Sigma-Aldrich, 209139 |

| Tin(II) Chloride Dihydrate | Precursor for Sn deposition/formate-selective catalysts. | Sigma-Aldrich, 208256 |

| Potassium Bicarbonate (KHCO₃) | Standard CO₂-saturated electrolyte for CO₂ reduction reaction (CO₂RR). | Sigma-Aldrich, 237205 |

| Nafion Perfluorinated Resin Solution | Binder and proton conductor for electrode preparation. | Sigma-Aldrich, 527483 |

| Polytetrafluoroethylene (PTFE) Binder | Hydrophobic binder for gas diffusion electrode preparation in flow cells. | Sigma-Aldrich, 665800 |

The performance of 3D-printed porous carbon electrodes in electrocatalytic CO₂ reduction reactions (CO2RR) is dictated by a triad of interdependent properties: morphology (which influences mass transport and active site availability), porosity (which governs surface area and diffusion pathways), and surface chemistry (which determines catalytic activity and selectivity). This application note details integrated protocols for characterizing these properties, providing a foundational toolkit for researchers developing next-generation CO2 conversion systems.

Scanning/Transmission Electron Microscopy (SEM/TEM): Morphology & Structure

Application Note: SEM provides topographical and compositional contrast of the 3D printed macro/micro-structure, while HR-TEM and SAED reveal the atomic-scale crystallinity and defect structures critical for catalysis.

Table 1: Representative SEM/TEM Data for 3D-Printed Carbon Electrodes

| Sample ID | Print Technique | Avg. Filament Diameter (SEM) | Pore Size Range (SEM) | Lattice Fringe Spacing (HR-TEM) | Identified Defects (TEM/SAED) |

|---|---|---|---|---|---|

| CP-PLA-900 | Direct Ink Writing (DIW) | 150 ± 20 µm | 10-50 µm | 0.34 nm (graphitic) | Amorphous regions, few-layer graphene |

| rGO-ZnO-700 | DIW, sacrificial template | 200 ± 30 µm | 0.5-5 µm (meso) | 0.26 nm (ZnO (002)) | Edge defects, oxygen vacancies |

| CNT-Fe-N-C | Stereolithography (SLA) | N/A (monolithic) | 100 nm-2 µm | 0.21 nm (Fe₃C (121)) | Single-atom Fe sites, carbon vacancies |

N₂ Physisorption (BET): Porosity & Surface Area

Application Note: BET analysis quantifies the specific surface area, pore volume, and pore size distribution (PSD). A hierarchical pore network (macro/meso/micro) is ideal for CO2RR, facilitating reactant diffusion and providing abundant active sites.

Table 2: BET Analysis of Pyrolyzed 3D-Printed Carbon Electrodes

| Sample ID | Sʙᴇᴛ (m²/g) | Total Pore Volume (cm³/g) | Micropore Volume (cm³/g) | Avg. Pore Width (nm) | PSD Peak (nm) |

|---|---|---|---|---|---|

| CP-PLA-900 | 650 | 0.45 | 0.18 | 2.8 | 0.7, 3.5 |

| rGO-ZnO-700 | 420 | 0.78 | 0.05 | 7.4 | 4.0, 30 |

| CNT-Fe-N-C | 890 | 1.20 | 0.25 | 5.4 | 0.9, 5.0, 100 |

X-ray Photoelectron Spectroscopy (XPS): Surface Chemistry & States

Application Note: XPS identifies elemental composition, chemical bonding, and dopant states on the top 5-10 nm of the electrode. Key for correlating N-/O- species and metal states (e.g., pyridinic N, M-Nx) with CO2RR activity/selectivity.

Table 3: XPS Surface Analysis of Doped Carbon Electrodes

| Sample ID | Atomic % C | Atomic % O | Atomic % N | N1 Species (% of N) | Key Metal State |

|---|---|---|---|---|---|

| CP-PLA-900 | 89.2 | 10.8 | 0.0 | N/A | N/A |

| rGO-ZnO-700 | 78.5 | 20.1 | 1.4 | Graphitic (45%) | Zn²⁺ (1022.2 eV) |

| CNT-Fe-N-C | 91.3 | 4.5 | 3.8 | Pyridinic (38%), Fe-Nₓ (19%) | Fe²⁺ (711.1 eV) |

Experimental Protocols

Protocol: SEM/TEM Analysis of 3D-Printed Electrodes

A. Sample Preparation:

- SEM: Securely mount a small fragment of the electrode (<5mm) on an Al stub using conductive carbon tape. Sputter-coat with 5 nm Au/Pd using a low-current, short-duration cycle (~30 seconds) to minimize pore masking.

- TEM: Mechanically crush a filament and disperse in ethanol via 10-minute ultrasonication. Drop-cast the supernatant onto a lacey carbon Cu grid (300 mesh). Dry under an IR lamp.

B. Data Acquisition:

- SEM (e.g., Zeiss GeminiSEM 460): Operate at 3-5 kV, using the In-lens SE detector for high-resolution surface topography. For cross-sections, use the SE2 detector at 5-10 kV.

- TEM/HR-TEM (e.g., FEI Talos F200X): Operate at 200 kV. Acquire SAED patterns from multiple regions to assess crystallinity. Use high-resolution imaging to measure lattice fringes. Perform EDS mapping for elemental distribution (C, O, N, metals).

Protocol: N₂ Physisorption (BET) for Hierarchical Porosity

A. Sample Pretreatment (Degassing):

- Weigh 80-120 mg of crushed electrode material in a clean 9 mm cell.

- Degas on a station (e.g., Micromeritics VacPrep) at 150°C for 12 hours under dynamic vacuum (<10 µmHg) to remove physisorbed contaminants.

B. Isotherm Measurement (Analysis):

- Transfer the degassed cell to the analysis port (e.g., Micromeritics 3Flex).

- Immerse the sample cell in liquid N₂ (77 K). Collect the adsorption/desorption isotherm across a relative pressure (P/P₀) range of 0.001 to 0.995.

- Data Analysis: Use dedicated software (e.g., ASiQwin).

- Sʙᴇᴛ: Apply the BET equation in the linear range (typically P/P₀ = 0.05-0.25).

- Total Pore Volume: Estimate from volume adsorbed at P/P₀ ≈ 0.99.

- Micropore Volume: Apply t-plot or NLDFT methods.

- Pore Size Distribution: Apply the BJH model to the desorption branch for meso/macropores; use NLDFT for micropores.

Protocol: XPS Surface Analysis of Catalytic Sites

A. Sample Mounting & Transfer:

- Mount a flat sample fragment (~5x5 mm) on a stainless steel holder using double-sided Cu tape. Do not use conductive coatings.

- Transfer to the XPS introduction chamber swiftly (<5 min air exposure) and evacuate to <5 x 10⁻⁷ Torr prior to entry into the analysis chamber.

B. Spectral Acquisition & Processing (e.g., Thermo Scientific K-Alpha+):

- Use a monochromatic Al Kα source (1486.6 eV), spot size 400 µm, flood gun for charge neutralization.

- Acquire a survey spectrum (pass energy 150 eV, step 1.0 eV).

- Acquire high-resolution regions for C 1s, O 1s, N 1s, and relevant metals (e.g., Fe 2p, Zn 2p) (pass energy 20-50 eV, step 0.1 eV).

- Data Processing (Avantage Software):

- Calibrate spectra to the C 1s peak (C-C/C=C) at 284.8 eV.

- Perform Shirley or Smart background subtraction.

- Deconvolute high-resolution peaks using a mix of Gaussian-Lorentzian (GL) line shapes (typically 70% G, 30% L). Constrain spin-orbit doublets with appropriate separation and area ratios.

Visualized Workflows & Relationships

Title: Characterization Triad for Carbon Electrodes

Title: Sequential Characterization Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Reagent/Material | Function in Characterization | Key Consideration for CO2RR Electrodes |

|---|---|---|

| Conductive Carbon Tape | Mounts non-powder samples for SEM. Provides electrical grounding to prevent charging. | Use minimal amount to avoid obscuring pore structure at the sample base. |

| Lacey Carbon TEM Grids | Supports crushed powder samples for TEM imaging. The "lacey" structure provides ample void space for analysis. | More suitable than continuous carbon films for porous, irregular carbon materials. |

| Liquid Nitrogen (LN₂) | Cryogenic bath (77 K) for BET isotherm measurement. Provides the temperature for N₂ physisorption. | Purity is critical. Ensure steady boil-off during analysis for stable P/P₀. |

| Au/Pd Target (99.99%) | Source material for sputter-coating non-conductive samples for SEM. | Ultra-thin coating (<5 nm) is vital to preserve nanoscale surface features and pore openings. |

| XPS Charge Neutralizer (Flood Gun) Filament | Provides low-energy electrons/ions to neutralize positive charge buildup on insulating samples. | Correct flood gun settings are essential for accurate peak positioning on porous, non-conductive carbons. |

| Certified Reference Materials (e.g., Al₂O₃, Carbon Black) | Calibration standards for BET surface area and pore size. | Use standards with known Sʙᴇᴛ and porosity to validate instrument and method performance. |

| High-Purity Ethanol (Anhydrous) | Solvent for dispersing powder samples for TEM grid preparation. | Prevents contamination and ensures good dispersion of hydrophobic carbon materials. |

Overcoming Practical Hurdles: Solving Common Issues in Electrode Performance and Durability

Introduction and Thesis Context Within the broader thesis on 3D printing porous carbon electrodes for electrochemical CO₂ conversion research, mechanical robustness is a critical, non-negotiable parameter. The electrode's structural integrity and layer adhesion directly dictate its functional longevity, electrical conductivity stability under operational stress, and ultimately, the reproducibility of catalytic CO₂ reduction data. This document provides targeted Application Notes and Protocols to diagnose, quantify, and mitigate mechanical failures in 3D-printed carbon architectures.

1. Quantitative Data on Failure Modes and Interventions Table 1: Common Mechanical Failure Modes in 3D-Printed Carbon Electrodes

| Failure Mode | Primary Cause | Quantitative Impact | Diagnostic Method |

|---|---|---|---|

| Interlayer Delamination | Insufficient bonding between deposited filaments; thermal stress. | Up to 80% reduction in through-plane conductivity. | Cross-sectional SEM, tensile testing (Z-axis). |

| Intralayer Fracture | Incomplete pyrolysis; weak particle fusion. | Flexural strength < 5 MPa. | 3-point bending test, nanoindentation. |

| Macro-Pore Collapse | Inadequate support during pyrolysis; low green strength. | Pore volume reduction > 50%. | Mercury porosimetry, micro-CT scanning. |

| Warping/Cracking | High thermal stress gradient during pyrolysis. | Dimensional deviation > 20% from design. | Digital image correlation (DIC). |

Table 2: Efficacy of Common Reinforcement Strategies

| Intervention Strategy | Material/Protocol Modifications | Result on Flexural Strength | Effect on Electrical Conductivity |

|---|---|---|---|

| Polymer Binder Optimization | Increase high-Tₑ thermoplastic (e.g., PAN) content from 10% to 25% wt. | Increase from 4.2 ±0.8 to 12.5 ±1.5 MPa. | Decrease from 120 to 85 S/cm. |

| Carbon Nanotube (CNT) Reinforcement | Add 2% wt. MWCNTs to feedstock. | Increase by ~150%. | Increase by ~200%. |

| Interlayer Remelting | Use focused IR laser post-deposition per layer. | Increase interlayer adhesion by ~300%. | Negligible negative impact. |

| Graded Pyrolysis Profile | Slow ramp (1°C/min) through Tₑ of binder (200-400°C). | Reduce cracks by >90%. | Preserves conductive network. |

2. Experimental Protocols

Protocol 2.1: Quantifying Interlayer Adhesion via Z-Axis Tensile Test Objective: To measure the bond strength between successive layers of a 3D-printed carbon electrode. Materials: 3D-printed electrode sample (e.g., 10x10x5 mm), epoxy adhesive (high-temperature), flat metal mounting plates, universal testing machine (UTM). Procedure:

- Adhere the sample's top and bottom surfaces to clean metal plates using a thin, uniform layer of epoxy. Cure fully per manufacturer instructions.

- Mount the assembly vertically (Z-axis) in the UTM, ensuring aligned, uniaxial tension.

- Apply a constant displacement rate of 0.5 mm/min until failure.

- Record the maximum force (F_max) at point of failure.

- Calculate adhesion strength: σ = F_max / A, where A is the cross-sectional area (x*y dimensions).

- Inspure failure surface via SEM to determine failure mode (cohesive within layer or adhesive at interface).

Protocol 2.2: Optimizing Feedstock for Enhanced Green Strength Objective: To formulate a printable composite with high post-printing, pre-pyrolysis ("green") strength. Materials: Carbon precursor (e.g., activated carbon powder, ~50 nm), primary binder (Polyacrylonitrile, PAN, MW ~150,000), secondary binder/plasticizer (Polyethylene Glycol, PEG 400), solvent (N,N-Dimethylformamide, DMF), dispersant (BYK-110), mixer (planetary centrifugal). Procedure:

- Prepare a 12% w/v solution of PAN in DMF by stirring at 60°C for 6 hours.

- In a planetary mixer, combine: 60 wt.% carbon powder, 25 wt.% PAN solution (solid basis), 10 wt.% PEG 400, 5 wt.% solvent for rheology, 0.5 wt.% dispersant.

- Mix at 2000 rpm for 10 minutes, pause to scrape walls, then mix for another 5 minutes until a homogeneous, putty-like paste is achieved.

- Load into syringe barrel, degas in vacuum desiccator for 30 minutes.

- Print test structures (e.g., ASTM D695 compression specimens).

- Qualitatively assess "green" strength by resistance to deformation under gentle fingertip pressure.

3. Visualization of Workflow and Relationships

Diagram 1: Integrated Workflow for Robust Electrode Fabrication (83 chars)

Diagram 2: Failure Root Causes and Targeted Solutions (77 chars)

4. The Scientist's Toolkit: Research Reagent Solutions Table 3: Essential Materials for Mechanically Robust Carbon Electrode R&D

| Material/Reagent | Function in Research | Key Consideration |

|---|---|---|

| Polyacrylonitrile (PAN) | Primary polymeric binder. Provides green strength and converts to conductive carbon during pyrolysis. | Molecular weight distribution dictates viscosity and carbon yield. |

| Multi-Walled Carbon Nanotubes (MWCNTs) | Nano-reinforcement. Bridges particles and cracks, enhancing toughness & electrical pathways. | Functionalization (e.g., carboxyl) improves dispersion in feedstock. |

| N,N-Dimethylformamide (DMF) | Polar aprotic solvent. Dissolves PAN and wets carbon particles for homogeneous paste. | High purity required to prevent residue that alters pyrolysis. |

| Polyethylene Glycol (PEG 400) | Plasticizer & pore former. Improves printability and modulates final porosity upon pyrolysis. | Volatilizes cleanly; molecular weight affects plasticization vs. burnout. |

| Rheology Modifier (e.g., Fumed Silica) | Controls viscoelasticity. Prevents paste slumping post-extrusion for shape fidelity. | Hydrophobic type preferred for carbon/polymer systems. |

| High-Temp Epoxy (e.g., Ceramabond) | For mechanical fixture. Bonds electrodes to test platens without infiltrating pores. | Must withstand pyrolysis temperatures if used pre-firing. |

Within the context of 3D printing porous carbon electrodes for CO2 conversion, managing pore architecture is critical. The electrochemical reduction of CO2 requires a high surface area for catalyst loading, efficient mass transport of gaseous/reactant species, and rapid electron transfer. A hierarchical pore structure, integrating micro- (<2 nm), meso- (2-50 nm), and macropores (>50 nm), is ideal. Micropores maximize specific surface area for catalyst dispersion, mesopores facilitate ion transport, and macropores ensure bulk gas diffusion. However, during synthesis, drying, and pyrolysis, capillary forces can cause pore collapse, destroying this delicate architecture. This Application Note details protocols to prevent collapse and optimize the pore size distribution for enhanced electrochemical CO2 reduction reaction (CO2RR) performance.

Application Notes & Protocols

Protocol 1: Synthesis of Hierarchically Porous 3D Printable Carbon Inks

Objective: To formulate a shear-thinning ink containing a carbon precursor, porogens, and a structural additive to yield a controlled triple-modal pore distribution post-printing and pyrolysis.

Key Principle: Use a combination of sacrificial templating (for macropores), phase separation (for mesopores), and chemical activation (for micropores).

Materials (Research Reagent Solutions):

| Reagent/Material | Function | Supplier Example (for reference) |

|---|---|---|

| Polyacrylonitrile (PAN) | Primary carbon precursor. Provides structural integrity during pyrolysis. | Sigma-Aldrich |

| N,N-Dimethylformamide (DMF) | Solvent for PAN. Facilitates ink formulation and phase separation. | Fisher Scientific |

| Polymethyl methacrylate (PMMA) microspheres (5 µm) | Sacrificial macro-porogen. Creates macropores via thermal decomposition. | Microbeads AS |

| Pluronic F-127 | Soft template / surfactant. Self-assembles to create mesopores; aids ink rheology. | BASF |

| Zinc Chloride (ZnCl₂) | Chemical activating agent. Generates micropores via high-temperature etching. | Alfa Aesar |

| Carbon Black (Vulcan XC-72) | Conductive additive. Enhances electrical conductivity of the carbon matrix. | Cabot Corporation |

Detailed Methodology:

- Ink Preparation: Dissolve 10 wt% PAN in DMF under magnetic stirring at 60°C for 6 hours.

- Porogen Incorporation: To the cooled solution, sequentially add:

- 20 wt% (relative to PAN) of PMMA microspheres. Stir gently for 1 hour.

- 15 wt% (relative to PAN) of Pluronic F-127. Stir for 2 hours.

- 50 wt% (relative to PAN) of ZnCl₂. Stir until fully dissolved.

- 5 wt% (relative to PAN) of Carbon Black. Sonicate for 30 minutes to ensure dispersion.