UHV Surface Verification in Pharma: A Technical Comparison of LEED vs AES for Critical Cleanliness

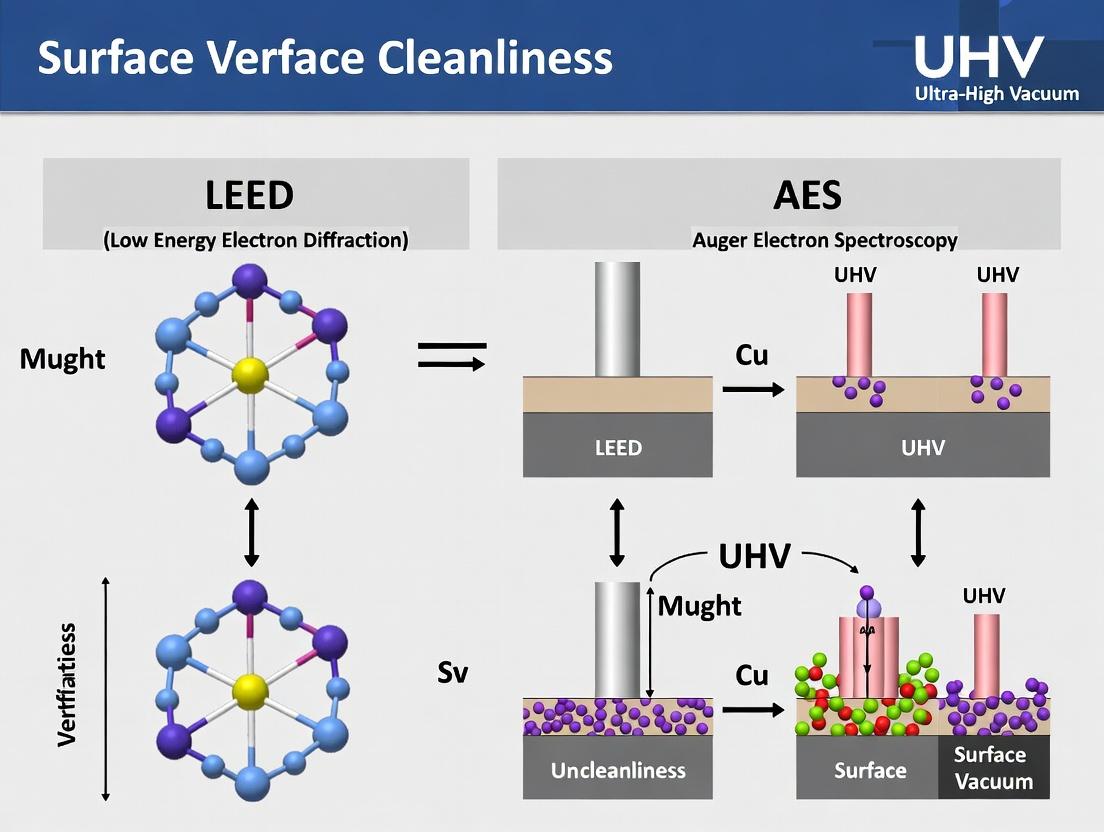

This article provides a comprehensive technical analysis of Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for verifying ultra-high vacuum (UHV) surface cleanliness in biomedical and pharmaceutical research.

UHV Surface Verification in Pharma: A Technical Comparison of LEED vs AES for Critical Cleanliness

Abstract

This article provides a comprehensive technical analysis of Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for verifying ultra-high vacuum (UHV) surface cleanliness in biomedical and pharmaceutical research. Targeting researchers, scientists, and drug development professionals, it explores the foundational principles of both techniques, details their practical application in ensuring contamination-free surfaces for sensitive experiments, addresses common troubleshooting and optimization challenges, and delivers a comparative validation of their performance against other surface science tools. The scope encompasses methodological workflows, data interpretation, and the critical role of surface verification in ensuring the integrity of materials science and drug-device interface studies.

Foundations of Surface Science: Understanding LEED and AES Principles for UHV Cleanliness

The Critical Role of Surface Cleanliness in Biomedical Device Development and Advanced Materials

Surface cleanliness is a deterministic factor for the performance and biocompatibility of biomedical devices and advanced materials. Contaminant layers, even at sub-monolayer levels, can drastically alter surface energy, corrosion resistance, and protein adsorption profiles, leading to device failure or adverse biological responses. Within ultra-high vacuum (UHV) research and development, two primary surface-sensitive techniques are employed for cleanliness verification: Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES). This guide compares their performance within the context of advanced biomedical material development.

Comparison Guide: LEED vs. AES for UHV Surface Analysis

Table 1: Core Technique Comparison

| Feature | Low-Energy Electron Diffraction (LEED) | Auger Electron Spectroscopy (AES) |

|---|---|---|

| Primary Information | Surface crystallographic structure & long-range order. | Elemental composition (except H, He) & chemical state. |

| Detection Limit | Indirect; disorder from ~1% of a monolayer. | Direct; typically 0.1 - 1.0 atomic %. |

| Spatial Resolution | Low (~1 mm). Typical for macro-area analysis. | High (< 10 nm possible with SAM). |

| Sample Damage Risk | Very low (typical beam currents ~1-100 nA). | Moderate (localized electron beam heating/desorption). |

| Key Strength for Cleanliness | Verifies atomic-level structural perfection. | Identifies and quantifies specific contaminant elements. |

| Key Limitation for Cleanliness | Cannot identify chemical nature of contaminants. | Poor sensitivity for light elements (C, O) on heavy substrates. |

Table 2: Experimental Data from a Titanium Alloy (Ti-6Al-4V) Study

| Analysis Parameter | LEED Results | AES Results | Interpretation |

|---|---|---|---|

| As-Received Surface | Diffuse background, no clear spots. | Strong C, O peaks; weak Ti, Al signals. | Amorphous carbonaceous/oily layer >5 nm thick. |

| After Ar+ Sputtering | Sharp (1x1) hexagonal pattern. | C peak reduced to ~15 at%, O ~45 at%, Ti increased. | Ordered Ti surface achieved, but persistent oxide & carbon. |

| After UHV Annealing at 800°C | Sharp, reconstructed patterns. | C < 5 at%, O ~30 at% (subsurface), Ti dominant. | Thermally cleaned surface; oxygen diffuses into bulk. |

Experimental Protocols

Protocol 1: Combined LEED/AES Analysis of Implant Surfaces

- Sample Mounting: Secure the biomedical sample (e.g., polished Ti alloy, stainless steel) on a UHV-compatible sample holder using tantalum clips.

- UHV Introduction: Transfer sample into the analysis chamber (base pressure ≤ 5×10⁻¹⁰ mbar).

- Initial Survey (AES): Acquire a survey spectrum (e.g., 20 eV to 2000 eV) from a representative ~500 µm area. Use primary beam: 10 keV, 10 nA.

- Initial Structural Check (LEED): Attempt LEED observation at electron energies 50-200 eV. Note pattern quality.

- In-situ Cleaning: Perform sequential Ar⁺ sputtering (1-3 keV, 15-30 minutes, sample current ~2 µA/cm²) with concurrent annealing up to 600°C (material dependent).

- Post-Cleaning Analysis: Iterate between AES (quantitative atomic% via sensitivity factors) and LEED until contaminant levels are minimized and a clear diffraction pattern is observed.

- Data Correlation: Correlate the reduction of AES carbon/oxygen signals with the emergence and sharpening of LEED patterns.

Protocol 2: Contamination Monitoring During Functionalization

- Establish Baseline: Clean sample as per Protocol 1 and record reference AES spectrum and LEED pattern.

- Ex-situ Functionalization: Remove sample from UHV; apply surface modification (e.g., silanization, peptide coating) under controlled (but non-UHV) environment.

- Re-introduction Analysis: Re-insert sample into UHV. Perform AES survey and high-resolution scans on key elements (C, N, O, substrate signals).

- Assessment: Calculate the increase in carbon signal and the attenuation of substrate signals to estimate coating thickness/coverage. LEED will typically show pattern extinction, confirming the presence of an amorphous adlayer.

Visualization of Method Selection

Title: Decision Workflow for LEED vs AES Surface Analysis

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for UHV Surface Cleanliness Studies

| Item | Function & Rationale |

|---|---|

| UHV-Compatible Samples | Pre-polished coupons of materials (Ti, 316L SS, CoCr, Silicon). Must withstand high-temperature annealing. |

| High-Purity Argon Gas (99.9999%) | Source gas for ion sputter guns. High purity prevents implantation of new contaminants during cleaning. |

| UHV-Compatible Solvents | e.g., HPLC-grade isopropanol, acetone. For initial ex-situ degreasing to remove gross contamination. |

| Degassed Tantalum Foil/Clips | For sample mounting. Must be pre-outgassed to prevent being a contamination source in UHV. |

| Standard Reference Samples | e.g., Clean single crystal silicon (with native oxide) or gold. Used for instrument function verification. |

| Ion Sputter Gun (Ar+ Source) | Integrated into UHV system. Provides in-situ cleaning via physical sputtering of surface atoms. |

| Direct/Indirect Sample Heater | Capable of heating samples to ≥1000°C. Enables thermal desorption of contaminants and surface reconstruction. |

| Electron Gun & Hemispherical Analyzer | Core components of AES system for electron excitation and energy-resolved electron detection. |

| LEED Optics (Screen, Gun, Grids) | Integrated reverse-view optics for displaying elastically backscattered electron diffraction patterns. |

Thesis Context: Within the field of ultra-high vacuum (UHV) surface science, verifying surface cleanliness and atomic order is paramount. This guide compares Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) as complementary but distinct techniques for this purpose, focusing on LEED's unique ability to probe surface crystallography.

LEED vs. AES: Core Principles and Comparison

LEED and AES are foundational UHV techniques, but they provide fundamentally different information.

| Feature | Low-Energy Electron Diffraction (LEED) | Auger Electron Spectroscopy (AES) |

|---|---|---|

| Primary Information | Long-range surface crystallography, unit cell size & symmetry, surface order/disorder. | Surface chemical composition (elements except H, He), cleanliness verification. |

| Probing Mechanism | Elastic backscattering of low-energy electrons (20-200 eV). Wave interference creates diffraction patterns. | Inelastic scattering & core-hole decay. Measurement of characteristic Auger electron kinetic energies. |

| Data Output | Diffraction pattern (reciprocal space image). | Electron energy spectra (intensity vs. kinetic energy). |

| Key Metrics | Spot sharpness, background intensity, spot positions. | Peak positions (for element ID), peak heights/areas (for quantification). |

| Sensitivity | Extremely sensitive to atomic order and periodicity. Insensitive to amorphous contaminants. | Extremely sensitive to atomic composition (~0.1-1 at. %). Less sensitive to order. |

| Main Use in Cleanliness Verification | Verifies the structural quality of the substrate (e.g., a sharp (1x1) pattern). A dirty surface often shows high background or extra spots. | Directly identifies and quantifies chemical contaminants (e.g., C, O, S). |

Experimental Comparison: Verifying a Clean Si(100) Surface

Protocol 1: AES for Chemical Cleanliness Verification

- Sample Mounting: Install the Si sample on a UHV-compatible manipulator with heating capability.

- UHV Preparation: Pump system to base pressure (< 5 x 10⁻¹⁰ mbar).

- Electron Gun Alignment: Align a coaxial electron gun (typical beam: 3-10 keV, 10 nA-1 µA, ~100 nm spot) with the sample surface.

- Spectrum Acquisition: Sweep the analyzer's energy pass window (e.g., from 50 eV to 1000 eV kinetic energy) while collecting the first derivative (dN(E)/dE) of the electron energy distribution to enhance Auger peaks.

- Data Analysis: Identify peaks via known kinetic energies: Si LVV (~92 eV), O KLL (~503 eV), C KLL (~272 eV).

- Cleanliness Criterion: A surface is considered chemically clean when the peak-to-peak heights of major contaminant signals (C, O) are ≤ 1% of the dominant substrate peak (Si).

Protocol 2: LEED for Crystallographic Order Verification

- Post-AES Verification: Use the same sample prepared for AES.

- LEED Setup: Position the sample in front of a display-type LEED optics (typically 4-grid). The system consists of a fluorescent screen, biased grids, and an electron gun.

- Electron Beam Conditions: Direct a collimated, monochromatic electron beam (typically 50-150 eV, current ~1-100 nA) at normal incidence onto the sample.

- Diffraction Pattern Observation: Apply retardation voltages to the grids to allow only elastically scattered electrons to reach the screen. The resulting pattern is a direct image of the surface's reciprocal lattice.

- Pattern Analysis: For a clean, well-ordered Si(100) surface, expect a sharp (2x1) reconstruction pattern due to dimerization. Assess spot sharpness, background intensity, and presence of reconstruction spots versus a simple (1x1) pattern.

- Order Criterion: A high-quality surface shows bright, sharp diffraction spots on a low-background screen.

Quantitative Comparison of LEED and AES Data

The table below presents typical experimental data from a study preparing a clean nickel (Ni(100)) surface through cycles of sputtering and annealing.

| Condition | AES Peak-to-Peak Ratio (C/Ni, O/Ni) | LEED Pattern Observation | Conclusion |

|---|---|---|---|

| As-Inserted | C: 0.45, O: 0.60 | No discernible spots; high diffuse background. | Heavily contaminated, disordered surface. |

| After Sputter (1 cycle) | C: 0.15, O: 0.10 | Faint, diffuse (1x1) spots; very high background. | Residual contaminants; poor crystallinity. |

| After Anneal (700°C) | C: 0.03, O: 0.02 | Bright, sharp (1x1) spots; low background. | Chemically clean and well-ordered surface. |

| After Brief Air Exposure | C: 0.25, O: 0.40 | High background, very faint spots. | Rapid contamination degrades both chemistry and order. |

The Scientist's Toolkit: Essential Research Reagent Solutions for UHV Surface Science

| Item | Function / Explanation |

|---|---|

| UHV System (≤10⁻¹⁰ mbar) | Provides contamination-free environment where surface lifetimes are hours to days, enabling accurate analysis. |

| Ion Sputtering Gun (Ar⁺) | Supplies inert gas ions (typically Ar⁺ at 0.5-5 keV) for physical removal of surface contaminants via momentum transfer. |

| Sample Heater (e-beam or radiative) | Allows thermal annealing to heal sputter damage, induce reconstruction, and promote surface diffusion for ordering. |

| LEED Optics (4-Grid) | Integrated electron gun and display system for visualizing the surface reciprocal lattice via elastic backscattering. |

| Cylindrical Mirror Analyzer (CMA) or Concentric Hemispherical Analyzer (CHA) | High-sensitivity electron energy filter for collecting Auger electron spectra to determine chemical composition. |

| Standard Reference Samples (e.g., Au foil) | Provides known, clean surfaces (Au(111)) for instrument calibration and energy scale verification. |

Visualization: UHV Surface Analysis Workflow

Title: Workflow for UHV Surface Cleanliness and Order Verification

Visualization: Information Yield from LEED vs. AES

Title: Physical Principles and Data Output of LEED and AES

In the context of Ultra-High Vacuum (UHV) surface cleanliness verification, researchers must choose between powerful analytical techniques. This guide compares Auger Electron Spectroscopy (AES) with Low-Energy Electron Diffraction (LEED) for surface analysis, focusing on their efficacy in identifying elemental composition and contaminants—a critical concern in fields like semiconductor fabrication and pharmaceutical device development.

Core Physics of AES

Auger Electron Spectroscopy (AES) functions by focusing a primary electron beam (typically 3-10 keV) onto a solid surface in UHV. This beam ionizes a core-level electron from a target atom. An electron from a higher energy level fills this vacancy, and the released energy ejects a third electron—the Auger electron. The kinetic energy of this ejected Auger electron is characteristic of the parent element, enabling qualitative and quantitative analysis of the top 2-10 nanometers of the surface.

Performance Comparison: AES vs. LEED for Cleanliness Verification

While both AES and LEED are UHV surface science techniques, their primary functions differ significantly. LEED excels at determining surface crystalline structure and ordering, whereas AES is optimized for direct elemental identification and contaminant detection.

Table 1: Core Analytical Capabilities Comparison

| Feature | Auger Electron Spectroscopy (AES) | Low-Energy Electron Diffraction (LEED) |

|---|---|---|

| Primary Output | Elemental composition (all except H, He), chemical state hints. | Surface crystallographic structure, symmetry, unit cell size. |

| Detection Capability | Direct detection of contaminant atoms (C, O, S, etc.). | Indirect; infers cleanliness from quality of diffraction pattern. |

| Information Depth | 2-10 nm (escape depth of Auger electrons). | 0.5-1 nm (very surface sensitive due to low e- energy). |

| Lateral Resolution | Excellent (~10 nm in SAM mode). | Poor (beam diameter ~0.5-1 mm). |

| Quantification | Semi-quantitative (accuracy ~20-30% atomic). | Not applicable for composition. |

| Best For | Identifying what contaminants are present. | Assessing if the surface is atomically ordered/clean. |

Table 2: Supporting Experimental Data from UHV Surface Studies

| Experiment Objective | AES Results | LEED Results | Conclusion |

|---|---|---|---|

| Verify Si(100) wafer cleaning | Detected 0.8 at.% carbon, 0.2 at.% oxygen post-anneal. | Showed sharp (2x1) reconstruction pattern. | AES confirms trace contaminants; LEED confirms ordered surface. |

| Assess metal surface oxidation | Identified increasing O KLL peak; metal peak attenuation. | Pattern degraded and disappeared as oxide amorphous layer grew. | AES quantified oxide growth; LEED signaled loss of crystalline order. |

| Map particulate contamination | SAM image showed 50nm carbon-rich particle on Ni surface. | No spatial information on contaminant; overall pattern was weak. | AES directly imaged and identified the contaminant source. |

Experimental Protocols for UHV Surface Verification

Protocol 1: Combined AES/LEED Analysis of Surface Cleanliness

- Sample Introduction: Load sample into UHV chamber (< 10⁻⁹ mbar).

- Initial LEED: Acquire a LEED pattern at electron energies 50-150 eV to establish baseline surface order.

- AES Survey Scan: Using a 10 keV, 10 nA primary beam, acquire a survey spectrum from 20 eV to 2000 eV.

- Data Analysis: Identify all elements present from characteristic Auger peaks (e.g., C KLL at ~272 eV, O KLL at ~503 eV).

- Sputter Cleaning: Use inert gas ion sputtering (Ar⁺, 1 keV) to remove surface layers.

- Iterative Measurement: Repeat steps 2 and 3 until AES shows contaminant peaks are minimized and LEED shows a sharp, well-defined pattern.

- Quantification: Use relative sensitivity factors to calculate approximate atomic concentrations from AES peak-to-peak heights in derivative spectrum.

Protocol 2: Contaminant Depth Profiling via AES

- Surface Measurement: Acquire high-resolution AES spectrum of key element peaks (e.g., C, O, substrate).

- Ion Sputtering: Begin controlled etching with a focused Ar⁺ ion gun (typical 1-5 keV).

- Cyclic Analysis: Interrupt sputtering at fixed time intervals to acquire AES spectra at the same spot.

- Data Compilation: Plot atomic concentration (from AES) vs. sputter time (converted to depth using a calibration standard).

- Interpretation: Determine if contaminants are surface-adventitious or have diffused into the bulk.

Visualization of AES Process and Workflow

Title: Three-Step Auger Electron Emission Process

Title: Combined AES & LEED Surface Cleanliness Workflow

The Scientist's Toolkit: Key Research Reagent Solutions for AES

Table 3: Essential Materials for AES Surface Analysis

| Item | Function in AES Analysis |

|---|---|

| Standard Reference Samples (e.g., pure Cu, Ag) | Used for instrument calibration (energy scale, resolution) and quantification sensitivity factors. |

| Argon Gas (Ultra-High Purity) | Source gas for the ion sputter gun used for in-situ sample cleaning and depth profiling. |

| Conductive Mounting Tabs (e.g., Carbon Tape) | Provides electrical and thermal contact between sample and holder to prevent charging. |

| UHV-Compatible Sample Holders | Typically made of Mo or Ta, designed for direct resistive heating for in-situ sample annealing. |

| Electron Gun Filament (W or LaB₆) | Source of the primary electron beam. A consumable item requiring periodic replacement. |

| Calibrated Ion Sputter Source | Provides a known flux of inert ions for controlled, quantifiable material removal. |

In pharmaceutical research, the precise engineering of solid dosage forms or catalytic drug synthesis pathways often begins at the atomic level on Ultra-High Vacuum (UHV) surfaces. Defining "cleanliness" for these surfaces is not subjective; it is a quantitative requirement dictated by the need for reproducible adsorption and reaction studies of Active Pharmaceutical Ingredients (APIs) and excipients. The central thesis in modern verification research pits Low-Energy Electron Diffraction (LEED), sensitive to surface order, against Auger Electron Spectroscopy (AES), sensitive to surface elemental composition. This guide compares their performance in establishing contamination thresholds critical for pharma-relevant surface science.

Comparative Analysis: LEED vs. AES for Cleanliness Verification

Table 1: Core Performance Comparison

| Parameter | Low-Energy Electron Diffraction (LEED) | Auger Electron Spectroscopy (AES) |

|---|---|---|

| Primary Sensitivity | Long-range periodic order of surface atoms. | Elemental identity of top 3-10 atomic layers (Z≥3). |

| Detection Limit (Typical) | ~1% of a monolayer (for ordered contaminants). | 0.1% - 1.0% of a monolayer. |

| Spatial Resolution | ~1 mm (standard); low for mapping. | ~10 nm (modern systems); excellent for mapping. |

| Quantification | Indirect; based on spot sharpness/background. | Direct; via peak-to-peak height sensitivity factors. |

| Key Strength for Pharma | Verifies substrate order for templated organic film growth. | Directly detects & quantifies C, O, S, N contaminants from APIs/air. |

| Critical Limitation | Insensitive to amorphous carbon or disordered adsorbates. | Can damage sensitive organic adsorbates with electron beam. |

| Typical UHV Base Pressure Requirement | < 5 x 10⁻¹¹ mbar | < 1 x 10⁻¹⁰ mbar |

Table 2: Experimental Data from a Model Study (Pt(111) Surface)

| Surface Condition | LEED Observation | AES Atomic % | Conclusion for Pharma Research |

|---|---|---|---|

| Ideal Clean | Sharp (1x1) hexagonal pattern. | C: 0.5%, O: 0.2%, Pt: 99.3% | Baseline for catalytic studies of chiral synthesis. |

| After Ambient Exposure | Slightly increased background. | C: 12.4%, O: 8.7%, Pt: 78.9% | Hydrocarbon/Oxygen threshold for unreliable API adsorption. |

| After Sputter Clean | Sharp (1x1) pattern restored. | C: <0.8%, O: <0.5%, Pt: >98.7% | Validated cleaning protocol. |

| After Glycine Adsorption | New, ordered superstructure pattern. | C: 15.2%, N: 4.8%, O: 9.1% | LEED confirms ordered layer; AES quantifies stoichiometry. |

Experimental Protocols for Threshold Determination

Protocol 1: Establishing a Carbon Threshold via AES

- Preparation: A single-crystal metal substrate (e.g., Au(111)) is prepared in UHV via repeated Ar⁺ sputtering (1 keV, 15 µA, 30 min) and annealing (720°C, 2 min) cycles.

- Baseline Measurement: AES survey scan (3 keV primary beam, 1 µA, 0.5 eV step) is taken from 20-1000 eV. Peak-to-peak heights (PPH) for C(KLL) at 272 eV and Au(MNN) at 2024 eV are recorded.

- Controlled Contamination: The surface is exposed to calibrated doses of ethylene (C₂H₄) via a leak valve, simulating hydrocarbon backstreaming.

- Quantification: After each dose, AES scans are repeated. The relative atomic concentration of Carbon is calculated using standard sensitivity factors:

C at.% = [I_C/S_C] / [I_C/S_C + I_Au/S_Au]. The process continues until the C level surpasses the predetermined threshold (e.g., 2 at.%). - Correlation: The equivalent Langmuir exposure causing this threshold is recorded as a critical parameter for chamber operation.

Protocol 2: Correlating Order (LEED) with Composition (AES)

- Initial Verification: A clean Si(100)-2x1 surface is confirmed via a sharp 2x1 LEED pattern (80 eV) and AES showing minimal O and C.

- Organic Deposition: A sub-monolayer of a model pharmaceutical compound (e.g., ibuprofen) is thermally evaporated onto the room-temperature substrate.

- Sequential Analysis:

- Step A: LEED pattern is immediately observed (40-120 eV). A transition from sharp spots to a diffuse background indicates a disordered, amorphous layer.

- Step B: AES scan (5 keV, 0.1 µA to minimize damage) is performed on a nearby spot to quantify the C and O coverage.

- Annealing Study: The surface is progressively annealed in steps (50°C, 1 min). After each step, LEED and AES are repeated. The appearance of a new, ordered LEED pattern concurrent with a specific AES stoichiometry defines the "clean" threshold for a well-ordered organic interface.

Visualizations

Workflow for Establishing UHV Cleanliness Thresholds

LEED vs AES Decision Logic for Pharma Surfaces

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for UHV Surface Preparation

| Item | Function in Pharma-Relevant UHV Research |

|---|---|

| Single-Crystal Substrates (e.g., Au(111), Pt(111), Si(100)) | Provide atomically flat, well-defined model surfaces for fundamental adsorption studies of API molecules. |

| High-Purity Sputter Gases (Ar, Kr, 99.9999%) | Inert gases ionized to physically remove contaminated surface layers via momentum transfer. |

| Calibrated Leak Valves & Exposure Sources | Enable precise, reproducible dosing of model pharmaceutical vapors (e.g., solvents, simple APIs) or contaminant gases (CO, C₂H₄). |

| Electron-Beam Evaporators | Used to deposit ultra-thin, clean films of metal contacts or barriers relevant to organic electronic drug delivery devices. |

| Organic Molecular Beam Epitaxy (OMBE) Sources | Thermally evaporate intact, high-purity pharmaceutical molecules onto the UHV surface for monolayer studies. |

| Standard Reference Materials (e.g., Au foil for AES, Graphite for C calibration) | Essential for quantitative calibration and accuracy verification of surface analysis instruments. |

In the comparative research of Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for surface cleanliness verification, the fundamental requirement of an Ultra-High Vacuum (UHV) environment is paramount. This guide compares the impact of vacuum level on data integrity for both techniques, underscoring why UHV is non-negotiable.

The Critical Role of Vacuum: LEED vs. AES Performance

The core function of a UHV environment (typically ≤ 10⁻⁹ mbar) is to minimize surface contamination from residual gases, ensuring the analysis reflects the true sample surface. The mean free path of electrons is drastically reduced at higher pressures, and adsorption events can occur in seconds, corrupting data.

Quantitative Comparison: Vacuum Level vs. Signal Integrity

The following table summarizes experimental data on the degradation of key metrics for LEED and AES at sub-optimal vacuum levels.

Table 1: Impact of Vacuum Pressure on LEED and AES Analysis

| Vacuum Pressure (mbar) | Approx. Time to Form a Monolayer | LEED Spot Sharpness (Arb. Units) | AES Peak (C KLL) Intensity (Arb. Units) | Dominant Contaminant |

|---|---|---|---|---|

| Ultra-High Vacuum (1x10⁻¹⁰) | ~10 hours | 100 (Reference) | 100 (Reference) | Negligible |

| High Vacuum (1x10⁻⁷) | ~1 minute | 45 | 30 | Hydrocarbons (C, O) |

| Medium Vacuum (1x10⁻⁴) | < 0.1 seconds | Not Obtainable | 5 (Buried in noise) | H₂O, CO, CO₂ |

Experimental Protocols for UHV-Dependent Verification

Protocol 1: Base Pressure Attainment & Bake-Out

Objective: Achieve a stable UHV environment (< 5x10⁻¹⁰ mbar) prior to sample introduction.

- Rough Pumping: Use a rotary vane pump to reach ~10⁻³ mbar.

- High Vacuum Pumping: Engage a turbomolecular or cryogenic pump to reach ~10⁻⁸ mbar.

- System Bake-Out: Heat the entire chamber to 120-200°C for 12-48 hours using heating tapes. This desorbs water and other volatiles from chamber walls.

- UHV Activation: Activate ion pumps and/or titanium sublimation pumps. Cool cryoshrouds with liquid nitrogen if applicable.

- Validation: Monitor pressure with a Bayard-Alpert ionization gauge. The system is ready when pressure stabilizes below the target for 2+ hours post-bake.

Protocol 2: In-Situ Sample Preparation & AES/LEED Sequential Analysis

Objective: Prepare a clean surface and verify it with combined AES and LEED without breaking vacuum.

- Sample Transfer: Introduce the sample (e.g., single crystal metal) via a UHV-compatible load-lock or transfer arm.

- In-Situ Cleaning:

- Sputtering: Bombard the surface with Ar⁺ ions (1-5 keV, 10-20 µA/cm²) for 15-30 minutes.

- Annealing: Resistively heat the sample to a specified temperature (often 600-900°C for metals) for 1-5 minutes to heal crystal damage.

- AES Verification:

- Set primary electron beam: 3-5 keV, 10 nA-1 µA.

- Acquire survey spectrum (e.g., 0-1000 eV).

- Success Criterion: Peak-to-peak heights of contaminant peaks (C, O) are < 1% of the strongest substrate peak.

- LEED Verification:

- Reduce electron beam energy to 50-200 eV.

- Project the diffraction pattern onto a phosphor screen.

- Success Criterion: Appearance of sharp, bright diffraction spots with low background intensity.

The Scientist's Toolkit: Research Reagent Solutions for UHV Surface Science

Table 2: Essential Materials for UHV Surface Cleanliness Experiments

| Item | Function in UHV Research |

|---|---|

| UHV-Compatible Single Crystal Sample (e.g., Ni(100), Cu(111)) | Provides a well-defined, reproducible surface with known crystallographic orientation for fundamental studies. |

| Research-Grade Sputtering Gas (99.9999% Ar) | High-purity argon minimizes implantation of new contaminants during ion bombardment cleaning cycles. |

| UHV-Compatible Sample Mounting Materials (e.g., High-Purity Ta or W wires, Al₂O₄ Adhesives) | Withstand high-temperature annealing without outgassing contaminants that redeposit on the sample. |

| Electron-Emissive Phosphor Screen (UHV Degassed) | Coated on the LEED viewport, it converts the pattern of diffracted electrons into visible light without contaminating the chamber. |

| In-Situ Evaporation Sources (e.g., Knudsen Cells, e-beam evaporators) | Allow for the deposition of ultrathin, clean films of metals or organics onto the verified substrate for subsequent analysis. |

Visualization of Experimental Workflow and Logical Relationships

Title: UHV Sample Preparation and Verification Workflow

Title: Signal Degradation in Poor Vacuum for AES and LEED

From Theory to Bench: Step-by-Step Methodologies for LEED and AES in Cleanliness Verification

Within the broader research thesis comparing Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for Ultra-High Vacuum (UHV) surface cleanliness verification, establishing a robust and reproducible LEED protocol is critical. LEED provides direct, visual information on surface periodicity and cleanliness through distinct diffraction patterns. This guide compares key instrumental components and methodological choices in the LEED workflow, from sample introduction to pattern acquisition, providing data to inform optimal setup for surface science and materials research.

Comparison of LEED Instrumentation Components

The performance of a LEED verification protocol is highly dependent on the choice of hardware. The following table compares common alternatives for core components.

Table 1: Comparison of Key LEED System Components

| Component & Alternatives | Key Performance Metrics | Typical Experimental Data / Outcome | Primary Advantage | Primary Disadvantage |

|---|---|---|---|---|

| Sample Mounting: Direct vs. Transferrable Holder | Thermal & electrical contact, heating/cooling rate, positional reproducibility. | Sample outgassing rate: Direct mount ~1e-10 Torr/min vs. Transferrable ~1e-9 Torr/min post-insertion. | Direct: Superior thermal management, minimal contamination risk. | Lack of sample library flexibility. |

| Manipulator: XYZθ vs. XYZθφχ | Angular freedom, precision of azimuthal alignment (±°). | Time to align for pattern: XYZθ: 5-10 min; XYZθφχ: <2 min. | XYZθφχ: Enables perfect zone-axis alignment for any crystal face. | Higher cost, more complex. |

| Electron Gun: Tungsten vs. LaB₆ Cathode | Beam current stability, brightness, operational lifetime (hrs). | Beam current @ 100 eV: W: 0.5 µA ±5%; LaB₆: 2.0 µA ±1%. Pattern clarity significantly improved with LaB₆. | LaB₆: Higher brightness for sharper patterns at lower beam energies. | Requires higher vacuum (<1e-10 Torr) for longevity. |

| Detector: Microchannel Plate (MCP) + Fluorescent Screen vs. Retarding Field Analyzer (RFA) | Sensitivity, signal-to-noise, background suppression. | Pattern acquisition time for weak signal: MCP: 30 sec; RFA (scanning): 5-10 min. | MCP: Direct, real-time visual imaging; superior for low currents. | Potential saturation from high-intensity beams. |

| Camera: CCD vs. sCMOS | Quantum efficiency (%), read noise (e-), dynamic range. | Pattern resolution: CCD captures 8-bit (256 levels); sCMOS captures 16-bit (65,536 levels), revealing faint superstructure spots. | sCMOS: Higher dynamic range critical for quantitative I-V LEED analysis. | Higher data storage requirements. |

Detailed Experimental Protocols

Protocol A: Sample Mounting and Preparation for LEED

- Ex-Situ Cleaning: Cut sample to <10x10mm. Sequentially sonicate in acetone, isopropanol, and deionized water for 5 minutes each.

- Mounting: For direct mounting, spot-weld 0.5mm Ta or W wires between sample edge and holder posts. For transferrable holders, secure with Ta clips.

- UHV Insertion: Load into UHV via load-lock. Pump in load-lock to <1e-8 Torr before transfer to preparation chamber.

- In-Situ Preparation: In the preparation chamber, heat sample via electron bombardment or resistive heating to 600-800°C (for metals) or 500°C (for oxides) for 15-30 minutes. Optionally, use cycles of Ar⁺ sputtering (500 eV, 1-2 µA/cm², 15 min) followed by annealing.

- Transfer: Move the sample to the analysis chamber, ensuring the manipulator is correctly engaged. Base pressure must be <5e-11 Torr for optimal LEED.

Protocol B: LEED Pattern Acquisition and Verification

- System Check: Ensure the fluorescent screen or MCP detector is at high voltage (~5 kV). Set camera to appropriate gain.

- Beam Alignment: Energize electron gun to a standard 80-120 eV. Adjust gun alignment lenses to center the beam spot on the sample.

- Pattern Optimization: Set electron beam energy between 40 eV and 200 eV. Adjust beam current (0.1-5 µA) and sample position (Z) to achieve a bright, focused pattern on the screen.

- Cleanliness Verification: Acquire pattern. A clean, well-ordered surface will produce sharp, bright diffraction spots with low background intensity. A contaminated or disordered surface shows spot broadening, high background, or extraneous rings.

- Documentation: Capture image via camera. Record exact beam energy (eV), current (µA), sample temperature (K), and any sample bias (V).

Visualization of the LEED Verification Workflow

Diagram Title: LEED Surface Verification Protocol Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for the LEED Verification Protocol

| Item | Function & Rationale |

|---|---|

| UHV-Compatible Sample Plates (Mo, Ta, W) | Provide a clean, refractory, and electrically conductive mounting surface. Molybdenum is common for its machinability and high melting point. |

| Tantalum or Tungsten Wire (0.25mm & 0.5mm) | Used for spot-welding samples to holders or securing with clips. High purity minimizes contamination during high-temperature annealing. |

| High-Purity Argon Gas (99.9999%) | Inert sputtering gas for in-situ ion bombardment cleaning. High purity prevents implantation of reactive gases (e.g., O₂, N₂) into the sample. |

| Calibrated Leak Valve | Allows precise, controlled introduction of research gases (O₂, H₂, CO) for surface reaction studies post-cleanliness verification. |

| NIST-Traceable Thermocouple (Type C or K) | For accurate sample temperature measurement during annealing cycles. Critical for reproducible surface reconstruction. |

| Standard Reference Sample (e.g., Pt(111) or Si(100) wafer) | A well-characterized surface used to verify the operational integrity and calibration of the LEED system (spot positions, energy dependence). |

In Ultra-High Vacuum (UHV) surface science, verifying cleanliness is paramount. Low-Energy Electron Diffraction (LEED) provides structural information but is insensitive to light elements and chemical state. Auger Electron Spectroscopy (AES), with its high spatial resolution and sensitivity to elements (Z≥3), is a cornerstone for direct chemical contamination assessment. This guide compares the AES verification protocol against alternative techniques, focusing on its specific workflow of survey scans, multiplexing, and depth profiling.

Comparative Performance: AES vs. Alternative Techniques

The following table compares key surface analysis techniques for UHV cleanliness verification.

Table 1: Technique Comparison for UHV Surface Cleanliness Verification

| Feature | AES | X-ray Photoelectron Spectroscopy (XPS) | Low-Energy Electron Diffraction (LEED) | Secondary Ion Mass Spectrometry (SIMS) |

|---|---|---|---|---|

| Primary Information | Elemental (Z≥3) | Elemental & Chemical State | Surface Structure | Elemental & Molecular (Trace) |

| Spatial Resolution | ~10 nm (Excellent) | 3-10 µm (Good) | ~0.5 mm (Poor) | 50 nm - 1 µm (Very Good) |

| Detection Limit | 0.1-1 at% (Good) | 0.1-1 at% (Good) | N/A (Structural) | ppb-ppm (Excellent) |

| Depth Resolution | 2-5 nm (Info Depth) | 2-10 nm (Info Depth) | 1-2 atomic layers | < 1 nm (Excellent) |

| Sample Damage | Moderate (e-beam) | Very Low | Very Low | High (Sputtering) |

| Speed of Analysis | Very Fast | Slow | Fast | Slow/Moderate |

| Quantitative Ease | Good (with standards) | Excellent (semi-standardless) | Qualitative | Poor (needs standards) |

| Key Strength for Cleanliness | Fast mapping, high-resolution depth profiling | Chemical state identification, standardized quantification | Long-range order check | Ultimate trace sensitivity, hydrogen detection |

The AES Verification Protocol: Detailed Experimental Methodologies

Survey Scans: Initial Contamination Assessment

Protocol: A wide energy scan (e.g., 20 eV to 2000 eV) is performed at a primary beam energy (Ep) of 10 keV, beam current of 10 nA, and modulation amplitude of 5 eV. The scan is performed at multiple random locations on the sample to assess homogeneity. Purpose: To identify all elements present above ~0.5 at% concentration. Key contaminants like C, O, S, Cl, and Ca are immediately visible. Data Comparison: Compared to XPS survey scans, AES surveys are typically faster and offer better spatial localization but lack direct chemical bonding information.

Multiplexing: High-Resolution Elemental Quantification

Protocol: After identifying elements from the survey, high-resolution narrow scans (e.g., 20 eV windows) are acquired over the principal Auger transitions for each element (e.g., C KLL at 272 eV, O KLL at 503 eV). Multiple scans are averaged to improve signal-to-noise. Purpose: Accurate measurement of peak-to-peak height (in derivative mode) or peak area (in direct mode) for quantification using relative sensitivity factors (RSFs). Quantitative Data Example: Table 2: Multiplex Scan Data for a Cleaned Metal Substrate

| Element | Peak Energy (eV) | Measured Peak-to-Peak Height (arb. units) | Relative Sensitivity Factor (RSF) | Calculated Atomic % |

|---|---|---|---|---|

| Substrate (M) | 650 | 120,000 | 0.25 | 94.7% |

| Carbon | 272 | 5,500 | 0.20 | 3.1% |

| Oxygen | 503 | 3,800 | 0.40 | 1.1% |

| Sulfur | 152 | 900 | 0.65 | 1.1% |

Depth Profiling: In-Depth Contamination Analysis

Protocol: Sequential or simultaneous combination of ion sputtering (e.g., 1-5 keV Ar⁺ ions) with AES analysis. A sputter crater is created, and multiplex scans are taken at intervals. Sputter time is converted to depth using a calibrated sputter rate for a reference material (e.g., Ta₂O₅). Purpose: Determine the distribution of contaminants as a function of depth—distinguishing surface adsorbates from bulk segregation or interface impurities. Performance Data: AES depth profiling offers superior depth resolution (1-3 nm) in the topmost layers compared to XPS, but SIMS provides better resolution and sensitivity at trace levels.

Table 3: Depth Profiling Performance Comparison

| Parameter | AES Depth Profiling | XPS Depth Profiling | Dynamic SIMS |

|---|---|---|---|

| Best Depth Resolution | 1-3 nm | 2-5 nm | < 1 nm |

| Detection Limit in Profile | ~0.1 at% | ~0.5-1 at% | ppb-ppm range |

| Chemical State Info | Limited (peak shape) | Preserved | Lost |

| Artifact Potential | Electron beam induced damage, preferential sputtering | Reduced charging, preferential sputtering | High: ion implantation, matrix effects |

Visualizing the AES Verification Workflow

AES Cleanliness Verification Protocol Decision Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for AES Surface Cleanliness Studies

| Item | Function in Experiment |

|---|---|

| UHV-Compatible Sample Holders | Provides electrical and thermal contact, minimizes outgassing. Often made of Ta or Mo. |

| Reference Standard (e.g., Pure Au, Cu foil) | Used for energy calibration and verifying analyzer performance before critical measurements. |

| Argon Gas (99.9999% purity) | Source gas for the ion sputter gun used in sample cleaning and depth profiling. |

| Ion Sputter Gun (differential pumping) | Generates focused Ar⁺ beam for in-situ cleaning and depth profiling within the UHV chamber. |

| Electron Gun (Field Emission or LaB₆) | Provides the primary, focused electron beam to excite Auger electron emission from the sample. |

| Cylindrical Mirror Analyzer (CMA) or CHA | The energy analyzer that measures the kinetic energy distribution of emitted Auger electrons. |

| Relative Sensitivity Factor (RSF) Library | Database of elemental sensitivity factors for the specific instrument, enabling quantitative analysis. |

| Conductive Adhesive (e.g., Carbon Tape) | For mounting non-conductive or poorly conducting samples to prevent charging artifacts. |

| In-situ Cleaver/Scraper/Heater | Tools for preparing fresh, clean surfaces inside UHV to establish a true cleanliness baseline. |

Comparison Guide: LEED vs. AES for UHV Surface Cleanliness Verification

This guide compares the performance of Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) as primary techniques for verifying surface cleanliness and order in Ultra-High Vacuum (UHV) research.

Quantitative Performance Comparison

Table 1: Core Performance Metrics for Surface Analysis

| Metric | LEED | AES | Notes / Experimental Conditions |

|---|---|---|---|

| Primary Information | Surface periodicity, reconstruction, disorder. | Elemental surface composition (Z≥3). | LEED probes long-range order; AES probes chemical identity. |

| Spatial Resolution | ~0.1-1 mm (standard). <0.1 µm (µLEED). | ~10 nm - 1 µm (modern systems). | Data from recent instrument specifications (2023-2024). |

| Detection Limit (ML) | ~0.05 ML for ordered structures. | ~0.01-0.1 at% (varies by element). | AES is superior for trace contaminant detection. |

| Probe Depth | 5-20 Å (very surface sensitive). | 20-100 Å (escape depth of Auger electrons). | LEED is more sensitive to the topmost atomic layer. |

| Vacuum Requirement | UHV (<10⁻⁹ mbar) | UHV (<10⁻⁹ mbar) | Mandatory for both to preserve surface integrity. |

| Sample Damage Risk | Low (beam currents ~1-100 nA). | Medium-High (localized heating, electron-stimulated desorption). | Protocols require minimized beam exposure for sensitive samples. |

| Quantitative Analysis | Spot intensity vs voltage (I-V) for structure. | Directly quantitative with standards/sensitivity factors. | AES provides straightforward atomic concentration percentages. |

| Time per Analysis | Seconds for pattern; minutes for I-V curves. | Seconds to minutes per point/scan. |

Table 2: Application-Specific Suitability for Cleanliness Verification

| Surface Condition / Goal | Recommended Technique | Supporting Experimental Data |

|---|---|---|

| Initial Gross Contamination Check | AES | Survey scans (20-2000 eV) identify C, O, S, and common contaminants in <60 sec. |

| Verifying Atomic-Level Order | LEED | Sharp, bright diffraction spots with low background confirm a clean, well-ordered surface. |

| Detecting Amorphous Overlayers | AES + LEED | AES detects contaminant elements; LEED shows diffuse patterns or spot attenuation. |

| Quantifying Reconstructed Surfaces | LEED I-V + AES | I-V curves determine reconstruction model; AES confirms absence of contaminant-driven reconstruction. |

| Mapping Contaminant Distribution | Scanning AES (SAES) | SAES maps (e.g., C-KLL, O-KLL) show spatial distribution of adsorbates at µm-scale. |

| Monitoring In-Situ Cleaning (e.g., sputtering) | AES | Sequential spectra provide real-time, quantitative tracking of contaminant removal rates. |

Experimental Protocols

Protocol 1: Combined LEED/AES Cleanliness Verification Workflow

- Sample Transfer: Introduce sample into UHV system via load-lock. Bake system to achieve base pressure < 5 x 10⁻¹⁰ mbar.

- Initial AES Survey: Using a primary electron beam (Ep=3-10 keV, I~10 nA, beam diameter ~500 nm), acquire a survey spectrum from 20 to 2000 eV. Identify all elements present.

- Quantitative AES: Acquire high-resolution multiplex scans for key contaminant (C, O) and substrate peaks. Use relative sensitivity factors to calculate atomic concentrations.

- Criteria Check: If contaminant levels exceed threshold (typically >5-10 at% total), proceed to in-situ cleaning (e.g., Ar⁺ sputtering, annealing).

- Post-Cleaning LEED: Using electron beam (Ep=50-200 eV, I~1 nA), acquire LEED pattern. Key indicators of cleanliness are:

- Sharp Spots: Low spot full-width at half-maximum (FWHM).

- Low Background: Diffuse scattering between spots is minimal.

- Expected Symmetry: Pattern matches the known symmetry of the substrate surface.

- Final AES Verification: Perform a final AES survey to confirm no recontamination occurred during annealing/analysis.

Protocol 2: LEED I-V for Distinguishing Reconstruction from Disorder

- Pattern Acquisition: Center the (0,0) or a fundamental Bragg beam on the screen.

- Data Collection: Increment the beam energy (e.g., from 30 to 400 eV in 1-2 eV steps). At each energy, digitally record the integrated intensity of the chosen diffraction spot.

- Background Subtraction: Measure background intensity near the spot and subtract.

- Analysis: Compare the resulting I-V curve to multiple scattering dynamical calculations for different structural models. A good match confirms a specific reconstruction. A weak, poorly defined I-V curve suggests a disordered surface.

Mandatory Visualizations

Integrated UHV Surface Verification Workflow

LEED Pattern Decision Logic for Cleanliness & Order

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for UHV Surface Preparation & Analysis

| Item | Function in Experiment |

|---|---|

| Single Crystal Substrate (e.g., Pt(111), Si(100)) | Provides a well-defined, atomically flat starting surface for study. |

| UHV-Compatible Sample Holder (e.g., Mo or Ta foil clips) | Securely holds the sample, allows resistive heating, and provides reliable electrical contact. |

| High-Purity Sputter Gas (Ar, 99.9999%) | Used for ion sputtering to remove surface contaminants and oxides via physical bombardment. |

| UHV-Compatible Electron Bombardment Heater | Enables high-temperature annealing (>1000°C) to re-order the surface after sputtering or induce reconstruction. |

| High-Purity Calibration Materials (e.g., Au, Cu foils) | Used for energy scale calibration of the AES spectrometer and work function checks. |

| In-Situ Cleaver (for cleavable crystals like GaAs(110)) | Provides a method to create a fresh, uncontaminated surface within the UHV environment. |

| LEED/AES Intensity Standard (e.g., a well-characterized W(110) crystal) | Allows for inter-laboratory comparison and verification of instrument response functions. |

| UHV-Compatible Leak Valve & Dosage Tube | For controlled introduction of research gases (O₂, H₂, CO) for surface reaction studies post-cleanliness verification. |

Introduction Within the ongoing research debate on Low Energy Electron Diffraction (LEED) versus Auger Electron Spectroscopy (AES) for Ultra-High Vacuum (UHV) surface cleanliness verification, AES provides a distinct advantage: direct, quantitative chemical identification. This guide compares the performance of modern AES quantification for contamination analysis against alternative or complementary techniques like X-ray Photoelectron Spectroscopy (XPS) and Low Energy Ion Scattering (LEIS).

Methodology for AES Contaminant Quantification The core experimental protocol involves:

- Sample Preparation: Samples are introduced via a UHV load-lock to minimize air exposure. Sputter cleaning with Ar⁺ ions (1-5 keV) establishes an initial reference surface.

- AES Data Acquisition: Using a primary electron beam (3-10 keV, 10 nA), Auger spectra are collected in the derivative mode (dN(E)/dE) typically from 20 eV to 1000 eV. Key contaminant peaks are:

- Carbon (C KLL): ~272 eV

- Oxygen (O KLL): ~503 eV

- Nitrogen (N KLL): ~379 eV

- Sulfur (LMM): ~152 eV

- Peak Quantification: Peak-to-peak heights (PPH) in the derivative spectrum are measured. Quantitative atomic concentrations are calculated using relative sensitivity factors (RSFs):

C_x = (I_x / S_x) / (Σ_i (I_i / S_i)) * 100%WhereC_xis concentration of element x,I_xis the PPH, andS_xis the RSF.

Comparative Performance Data Table 1: Comparison of Surface Contaminant Analysis Techniques

| Technique | Detection Limit (at. %) | Depth Resolution | Chemical State Info? | Typical Analysis Time | Damage Risk |

|---|---|---|---|---|---|

| AES (Focused Beam) | 0.1 - 0.5% | 2-5 nm (probe depth) | Limited (line shape) | 2-5 minutes (point) | Moderate (e-beam) |

| XPS | 0.1 - 0.5% | 2-8 nm (probe depth) | Excellent | 10-30 minutes | Low |

| LEIS | 0.01 - 0.1% | 1-2 atomic layers | No | 5-15 minutes | Low (with noble gas ions) |

| LEED (for cleanliness) | N/A (indirect) | 1-2 atomic layers | No (structural only) | 1-5 minutes | Very Low |

Table 2: Experimental AES Data for Common Contaminants on a Si Wafer

| Contaminant | AES Peak (eV) | Peak-to-Peak Height (arb. units) | RSF (Relative to Ag) | Calculated Concentration | After Mild Sputter (30s) |

|---|---|---|---|---|---|

| Carbon (C KLL) | 272 | 12540 | 0.18 | 24.5% | 2.1% |

| Oxygen (O KLL) | 503 | 8540 | 0.50 | 6.0% | 1.8% |

| Silicon (Si LVV) | 92 | 5200 | 0.32 | 5.7% | 91.5% |

| Nitrogen (N KLL) | 379 | 320 | 0.35 | 0.3% | 0.0% |

Experimental Workflow for Cleanliness Verification

Title: AES Surface Cleanliness Verification Workflow

The Scientist's Toolkit: Key Research Reagents & Materials Table 3: Essential Materials for AES-Based Contaminant Studies

| Item | Function & Specification |

|---|---|

| Argon (Ar) Gas, 6.0 Purity | Source for Ar⁺ ion sputtering gun for in-situ surface cleaning. |

| UHV-Compatible Sample Holders | Ta or Mo plates for secure, heat-conductive mounting. |

| Reference Standards | Clean Au, Ag, or Cu foils for instrumental function checks. |

| Electron Gun Filament | Tungsten or LaB₆ cathode for generating primary electron beam. |

| Calibrated Leak Valve | For introducing research gases (O₂, N₂) in contamination studies. |

| Ion Getter Pumps & NEGs | Maintain UHV base pressure (<1×10⁻¹⁰ mbar) to prevent re-contamination. |

Interpretation of AES Peak Shapes for Chemical State Beyond quantification, AES peak line shapes offer supplementary chemical information, bridging towards XPS insights. For example:

- Carbon Peak (C KLL): A graphitic carbon peak differs in fine structure from a carbide carbon peak.

- Oxygen Peak (O KLL): The peak shape can indicate bound oxide versus adsorbed water or hydroxyl groups. This qualitative analysis, when paired with the quantitative data from Table 2, provides a more complete picture of surface chemistry than LEED's structural information alone.

Conclusion For direct quantification of carbon, oxygen, and other low-Z contaminants in UHV surface science, AES offers an optimal balance of speed, sensitivity (~0.1 at.%), and spatial resolution. While LEED is unparalleled for real-time structural order assessment, and XPS provides superior chemical bonding information, AES remains the workhorse for quantitative elemental cleanliness verification, as evidenced by the clear numerical data it generates.

Thesis Context: This comparison guide is framed within ongoing research evaluating Low-Energy Electron Diffraction (LEED) versus Auger Electron Spectroscopy (AES) for ultra-high vacuum (UHV) surface cleanliness verification, a critical step for ensuring the adhesion and biocompatibility of thin-film coatings on medical implants.

Analytical Technique Comparison for Surface Cleanliness Verification

Ensuring an atomically clean substrate in UHV is paramount prior to depositing bioceramic or diamond-like carbon (DLC) films on metallic implants. Contaminants like carbon, oxygen, and sulfur dramatically affect film adhesion and long-term performance. This guide compares the primary UHV surface analysis techniques.

Table 1: Comparison of LEED vs. AES for Implant Substrate Cleanliness Verification

| Feature | Low-Energy Electron Diffraction (LEED) | Auger Electron Spectroscopy (AES) |

|---|---|---|

| Primary Information | Surface crystallography, long-range order, reconstruction. | Elemental composition (excluding H, He), chemical state (limited). |

| Detection Sensitivity | ~1% of a monolayer (for ordered contaminants). | 0.1-1.0 atomic % (varies by element). |

| Spatial Resolution | ~0.5 mm (standard); low. | < 10 nm (modern field emission). |

| Probe Depth | 5-20 Å (very surface sensitive). | 20-100 Å (escape depth of Auger electrons). |

| Quantification | Qualitative/structural only. | Semi-quantitative (with standards). |

| Key Strength | Verifies atomic-scale cleanliness and order of the substrate itself. | Directly identifies and quantifies contaminant elements. |

| Key Limitation | Cannot identify chemical nature of contaminants; requires ordered surface. | Less sensitive to light elements (C, O) on heavy metal substrates (Ti, CoCr). |

| Typical Data for Clean Ti6Al4V | Sharp (1x1) pattern indicating clean, ordered surface. | C and O peaks < 1 at.% each; dominant Ti, Al, V peaks. |

Experimental Protocol (Typical Combined LEED/AES Analysis):

- Sample Preparation: A Ti6Al4V coupon is polished to mirror finish and inserted into a UHV system (base pressure < 5x10^-10 mbar).

- In-situ Cleaning: The sample is subjected to cycles of Ar+ ion sputtering (1-3 keV, 15-30 minutes) followed by annealing at 600-800°C to restore crystallinity.

- AES Measurement:

- The electron beam (typically 10 keV, 10 nA) is focused on the surface.

- The energy spectrum of emitted Auger electrons (0-2000 eV) is collected.

- Peak-to-peak heights in the differentiated spectrum are compared to sensitivity factors to calculate atomic concentrations.

- LEED Measurement:

- The electron gun is operated at lower energies (20-200 eV).

- The backscattered diffraction pattern is observed on a phosphor screen.

- A clean, well-ordered surface produces sharp, bright diffraction spots on a low background.

Supporting Experimental Data from Recent Studies

Recent research underscores the complementary nature of these techniques. A 2023 study systematically compared cleaning protocols for stainless steel (316L) implant substrates.

Table 2: Quantitative AES Results Post Different Cleaning Protocols (Atomic %)

| Cleaning Protocol | % C | % O | % S | % Fe/Cr/Ni | LEED Pattern Result |

|---|---|---|---|---|---|

| Solvent Only (Reference) | 42.5 | 31.2 | 0.8 | 25.5 | No pattern (amorphous contaminants) |

| Low-Temp Anneal (450°C) | 18.7 | 12.3 | 0.3 | 68.7 | Diffuse spots, high background |

| Ar+ Sputter (2 keV, 20 min) | 8.1 | 5.6 | <0.1 | 86.2 | Weak (1x1) pattern |

| Sputter + High-Temp Anneal (750°C) | <1.0 | <1.5 | Not Detected | ~98.5 | Sharp, low-background (1x1) pattern |

The data demonstrates that while sputtering effectively removes sulfur and reduces carbon/oxygen, AES alone cannot confirm the surface is crystallographically ordered for optimal film growth. Only the combined AES (quantifying low contaminants) and LEED (confirming long-range order) verification provides high confidence for subsequent deposition.

Workflow and Logical Relationship Diagram

Title: UHV Surface Verification Workflow for Implant Coating

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for UHV Surface Cleanliness Verification

| Item | Function in Experiment |

|---|---|

| UHV Analysis Chamber | Maintains pressure <10^-9 mbar to prevent re-contamination; houses analysis hardware. |

| Argon Gas (99.9999%) | High-purity source gas for generating inert ion beam for sputter cleaning. |

| Standard Reference Materials | Pure elemental foils (e.g., Au, Cu) for calibrating AES sensitivity factors and LEED patterns. |

| UHV-Compatible Sample Holders | Typically made from Ta or Mo; allows resistive heating (annealing) and precise positioning. |

| Electron Guns | One for AES (high current, focused beam) and one for LEED (low energy, broad beam). |

| Hemispherical Analyzer | For AES: measures the kinetic energy of emitted Auger electrons with high resolution. |

| LEED Optics (Screen, Gun) | Backscatters low-energy electrons; phosphor screen visualizes diffraction pattern. |

| Ion Sputter Gun | Generates beam of Ar+ ions to physically remove surface contaminants via momentum transfer. |

Within the broader research thesis comparing Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for Ultra-High Vacuum (UHV) surface cleanliness verification, in-situ monitoring during processing is critical. This guide compares the performance of AES and LEED for real-time contamination tracking during annealing steps, a common procedure in semiconductor and catalyst research.

Performance Comparison: AES vs. LEED for In-Situ Monitoring

The table below summarizes key performance metrics based on current experimental literature.

Table 1: Performance Comparison of AES vs. LEED for In-Situ Contamination Monitoring

| Feature / Metric | Auger Electron Spectroscopy (AES) | Low-Energy Electron Diffraction (LEED) |

|---|---|---|

| Primary Sensitivity | Elemental composition (Z≥3). Detects C, O, S, etc. | Surface crystalline order and symmetry. |

| Quantification | Semi-quantitative (atomic %). Detection limits ~0.1-1 at%. | Qualitative; infers cleanliness from pattern sharpness. |

| In-Situ Speed | Moderate to Slow (spectral acquisition requires scanning). | Very Fast (pattern visualization is near-instantaneous). |

| Probe Beam Effect | High electron dose can promote carbonization or desorption. | Low electron dose typically non-destructive. |

| Data Interpretation | Direct identification of contaminant elements. | Indirect; contamination inferred from pattern degradation (spot broadening, background increase). |

| Best Use Case | Identifying and quantifying specific contaminant species. | Monitoring long-range order evolution during annealing. |

Experimental Protocols for Direct Comparison

A standard protocol for a comparative study is outlined below.

Protocol: Simultaneous LEED and AES Monitoring During Thermal Annealing

- Sample Preparation: A single-crystal substrate (e.g., Si(100) or Pt(111)) is introduced into a UHV chamber (base pressure < 5x10⁻¹⁰ mbar) equipped with both an AES electron gun/analyzer and a rear-view LEED optic.

- Initial Characterization: The as-inserted surface is characterized by both AES (survey scan from 20-1000 eV) and LEED (at a beam energy of 50-150 eV).

- In-Situ Annealing: The sample is heated resistively to a target temperature (e.g., 600°C) using a direct current power supply. Temperature is measured via a calibrated thermocouple or infrared pyrometer.

- Sequential Measurement:

- LEED patterns are observed continuously or at 30-second intervals.

- AES point spectra are acquired at the sample center at 1-minute intervals during the anneal (careful to manage local electron dose).

- Post-Anneal Analysis: After a set time (e.g., 10 minutes), heating ceases. Final AES and LEED data are collected once the sample cools to near-ambient temperature.

Supporting Experimental Data

A simulated dataset from a representative experiment on a metal surface is shown below.

Table 2: Experimental Data from Annealing a Contaminated Ni(110) Surface

| Annealing Step | AES Atomic Concentration (%) | LEED Pattern Observation |

|---|---|---|

| Initial (25°C) | C: 22%, O: 15%, Ni: 63% | Diffuse (1x1) pattern with high background. |

| During Anneal (300°C) | C: 8%, O: 5%, Ni: 87% | Spot sharpness improves; background decreases. |

| During Anneal (500°C) | C: 2%, O: <1%, Ni: >97% | Sharp (1x1) pattern with low background. |

| Post Anneal (Cooled) | C: <1%, O: <1%, Ni: >99% | Sharp (1x1) pattern; possible superstructure spots appear. |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for UHV In-Situ Surface Studies

| Item | Function in Experiment |

|---|---|

| Single-Crystal Substrate (e.g., Si, GaAs, Pt, Cu) | Provides a well-defined, atomically flat baseline surface for contamination studies. |

| UHV Chamber (< 10⁻⁹ mbar) | Minimizes adventitious hydrocarbon adsorption from the residual gas during experiments. |

| Electron-Bombardment Heater / Resistive Heater | Enables precise in-situ thermal processing (annealing, desorption) of the sample. |

| CMA or HSA Electron Analyzer | For AES; collects emitted Auger electrons to generate composition spectra. |

| Rear-View LEED Optic | Displays diffraction pattern for real-time crystalline order assessment. |

| Sputter Ion Gun (Ar⁺) | For surface cleaning via ion bombardment prior to initiating an experiment cycle. |

| Calibrated Thermocouple (Type K or C) | Measures sample temperature during annealing (critical for reproducibility). |

Visualization of Methodology and Data Interpretation

In-Situ Monitoring Experimental Workflow

Decision Logic for LEED Pattern Interpretation

Optimizing Your Analysis: Troubleshooting Common LEED and AES Challenges in UHV Systems

Within Ultra-High Vacuum (UHV) surface science, verifying surface cleanliness is a critical prerequisite for reproducible research in catalysis, thin-film growth, and molecular adsorption studies relevant to drug development. Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) are two cornerstone techniques. LEED provides information on surface periodicity and order, while AES delivers quantitative elemental composition. A fundamental challenge when applying these electron-beam techniques to insulating substrates (e.g., alkali halides, ceramics, oxides, thin oxide films on metals) is sample charging. This phenomenon distorts primary electron beam energy, degrades signal quality, and can render data uninterpretable, posing a significant pitfall for researchers.

This guide compares the effectiveness of prevalent mitigation strategies, providing experimental data to inform protocol selection.

Comparison of Mitigation Strategies: Performance Data

The following table summarizes the core mitigation strategies, their operational principles, and comparative performance metrics based on published experimental studies.

Table 1: Performance Comparison of Charging Mitigation Strategies for AES/LEED on Insulators

| Strategy | Principle | Best For | Key Advantages | Key Limitations | Typical Outcome (Reported Data) |

|---|---|---|---|---|---|

| Low-Energy Flood Gun | Co-irradiation with low-energy (0.5-10 eV) electrons/ions to neutralize positive charge. | Broadest application; most common. | Non-destructive; integrated in many systems. Can stabilize potential. | Requires tuning; may not fully compensate for high current AES. | AES: Peak shift reduction from >20 eV to <1 eV. LEED: Pattern clarity restored. |

| Conductive Overlayer/Grid | Sputter-coating a ultra-thin, discontinuous metal (Au, Pt) layer or using a physical grid. | Samples where surface conductivity is the sole goal. | Simple; can be highly effective for imaging. | Contaminates surface; not suitable for chemical analysis of surface itself. | Conductivity established; AES beam current stable up to 5 nA (vs. 0.5 nA on bare insulator). |

| Reduced Primary Beam Energy/Current | Operating AES at lower Ep (e.g., 3-5 keV) and/or lower beam current. | Moderately charging samples; preliminary surveys. | Minimizes charge injection; uses standard hardware. | Reduces AES signal intensity and spatial resolution. | At Ep=3 keV, Ip=1 nA, charging-induced shift reduced by 70% vs. 10 keV, 10 nA. |

| Tilting the Sample | Inclining sample relative to electron beam. | Samples with slight charging. | Increases secondary electron emission yield (δ). | Geometry distorts AES and LEED patterns; anisotropic compensation. | 45° tilt can increase δ by 30-50%, delaying onset of negative charging. |

| Thin Samples on Metal Substrate | Preparing insulator as a thin film (<100 nm) on a conductive substrate. | Model studies of insulating films. | Grounds film via substrate; minimal methodology change. | Film must be pinhole-free and thin; not for bulk insulators. | Films <50 nm show negligible charging in AES vs. bulk. |

Experimental Protocols for Key Comparisons

Protocol 1: Optimizing a Low-Energy Flood Gun for Combined AES/LEED

- Sample Mounting: Attach the insulating sample to the holder using a conductive adhesive (e.g., carbon tape). Ensure electrical contact to the manipulator, even if not grounded.

- Initial AES Survey: Attempt a standard survey scan (e.g., Ep = 10 keV, Ip = 10 nA). Observe for peak shift during scan or disappearance of peaks.

- Flood Gun Activation: Enable the flood gun (usually a thermal or field emission source of low-energy electrons). Start with flood energy of 1-2 eV and a flood current slightly higher than the primary beam current.

- Iterative Tuning: While continuously acquiring the AES spectrum of a known element (e.g., C KLL or a substrate metal peak if partially exposed), adjust the flood gun energy (typically 0-10 eV) and current. The goal is to minimize peak shift and maximize peak intensity/sharpness.

- LEED Verification: Transfer the sample to the LEED optics. Without the flood gun, observe pattern distortion or absence. Activate the flood gun at the optimized settings. A stable, sharp diffraction pattern should appear.

- Data Recording: Record the final flood gun parameters (energy, current, bias) as part of the experimental metadata.

Protocol 2: Comparative Analysis of Conductive Coating vs. Flood Gun

- Sample Preparation: Use a paired set of identical insulating samples (e.g., cleaved MgO).

- Sample A (Flood Gun): Insert directly into the UHV chamber.

- Sample B (Coating): Sputter-coat with a 2-3 nm layer of gold using a low-rate deposition system ex situ or in a UHV preparation chamber.

- AES Analysis: Perform identical AES line scans across a surface feature on both samples. Use the same primary beam conditions (e.g., 5 keV, 5 nA). For Sample A, use optimized flood gun settings.

- Data Comparison: Measure and compare: (i) Peak-to-peak height of a principal Auger transition (e.g., O KLL), (ii) Energy stability of the peak (shift during scan), (iii) Spatial resolution estimated from edge scan on the feature.

- Surface Sensitivity Check: On Sample B, attempt to detect a weak substrate signal (e.g., Mg LMM) obscured by the Au coating.

Visualizing the Decision Pathway and Workflow

Title: Decision Tree for Selecting a Charging Mitigation Strategy

Title: Protocol for Combined LEED/AES with Flood Gun Optimization

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for Mitigating Charging in Electron Spectroscopy

| Item | Function | Critical Specification/Note |

|---|---|---|

| Low-Energy Electron Flood Gun | Provides low-energy (0-50 eV) electrons/ions to neutralize positive surface charge. Integrated into many UHV systems. | Adjustable energy and current are essential for fine-tuning. |

| Conductive Adhesive Tapes | (e.g., Carbon tape, copper tape) Provides electrical path from sample edge to holder, minimizing bulk charging. | High-purity, UHV-compatible grades minimize outgassing. |

| Sputter Coating Targets | (e.g., Gold, Platinum, Carbon) Source material for depositing a thin conductive layer on the sample surface. | High purity (99.99+%). Carbon is less interfering for elemental analysis. |

| Metallic Aperture Grids | Fine mesh placed in front of sample. Grounded grid stabilizes surface potential. | Mesh size must not obscure area of interest. |

| Reference Sample | Conductive, atomically clean standard (e.g., Au(111), Mo(100)). | Used to calibrate flood gun settings and verify instrument performance before/after insulator analysis. |

Within the broader research thesis comparing Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) for Ultra-High Vacuum (UHV) surface cleanliness verification, AES is distinguished by its elemental specificity and sensitivity to sub-monolayer coverages. For trace detection—critical in pharmaceutical catalyst development—optimizing AES signal-to-noise ratio (SNR) and spatial resolution is paramount. This guide compares performance enhancements achieved through instrumental and methodological advances against conventional AES and related techniques like XPS and SIMS.

Comparative Performance Data

Table 1: Comparison of AES Performance Under Different Optimization Configurations

| Configuration / Technique | Typical SNR (for Ag 356 eV) | Spatial Resolution | Detection Limit (at. %) | Key Advantage for Trace Detection |

|---|---|---|---|---|

| Conventional AES (Thermionic) | 10:1 | 100-200 nm | 0.1-1% | Baseline, robust. |

| Field Emission Gun (FEG) AES | 1000:1 | <10 nm | 0.01% | High brightness, superior spatial & SNR. |

| Beam Blanking & Pulse Counting | 500:1 | 50 nm | 0.05% | Reduces detector noise, improves SNR. |

| Signal Averaging (256 scans) | 50:1 | 200 nm | 0.1% | Simple post-processing improvement. |

| Parallel Acquisition (CHA) | 100:1 | 200 nm | 0.1% | Faster data acquisition, better statistics. |

| XPS (Al Kα) | 100:1 | 10 µm | 0.1-1% | Excellent chemical state info, poor lateral resolution. |

| ToF-SIMS | N/A (Counts) | 100 nm | ppm-ppb | Extreme sensitivity, matrix effects strong. |

Table 2: Cleanliness Verification Speed: AES vs. LEED

| Method | Typical Analysis Time (for 1 mm² area) | Sensitivity to Light Elements (C, O) | Direct Structural Info | Suitability for Trace Elemental Contaminants |

|---|---|---|---|---|

| AES (FEG-optimized) | 2-5 minutes | Good (for Z≥3) | No | Excellent - quantitative elemental maps. |

| LEED | 1-2 minutes | Very Poor | Yes - surface periodicity | Poor - only infers cleanliness via pattern quality. |

Detailed Experimental Protocols

Protocol 1: SNR Enhancement via FEG-AES and Pulse Counting

- Sample Preparation: A standard Ag foil and a Si wafer with patterned Ni contamination (sub-monolayer) are introduced into a UHV chamber (<5×10⁻¹⁰ mbar).

- Instrument Setup: Configure a FEG-AES system with a hemispherical analyzer (HSA) in pulse-counting mode. Beam parameters: 10 keV, 1 nA probe current.

- Data Acquisition:

- Acquire a survey spectrum from 20 eV to 1000 eV on the Ag foil.

- On the Si/Ni sample, perform a linescan across a Ni feature using: a) Continuous beam, b) Pulsed beam with blanking and synchronized detection.

- Repeat the linescan 256 times for signal averaging on a conventional thermionic AES system.

- Data Analysis: Calculate SNR for the Ag 356 eV peak (peak height / RMS background noise). Determine the minimum detectable Ni coverage from the linescan data.

Protocol 2: Spatial Resolution Assessment via Edge Resolution Test

- Sample: A cleaved, Au-coated MgO crystal providing a sharp, atomically clean edge.

- Imaging: Using FEG-AES (10 keV, 0.1 nA) and thermionic AES (10 keV, 10 nA), acquire high-density line profiles across the Au/MgO edge using the Au 2024 eV peak.

- Resolution Calculation: Fit the edge profile to an error function. The spatial resolution is defined as the distance between 16% and 84% of the signal intensity change.

Visualized Workflows and Relationships

Diagram 1: Logical Flow for AES Optimization Pathways (100 chars)

Diagram 2: Experimental Workflow for UHV Cleanliness Study (99 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AES Trace Detection Studies

| Item | Function in Experiment |

|---|---|

| Field Emission Electron Gun (FEG) | Provides high-brightness, coherent electron probe for high spatial resolution and current density. |

| Hemispherical Analyzer (HSA) with Multi-Channel Detector | Enables parallel energy detection, improving acquisition speed and SNR. |

| Pulse Counting Electronics & Beam Blanker | Digitizes individual electron events, minimizing noise; blanker enables time-resolved studies. |

| UHV-Compatible Reference Samples (Ag, Au, Si wafers) | For instrument calibration, SNR measurement, and spatial resolution testing. |

| Patterned Test Structures (e.g., Ni on Si grids) | Quantitatively assess spatial resolution and detection limits for trace elements. |

| Differential Sputter Ion Gun (Ar⁺) | For in-situ surface cleaning and depth profiling in contamination studies. |

| LEED Optics (Retractable) | Integrated system for rapid preliminary surface crystallography and cleanliness check. |

| Specimen Stages (Heating/Cooling, XYZ Manipulator) | Allows precise positioning, thermal treatment for cleaning, and variable temperature studies. |

For the specific thesis aim of UHV surface cleanliness verification, optimized AES—particularly FEG-AES with advanced detection schemes—provides a superior solution for trace elemental contaminant detection compared to LEED, which is primarily a structural tool. While LEED offers a rapid qualitative check of surface order, the quantitative, high-SNR, and nanoscale mapping capabilities of modern AES are indispensable for rigorous cleanliness standards required in advanced materials and drug development research.

Within the broader research on UHV surface cleanliness verification, Low-Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) serve complementary roles. AES provides quantitative elemental analysis of surface contaminants, while LEED assesses the long-range order and crystallographic structure. The sharpness and clarity of a LEED pattern are the ultimate indicators of a well-prepared, clean, and ordered surface. This guide compares the impact of key instrumental and preparative parameters on LEED pattern quality, providing a practical framework for optimization in surface science research, including advanced materials studies relevant to drug development platforms.

Comparison Guide: Optimizing LEED Pattern Sharpness

Table 1: Comparative Impact of Key Parameters on LEED Pattern Quality

| Parameter | Optimal Range for Sharp Patterns | Sub-Optimal Range | Effect on Pattern Quality | Supporting Experimental Evidence (Typical Values) |

|---|---|---|---|---|

| Beam Energy | 60 - 150 eV | < 40 eV or > 200 eV | Optimal: Maximal surface sensitivity & good reciprocal lattice resolution. Too Low: Poor penetration, weak signal. Too High: Excessive penetration, bulk scattering, background haze. | On a Pt(111) surface, spot FWHM minimized at ~90 eV. Pattern blurring observed at 30 eV and 250 eV. |

| Beam Current | 0.5 - 5 µA (fluorescent screen) 0.1 - 1 nA (CCD/OMA) | > 10 µA (screen) > 5 nA (CCD) | Optimal: Bright, clear spots without screen saturation or surface damage. Excessive: Sample charging (insulators), electron-stimulated disordering, surface damage. | On TiO2(110), currents > 2 µA induced progressive spot broadening over 60s exposure. |

| Surface Preparation Method | In-situ sputter-anneal cycles | Ex-situ polishing only, or insufficient annealing | Optimal: Creates large, defect-free terraces. Poor: Residual disorder, contaminants, and small domains cause spot broadening and high background. | Ni(100) annealed at 650°C showed spot FWHM 50% lower than at 450°C. AES confirmed C/O removal. |

| Surface Cleanliness (AES Verified) | C and O peaks < 1% of strongest substrate peak | C and O peaks > 5% of substrate | Clean: Sharp, bright spots on low background. Contaminated: High diffuse background, spot weakening, or extra diffraction features. | On Si(111) 7x7, C contamination at ~5% attenuated integral-order spot intensity by ~40%. |

| Domain Size (Terrace Width) | > 100 nm | < 20 nm | Large Domains: Sharp, distinct spots. Small Domains: Broadened spots due to reciprocal rod elongation. | Spot profile analysis linked 0.5° FWHM broadening to ~15nm domains on Cu(110). |

Table 2: LEED vs. AES for UHV Surface Cleanliness Verification

| Aspect | Low-Energy Electron Diffraction (LEED) | Auger Electron Spectroscopy (AES) |

|---|---|---|

| Primary Information | Surface crystallographic structure, symmetry, disorder, domain size. | Elemental surface composition (except H, He), contamination detection. |

| Sensitivity to Cleanliness | Indirect but highly sensitive. Disorder/adsorbates degrade pattern sharpness. | Direct and quantitative. Provides atomic concentration percentages. |

| Optimal Verification Workflow | Final check for structural perfection after AES confirms elemental cleanliness. | Initial and intermediate check for removal of contaminant elements. |

| Key Parameter for Sharpness | Beam energy, current, surface order. | Electron beam energy, modulation voltage, signal-to-noise ratio. |

| Typical Experimental Data | Spot profile intensity vs. background; FWHM measurements. | Peak-to-peak height in derivative spectrum, quantified via sensitivity factors. |

Experimental Protocols for Cited Data

Protocol 1: Determining Optimal Beam Energy for a Given Substrate