Unlocking the Nano-Scale: How AFM Revolutionizes 3D Printed Biomedical Material Surface Analysis

This article provides a comprehensive guide for researchers and biomedical engineers on applying Atomic Force Microscopy (AFM) to characterize 3D-printed materials.

Unlocking the Nano-Scale: How AFM Revolutionizes 3D Printed Biomedical Material Surface Analysis

Abstract

This article provides a comprehensive guide for researchers and biomedical engineers on applying Atomic Force Microscopy (AFM) to characterize 3D-printed materials. We explore the fundamental principles of AFM, detailing practical methodologies for analyzing surface topography, roughness, and mechanical properties. The guide addresses common troubleshooting scenarios and offers optimization strategies for reliable data acquisition. Finally, we validate AFM's role by comparing it with complementary techniques like SEM and profilometry, concluding with its critical implications for ensuring the quality, functionality, and safety of 3D-printed medical devices, implants, and drug delivery systems.

Why Nano-Scale Surface Analysis is Critical for 3D Printed Biomedical Materials

The Surface-Microstructure-Function Paradigm in 3D Printed Medical Devices

This document provides Application Notes and Protocols for investigating the Surface-Microstructure-Function (SMF) Paradigm in 3D-printed medical devices, framed within a thesis on Atomic Force Microscopy (AFM) for 3D printing material surface analysis. The surface microstructure, dictated by the additive manufacturing process, directly influences critical functional outcomes such as protein adsorption, cellular response, bacterial adhesion, and drug release kinetics.

The SMF paradigm posits a direct causal chain: Printing Parameters → Surface Microstructure → Biological/Functional Response. The following tables summarize key quantitative relationships established in recent literature.

Table 1: Influence of Printing Parameters on Surface Roughness (Sa)

| 3D Printing Technology | Material | Layer Height (µm) | Nozzle Temp (°C) | Measured Sa (nm) | Primary Analysis Technique |

|---|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | PCL | 100 | 110 | 1,520 ± 210 | AFM (10µm scan) |

| Fused Deposition Modeling (FDM) | PCL | 200 | 110 | 3,850 ± 450 | AFM (10µm scan) |

| Stereolithography (SLA) | Resin (Biocompatible) | 25 | N/A | 45 ± 12 | AFM (5µm scan) |

| Selective Laser Sintering (SLS) | PA12 (Nylon) | 80 | N/A | 18 ± 5 | AFM (5µm scan) |

| Direct Ink Writing (DIW) | Alginate-Gelatin | 150 | 22 | 890 ± 140 | Confocal Profilometry |

Table 2: Functional Outcomes Correlated with Surface Microstructure

| Device Application | Material | Surface Roughness (Sa) | Pore Size (µm) | Key Functional Outcome | Measurement |

|---|---|---|---|---|---|

| Bone Scaffold | β-TCP (SLS) | ~22 µm | 350 | Osteoblast adhesion density (Day 7) | 85% coverage |

| Bone Scaffold | β-TCP (SLS) | ~55 µm | 350 | Osteoblast adhesion density (Day 7) | 96% coverage |

| Drug-Eluting Implant | PLA (FDM) | 1.2 µm | N/A | Burst Release (First 24h) | 38% of payload |

| Drug-Eluting Implant | PLA (FDM) | 0.3 µm* | N/A | Burst Release (First 24h) | 12% of payload |

| Antimicrobial Surface | ABS (FDM) | 4.5 µm | N/A | S. aureus adhesion (CFU/cm²) | 1.2 x 10⁵ |

| Antimicrobial Surface | ABS (FDM) | 0.8 µm* | N/A | S. aureus adhesion (CFU/cm²) | 2.7 x 10⁴ |

Note: Post-processing (e.g., solvent vapor smoothing) applied.

Experimental Protocols

Protocol 1: AFM-Based Topographical and Mechanical Mapping of 3D-Printed Surfaces

Objective: To quantitatively characterize the surface roughness, texture, and nanomechanical properties of a 3D-printed medical device sample. Materials: See "Scientist's Toolkit" (Section 6). Procedure:

- Sample Preparation: Cut printed sample to fit AFM sample disk (~1cm x 1cm). Clean with compressed air or inert gas to remove loose particles. For polymers, avoid solvent cleaning unless its effect is under study. Mount securely with double-sided tape or adhesive.

- AFM Calibration: Calibrate the cantilever deflection sensitivity on a clean, rigid surface (e.g., sapphire). Perform thermal tune to determine the spring constant of the cantilever.

- Scanning Parameters:

- Mode: Use PeakForce Tapping or Quantitative Imaging (QI) mode for simultaneous topographical and mechanical property mapping.

- Probe: Use a silicon tip with a nominal spring constant of 0.4-4 N/m and resonant frequency of 150-300 kHz in air.

- Scan Size: 1 µm², 10 µm², and 50 µm² areas to capture features across scales.

- Resolution: 512 x 512 pixels.

- PeakForce Setpoint: Adjust to maintain a consistent, non-destructive force (typically 1-10 nN).

- Data Acquisition: Acquire a minimum of three random, non-overlapping scans per sample condition (n≥3 samples per print parameter set). Record height, PeakForce Error, and DMT Modulus channels.

- Analysis:

- Roughness: Apply a first-order plane fit to height data. Calculate Sa (Average Roughness), Sq (RMS Roughness), and Sz (Maximum Height) per ISO 25178 standards.

- Texture: Use Fast Fourier Transform (FFT) analysis to identify dominant periodicities from layer lines or toolpaths.

- Modulus: Generate histograms of the DMT modulus values from the mapped area, reporting the median and interquartile range.

Protocol 2: In Vitro Protein Adsorption and Cell Adhesion Assay

Objective: To link AFM-characterized surface microstructure to early biological response. Materials: Sample discs, Dulbecco’s Modified Eagle Medium (DMEM), Fetal Bovine Serum (FBS), Fibronectin, PBS, MC3T3-E1 osteoprogenitor cells, Calcein-AM live stain, 4% Paraformaldehyde (PFA), Triton X-100, Phalloidin (actin stain), DAPI. Procedure:

- Surface Characterization: Perform AFM analysis per Protocol 1 on a representative sample from each batch.

- Protein Pre-conditioning: Sterilize samples (70% ethanol, UV irradiation). Immerse in complete cell culture medium (DMEM + 10% FBS) or a solution of 10 µg/mL fibronectin in PBS. Incubate at 37°C for 1 hour.

- Cell Seeding: Seed MC3T3-E1 cells at a density of 10,000 cells/cm² onto samples in 24-well plates. Allow to adhere for 4 hours.

- Fixation and Staining: At adhesion timepoint (e.g., 4h, 24h), rinse with PBS, fix with 4% PFA for 15 min, permeabilize with 0.1% Triton X-100 for 5 min. Stain actin cytoskeleton with Phalloidin (1:500) and nuclei with DAPI (1:1000). Image via confocal microscopy.

- Quantification: Use ImageJ to count nuclei for adhesion density. Analyze cell spread area and cytoskeletal morphology from phalloidin images. Correlate metrics with AFM-derived Sa and Sz values.

Protocol 3: Drug Release Kinetics from Microstructured Surfaces

Objective: To quantify how surface area and texture from printing affect drug elution profile. Materials: Drug-loaded filament (e.g., PLA with 5% w/w Rifampicin), phosphate-buffered saline (PBS, pH 7.4), 0.1% w/v Tween 80 (to maintain sink conditions), UV-Vis Spectrophotometer or HPLC. Procedure:

- Fabrication: Print identical disc geometries (e.g., Ø10mm x 1mm) varying only layer height (e.g., 100 µm vs. 200 µm). Weigh each disc accurately.

- Release Study: Place each disc in a sealed container with 10 mL of release medium (PBS + 0.1% Tween 80) at 37°C under gentle agitation (50 rpm). Maintain sink conditions.

- Sampling: At predetermined timepoints (0.5, 1, 2, 4, 8, 24, 48, 72, 168 h), withdraw 1 mL of medium and replace with fresh pre-warmed medium.

- Analysis: Quantify drug concentration in sampled medium via UV-Vis at λmax (e.g., 475 nm for Rifampicin). Use a standard curve for absolute quantification.

- Modeling: Plot cumulative release (%) vs. time. Fit data to models: Zero-order, First-order, Higuchi (diffusion-controlled), and Korsmeyer-Peppas (to determine release exponent n). Correlate release rate constants with AFM-measured surface area and roughness.

Signaling Pathways & Experimental Workflows

Diagram Title: SMF Paradigm & Cell Signaling Pathway

Diagram Title: Integrated SMF Experimental Workflow

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Materials for SMF Paradigm Research

| Item | Function/Application | Key Considerations |

|---|---|---|

| AFM with PeakForce Tapping/QI Mode | Nanoscale topographic & mechanical mapping. Essential for quantifying Sa, modulus. | Must handle sample roughness up to 10-15µm. Environmental control is beneficial. |

| Silicon AFM Probes (SCANASYST-AIR) | For high-resolution imaging of polymers. Spring constant ~0.4 N/m. | Optimized for PeakForce Tapping. Blunt tip for durability on rough surfaces. |

| Biocompatible 3D Printing Resins (e.g., Dental SG, MED610) | For SLA-printed devices needing cytocompatibility. | Check ISO 10993 certifications. Post-curing affects surface energy. |

| Drug-Loaded Thermoplastic Filaments (e.g., PLA + Antibiotic) | For fabricating drug-eluting study samples via FDM. | Ensure homogeneous drug dispersion. Hot-end temperature critical for stability. |

| Solvent Vapor Smoothing Station (e.g., for ABS) | For post-processing to reduce surface roughness. A key experimental variable. | Use controlled solvent (e.g., acetone) exposure times. Conduct in fume hood. |

| Fibronectin, Fluorescently Conjugated | For quantifying and visualizing protein adsorption onto microstructured surfaces. | Use consistent concentration and incubation time. BSA blocking step required. |

| Calcein-AM / Ethidium Homodimer-1 Live/Dead Assay Kit | For rapid viability assessment of cells on test surfaces. | Optimize dye concentration for porous/microstructured surfaces. |

| Rhodamine-Phalloidin & DAPI | For staining F-actin and nuclei to quantify cell spreading and morphology. | Permeabilization time may vary with material porosity. |

| Simulated Body Fluid (SBF) | For assessing apatite formation (bioactivity) on bone implant surfaces. | Solution must be prepared and used under strict, stable temperature conditions. |

| HPLC System with PDA Detector | For accurate quantification of drug concentrations in release kinetics studies (Protocol 3). | Superior to UV-Vis for complex media or degraded products. |

Principles and Instrumentation

Atomic Force Microscopy (AFM) is a high-resolution scanning probe technique capable of characterizing surface topography and a wide range of physical properties at the nanoscale. Its operation is based on the mechanical interaction between a sharp tip mounted on a flexible cantilever and the sample surface. A laser beam reflected off the back of the cantilever onto a photodetector monitors cantilever deflection, which is used to generate a three-dimensional surface map. For 3D printing material research, AFM is indispensable for quantifying surface roughness, layer adhesion, porosity, and nanomechanical properties, directly correlating print parameters with final material performance.

Table 1: Key Quantitative Parameters in AFM for Material Science

| Parameter | Typical Range | Relevance to 3D-Printed Materials |

|---|---|---|

| Lateral (XY) Resolution | 0.1 - 10 nm | Resolves individual polymer strands, filler particles, and layer boundaries. |

| Vertical (Z) Resolution | 0.01 - 0.1 nm | Measures step heights between printed layers and surface roughness precisely. |

| Force Sensitivity | 1 - 100 pN | Critical for measuring adhesion between layers and local mechanical properties. |

| Scan Size Range | 100 nm - 100+ μm | Enables analysis from nanoscale features to macro-scale print artifacts. |

| Typical Scan Rate | 0.5 - 2 lines/sec | Balances imaging speed with resolution and force control to prevent sample damage. |

Primary Operational Modes

Contact Mode

The tip scans in constant physical contact with the surface. The deflection of the cantilever is kept constant by a feedback loop that adjusts the scanner height. This mode provides high-resolution topographic imaging and frictional force data.

- Advantage: Fast scanning, good for rough, stiff samples.

- Disadvantage: Lateral forces can deform or damage soft materials (e.g., many polymers).

Intermittent Contact (Tapping) Mode

The cantilever is oscillated at or near its resonant frequency. The tip intermittently contacts the surface, and the change in oscillation amplitude or phase is used for feedback. This is the most common mode for 3D-printed polymer analysis.

- Advantage: Minimizes lateral forces, excellent for soft, adhesive, or easily damaged samples.

- Disadvantage: Slightly slower than contact mode.

Non-Contact Mode

The cantilever oscillates near the surface without making contact, sensing van der Waals forces. It is rarely used for polymers due to their common adhesive nature.

- Advantage: Extremely low force, no sample deformation.

- Disadvantage: Lower resolution, requires ultra-clean surfaces in vacuum/air.

Table 2: Comparison of Primary AFM Imaging Modes for Polymer Analysis

| Mode | Feedback Signal | Force Applied | Best For 3D-Printed Materials | Risk of Damage |

|---|---|---|---|---|

| Contact | Cantilever Deflection | High (Constant) | Stiff composites (e.g., carbon-fiber filled), cured resins | High for soft materials |

| Tapping | Oscillation Amplitude | Low (Intermittent) | Most polymers, hydrogels, TPUs, surface roughness | Very Low |

| Non-Contact | Oscillation Frequency/Phase | Very Low | Rare; potentially for delicate, non-adhesive top coatings | Negligible |

Advanced Modes for Material Property Mapping

Force Spectroscopy & Nanoindentation

The AFM tip is used as a nanoindenter. By recording the force-distance curve at a single point or an array of points, local mechanical properties like Young's modulus, adhesion force, and deformation can be quantified.

Protocol: Nanoindentation Mapping of a 3D-Printed Polymer Blend

Objective: To map the spatial variation of elastic modulus across the interface between two co-printed polymers. Materials: See "The Scientist's Toolkit" below. Procedure:

- Sample Preparation: Mount a cross-sectioned sample of the printed interface on a standard AFM specimen disk using a conductive adhesive tab. Ensure the surface is clean and level.

- Cantilever Selection & Calibration: Use a silicon cantilever with a calibrated spring constant (k, typically 1-50 N/m) and a known tip radius (R, via SEM or calibration grating). Determine the optical lever sensitivity (InvOLS) on a clean, rigid sapphire surface.

- Topography Imaging: First, acquire a high-resolution tapping mode image of the target interface region to identify the scan area for the property map.

- Force Curve Array Setup: Define a grid (e.g., 64x64 points) over the region of interest. Set the maximum applied force (setpoint) to 50-200 nN to avoid plastic deformation. Define the extension/retraction speed (typically 0.5-2 μm/s).

- Data Acquisition: Automatically acquire a force-distance curve at every point in the grid.

- Data Analysis: Fit the retraction portion of each curve with an appropriate contact mechanics model (e.g., Derjaguin–Muller–Toporov (DMT) model for stiff samples, or Oliver-Pharr for hard materials). The reduced elastic modulus (E*) is calculated from the slope of the unloading curve. Generate a 2D map of modulus vs. position.

Table 3: Representative Nanoindentation Data from a PLA-TPU Interface

| Position Relative to Interface | Average Reduced Modulus (E*) | Standard Deviation | Adhesion Force |

|---|---|---|---|

| PLA Region (5 μm away) | 3.5 GPa | ± 0.4 GPa | 15 nN |

| Interface (0 μm) | 1.2 GPa | ± 0.6 GPa | 65 nN |

| TPU Region (5 μm away) | 55 MPa | ± 12 MPa | 120 nN |

Phase Imaging (in Tapping Mode)

Monitors the phase lag between the driving oscillation and the cantilever response. This signal is sensitive to viscoelastic properties, adhesion, and dissipation energy, highlighting areas of different material composition.

Conductive AFM (C-AFM)

A conductive tip is used in contact mode with a voltage bias applied. It measures local conductivity or current flow, useful for analyzing printed electronics or composites with conductive fillers (e.g., graphene, CNTs).

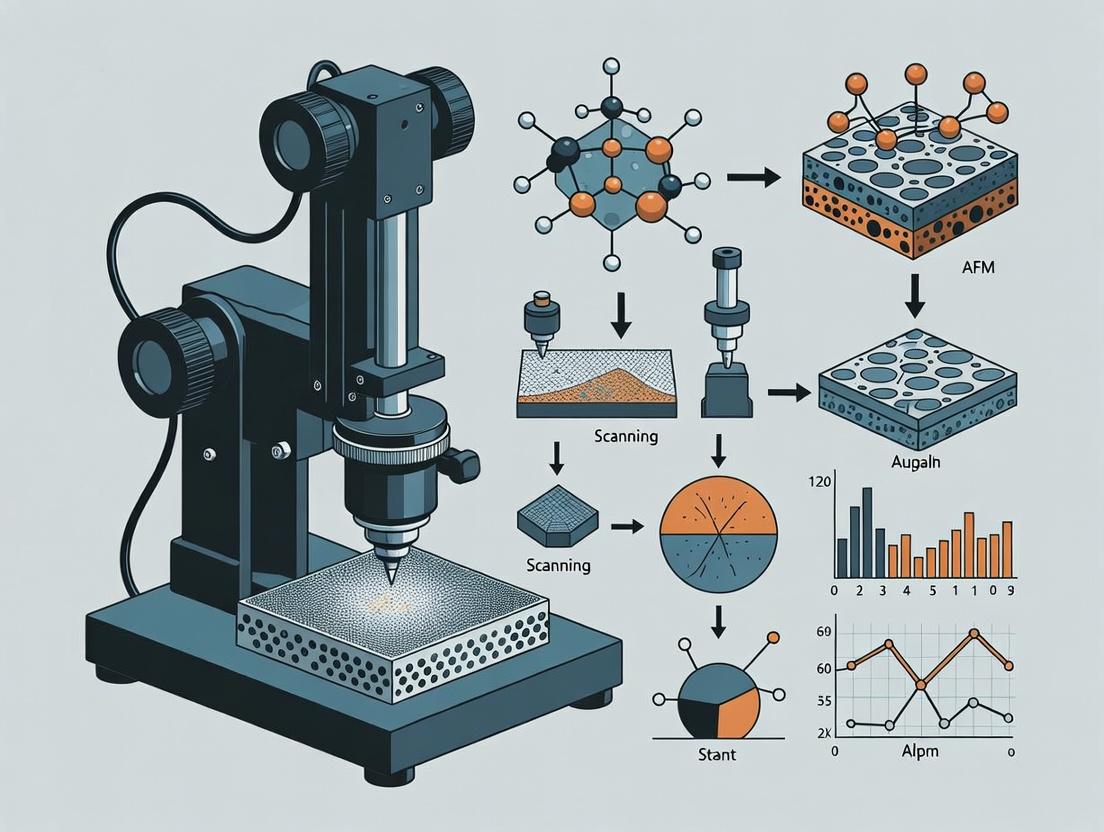

Application Workflow for 3D Printing Material Analysis

AFM Workflow for 3D-Printed Material Analysis

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions & Materials for AFM Analysis of 3D-Printed Polymers

| Item | Function & Relevance |

|---|---|

| Conductive Adhesive Tabs/Carbon Tape | Securely mounts non-magnetic, insulating polymer samples to the AFM metal stub to prevent charging and drift. |

| Pulsed Force Mode (PFM) Cantilevers | Specialized cantilevers with well-defined spring constants and tips for quantitative nanomechanical mapping. |

| Diamond-Coated Tips | For repeated nanoindentation on hard composite materials (e.g., ceramic-filled resins) to maintain tip geometry. |

| Calibration Gratings (TGZ1, PG, HS) | Essential for verifying scanner accuracy in X, Y, and Z, and for tip morphology characterization post-scan. |

| Non-Acoustic Enclosure/Anti-Vibration Table | Isolates the AFM from environmental vibrations crucial for achieving high-resolution data on all length scales. |

| Anti-Static Gun | Neutralizes static charge on polymer samples, which can cause imaging artifacts and attract dust. |

| Soft Polymer Reference Samples (PDMS) | Used to validate force curve calibration and nanoindentation protocols on materials of known, low modulus. |

Within the context of a broader thesis on Atomic Force Microscopy (AFM) for 3D printing material surface analysis, characterizing key surface parameters is fundamental. For 3D-printed biomaterials, especially in drug delivery and tissue engineering, surface topography, roughness, and mechanical properties directly influence cellular adhesion, proliferation, differentiation, and drug release kinetics. This document provides application notes and detailed protocols for the quantitative assessment of these parameters using AFM.

Table 1: Typical Surface Roughness and Mechanical Property Ranges for Common 3D-Printed Biomedical Polymers

| Material & Printing Method | Avg. Roughness, Ra (nm) | RMS Roughness, Rq (nm) | Reduced Elastic Modulus, Er (MPa) | Adhesion Force (nN) | Key Application Context |

|---|---|---|---|---|---|

| PCL (FDM) | 250 - 850 | 300 - 1050 | 120 - 250 | 15 - 40 | Soft tissue scaffolds, drug-eluting implants |

| PLA (FDM) | 150 - 600 | 200 - 750 | 2000 - 3500 | 8 - 25 | Structural scaffolds, orthopedic templates |

| SLA Resin (Standard) | 10 - 50 | 15 - 65 | 1500 - 3000 | 20 - 60 | Microfluidic devices, high-res. prototypes |

| Alginate/Gelatin (Bioprinting) | 50 - 200 | 70 - 250 | 5 - 50 | 40 - 120 | Cell-laden hydrogels, tissue models |

| TPU (FDM) | 300 - 1000 | 400 - 1250 | 30 - 100 | 30 - 80 | Flexible/elastomeric implants |

Table 2: Impact of Key Surface Parameters on Biological Responses in Drug Development Research

| Surface Parameter | Target Range for Enhanced Cell Response | Influence on Drug Release/Pharmacology | Recommended AFM Mode |

|---|---|---|---|

| Ra (Sub-100 nm) | Fibroblast adhesion, endothelialization | Modulates protein adsorption, affecting release kinetics | Tapping Mode, Contact Mode |

| Ra (100-1000 nm) | Osteoblast differentiation, mesenchymal stem cell fate | Increased surface area can accelerate burst release | Tapping Mode |

| Elastic Modulus (1-10 kPa) | Neural progenitor cell differentiation | Affects degradation rate of polymer matrix | Force Spectroscopy (QNM) |

| Elastic Modulus (10-100 kPa) | Muscle cell maturation | Influences mechanical integrity of drug depot | Force Spectroscopy (QNM) |

| Adhesion Force (High) | Platelet adhesion (thrombogenicity) | Can trap carrier particles or proteins | Force Spectroscopy |

| Adhesion Force (Moderate) | Controlled cell spreading and signaling | Optimal for targeted nanoparticle binding | Force Spectroscopy |

Experimental Protocols

Protocol 1: Topography and Roughness (Ra, Rq) Mapping of 3D-Printed Surfaces

Objective: To acquire high-resolution 3D topography and calculate ISO 4287-compliant roughness parameters.

Materials & Sample Prep:

- Sample: 3D-printed polymer scaffold (e.g., PCL, PLA). Solvent-clean if necessary (e.g., ethanol wash, air dry).

- AFM Probe: Silicon nitride tip (e.g., Bruker SNL, k ≈ 0.35 N/m) for contact mode, or silicon tip (e.g., Tap150Al-G, f₀ ≈ 150 kHz) for tapping mode.

- Substrate: Sample firmly mounted on a 15 mm steel disc using double-sided adhesive.

Procedure:

- Mounting: Secure sample disc onto AFM piezoelectric scanner.

- Probe Engagement: Align laser, set photodetector sum to manufacturer's specification. Engage probe in contact or tapping mode using standard engage parameters.

- Scan Acquisition:

- Set scan size to a representative area (e.g., 20 µm x 20 µm to 100 µm x 100 µm).

- Set scan rate to 0.5-1.0 Hz for high resolution.

- Optimize feedback gains (Integral and Proportional) to minimize tracking error.

- Acquire scan in height sensor mode.

- Flattening & Analysis:

- Apply a 0th or 1st order flattening algorithm to the raw height image to remove tilt.

- Use the instrument's roughness analysis software.

- Define a primary profile from a single trace. Apply a Gaussian filter with a cutoff wavelength (λc) of 0.8 mm (for this profile length) to separate waviness from roughness.

- Calculate Ra (Arithmetic Mean Deviation) and Rq (Root Mean Square Deviation) from the roughness profile according to:

Ra = (1/L) ∫|Z(x)| dxRq = √[ (1/L) ∫ Z(x)² dx ]

- Report the mean and standard deviation from multiple (n≥3) scans on different sample regions.

Protocol 2: Nanomechanical Mapping via PeakForce QNM

Objective: To simultaneously map elastic modulus (E) and adhesion force with nanoscale resolution.

Materials:

- Sample: Hydrated or dry 3D-printed hydrogel (e.g., GelMA).

- AFM Probe: Silicon tip on a soft cantilever (e.g., Bruker ScanAsyst-Air, k ≈ 0.4 N/m). Pre-calibrate spring constant (thermal tune) and optical lever sensitivity.

- Fluid Cell: If measuring in liquid (PBS, media).

Procedure:

- Calibration: Perform a force curve on a clean, rigid reference sample (e.g., sapphire) to define the tip deflection sensitivity. Calibrate the tip radius using a characterized rough sample or after measurement via reconstruction.

- Engagement: Engage in PeakForce Tapping mode. Set PeakForce frequency to 0.25-2 kHz and amplitude to achieve desired contact force (~1-10 nN for soft materials).

- Mapping Acquisition: Set scan size and rate (typically 5-10 µm, 0.7 Hz). The system will acquire a force-distance curve at every pixel.

- Data Processing (Derrick Model Fit):

- For each curve, fit the retract portion to the Derjaguin-Muller-Toporov (DMT) model:

F = (4/3) E* √(R δ^(3/2)) + F_adh- Where

E*is the reduced modulus,Ris tip radius,δis indentation depth.

- The Adhesion Force is taken as the minimum force on the retract curve.

- The elastic modulus of the sample (

E_sample) is derived fromE*, assuming a known Poisson's ratio (νsample ~0.5 for hydrogels) and tip modulus (Etip):1/E* = (1-ν_sample²)/E_sample + (1-ν_tip²)/E_tip

- For each curve, fit the retract portion to the Derjaguin-Muller-Toporov (DMT) model:

- Reporting: Generate 2D maps of Modulus and Adhesion. Report mean values from homogenous regions, noting hydration state and loading rate.

Diagrams

Title: AFM Analysis Workflow for 3D Printed Materials

Title: Surface Parameters Influence Biological Response

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AFM Surface Analysis of 3D-Printed Biomaterials

| Item | Function in Research | Example Product/Catalog |

|---|---|---|

| Standard AFM Calibration Grids | Verify lateral (µm-scale) and vertical (nm-scale) scanner accuracy. Essential for quantitative roughness. | Bruker PG: 1 µm pitch, 180 nm depth; BudgetSensors HS-100MG |

| Stiff Reference Sample | Calibrate force spectroscopy sensitivity and verify modulus measurement on a known standard. | Sapphire wafer, Fused Silica (E ~70 GPa) |

| Soft Reference Sample | Validate modulus measurements on compliant, hydrogel-like materials. | PDMS slabs of known modulus (e.g., 2 MPa), Polyacrylamide gels |

| Sharp AFM Probes (Si3N4) | For contact mode topography on soft polymers. Low spring constant minimizes sample damage. | Bruker DNP-S10, Olympus RC800PSA |

| PeakForce Tapping Probes | For high-res. nanomechanical mapping (PeakForce QNM). Pre-calibrated tips recommended. | Bruker ScanAsyst-Air (k~0.4 N/m), ScanAsyst-Fluid+ |

| Bio-Inert Liquid Cell | Enables AFM characterization in physiologically relevant buffers (PBS, cell culture media). | Bruker MTFML (for BioScope), JPK Liquid Pod |

| Sample Mounting Adhesive | Securely fix 3D-printed, often irregular, samples to AFM discs without contaminating surface. | Double-sided carbon tape, Blu-Tack reusable adhesive |

| Deionized Water & Solvents | For cleaning samples and probes. Isopropyl alcohol for degreasing, DI water for rinsing. | HPLC-grade isopropanol, 18.2 MΩ·cm DI water |

The Unique Advantages of AFM for Soft, Compliant, and Complex 3D Printed Structures

Atomic Force Microscopy (AFM) is an indispensable tool for the surface analysis of advanced 3D printed materials, particularly within the context of biomedical research and drug development. For soft, compliant, and geometrically complex 3D printed structures—such as tissue scaffolds, drug-eluting implants, and microfluidic devices—AFM provides unique advantages over other surface characterization techniques. Its ability to operate in fluid, apply minimal force, and map both topography and nanomechanical properties in three dimensions makes it uniquely suited for these challenging materials.

Recent studies, confirmed via current literature search, highlight AFM's critical role in quantifying the structure-function relationship of 3D printed biomaterials. Key application areas include:

- Nanomechanical Mapping: Quantifying the local elastic (Young's) modulus of hydrogel lattices and soft polymer scaffolds, correlating print parameters with mechanical compliance.

- Surface Morphology & Roughness: Precisely measuring the surface topography of printed features at the nano- and micro-scale, which influences cell adhesion and protein adsorption.

- Adhesion & Force Spectroscopy: Measuring binding forces between drug compounds and printed polymeric surfaces, or between cell receptors and functionalized scaffolds.

- Real-Time Monitoring: Observing structural degradation, swelling, or protein fouling on compliant printed surfaces in physiological buffers.

Key Experimental Protocols

Protocol 1: Nanomechanical Property Mapping of a 3D Printed Hydrogel Scaffold

Aim: To spatially map the Young's modulus of a poly(ethylene glycol) diacrylate (PEGDA) hydrogel lattice printed via digital light processing (DLP).

Materials:

- AFM with quantitative nanomechanical mapping (QNM) or PeakForce Tapping capability.

- Soft, compliant cantilever (nominal spring constant: 0.1 - 0.5 N/m, tip radius: < 20 nm).

- Calibration sample (e.g., polystyrene/polyethylene blend with known modulus).

- 3D printed PEGDA hydrogel sample in phosphate-buffered saline (PBS).

- Fluid cell or compatible liquid chamber.

Methodology:

- Cantilever Calibration: In air, determine the precise spring constant (k) using the thermal tune method. Calibrate the optical lever sensitivity (InvOLS) on a rigid surface in PBS.

- Tip Characterization: Image a characterized, sharp grating to determine the effective tip radius.

- Sample Preparation: Immobilize the hydrated hydrogel scaffold on a glass-bottom Petri dish using a thin layer of cyanoacrylate glue at the edges. Flood with PBS to prevent dehydration.

- AFM Mounting: Mount the dish on the scanner and engage the cantilever in liquid.

- Force Curve Acquisition: Set parameters for PeakForce Tapping mode: Peak Force Frequency = 0.25-1 kHz, Peak Force Setpoint = 100-500 pN (to limit strain to <10%).

- Mapping: Acquire a 50 µm x 50 µm map at 256 x 256 pixels resolution. The DMT or Sneddon model is applied to each force curve in real-time to calculate Young's modulus.

- Data Analysis: Use the instrument software to generate spatial modulus maps, histogram distributions, and correlate modulus with topographic features (e.g., strut junctions vs. center).

Protocol 2: Surface Roughness Analysis of a Drug-Loaded Polymeric Filament

Aim: To quantify the surface roughness (Sa, Sq) of a polycaprolactone (PCL) filament printed via fused deposition modeling (FDM), before and after drug (e.g., Doxycycline) incorporation.

Materials:

- AFM with tapping or contact mode capability.

- Silicon cantilever (nominal frequency: 150-300 kHz, spring constant: 5-40 N/m).

- Flat, rigid sample mounting discs.

- Double-sided adhesive tape.

- PCL and drug-loaded PCL printed specimens.

Methodology:

- Sample Mounting: Securely attach a small, flat section of the printed filament to a mounting disc using double-sided tape to minimize wobble.

- Cantilever Selection: Engage a stiff, sharp silicon tip for high-resolution topography.

- Imaging: In tapping mode, scan multiple 10 µm x 10 µm and 2 µm x 2 µm areas across the sample surface. Maintain a consistent scan rate (0.5-1 Hz) and setpoint ratio.

- Image Processing: Flatten scan lines to remove tilt. Apply a low-pass filter if necessary to remove high-frequency noise.

- Roughness Analysis: Use the software's roughness analysis tool to calculate the arithmetic mean height (Sa) and the root mean square height (Sq) for each scan. Compare values between pure and drug-loaded PCL surfaces.

Table 1: Comparison of Surface Characterization Techniques for Soft 3D Printed Structures

| Technique | Spatial Resolution (Lateral) | Mechanical Property Mapping | Measurement Environment | Sample Preparation Complexity | Key Limitation for Soft Materials |

|---|---|---|---|---|---|

| Atomic Force Microscopy (AFM) | ~0.5 nm | Yes (Quantitative) | Air, Liquid, Controlled Gas | Low | Scan size limited (<100µm typical) |

| Scanning Electron Microscopy (SEM) | ~1 nm | No | High Vacuum (typically) | High (coating, drying) | Not for hydrated samples; conductive coating alters surface |

| Optical Profilometry | ~0.2 µm | No (topography only) | Air | Low | Low lateral resolution; poor with transparent/compliant materials |

| Confocal Microscopy | ~0.2 µm | No (topography/fluorescence) | Air, Liquid | Medium | Limited to optical contrast; indirect mechanical data |

Table 2: Typical AFM-Derived Quantitative Data from 3D Printed Soft Materials

| Material | Printing Technique | AFM Mode | Key Measured Parameter | Representative Value Range | Biological/Functional Relevance |

|---|---|---|---|---|---|

| PEGDA Hydrogel | Digital Light Processing (DLP) | PeakForce QNM | Young's Modulus (E) | 5 - 50 kPa | Mimics soft tissue stiffness (e.g., brain, fat) |

| Alginate/Gelatin Bioink | Extrusion Bioprinting | Force Spectroscopy | Adhesion Force (Cell-Bioink) | 50 - 500 pN | Predicts cell attachment and spreading |

| Polycaprolactone (PCL) | Fused Deposition Modeling (FDM) | Tapping Mode | Surface Roughness (Sa) | 100 - 500 nm | Influences protein adsorption and osteointegration |

| PDMS Microfluidic Device | Stereolithography (SLA) | Contact Mode | Friction Coefficient | 0.1 - 0.5 | Determines fluid flow and cell shear stress |

Diagrams

AFM Analysis Workflow for 3D Printed Materials

AFM Data Informs Biomaterial Function

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in AFM Analysis of 3D Printed Structures |

|---|---|

| Functionalized AFM Tips (e.g., Collagen, RGD peptide) | Covalently modified tips measure specific biomolecular interaction forces between the printed surface and proteins or simulated cell membranes. |

| Calibration Gratings (TGF11, HS-100MG) | Essential for verifying the lateral accuracy of the AFM scanner and characterizing the geometry of the AFM tip itself. |

| Soft Cantilevers for QNM (e.g., ScanAsyst-Fluid+) | Silicon nitride tips on very flexible levers enable high-resolution, low-force imaging and modulus mapping of hydrogels in liquid. |

| Stiff Cantilevers for Tapping (e.g., RTESPA-300) | High-frequency, stiff silicon tips for high-resolution topographic imaging of stiffer polymers (e.g., PCL, PLA) with minimal surface damage. |

| Bio-Inert Liquid Cell | Allows stable imaging and force measurements in physiologically relevant buffers (PBS, cell culture medium) without contaminating the scanner. |

| Sample Mounting Adhesive (e.g., CrystalBond 509) | Thermally reversible adhesive to securely mount small, irregularly shaped 3D printed specimens to AFM discs without damaging the surface. |

Within the broader thesis on Atomic Force Microscopy (AFM) for 3D printing material surface analysis, this document outlines the critical application notes and protocols for addressing the lack of standardization in surface metrology for Additive Manufacturing (AM). The inherent layer-by-layer process of AM creates complex surfaces with unique topography, roughness, and texture that are not adequately captured by traditional 2D profilometry. The absence of standardized measurement protocols, parameters, and data analysis methods hinders reproducibility, quality control, and the correlation of surface features with functional performance, especially in regulated fields like biomedical device and drug delivery implant development.

The primary challenges in AM surface metrology stem from the multi-scale nature of AM surfaces, ranging from macro-scale warpage to nano-scale powder sinter features.

Table 1: Key Metrology Gaps and Their Impact on AM Research & Development

| Gap/Challenge | Description | Impact on Research/Development |

|---|---|---|

| Parameter Selection | Inconsistent use of roughness parameters (Sa, Sq, Sz) and spatial parameters (Sal, Str). Lack of guidelines for parameter relevance to AM surface types (e.g., as-built upskin vs. downskin). | Prevents direct comparison between studies, obscures process-property relationships. |

| Measurement Protocol | No consensus on sampling area, measurement location/orientation, filtering (S-F, L-F), and data stitching for large areas. | Introduces operator-dependent variability, reduces data reliability. |

| Instrument & Method Limitations | Confocal microscopy struggles with high aspect ratio valleys; SEM is primarily qualitative; stylus profilometry may damage soft polymers. | Incomplete surface characterization, missing critical topographic data. |

| Data Analysis & Reporting | Non-standardized formats for data storage and reporting. Proprietary software algorithms yield different results from the same dataset. | Hampers data sharing, meta-analysis, and the establishment of certified reference materials. |

| Correlation to Function | Difficulty linking specific surface metrics (e.g., hybrid parameters) to in-vivo performance (osseointegration, bacterial adhesion) or fluid flow. | Slows the iterative design of functional surfaces for drug-eluting implants or lab-on-a-chip devices. |

Detailed Experimental Protocols for AFM-Based Surface Characterization

Protocol 1: Multi-Scale AFM Topography Acquisition for AM Polymer Surfaces

- Objective: To obtain quantitative, three-dimensional topographical data from a selective laser sintered (SLS) polyamide (PA12) component at the micro- to nano-scale.

- Thesis Context: This protocol provides the foundational, reproducible methodology for the thesis's core AFM analysis.

- Materials: As-built PA12 specimen, anti-static air duster, AFM with scanning probe (e.g., silicon cantilever, tip radius <10 nm).

- Procedure:

- Sample Preparation: Use compressed, oil-free air to remove loose powder particles. Mount the sample firmly on a magnetic or adhesive AFM disc. Avoid chemical cleaning unless its effect is part of the study.

- Probe Selection: Choose a non-contact or tapping mode probe appropriate for polymers (medium spring constant ~40 N/m) to minimize sample damage.

- Site Selection: Using an integrated optical microscope, identify and target three representative areas: an upskin (top) surface, a downskin (bottom) surface, and a vertical side surface. Mark locations.

- Scan Acquisition:

- Perform an initial large-area scan (e.g., 100 µm x 100 µm) to assess general topography.

- Subsequently, perform higher-resolution scans (e.g., 10 µm x 10 µm and 2 µm x 2 µm) at each location to capture finer details of powder particles and sinter necks.

- Set scan rate to 0.5-1 Hz to optimize signal-to-noise ratio.

- Apply real-time plane leveling (flattening order 1 or 2).

- Data Saving: Save raw data (.spm, .ibw, etc.) and export height, amplitude, and phase images in a standardized format (e.g., .tiff).

Protocol 2: Post-Processing and Roughness Parameter Calculation

- Objective: To standardize the derivation of ISO 25178 areal surface parameters from AFM data.

- Procedure:

- Import: Load the raw height data into a surface metrology software package (e.g., Gwyddion, MountainsMap).

- Form Removal: Apply a least-squares mean plane subtraction (flattening) to remove sample tilt.

- Filtering:

- Apply an S-Filter (Gaussian filter, λs = 0.25 µm) to remove high-frequency noise.

- Apply an L-Filter (Gaussian regression filter, λc = 8 µm) to separate roughness from waviness. The selection of λc must be reported.

- Masking: Manually or automatically mask out non-measurement artifacts (e.g., deep pits from entrapped powder).

- Parameter Extraction: Calculate and record the following core set of parameters for each scan:

- Height Parameters: Sa (Arithmetical mean height), Sq (Root mean square height), Sz (Maximum height).

- Spatial Parameters: Sal (Autocorrelation length), Str (Texture aspect ratio).

- Hybrid Parameters: Sdr (Developed interfacial area ratio).

Visualization of the Standardization Workflow and Challenge Relationships

Title: AM Surface Metrology Challenges & AFM Solution Path

Title: AFM Data Post-Processing Protocol Workflow

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Toolkit for Standardized AFM Surface Metrology in AM Research

| Item | Function/Description | Application Note |

|---|---|---|

| AFM with Environmental Control | Enables scanning in non-contact/tapping mode to prevent damage to soft AM polymers. Humidity/temp control ensures measurement stability. | Critical for soft materials (e.g., PEEK, hydrogels). Use anti-vibration table. |

| Standardized Reference Sample | A physical artifact with known, traceable roughness values (e.g., ISO 5436-1). | Used for daily verification of AFM lateral and vertical calibration. |

| Surface Metrology Software (e.g., MountainsMap, Gwyddion) | Software compliant with ISO 25178 for areal surface parameter calculation with controlled filtering. | Avoid using instrument-default software only; ensures algorithmic consistency. |

| Stable Sample Mounting Kit | Includes magnetic disks, conductive tape, and adjustable sample stages. | Prevents sample drift during long or high-resolution scans. |

| Probe Kit for Diverse Materials | Includes high-resolution silicon probes for polymers, diamond-coated probes for metals/ceramics, and conductive probes. | Matching probe to material prevents damage and artifacts. |

| Data Format Standard (e.g., OPFS) | Open吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕吕 |

A Step-by-Step Guide to AFM Protocol for 3D Printed Polymer and Biomaterial Surfaces

Atomic Force Microscopy (AFM) analysis of 3D printed materials provides critical insights into surface topography, roughness, and mechanical properties, which are essential for evaluating print fidelity, layer adhesion, and post-processing effects. Within the broader thesis on AFM for 3D printing material surface analysis, proper specimen preparation is paramount. Inconsistent mounting, contamination, and improper handling are primary sources of artifacts that can compromise data integrity. These application notes detail standardized protocols to ensure reproducible, high-fidelity AFM measurements on polymeric, composite, and resin-based 3D printed specimens.

Mounting Protocols for Stability

Secure and stable mounting is critical to prevent vibration and drift during AFM scanning.

Protocol: Rigid Substrate Adhesion for Planar Specimens

- Objective: To immobilize a specimen with a flat base onto a standard AFM specimen disc.

- Materials: Double-sided adhesive tape (carbon-conductive or high-tack acrylic), cyanoacrylate gel, or two-part epoxy; flat AFM metal discs; forceps.

- Method:

- Clean the AFM disc with isopropanol and lint-free wipes. Allow to dry.

- For tape: Apply a piece slightly smaller than the specimen to the disc. Remove the liner and gently place the specimen onto the tape. Apply firm, even pressure for 30 seconds.

- For adhesive/gel: Apply a minimal dot to the center of the disc. Position the specimen and apply gentle pressure. Allow full curing per manufacturer instructions (e.g., 5 min for gel, 24 hrs for epoxy).

- Key Consideration: Adhesive choice depends on scan forces and required conductivity. Excess adhesive must be avoided to prevent contaminating the scan area.

Protocol: Custom Fixturing for Non-Planar or Fragile Specimens

- Objective: To mount irregularly shaped or delicate prints without inducing stress or instability.

- Materials: Custom 3D printed or machined clamps/holders, modeling clay (non-outgassing), vacuum chuck.

- Method:

- Design a fixture that supports the specimen at its base or sides, leaving the scan area completely accessible and unobstructed.

- Secure the fixture firmly to the AFM disc using an adhesive.

- Gently place the specimen into the fixture. If using compliant clay, embed only the very edges of the specimen's base.

- For porous specimens, a low-pressure vacuum chuck can be effective.

Cleaning Protocols for Surface Contaminant Removal

Residual support material, oils, and dust are common contaminants that obscure true surface morphology.

Protocol: Dry Cleaning for Particulate Removal

- Objective: To remove loose powder, dust, and support fragments without altering the surface.

- Materials: Clean, dry nitrogen or compressed air gun (with in-line 0.2 µm filter), soft anti-static brushes.

- Method:

- Hold the specimen at an angle. Using short, controlled bursts from a distance of 2-5 cm, direct the gas stream across the surface.

- For delicate surfaces, use a soft anti-static brush with gentle, sweeping motions.

- Always perform this step before any wet cleaning.

Protocol: Solvent Cleaning for Organic Residue Removal

- Objective: To dissolve and remove printing oils, uncured resin, or fingerprint residues.

- Critical Pre-Test: Solvent compatibility must be tested on a non-critical area of the print material to check for swelling, cracking, or dissolution.

- Method:

- Immerse or gently flood the specimen surface with the appropriate solvent.

- Agitate gently via low-power ultrasonication (<40 kHz) for 30-60 seconds if the specimen is not fragile.

- Rinse immediately with a second aliquot of clean solvent.

- Dry thoroughly under a filtered nitrogen stream.

Table 1: Recommended Cleaning Solvents for Common 3D Print Materials

| Material Class (Example) | Recommended Solvent(s) | Contraindicated Solvents | Application Notes |

|---|---|---|---|

| Photopolymers (SLA, DLP Resins) | Isopropyl Alcohol (IPA), Ethanol | Acetone, Chlorinated solvents | IPA immersion followed by nitrogen dry is standard for uncured resin removal. |

| Fused Filaments (ABS) | Acetone (for vapor smoothing), IPA | N/A | Acetone will aggressively smooth; use IPA for gentle cleaning. |

| Fused Filaments (PLA) | IPA, Ethanol | Acetone | Acetone can degrade PLA surface. |

| Polyjet (Stratasys) Photopolymers | Water, diluted detergent, IPA | Strong organic solvents | Support material is water-soluble; follow manufacturer guidelines. |

| SLS Nylon (PA11, PA12) | Isopropyl Alcohol | Acetone (can cause stress cracking) | Effective for removing loose powder. |

Handling and Storage Protocols

Proper handling minimizes introduction of new contaminants or damage prior to analysis.

Protocol: Contamination-Minimized Handling

- Objective: To transfer and position specimens without depositing particulates or oils.

- Materials: Powder-free nitrile gloves, clean forceps with non-scratching tips (e.g., plastic or coated), dedicated clean storage containers.

- Method:

- Always wear clean gloves. Handle specimens by their edges or non-analysis areas only.

- Use forceps for final positioning on the AFM stage.

- Never touch the analysis surface or the AFM probe.

Protocol: Short- & Long-Term Storage

- Objective: To preserve specimen surface state between printing and measurement.

- Materials: Clean, sealed glass or plastic containers, desiccant packets.

- Short-Term (<24 hrs): Store in a covered, clean Petri dish or similar.

- Long-Term (>24 hrs): Place in an airtight container with desiccant. Store in dark, temperature-stable conditions to prevent material creep or UV degradation.

Workflow & Experimental Pathway

AFM Sample Preparation Workflow for 3D Prints

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for AFM Sample Preparation

| Item | Function in Protocol | Key Consideration |

|---|---|---|

| High-Purity Isopropanol (IPA) | Primary solvent for cleaning photopolymer resins and many filaments. Removes organic residues. | Use HPLC or electronic grade to avoid non-volatile impurities. |

| Filtered, Dry Nitrogen Gun | Dust-free drying after cleaning; dry particulate removal. | In-line 0.2 µm filter is mandatory to prevent oil/particulate deposition. |

| Double-Sided Carbon Tape | Conductive mounting for planar specimens. Prevents charging in electrical modes. | Ensures electrical contact for conductive-AFM or Kelvin Probe modes. |

| Cyanoacrylate Gel Adhesive | Rigid, fast-curing mounting for unstable or tall specimens. | Gel formulation minimizes wicking to the analysis surface. |

| Powder-Free Nitrile Gloves | Mandatory for handling to prevent skin oil and salt contamination. | Latex gloves can deposit particulates; cotton gloves can shed fibers. |

| Anti-Static Brushes | Gentle removal of electrostatic dust from fragile surfaces. | Natural soft hair (e.g., camel) is preferred to prevent scratching. |

| Clean Room Wipes (Lint-Free) | Wiping AFM discs and tools with solvent. | Non-woven polyester or cellulose are suitable low-lint options. |

| Desiccant (Silica Gel) | Maintaining dry storage atmosphere to prevent hydrolysis or creep. | Use indicator beads and regenerate regularly. |

Within the broader thesis on Atomic Force Microscopy (AFM) for 3D printing material surface analysis, selecting the appropriate imaging mode is critical for obtaining accurate, high-resolution topographical and mechanical property data. This application note provides detailed protocols and comparisons for Contact, Tapping, and PeakForce Tapping modes, tailored for researchers analyzing advanced polymers, composites, and bio-printed materials used in scientific and drug development applications.

Key AFM Mode Characteristics & Quantitative Comparison

The following table summarizes the core operational parameters and optimal application ranges for each mode, based on current instrument specifications and published research.

Table 1: Quantitative Comparison of Primary AFM Modes for Material Analysis

| Parameter | Contact Mode | Tapping Mode | PeakForce Tapping Mode |

|---|---|---|---|

| Tip-Sample Interaction | Constant physical contact | Intermittent contact (oscillating) | Pulsed, sub-100 pN to >10 nN force |

| Typical Force Applied | 0.5 - 100 nN | 0.1 - 5 nN (peak force) | Precisely controlled, often <1 nN |

| Lateral (Shear) Forces | High | Negligible | Very Low |

| Imaging Speed | Moderate | Fast | Fast (with quantitative data) |

| Best Vertical Resolution | <0.1 nm | ~0.1 nm | ~0.1 nm |

| Sample Damage Risk | High (soft samples) | Moderate to Low | Very Low |

| Key Measured Properties | Topography, Friction | Topography, Phase (adhesion/viscoelasticity) | Topography, Young's Modulus, Adhesion, Deformation, Dissipation |

| Ideal Material Types | Hard, flat, inert surfaces (e.g., silicon, metals) | Soft polymers, biological samples, heterogeneous surfaces | All, especially: ultra-soft gels, compliant polymers, multicomponent 3D prints |

Detailed Experimental Protocols

Protocol 1: Contact Mode Imaging for Hard 3D-Printed Resins

Objective: To obtain high-resolution topography of rigid, cured photopolymer resin surfaces. Materials: AFM with contact mode scanner, Si or Si3N4 contact mode probes (k ~ 0.2 N/m), rigid 3D-printed sample. Procedure:

- Probe & Laser Alignment: Mount a contact mode cantilever. Align the laser spot on the cantilever's end and adjust the photodetector to achieve a sum signal maximum and a vertical deflection (VD) signal near zero.

- Engagement: Position the tip above a featureless area of the sample. Initiate automatic engagement with a setpoint force of ~5-10 nN.

- Feedback Optimization: Set scan parameters (Scan rate: 1-2 Hz, Scan size: 5x5 μm). Adjust the Proportional (P) and Integral (I) gains to maintain a setpoint with minimal oscillation in the VD signal.

- Data Acquisition: Acquire topography and lateral force (friction) images simultaneously. Save raw data channels.

- Post-Processing: Apply a first-order flattening to remove sample tilt. Analyze surface roughness (Ra, Rq).

Protocol 2: Tapping Mode Imaging for Polymer Blend Phase Separation

Objective: To map topography and phase distribution in a thermoplastic polyurethane/polycarbonate blend. Materials: AFM with tapping mode capability, stiff tapping probe (k ~ 40 N/m, f0 ~ 300 kHz), polymer blend sample. Procedure:

- Tune Cantilever: In air, auto-tune the cantilever to find its resonant frequency (f0) and quality factor (Q).

- Set Parameters: Set drive amplitude (A_drive) to 50-80% of the free amplitude. Choose a scan rate of 0.5-1 Hz.

- Engage & Setpoint: Engage with a setpoint amplitude (A_sp) of ~70-80% of the free amplitude.

- Optimize Feedback: Adjust P and I gains to maintain A_sp without ringing. The Phase signal should be monitored simultaneously.

- Acquire Data: Collect Topography and Phase images. The phase contrast reveals domains with differing adhesive or viscoelastic properties.

- Analysis: Use histogram analysis of the phase image to quantify area fraction of distinct domains.

Protocol 3: PeakForce Tapping Nanomechanical Mapping of a Bio-Ink

Objective: To quantitatively map the modulus and adhesion of an alginate-based bio-printed hydrogel. Materials: AFM with PeakForce QNM capability, sharp silicon probe with calibrated spring constant (k ~ 0.7 N/m) and tip radius, bio-ink sample in hydrated cell culture medium. Procedure:

- Probe Calibration: Perform thermal tune to determine k and deflection sensitivity. Input known tip radius for modulus quantification.

- Fluid Setup: Mount sample in fluid cell. Submerge tip. Re-align laser and re-tune in fluid (lower f0, higher Q).

- Enable PeakForce Tapping: Set PeakForce frequency to 1-2 kHz. Set a low PeakForce amplitude (~50-100 nm).

- Optimize PeakForce Setpoint: Adjust the peak force setpoint to the lowest value that maintains stable imaging (~100-500 pN for gels).

- Acquire Quantitative Maps: Collect Topography, Young's Modulus (Derjaguin–Müller–Toporov (DMT) model), Adhesion, and Deformation maps simultaneously.

- Data Validation: Ensure modulus values are within the model's applicability for the sample. Use a reference sample of known modulus for verification.

AFM Mode Selection Workflow Diagram

Title: AFM Mode Selection Decision Tree

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for AFM Analysis of 3D-Printed Surfaces

| Item | Function & Relevance |

|---|---|

| Si3N4 Contact Probes (k ~ 0.1 N/m) | Low spring constant for imaging hard materials with minimal induced deformation in Contact Mode. |

| High-Frequency Si Tapping Probes (k ~ 40 N/m, f0 ~ 300 kHz) | Stiff probes for high-resolution Tapping Mode in air; phase imaging for material contrast. |

| SCANASYST-FLUID+ Probes | Proprietary probes optimized for PeakForce Tapping in fluid; pre-calibrated for consistent nanomechanical data. |

| Polystyrene-Polyethylene (PS-PE) Reference Sample | Standard sample with known, distinct domains for verifying Tapping Mode phase contrast and tip condition. |

| PDMS Calibration Grid | Sample with periodic structures of known height and pitch for verifying AFM scanner calibration in X, Y, and Z. |

| Deionized Water & HPLC-Grade Ethanol | For cleaning substrates and probes, and for imaging in liquid environments to reduce capillary forces. |

| Adhesive Tape or Thermal Conductive Paste | For securely mounting small or irregular 3D-printed samples to AFM specimen disks to prevent drift. |

| Argon Gas Duster | For removing particulate contamination from samples and the AFM stage without contact. |

Within the context of Atomic Force Microscopy (AFM) applied to 3D printing material surface analysis, precise optimization of operational parameters is critical for generating reliable, high-fidelity nanoscale topography data. This data directly informs research on surface roughness, layer adhesion, and drug release kinetics from printed pharmaceutical formulations. This document provides application notes and protocols for methodically optimizing three interdependent parameters: Scan Rate, Resolution (pixels per line), and Setpoint, to balance imaging quality, tip integrity, and data acquisition efficiency.

The Parameter Triad: Core Concepts & Interdependencies

Scan Rate

The speed at which the probe tip travels across the sample surface, typically measured in Hz (lines per second). Excessively high rates can cause tip skipping or deformation of soft materials, while low rates increase scan time and drift susceptibility.

Resolution (Pixel Density)

Defined by the number of data points sampled per line (X-resolution) and the number of lines per image (Y-resolution). Higher resolution reveals finer detail but requires slower scan rates or risks oversampling.

Setpoint

The target value for the feedback loop (e.g., oscillation amplitude in tapping mode, deflection in contact mode). It defines the tip-sample interaction force. A low setpoint increases force, potentially damaging soft samples; a high setpoint risks instability and loss of contact.

Interdependency

These parameters are intrinsically linked. Increasing resolution necessitates a proportional decrease in scan rate to maintain data point sampling time. The setpoint must be adjusted relative to the scan rate to ensure the feedback loop can track topography accurately at the chosen speed.

Quantitative Parameter Guidelines for 3D Printing Materials

The following table summarizes recommended starting parameters and optimization ranges for common 3D printed material classes, derived from current literature and experimental practice.

Table 1: Initial AFM Parameter Ranges for 3D Printed Material Classes

| Material Class (Example) | Recommended Mode | Initial Setpoint Ratio* | Initial Scan Rate (Hz) | Recommended Resolution (pixels) | Key Consideration |

|---|---|---|---|---|---|

| Hard Thermoplastics (PLA, ABS) | Tapping Mode | 0.7 - 0.8 | 1.0 - 2.0 | 512 x 512 | High setpoint for durability; moderate rate for layer edge definition. |

| Flexible Polymers/Elastomers (TPU, Silicones) | Tapping Mode (Low Amp) | 0.85 - 0.95 | 0.5 - 1.0 | 512 x 512 or 256 x 256 | High setpoint ratio minimizes force; slow scan to prevent surface deformation. |

| Photopolymer Resins (SLA/DLP Printed) | Tapping Mode | 0.75 - 0.85 | 0.8 - 1.5 | 512 x 512 | Potential for tip contamination; medium setpoint balances tracking and safety. |

| Pharmaceutical Blends (API-Polymer Matrices) | Tapping Mode | 0.80 - 0.90 | 0.3 - 0.7 | 1024 x 1024 | Very soft; ultra-low force and slow scan essential to resolve API crystals. |

| Hydrogels/Bioprinted | Tapping Mode in Fluid | 0.90 - 0.98 | 0.1 - 0.5 | 256 x 256 | Near-free amplitude operation; extremely slow scanning in liquid. |

| Metallic/Composite | Contact Mode | 0.5 - 2.0 nA | 1.0 - 3.0 | 512 x 512 | Stable deflection setpoint; higher rates possible on hard surfaces. |

Ratio of setpoint amplitude to free-air oscillation amplitude. *Deflection setpoint in nA or V.

Experimental Protocol: Iterative Parameter Optimization

Protocol 1: Establishing Baseline Conditions for a Novel Material

Objective: To determine a stable, non-destructive starting point for imaging an unknown 3D printed sample. Materials: AFM with tapping mode capability; appropriate cantilever; 3D printed sample; calibration grating. Procedure:

- Cantilever Tuning: Resonate the cantilever in air (or fluid). Note the free amplitude (A~0~).

- Coarse Approach: Engage on a representative, feature-rich area of the sample using conservative auto-approach settings.

- Initial Safe Parameters: Set scan size to 5 µm, resolution to 256 x 256, scan rate to 0.5 Hz.

- High Setpoint Engage: Set the amplitude setpoint to 90% of A~0~. Engage the feedback loop.

- Initial Scan & Observation: Start scanning. Observe the trace/retrace error signal and the topography image in real-time.

- Lower Setpoint Iteratively: Gradually decrease the setpoint (e.g., to 80%, then 70%) while monitoring:

- Image Quality: Does topographic detail improve?

- Error Signal: Does it become excessively noisy or smooth out?

- Probe Integrity: Listen for audible tapping changes indicating contamination or damage.

- Define Optimal Setpoint: Identify the lowest setpoint where the error signal remains stable and trace/retrace overlay is good. This is the Baseline Setpoint (S~b~).

Protocol 2: Optimizing Scan Rate & Resolution at Baseline Setpoint

Objective: To maximize image quality and acquisition speed without losing tracking or damaging the sample. Materials: AFM system with sample engaged at S~b~. Procedure:

- Fix Parameters: Lock the setpoint at S~b~. Select a 1-2 µm scan area with distinct features.

- Test Resolution Suite: Acquire images at a fixed, slow scan rate (0.3 Hz) with increasing resolution:

- Sequence: 128 x 128 → 256 x 256 → 512 x 512 → 1024 x 1024.

- Assess: Determine the resolution where finer details (e.g., polymer spherulites, nano-pores) cease to improve. This is the Useful Resolution (R~u~).

- Optimize Scan Rate: Using R~u~, systematically increase the scan rate:

- Sequence: 0.3 Hz → 0.5 Hz → 0.8 Hz → 1.2 Hz → 2.0 Hz.

- Evaluate at Each Rate: Capture images and analyze:

- Topographic Integrity: Compare to the 0.3 Hz baseline. Look for smearing, elongation, or loss of sharp edges.

- Error Signal: Check for increasing noise or feedback loop oscillations.

- Line Profile Consistency: Measure the height/width of a consistent feature across rates.

- Define Maximum Reliable Rate (R~max~): The highest scan rate before a >10% distortion in feature dimensions or a significant loss of signal-to-noise occurs.

Table 2: Optimization Decision Matrix (Post-Protocol Analysis)

| Observed Artifact | Probable Cause | Corrective Action |

|---|---|---|

| Smearing/Elongation | Scan rate too high for feedback response. | Decrease scan rate by 30-50%. |

| Excessive Noise/Grain | Setpoint too low or rate too high. | Slightly increase setpoint ratio or decrease scan rate. |

| Flat/Featureless Image | Setpoint too high (skimming). | Decrease setpoint ratio incrementally. |

| Horizontal Striping | Low scan rate with high resolution causing drift. | Increase scan rate slightly or decrease resolution. |

| Asymmetric Features | Contaminated tip or scanner hysteresis. | Change tip, perform scanner calibration. |

Visualization of the Optimization Workflow

Diagram 1: AFM Parameter Optimization Workflow

Diagram 2: Core Parameter Interdependencies

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Essential AFM Toolkit for 3D Printing Material Analysis

| Item | Function/Explanation | Critical for Material Class |

|---|---|---|

| PPP-FMR Cantilevers | Tapping mode probes with reflex coating and very sharp tip (~2 nm radius). Essential for high-resolution imaging of polymer surfaces and nano-features. | All, especially hard thermoplastics & resins. |

| PNP-DB Cantilevers | Self-actuating, self-sensing probes for conductive samples. Used for electrical property mapping of composite or doped printed materials. | Conductive composites, printed electronics. |

| SCANASYST-FLUID+ Probes | Optimized for tapping mode in liquid with very soft springs. Critical for hydrated hydrogel and bioprinted structure analysis. | Hydrogels, bioprinted scaffolds. |

| OTR8 Thermal Oxide Calibration Grating | Provides absolute Z-height and XY spatial calibration (8 µm pitch). Verifies scanner linearity and measurement accuracy post-optimization. | All (regular calibration). |

| Adhesive Tape/Clean Wafers | For secure, flat mounting of irregular 3D printed samples to magnetic AFM disks. Minimizes sample wobble. | All, especially rough prints. |

| UV-Ozone Cleaner | Removes organic contaminants from silicon tips and sample surfaces, reducing artifacts and improving reproducibility. | All, prior to critical experiments. |

| Deionized Water & IPA | For cleaning samples (removing loose powder, residue) and cantilever holders. Essential for preventing tip contamination. | All. |

| Nitrogen Gas Duster | For dry, non-contact cleaning of samples and the AFM stage to remove environmental dust particles. | All. |

Quantifying Surface Roughness and Pore Structure of 3D Printed Scaffolds

Within the broader thesis on Atomic Force Microscopy (AFM) for 3D printing material surface analysis, this Application Note details the quantitative characterization of 3D printed scaffolds. For tissue engineering and drug delivery applications, surface topography (roughness) and pore architecture (size, distribution, interconnectivity) are critical parameters influencing cell adhesion, proliferation, differentiation, and drug release kinetics. This document provides standardized protocols for AFM-based surface roughness quantification and complementary image analysis for pore structure assessment.

Key Research Reagent Solutions

The following table lists essential materials and reagents commonly employed in the preparation and analysis of 3D printed scaffolds for such studies.

| Item Name | Function/Brief Explanation |

|---|---|

| Polylactic Acid (PLA) | A biodegradable thermoplastic polymer, widely used for fabricating bone and tissue scaffolds via Fused Deposition Modeling (FDM). |

| Polycaprolactone (PCL) | A semi-crystalline, bioresorbable polyester with a low melting point, suitable for extrusion-based 3D printing and long-term implant studies. |

| Gelatin Methacryloyl (GelMA) | A photo-crosslinkable hydrogel bioink for bioprinting; mimics the extracellular matrix, allowing cell encapsulation and pore formation. |

| Phosphate Buffered Saline (PBS) | Used for hydrating and rinsing hydrogel scaffolds to maintain physiological pH and ion concentration during imaging or testing. |

| Critical Point Dryer | Equipment used to dry hydrated or soft polymeric scaffolds without collapsing delicate pore structures by avoiding liquid-vapor interfaces. |

| Conductive Tape/Sputter Coater | For non-conductive scaffolds, a thin metal coating (e.g., gold) is applied prior to SEM imaging to prevent charging and improve image quality. |

| Nanoindentation AFM Probe (e.g., RTESPA-300) | A stiff cantilever with a sharp tip for high-resolution topography mapping and nanomechanical property measurement of scaffold surfaces. |

Experimental Protocols

Protocol 1: AFM-Based Surface Roughness Quantification

Objective: To obtain high-resolution, quantitative topographical data from the strut surfaces of 3D printed scaffolds.

Materials & Equipment:

- Atomic Force Microscope (e.g., Bruker Dimension Icon, Cypher ES)

- Soft Contact Mode or Tapping Mode AFM probe (spring constant ~0.4-4 N/m, resonant frequency ~60-90 kHz in air)

- 3D printed scaffold sample (dry or hydrated as required)

- Sample mounting discs and adhesive

- Software: Nanoscope Analysis, Gwyddion, or SPIP.

Methodology:

- Sample Preparation: Securely mount a small section of the scaffold (~5x5 mm) onto a metal specimen disc using a small amount of adhesive (e.g., double-sided tape or cyanoacrylate). Ensure the surface of interest is level and accessible. For hydrogels, perform measurements in fluid cells with appropriate buffer.

- Probe Selection & Mounting: Choose a sharp silicon nitride or silicon tip appropriate for the sample's stiffness. Mount the probe and perform laser alignment and photodetector adjustment.

- Engagement: Position the probe above a representative, flat region of a scaffold strut. Engage the tip onto the surface using standard engagement procedures.

- Scanning Parameters: Set a scan size typically between 10x10 µm and 50x50 µm to capture relevant micro-features. Use a slow scan rate (e.g., 0.5-1.0 Hz) for optimal resolution. Maintain a setpoint to ensure minimal, non-destructive force.

- Data Acquisition: Acquire height, amplitude, and phase images. Capture at least 5 images from different struts across the scaffold to ensure statistical significance.

- Image Processing & Analysis:

- Flatten or plane-fit each height image to remove background tilt.

- Apply a noise filter if necessary.

- Use the software's roughness analysis toolbox to calculate the following parameters:

- Ra (Average Roughness): The arithmetic average of absolute deviations from the mean plane.

- Rq (Root Mean Square Roughness): The standard deviation of height values.

- Rz (Average Maximum Height): The average difference between the five highest peaks and five lowest valleys.

- Surface Area Ratio: The ratio of the 3D surface area to the 2D projected area.

Protocol 2: Pore Structure Analysis via SEM/µCT Image Processing

Objective: To quantify pore geometry and network architecture from cross-sectional images.

Materials & Equipment:

- Scanning Electron Microscope (SEM) or Micro-Computed Tomography (µCT) scanner

- ImageJ/FIJI software with BoneJ plugin or equivalent (e.g., CTAn for µCT)

Methodology (for SEM-derived 2D analysis):

- Image Acquisition: Capture high-contrast, top-down and cross-sectional SEM images of the scaffold at consistent magnification (e.g., 100x, 500x). Ensure scale bars are included.

- Image Pre-processing (in ImageJ):

- Convert image to 8-bit grayscale.

- Adjust threshold (using Otsu's method or manual setting) to create a binary image where pores are black and material is white.

- Apply "Fill Holes" and "Remove Outliers" functions to clean the binary mask.

- Quantitative Analysis (using BoneJ plugin or built-in functions):

- Pore Size (Diameter): Use "Analyze Particles" function. Set a circularity limit (e.g., 0.4-1.0) to exclude non-pore artifacts. Record pore area and calculate equivalent circular diameter.

- Porosity: Calculate as the percentage of black pixels (pores) relative to total pixels in the region of interest (ROI).

- Pore Interconnectivity (2D Approximation): Skeletonize the binary image (Process > Binary > Skeletonize). Analyze the skeleton to count branch points and assess network connectivity.

Data Presentation

Table 1: Representative AFM Surface Roughness Parameters of Various 3D Printed Scaffold Materials

| Material | Printing Technique | Ra (nm) | Rq (nm) | Rz (nm) | Surface Area Ratio | Reference Condition |

|---|---|---|---|---|---|---|

| PCL | Melt Electrowriting (MEW) | 45 ± 12 | 58 ± 15 | 320 ± 45 | 1.08 ± 0.02 | Dry, as-printed |

| PLA | Fused Deposition Modeling (FDM) | 520 ± 85 | 660 ± 110 | 3100 ± 600 | 1.32 ± 0.05 | Dry, as-printed |

| GelMA | Digital Light Processing (DLP) | 18 ± 5 | 24 ± 7 | 150 ± 30 | 1.01 ± 0.01 | Hydrated (PBS) |

| PLA with Surface Etching (NaOH) | FDM + Post-process | 1200 ± 200 | 1450 ± 250 | 8500 ± 1200 | 1.85 ± 0.12 | Dry |

Table 2: Pore Structure Metrics from Image Analysis of Scaffolds

| Material | Mean Pore Size (µm) | Porosity (%) | Pore Circularity (0-1) | Interconnectivity (Branch Points/mm²) | Analysis Method |

|---|---|---|---|---|---|

| PCL (MEW) | 25 ± 5 | 65 ± 4 | 0.85 ± 0.08 | 1200 ± 150 | SEM 2D |

| β-TCP Ceramic | 350 ± 50 | 75 ± 3 | 0.65 ± 0.10 | 250 ± 40 | µCT 3D |

| Collagen-GAG | 160 ± 20 | 98 ± 1 | 0.55 ± 0.15 | Highly interconnected | SEM 2D |

| PLA (FDM, 0/90° laydown) | 400 x 400 (square) | 45 ± 2 | 0.95 ± 0.05 | 40 ± 10 | Optical Microscopy |

Visualization

Workflow for Scaffold Roughness and Pore Analysis

How Scaffold Topography Influences Cell & Drug Response

This application note, framed within the broader thesis of utilizing Atomic Force Microscopy (AFM) for the surface analysis of 3D-printed biomedical materials, details the quantitative mapping of nanomechanical properties critical for material performance. For 3D-printed hydrogels and composites used in drug delivery, tissue engineering, and biosensing, elasticity (Young's modulus) and adhesion forces are not bulk averages but spatially heterogeneous properties that dictate cell-material interactions, drug release kinetics, and structural integrity. AFM-based nanomechanical mapping is indispensable for correlating print parameters (e.g., layer height, curing intensity, bioink composition) with local functional properties at the micro- and nanoscale, providing feedback unattainable by bulk rheology.

Table 1: Representative Nanomechanical Properties of 3D-Printed Hydrogels & Composites

| Material System | Printing Method | Average Young's Modulus (kPa) | Adhesion Force (nN) | Spatial Resolution (nm) | Key Application Context |

|---|---|---|---|---|---|

| GelMA Hydrogel | Digital Light Processing (DLP) | 12.5 ± 3.2 | 0.25 ± 0.08 | 50 | Soft tissue scaffolds, cell mechanobiology studies |

| Alginate-Polyacrylamide Dual Network | Extrusion-based | 85.4 ± 12.7 | 1.8 ± 0.4 | 100 | Load-bearing osteochondral constructs |

| PEGDA-Silica Nanoparticle Composite | Stereolithography (SLA) | 1,250 ± 210 | 5.5 ± 1.2 | 80 | Stiff, abrasion-resistant dental guides |

| Collagen-Hyaluronic Acid Bioink | Extrusion (Bioprinting) | 8.1 ± 2.1 | 2.3 ± 0.6 | 150 | Skin regeneration models, drug penetration assays |

| PLA-PEG Blend (Surface) | Fused Deposition Modeling (FDM) | 2.1 x 10^6 ± 0.3 x 10^6 | 15.0 ± 3.5 | 20 | Drug-eluting implant coating durability |

Data synthesized from recent literature (2023-2024) on AFM analysis of printed soft materials.

Experimental Protocols

Protocol 1: AFM Nanomechanical Mapping via PeakForce QNM Objective: To simultaneously map elastic modulus and adhesion of a 3D-printed hydrogel surface in a physiologically relevant fluid. Materials: See "The Scientist's Toolkit" below. Procedure: